MOJ

eISSN: 2381-182X

Research Article Volume 1 Issue 4

1College of Food Science and Engineering, Gansu Agriculture University, China

2Institute of Animal Science, Chinese Academy of Agricultural Sciences, China

Correspondence: Li Zhang, College of Food Science and Engineering, Gansu Agriculture University, Lanzhou, Gansu, China, Tel 13669352751

Received: October 22, 2015 | Published: November 25, 2015

Citation: Bao G, Zhang L, Sun B, et al. The correlation research on yak meat texture profile analysis (Tpa) and freshness parameters during refrigerated storage. MOJ Food Process Technol. 2015;1(4):94-102. DOI: 10.15406/mojfpt.2015.01.00020

The possible relationships of yak meat using PLSR between freshness and TPA parameters during cold storage were studied. Texture profile analysis (TPA) and freshness measurements of yak meat under the 4°C stored 0d, 2d, 4d, 6d, 8d, 10d and 12d were also performed. In addition, partial least squares regression analysis was carried out to find a correlation between the freshness data and TPA parameters. Significant (p<0.05) correlations among the freshness data and adhesiveness, cohesiveness, Springiness, chewiness and resilience were observed, Multivariate Regression analysis indicated that predictive regression equations of every parameters with all equations Fitting coefficient R2 greater than 0.800. Validation test R2 greater than 0.900, which showed a clear correlation between yak meat chemical changes and its texture properties during refrigeration. The results in this study could be used to explore the Texture profile analysis (TPA) important for using the TPA parameters rapidly evaluates yak meat freshness.

Keywords: freshness, yak meat, correlation, textural properties

TPA, texture profile analysis; TVB-N, total volatile basic nitrogen; TBA, thiobarbituric acid; POV, peroxide value; TMA-N, trimethylamine nitrogen; MDA, malondialdehyde

Yak (Bos grunniens) is the large ruminant species in the high altitude Qinghai–Tibetan Plateau, China, which is characterized by year-round low temperatures and hypoxic atmosphere. There is the most yaks in China,and yak meat is an natural green food.1 The protein content of yak meat is about 22%, fat content is lower than 3%,2 it’s a kind of high protein, low fat animal foods. A chemical change of yak meat by the endogenous enzymes and the pathogenic microorganisms, and also the sensory properties and the composition changed, nutritional value reduce, and there are some toxic or harmful substances the same time, it’s harmful to the consumers,3 it is a comprehensive evaluation index that freshness of yak meat could be used as a judgment during cold storage, it is largely reflects the meat quality, nutritional value and safety coefficient.4 So measuring the freshness of yak meat during cold storage, which can effectively prevent food health security problem occurs, how to accurately and objective measure of yak meat freshness using rapid methods, it’s a subject of intense interest in recent years.

At present,the methods of evaluation the yak meat freshness is mainly measuring the freshness parameters (TVB-N value, TBA value, POV value, TMA-N value).5 Proteins come into being the alkaline nitrogenous substances due to microorganism and endogenous enzymes during storage, One of the most main is volatile base nitrogen, TVB-N value is one of the important indicators to evaluate meat freshness, it is can be evaluate the meat freshness by measuring the value of TVB-N, and it is used as a national standard of measuring meat freshness.6 Fat occur different degree oxidation in the during storage, and TBA value show lipid secondary oxidation products or the number of the final products.7 However, there is a disadvantages that needs complicated sample preparation work and trival test operation, complex Procedure, consuming too much time. It is not convenient to frequently and widely implement, it cannot satisfy far from rapid and large quantities measurement,8 it is a urgent request that find a method of rapid measurement. In recent years, many scholars have studied the relationship between sensory evaluation and instrumental determination values. It is observed that three is a significant or extremely significant correlation between the textural properties and the sensory evaluation value of pork.9 The correlations between the textural properties and volume water content of date palm.10 It was observed that hardness and springiness decreased, whereas increased linearly with the increase of fat content.11

Despite the above investigations, there is no study reported yet about the determination of textural properties parameters for evaluation of yak meat freshness using PLSR. Therefore, in this study, we prepared yak meat emulsion samples and kept at 4°C stored 0d, 2d, 4d, 6d, 8d, 10d and 12d, the freshness and Texture profile analysis (TPA) measurements were also performed. The aim of this study was to analyze possible relationship the correlation of yak meat using PLSR between freshness and TPA parameters of yak meat.10

Description of the samples

Seven samples (1.0 kg for each sample, clear plastic wraps packaged) of Yak meats were obtained from amdo group. The 7 samples were kept at 4°C stored 0d, 2d, 4d, 6d, 8d, 10d and 12d. All the Yak meats were subjected to each type of chemical and textural analysis.

Chemicals

All reagents used were of analytical-reagent grade, PE composite packaging film was purchased from Tian Hua Xin Yu plastic products co., LTD, picric acid was obtained from Xin Ding Peng Fei development of science and technology co., LTD, methylbenzene, formaldehyde, trichloroacetic acid, magnesium oxide, boric acid, mixture indicator, hydrochloric acid, TBA, Potassium carbonate, anhydrous sodium sulfate, Saturated potassium iodide, starch indicator, Na2S2O3, trichloromethane were obtained from The recovery of Fine Chemical Industry Research Institute, and these reagents used were of analytical-reagent grade.

Apparatus

A Thermostat oscillator (Shanghai, China) was used to heat preservation, Spectrophotometric measurements were carried out using a spectrophotometer, employing a quartz cuvette with a 1.0 cm optical path, the TPA measurements were carried out using a TA.XT Express texture analyzer.

Experimental design

The study selected gannan amdo group yak meat as the research object and the average divided into seven groups packaged by PE composite packaging film, refrigeration 0d, 2d, 4d, 6d, 8d, 10d and 12d Under the condition of 0~4°C low temperature, freshness and textural properties measurement of yak meat were performed.

Determination of TVB-N: Using semi-micro distillation method, TVB-N value was determined by a stream distillation method with some modifications.12 Ten grams of long is simus dorsi muscle of yak was minced and then mixed with 100 mL water, filtered after immersion 30 min. The distillate was collected in a conical flask containing 50 mL aqueous solution of boric acid (40 g/L) and a mixed indicator created from dissolution of 0.1 g of methyl red and 0.1 g of bromocresol green into 100 mL of 95% ethanol. 5.0 mL of the filtrate in distiller reaction chamber, and 5.0 mL Magnesium oxide mixed suspension(10g/L)and distilled for 10 min in a 8100 Kjeltec Distillation Unit, Afterward, the obtained boric acid solution was titrated with a 0.01 M of hydrochloric acid solution. The violet colors was the titration end point, At the same time do a blank test. And each analysis was repeated in triplicate.

The TVB-N value was measured and expressed as mg N/100 g yak meat muscle according to the consumption of hydrochloric acid. The TVB-N value was calculated by the following formula:

Where X is the content of TVB-N value of meat sample (mg/100g), V1 is the volume of the hydrochloric acid standard solution for the titration (mL) of sample, V2 is the volume of the hydrochloric acid standard solution for the titration (mL) of blank, c is the concentration of hydrochloric acid solution, (mol/L), m is the quality of the meat sample (g).

Criterion: The content of TVB-N value less than 15mg/100g was Fresh meat, between 15 and 25mg/100g was Second level, more than 25mg/100g was metamorphic corruption meat.

TBA analysis: TBARS content was determined colorimetrically by the method of Pokorny and Dieffenbacher,13 Samples (2.0g) were homogenized in 10 ml of 7.5% Trichloroacetic acid solution (including 0.1%EDTA), centrifuged(1600r/min,5min, 5.0 mL of the filtrate heat preservation 40min in 90°C Water bath pot with 5.0mL TBA(0.02mol/L),and absorbance measurement in 532 nm and 600 nm wavelength

The TBA value was calculated by the following formula:

Where A532 is 532 nm wavelength absorbance values; A600 is 600 nm wavelength absorbance values.

Peroxide value (POV): The Peroxide value was determined according to Jung’s methods.14 2.0 g of meat sample was dissolved in 20 mL of chloroform and acetic acid (2:3) solution with 1.00mL Potassium iodide saturated solution, 30mL distilled water and 1.0mL Starch indicator. The POV of Yak meat was analyzed by titration with 0.002 M Na2S2O3 solution using an iodometry.

The POV was calculated using the equation:

Where V is the volume of the 0.002M Na2S2O3 solution for the titration (mL) of sample, V0 is the volume of the 0.002M Na2S2O3 solution for the titration (mL) of blank, c is the concentration of the 0.002M Na2S2O3 factor and m is the weight of the sample (g).

Procedure for TMA-N determination in yak meat samples: The Peroxide value was determined according to methods. Extraction of TMA-N from yak meat samples was performed according to Pena-Pereira’s15 procedure by homogenising 5.0 g of yak meat muscles with 17.5mL and 2.5 mL of 40% (mass/volume) aqueous trichloroacetic acid (TCA) solution and subsequent centrifugation of the homogenate at 3000 rpm for 15 min. The supernatant liquid was placed in a volumetric flask and enough TCA at 7.5% (mass/volume) concentration was added to make up to 25 ml. then 2 mL volume of the meat extract was placed into a 40 mL-amber vial containing a stirring bar together with 5 mL of a salted (30% mass/volume NaCl) aqueous solution and 1 mL of formaldehyde(39% mass/volume). Then 2 mL of NaOH (10 M) were injected trough the septum. 10mL xylene drop containing 0.02% mass/volume of picric acid was then formed at the needle tip of a and exposed to the headspace of the sample stirred at 1100 rpm for 3.5 min. The extractant solution must be refrigerated into a water–ice bath before extraction to extend the microextraction time and, therefore, enhance the extraction efficiency of TMAN. Finally, the remaining drop was retracted back into the microsyringe and placed on the pedestal of the Nanodrop spectrophotometer to obtain the corresponding analytical signal.

The TMA-N was calculated using the equation:

Where V is the volume of the sample solution diluted (mL), V1 is the volume of the consumed sample solution (mL), c is Equivalent to a standard liquid concentration (mol/L), m is the weight of the sample (g).

TPA: In general, four cylinders 1.5 cm high and 2 cm wide were prepared from every sample.16 A double compression cycle test was performed up to 50% compression of the original portion height with an aluminium cylinder probe of 2 cm diameter. A time of 5 s was allowed to elapse between the two compression cycles. Force–time deformation curves were obtained with a 25 kg load cell applied at a cross-head speed of 2 mm/s. The following parameters were quantified:17 hardness (N) maximum force required to compress the sample, springiness (m), ability of the sample to recover its original form after deforming force was removed, adhesiveness (N s), area under the abscissa after the first compression, and cohesiveness, extent to which the sample could be deformed prior to rupture.18

Statistical analyses

Data were analysed of various index determination results mean and standard deviation using Excel 2010 software and Data were analysed statistically using SPSS20.0 software. Selection of each freshness 0d, 2d, 6d, 8d, 12d experimental result doing regression analysis and 4d, 10d Validation test.

Freshness

The variance analysis of freshness determination results of yak meat in the process of refrigeration are shown in Table 1. The plots and regression of freshness of the yak meat during cold storage are shown in Figure 1-4. The regression equations of freshness of the yak meat during cold storage are shown in Table 2. Total volatile basic nitrogen (TVB-N) content is one of core indicators for evaluating meat freshness,19 Table 1 shows the TVB-N of yak meat during cold storage higher than the 28.16 mg /100g on the sixth day and rotten, inedible, TVB-N for all yak meat increased throughout storage and up to a final value of to 31.76 mg/100g on the twelfth day. This value is close to the determination results In the process of storage reported by Li Ting ting.20 TBARS has been used to determine the degree of lipid oxidation, and the presence of TBA reactive substances is due to the second stage of auto-oxidation, during which peroxides are oxidized to aldehydes and ketones. A TBA value of 2 mg MDA/kg is the limit. The change in TBARS of yak meat during cold storage is 0.31mg MDA/kg and under 2 mg MDA/kg, the determination results in agreement with the reported by Fan.21 The POV provides the oxidation state of the lipids.22 This value was used to measure the rancidity that occurred by auto-oxidation. The POV of meat extracted significant increased throughout storage, TMA-N value being of widespread use. Concentration of TMA-N in yak meat has been found to be closely related to organoleptic estimations, being an objective quality indicator for freshness determination in meat samples.23 TMA-N generation is attributed to the gradual conversion of trimethylamine oxide (TMA-O) by bacterial or enzymatic reduction. An increase on the level of TMA-N was observed from this initial value up to a final value of 1.08mg/100g ± 0.042 mg TMA-N/100g.

Table 1 The variance analysis of freshness determination results of yak meat in the process of refrigeration.

Different letters in the same column indicate significant differences (p < 0.05).

y values |

Equation of Linear Regression |

Fitting Coefficients R² |

TVB-N(mg/100g) |

y =2.0158x + 11.637 |

R² = 0.8421 |

TBA ( mg MDA / kg ) |

y = 0.0188x + 0.0886 |

R² = 0.9500 |

POV (mmol/kg) |

y = 0.1102x + 0.4336 |

R² = 0.9821 |

TMA-N (mg/100g) |

y = 0.0539x + 0.4639 |

R² = 0.9632 |

Table 2 The regression equation of freshness of the yak meat during cold storage

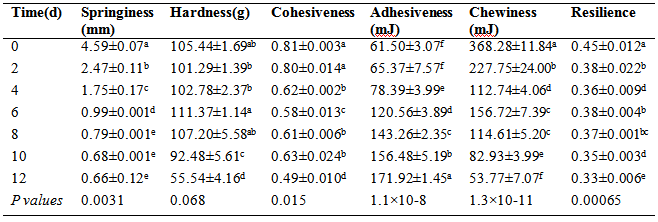

Table 3 The variance analysis of textural properties determination results

Different letters in the same column indicate significant differences (p < 0.05)

Index |

TVB-N |

TBA |

POV |

TMA-N |

Sp |

Ha |

Co |

Ad |

Ch |

|

TVB-N |

1 |

|

|

|

|

|

|

|

|

|

TBA |

0.878** |

1 |

|

|

|

|

|

|

|

|

POV |

0.854* |

0.940** |

1 |

|

|

|

|

|

|

|

TMA-N |

0.936** |

0.926** |

0.956** |

1 |

|

|

|

|

|

|

Sp |

-0.972** |

-0.856** |

-0.813** |

-0.888** |

1 |

|

|

|

|

|

Ha |

-0.36 |

-0.476 |

-0.627* |

-0.487 |

0.325 |

1 |

|

|

|

|

Co |

-0.906** |

-0.814** |

-0.836** |

-0.931** |

0.845** |

0.35 |

1 |

|

|

|

Ad |

0.863** |

0.957** |

0.956** |

0.961** |

-0.814* |

-0.496 |

-0.826** |

1 |

|

|

Ch |

-0.940** |

-0.838** |

-0.843* |

-0.874** |

0.956** |

0.455 |

0.860** |

-0.774** |

1 |

|

Re |

-0.817** |

-0.713** |

-0.751** |

-0.739** |

-0.871** |

0.515 |

0.749** |

-0.622* |

0.949** |

1 |

Table 4 Correlation coefficients (r) between the freshness and TPA parameters

Sp: Springiness; Ha: Hardness; Co: Cohesiveness; Ad: Adhesiveness; Ch: Chewiness; Re: Resilience

* p<0.05, ** p<0.01

TPA

The variance analysis of textural properties determination results of yak meat in the process of refrigeration are shown in Table 3 Hardness is the power of Cut off meat about textural properties, which was the internal binding force to maintain the shape of the meat.24 An increase on the level of Hardness was observed from this initial value up to 6 day value of 111.37±1.14g, after 6 day of storage, the Hardness was decline, Storage 12 days later than 0 days was reduced by 47%; Springiness was the meat deformation under the external force and the ability to restore the original state after the external force to remove.25 The Springiness decreased continuously during cold storage and up to 0.66±0.12mm on the 12 day. The cohesiveness is resistance to damage when chewing food, the properties of the intact of food, which show yak meat internal bond strength.26 Cohesivenessdecreases during the whole storage, a decrease on the level of Cohesiveness was observed from this initial value up to a final value of 0.49 ± 0.010on the 12 day, falling 39% than on the 0 day. Adhesiveness is the work of overcoming attractive power between yak meat surface and the contact surfaces, is the first extrusion negative peak area of Instrument definition,27 the adhesiveness increases in the storage, an Significant increase on the level of adhesiveness was observed from this initial value up to 12 day value of 171.92±1.45mJ. Chewiness is related to the hardness, springiness and cohesiveness, which is the power to chewing yak meat, it is equal to the product between the hardness and cohesiveness,28 in our study, the values of chewiness decrease in the storage. Resilience is restoration degree that the yak meat was pressured,29 the values of resilience decreases in the study and the final value Smaller than 0 day.

The correlation between freshness and TPA parameters

The correlation between the freshness and TPA parameters of yak meat during cold storage are shown in Table 4. Freshness and TPA attributes of different dates are presented in Table 4 respectively. Initial statistical analysis showed that Hardness did not improve correlation with the freshness parameters (p > 0.05). Springiness, Cohesiveness, Chewiness, Resilience negatively correlated with freshness parameters (p < 0.05) and Adhesiveness index positively correlated with freshness parameters (p < 0. 01). Therefore, the traditional multiple linear regression unsuitable to this analysis, using the freshness as the dependent variable and values of hardness et al. six textural parameters as independent variables were implemented to establish the innovative models for prediction of freshness quality of yak meat based upon the PLSR using SPSS and the statistical results are in Table 5.

Partial least squares regression analysis is a method of multivariate data analysis based on principal component analysis and principal component regression ,which is a dimension reduction techniques that dimension reduction space prediction the covariance matrix of each element and the prediction matrix to maximize.30 According to the standard of cumulative contribution to x more than 75%, the Table 5 shows that the first potential factors can preferable explain the original independent variables, the values of cumulative contribution TVB-N value, TBA value, POV value, TAM-N value based on the developed PLSR models were 79.0%, 79.1%, 79.0%, 79.1%, respectively which indicated the regression equation regression effect is very good. Meanwhile, the textural properties parameters was more powerful in predicting TVB-N values, TBA values, POV value, TMA-N value, which also demonstrated that PLSR was suitable and competent for selecting the informative variables in this study. Regression equations show in Table 5.

Y values |

Latent Factors |

X Variance |

Cumulative X Variance |

Y Variance |

Cumulative Y Variance (R2) |

Adjusted R2 |

TVB-N value

|

1 |

0.79 |

0.79 |

0.937 |

0.937 |

0.924 |

2 |

0.122 |

0.911 |

0.06 |

0.996 |

0.994 |

|

3 |

0.058 |

0.969 |

0.003 |

0.999 |

0.998 |

|

4 |

0.017 |

0.987 |

0 |

0.999 |

0.998 |

|

5 |

0.013 |

1 |

0 |

1 |

0.997 |

|

TBA value

|

1 |

0.791 |

0.791 |

0.835 |

0.835 |

0.801 |

2 |

0.086 |

0.876 |

0.062 |

0.897 |

0.845 |

|

3 |

0.074 |

0.951 |

0.024 |

0.921 |

0.843 |

|

4 |

0.045 |

0.996 |

0.006 |

0.927 |

0.782 |

|

5 |

0.004 |

1 |

0.011 |

0.939 |

0.631 |

|

POV value

|

1 |

0.79 |

0.79 |

0.902 |

0.902 |

0.882 |

2 |

0.11 |

0.9 |

0.068 |

0.97 |

0.955 |

|

3 |

0.06 |

0.96 |

0.02 |

0.99 |

0.98 |

|

4 |

0.036 |

0.996 |

0.004 |

0.994 |

0.983 |

|

5 |

0.004 |

1 |

0.006 |

1 |

1 |

|

TAM-N value

|

1 |

0.791 |

0.791 |

0.922 |

0.922 |

0.906 |

2 |

0.057 |

0.848 |

0.07 |

0.992 |

0.988 |

|

3 |

0.121 |

0.968 |

0.001 |

0.993 |

0.985 |

|

4 |

0.016 |

0.985 |

0.001 |

0.994 |

0.982 |

|

5 |

0.015 |

1 |

0.001 |

0.994 |

0.966 |

Table 5 Proportion of Variance Explained

Y is the dependent variable shows in Table 6, x1~x6 is the Springiness, hardness, cohesiveness, adhesiveness, chewiness, resilience respectively, the predicted value of the dependent variable can be obtained according to regression equation, the prediction results and the verification results of Each parameters shows in Figures 5-8.

The decay and Metamorphism, protein degradation and fat oxidation of yak meat during cold storage due to the endogenous enzymes and microorganisms. which has a great influence on yak meat textural properties,31 freshness and texture profile analysis (TPA) measured, Partial least squares regression analysis was performed to determine the degree of association freshness versus textural properties, were implemented to establish the predicted models for prediction of freshness quality of yak meat based upon the PLSR and the statistical results are illustrated in Figure 5-8, PLSR was used to analyze correlations between the values of freshness data and TPA parameters of the model system yak meat emulsions.

Using the 0d, 2d, 6d, 8d, 12d freshness measured results as the horizontal axis and predicted results as vertical axis obtained scatter diagrams, and 4d, 10dmeasured results as verification test. From the Figure 5-8 can be seen, the values of R2p of TVB-N value, TBA value, POV value, TAM-N value based on the developed PLSR models were 0.924, 0.801, 0.882, 0.906, respectively. In addition, the average relative error between predicted values and measured values of TVB-N value, TBA value, POV value, TAM-N value were 0.1%, 8.9%, 6.9%, 7.6%, respectively. Meanwhile, it could be seen from the above study that the Predicted value similar to the measured value, and the values of R2v were greater than 0.90, the relative errors were less than 5%. Therefore, the PLSR was more powerful in predicting TVB-N value, TBA value, POV value, TMA-N value with texture profile analysis (TPA) parameters, which also demonstrated that TPA could evaluate yak meat freshness during cold storage in this study.

The muscle long is simus dorsi of yak meat as the experimental material in this study, and conducted to determine the freshness and the texture profile analysis (TPA), using the PLSR establish the regression equation between freshness and the texture profile analysis (TPA), the values of R2p were greater than 0.80, From the statistics, it was more than 80% for evaluation of yak meat freshness quality using TPA parameters, and the value of R2v were greater than 0.90.The relative errors between predicted value and measured value were less than 10%, the value of R2p were greater than 0.80, and the value of the relative errors were less than 5%. Therefore, the regression model established based upon the PLSR using the TPA parameters predicted the freshness, it can be acquired the data close to measured value, which was more powerful in predicting the freshness of yak meat.

This work was supported by the Organization Department of Gansu Province "Long Yuan innovative talents" Program, the Qinghai-Tibet Plateau organic livestock production technology and industrial model of characteristics (201203009).

The author declares no conflict of interest.

©2015 Bao, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.