MOJ

eISSN: 2381-182X

Research Article Volume 12 Issue 1

1Programa de Pós-Graduação em Zootecnia, Dept. de Ciências Morfofisiológicas, Universidade Estadual de Maringá, Maringá, Brazil

2Dept. de Biología Marina y Medicina Veterinaria y Zootecnia, Universidad Autónoma de Yucatán, Mexico

3Dept. de Engenharia de Aquicultura, Faculdade de Ciências Agrárias, Dourados, Universidade Federal da Grande Dourados, Brazil

4Programa de Pós-Graduação em Ciências Ambientais, Universidade Federal de Rondônia, Brazil

5Laboratório de Aquicultura e Ecologia Aquática, Universidade Federal de Alagoas, Brazil

6Centro Universitário São Lucas, UniSL JPR AFYA, Ji-Paraná, Brazil

Correspondence: Jerônimo Vieira Dantas-Filho, Programa de Pós-Graduação em Ciências Ambientais, Universidade Federal de Rondônia, Av. Norte Sul, no. 7300 - Nova Morada, Rolim de Moura, Rondônia, 76940-000, Brazil, Tel +55069984968407

Received: December 27, 2023 | Published: January 8, 2024

Citation: Corrêa SS, Oliveira GG, Franco MC, et al. Strength and morphological characteristics Oreochromis niloticus, Arapaima gigas and Cynoscion virescens leathers. MOJ Food Process Technols. 2024;12(1):1-10 DOI: 10.15406/mojfpt.2024.12.00292

Background: Several species of fish are commercialized in Brazil, among them many have the potential to use the leathers for making clothes, shoes, and others.

Objective: This study aimed to carry out physicochemical and mechanical tests, as well as the morphological characterization of leathers from different fish species, Oreochromis niloticus, Arapaima gigas and Cynoscion virescens, as well as directions of the leather specimens and their correlations regarding quality and strength.

Main Body: A total of 10 specimens were removed by treatment, in certain thicknesses, taken diagonally, longitudinally, and transversely from leather as a length function of the fish's body, to determine tensile strength and percentage of extraction (stretching) and progressive tearing using an EMIC dynamometer. The skins subjected to tanning process with chromium salts demonstrated thickness ranging 0.89 to 1.04 mm after tanning. The thickness of O. niloticus leather demonstrated significant differences in the regions, whose average value was 0.96 mm. However, when evaluating thickness of the leathers in relation to directions, longitudinal showed the greatest thickness 1.11 mm, transversal and diagonal directions showed no difference between them, whose average was 0.94 mm. The directions of removal of the specimens influenced tensile strength where longitudinal direction 15.12 N mm-2 demonstrated greater strength and diagonal 11.41 N mm-2 less strength. However, the progressive tear test behaved in an inverse way, where longitudinal direction showed lowest 46.79 N mm-1 strength and diagonal 63.89 N mm-1 higher strength. Transversal direction did not differ statistically between the other directions for two parameters evaluated. The traction of O. niloticus leather regions did not influence strength, however, the tearing variable demonstrated lower strength 49.65N mm-1) for tail region, while the head and central regions did not show significant difference between regions, whose average was 61.49 N mm-1. When evaluating tensile strength of the leather, there were no significant differences, where an average value 13.46 N mm-1 was found depending on region, while for the direction of removal of the specimens, the average was 14.49 N mm-1. The average value for longitudinal and transverse directions independent of the analyzed region was 130.13 and 117.43 N mm-1, respectively. Tanning with vegetable tannin is recommended for the skins of the three fish studied. Leathers become high quality products, being the raw material for making various artifacts such as clothes and shoes. In addition, it is more environmentally friendly than conventional chemical tanning agents.

Keywords: aquaculture, aquatic food product technology, chromium salts, vegetable tannin, fish leathers

The generation of by-products within a processing line of an industry has become a growing concern among consumer population and generate concern in industries due to correct form of disposal and how to obtain the better use of the raw material.1 According to Matiucci et al.,2 among by-products generated, about 4.5 to 10% represent the fish skin. Variation in this number of by-products depends on the species and way in which it is removed. The skin can used to make new products, and can benefited in extraction of collagen, production of snacks in the form of crackling, and making fish leather.3 Faced with this opportunity, several species of fish are commercialized in Brazil, among them many have the potential to use the leathers for making clothes, shoes, and others.2 Faccioli et al.4 reported that Arapaima gigas (paiche) skin can represent 24% of residue. Morphometric characteristics associated with age and animal species influence yield,5 and evaluating these measures mainly in large species, it is observed that species with more elongated bodies have more viscera, due to intestinal tract size, although also have a larger skin, in proportion to size of the animal.

Arapaima gigas Schinz, 1822 (paiche) is a species that occurs in the Amazon basin and is considered the largest freshwater scale fish, reaching 200 kg and 300 cm in length,6 paiche has been shown potential for fish farming due to its zootechnical characteristics, as it is considered a large fish and for adapting well in environments with low demand for dissolved oxygen.7,8 Oreochomis niloticus Linnaeus, 1758 (Nile tilapia) is a of the most produced species worldwide, being considered the fourth most cultivated species in the world. Brazil is the fourth largest producer of Nile tilapia in the world and in Brazil it is the most produced and benefited species representing 55.4% of all national fish production in year 2018, about 400 thousand tons.9 The production of extractive fishing of Cynoscion virescens Cuvier, 1830 (croaker) represented 43 thousand tons in year 2019 in Brazil.10 Currently, croaker is a target species for fishing in coastal regions, due to its abundance and occurrence throughout the coastal region of Brazil, they form shoals, are migratory and have a great length, being considered a large species, with an elongated body, reaching the maximum size 115 cm.11

The transformation of skin into leather, there are several technologies used, and among them are use of chromium salts and vegetable or synthetic tannins.3 With growing concern to combine environmental management with industrial production, there is a search for cleaner technologies, use of tanning agents of mineral origin has been rejected, as is the case of chromium, as they can be harmful to environment, leading to many countries to give commercial preference to leathers that used vegetable tannins.12 The skins of fish differ from each other, where each species of fish can be showed its peculiarities, especially if comparing the skins of marine and freshwater fish,13 regarding chemical composition that depending on amount present in the leathers, it is necessary to adapt the tanning techniques, whether in terms of process time, quantity of products or repetition of steps, change of one or another chemical product.14 Vieira et al.15 proved that fish leather has the same strength showed by bovine leathers, if compared to thickness.

Therefore, from the overview presented, we have the hypothesis that fish leathers have high strength, with fish leather being a by-product generated in the fish processing industries, which in most of the times it is considered waste. However, after the tanning process it becomes a high-quality product, being raw material for making, clothing and artifacts in general. And finally, it can be considered by the Industry/Market as an innovative product. The quality characteristics of leathers have varied with the commercial dynamics of the new market niches, especially for the numerous purposes for which they are applied. In the past, only strength and durability were prioritized, nowadays the priority is the participation of fish leathers in new foreign market niches, with leathers that expand in terms of flexibility, visual characteristics, representativeness, and rusticity. Nonetheless, we expected fish leathers express interesting physicomechanical characteristics and have their added value when subjected to organic products and processes that maintain the natural characteristics of the product, such as the use of organic tanning and natural dyes.

In view of the assumptions, the aimed of this study was to carry out physicochemical and mechanical tests and morphologically characterize O. niloticus (Nile tilapia), A. gigas (paiche) and C. virescens (croaker) leathers. Considering the tanning agents (salts of chromium and vegetal tannin), regions (head, central and tail) and directions (longitudinal, transversal, and diagonal) of the leather in strength quality terms.

The study was conducted in the Laboratório de Processamento de Peles e Couros, at Experimental Farm of Iguatemi (EFI), belonging to Universidade Estadual de Maringá (UEM), Maringá city, Paraná state, Brazil. Raw material used in experimental tests were A. gigas (paiche) and C. virescens (croaker) skins from Macapá city, Amapá state, Brazil, and O. niloticus (Nile tilapia) skins from Maringá city, Paraná state, Brazil. The skins obtained from these three species of fish were tanned, in the same drum (equipment) to evaluate their physicochemical and mechanical characteristics, under the same processing conditions.

Processing samples, physicochemical and mechanical tests and morphologically leathers characterizations

Nile tilapia skins with an average weight 750±50g and 22±6 cm in length, paiche with 12610±802g and 120±9 cm and croaker with 2820±225g and 79±7 cm in length were used, totaling 10 kg of each species skins. The skin tanning process was carried out according to Souza et al.,13 whose steps were lime (2% lime and 3% soda ash), deliming, purge and pickling. This solution was pH 3.0 and another pH 4.0 for chromium tanning and vegetable tannin respectively for skins of the three species.3

In tanning, 8% chromium salts and 12% vegetable tannin were added to Píquel solutions, with pH 3.0 and 4.0, respectively. Following basification, neutralization, retanning (4% vegetable tannin) and dyeing and finished with fat liquoring (10% oils) for two tanning processes (chrome and vegetable) and fixing with formic acid (2 to 3%). All skins were dried and opened with a stainless-steel cylinder. To stretch the leather, getting more and smoother the surface to facilitate the removal of the specimens from leathers.3

After the entire tanning procedure was carried out, the skins were separated to remove the specimens for two tests performed. They are defined as Test 1. Physico mechanical characteristics of the regions and directions of removal specimens from skins of Nile tilapia, paiche and croaker tanned with chromium salts; Test 2. Resistance quality of the skins from three fish species tanned with chromium salts and vegetable tannin. The specimens were removed diagonally, longitudinally, and transversely along the length of the leather, to carry out the resistance tests, in three regions (head, central and tail).

Leathers after tanning were randomly separated to remove the specimens. They are 10 specimens per treatment (regions and directions) were taken from each leather of each species. A skin was used for each region of the Nile tilapia, removing only one direction. This was done because the Nile tilapia skin is smaller than the other fish studied in the current study. Figure 1 were 90 leathers used to remove the specimens. For that, the specimens were prepared using the rocker and sent to acclimatized laboratory (23º C and 50% relative humidity) for 24 hours. The thicknesses of each specimen were determined (ABNT-NBR ISO 2418, 2015)16 taken diagonally, longitudinally, and transversely from leather as a function of the length of the fish body to determine tensile strength and percentage of extraction (stretching) (ABNT–NBR ISO 3376, 2014)17 and progressive tearing (ABNT–NBR 11055, 2014).18 For strength tests, an EMIC dynamometer (model DL 300 kN, Unbrand®, Australia) was used with a distance between loads 100±20 mm min-1 using a 200 kgF load cell, the calibration was performed by EmicDcame, a calibration laboratory accredited by CGCRE/INMETRO under no. 197.

Samples were taken from central region of three fish species leather for histological analysis, which was performed at Laboratório de Pesquisa em Histopatologia, UEM, Maringá city, Paraná state, Brazil. Leather samples were embedded in paraffin and cut to a thickness of 5 μm and stained using Hematoxylin-eosin and Picrosirius-Hematoxylin technique, being used for the presentation of the histological architecture, and counting of collagen fibers.13

Scanning electron microscopy (SEM), samples in different leather directions in relation to the length of the fish were taken to analyze the distribution of collagen fibers in the dermis and insertion coverslips and scale protection. Small samples were taken in different directions (longitudinal, transversal, and diagonal), on the surface of the leather flower and on the face of the flesh. Leather samples were submitted to routine histological processing for paraffin embedding. Histological sections with a thickness of 5 µm were obtained on a microtome and were stained with Masson’s trichrome.

The histological slides were analyzed under a light microscope and were photo-micro graphed under the AXIOSKOP-ZEISS photomicroscope, Quanta™ 250 FEI, USA. Samples collected for analysis under SEM. The fragments were fixed in 2.5% buffered glutaraldehyde and postfixed in 1% osmium tetroxide for two hours. They were then washed in phosphate buffer, dehydrated in a series of ethanol of increasing concentrations, and dried to a critical point with CO2. Specimens were metallized with gold-palladium ions and electrographed with JEOL-JSM 5410.

The preparation of leather samples for chemical analysis followed the conditions required by ABNT standards, for the determination of chromium oxide Cr2O3, according to ABNT,18 determination of extractable substances with dichloromethane (CH2Cl2) according to ABNT19 and the determination of the pH and the pH differential figure of an aqueous extract in leathers of the three species of fish.20The analyzes were carried out at Laboratório de Controle de Qualidade e Análises Químicas, at Universidade Federal de Santa Maria (UFSM), São Leopoldo city, Rio Grande do Sul state, Brazil.

Data analysis

Concerning the statistical analysis, in Test 1, there was a completely randomized design in a 3x3 factorial, with three head regions (head, central and tail) and three directions (longitudinal, transversal and diagonal) of the leathers for each species of fish analyzed (Nile tilapia, paiche and croaker). While in Test 2, a completely randomized design was carried out in a 3x2 factorial, with leathers from three species of fish and two tanning agents used in the tanning process (chromium salts and vegetable tannin). The specimens used for the analyzes were the average of the tests of each leather results, regardless of region or leather directions obtained.

Results were submitted to analysis of variance and the averages were compared using the Tukey’s test, considering a 5% probability. All data obtained were stored and organized in Epi infoTM software, version 3.5.3 - 2011 (OS: MS-Windows, C Sharp programming language). The Statistical Analysis System Software (SAS Inst. Inc. Cary, NC, USA), version 9.2 (SAS, 2010) was used.

Test 1: Physicomechanical characteristics

Nile tilapia were slaughtered with 750 g, whose skin yield was 5.45%, weighing an average 48 g. The skins were subjected to tanning process with chromium salts. The leathers varied in thickness 0.89 to 1.04 mm after tanning. However, when evaluating thickness of the leathers in relation to directions, the longitudinal showed significantly the highest 1.00 mm thickness, the transverse and diagonal directions demonstrated no difference between them, whose averages were 0.93 and 0.95 mm, respectively. Everything indicates that depending on parameter evaluated in the leather, only the direction or region of the leather can influence strength, although on other hand the two factors can also influence the results at the same time, being observed through the interaction. In this test, the force applied in the tensile and stretching test, deformation and stretching showed interaction.

The direction of removal of the specimens in the Nile tilapia leathers influenced the tensile strength and progressive tearing. Corroborating Cavali et al.,3 who stated that direction of the leather influences results of its strength. Nile tilapia leathers in current study showed higher strength in the longitudinal direction 15.12 N mm-2 and lower in the diagonal direction 11.41 N mm-2 for tensile test, while for the progressive tearing, the opposite occurred, where the longitudinal direction showed the lowest 46.79 N mm-1 strength and longest diagonal 63.89 N mm-1 for progressive tearing. The transverse direction did not differ between the other directions for the two parameters evaluated.

Although there are also other important aspects in the evaluation of leather strength, such as the region where it is being analyzed. With the results of this study, it is noted that in addition to direction, region where the Nile tilapia leather specimens were removed may also have influenced strength. The traction of Nile tilapia leather regions did not influence the strength (Table 1), while for tearing, tail region showed lower strength 49.65 N mm-1 and head and central regions did not show a significant difference between them, whose average was 61.49 N mm-1 (p <0.05). These results corroborate Alla et al.14 who evaluated Nile tilapia leathers in relation to two regions (head and hindquarters) and three leather directions (longitudinal, transverse and diagonal). The author also reported that the analyzed region did not influence the tensile strength of the leather, whose average value was 12 N mm-2, lower than that of this test 13.46 N mm-2 (p <0.05). For direction of removal of the specimens, the results were similar to those of this test as well, due to diagonal direction, according to Alla et al.14 have shown lower strength 6.80 N mm-2 and longitudinal and transversal higher strength values, although shown no difference between them, whose average value was 15.20 N mm-2, being higher than that of this test 14.49 N mm-2.

This seems to be related to distribution of collagen fibers in the leather. Everything indicates that in the longitudinal direction it has a smaller number of fine fibers (reticulin), and these are intended to assist in tying collagen fibers and providing resistance in progressive tearing. According to Dias et al.8 and Souza et al.13 and when fish leather has a greater amount of reticulin fibers binding the collagen fibers, this leather presents greater tear strength. Therefore, everything indicates that in the transverse and diagonal direction leather has a greater amount of reticulin fibers tying to collagen fiber bundles. The number of thick layers of collagen fibers has an effect on mechanical properties of the skin, thus providing greater strength to leather when pulled.21

The force applied in the tensile and stretching test showed interaction between the regions and cutting direction of the specimens in the Nile tilapia leather. When analyzing regions, the force applied to head and tail region of the leather was greater than the central one (Table 1). Analyzing regions within each direction, the longitudinal and transverse directions showed similar strength in the head and central regions. However, the force applied in the diagonal direction of the head and central region showed significantly (p <0.05) the lowest value, while in the tail region it was in the transverse direction (Table 1).

Souza et al.13 tanned Nile tilapia leathers with chromium salts and observed that transverse direction of the leather required more force 125.78 N to perform the tensile and stretching determination test, proving to more strength. On the other hand, in current study, the directions that demonstrated greater strength were the longitudinal and transversal, in the head and central regions of the leather. Although the average value for the longitudinal and transverse direction independent of the analyzed region was 130.13 N and 117.43 N mm-1, respectively. These results are superior to those reported by Matiucci et al.2 which was 90.76 N.

Evaluating the stretching that determines the flexibility or elasticity of the leather and deformation (how much the length of the specimen increases after end of the test) it is noted in Table 1 that there was interaction between the regions and directions of the leather. Nile tilapia leather showed greater deformation and elasticity in the head region of the leather, in the longitudinal direction and the smallest in the diagonal. The lowest elasticity and deformation observed in Nile tilapia leathers tanned with chromium salts was in the central and tail regions of the leathers, in the transverse and diagonal directions, which showed no difference between them. Therefore, the longitudinal direction showed greater elasticity and deformation within each region and diagonal direction the smallest, not differing from transversal in the central and tail regions, whose average values were 32.25 and 29 mm for deformation and 53.80 and 48.45% for stretching, respectively (Table 1). Souza et al.13 analyzing elasticity of Nile tilapia leathers stated that the transverse position demonstrates greater elasticity in relation to the other directions, when tanned with chromium salts and re-tanned with vegetable, synthetic tannin or chromium salts. Therefore, both this study and de Souza et al. 13performed the tanning of Nile tilapia leather, although in current study the most elasticity found was in the head region, while in the study by Souza et al.13 the highest elasticity was in the transverse region. Furthermore, in the current study, unlike Souza et al.,13 there was interaction between the leather regions and directions.

In contrast, Alla et al.14 evaluated the regions and directions of Nile tilapia leathers tanned with chromium salts, observed that the deformation and elasticity of the leather was greater in the head region 52.60 mm and 87.70%, and considering leather directions the higher results for elasticity 104.60% and deformation 63mm were for longitudinal direction compared to other directions (transverse = 61.00%, 36.60 mm and diagonal 67.40%, 38.80 mm). Thus, it can infer that Nile tilapia leather, when evaluated in the region and direction of removal of the specimens, in the head region and longitudinal direction demonstrated greater elasticity, regardless of the tanning and retanning technique used in the process.

In this independent study of the fish region, the longitudinal direction showed greater elasticity, with the head region being significantly the highest stretching value 95.80%. These results corroborate with Matiucci et al.1,2 who reported that Nile tilapia leather in the longitudinal direction has greater elasticity compared to transverse direction of the leather in this fish species. However, it is possible that the leather demonstrates different results, even if the leathers are from same species of fish and are evaluated in the same directions as the leather. Cavali et al.3 evaluating strength of leathers tanned from paiche with chromium salts and re-tanned with three different tanning agents (vegetable tannin, synthetic and chromium salts), when evaluating the directions of these leathers in relation to length of the fish, the authors observed that the leathers in the transverse direction 11.92 N mm-2 showed greater elasticity compared to other directions (longitudinal= 7.68 N mm-2 and diagonal= 7.01 N mm-2).

Everything indicates that there is a difference in the tensile strength and progressive tearing, as well as in the elasticity of the leather in relation to leather direction, tanning agents used in the tanning or retanning, although there are other factors involved, such as the amount of oil added in the process of leather grease. Dias et al.8 reported that the increase in the addition of oils in the fatliquoring stage provides a greater slip between the collagen fibers, thus shown greater flexibility or elasticity (greater stretching value).22 According to Vieira et al.15 to 73.93% (head), in relation to leather regions. As for the directions, the longitudinal was more region elastic regardless of the evaluated leather.

Paiche skins weighing 12.61 kg and 1.20 m in length were used, whose skin with scale yield was 16.80%, with an average skin weight 2.120 kg. The skins were used to tan with chromium salts and evaluated for the leather regions and directions. After tanning, the leathers showed thickness ranging 1.96 to 2.77 cm.

The thickness of the leather of fish can vary greatly and this variation is related not only to species and different body regions, although also to animal's habitat. According to Vieira et al.,15 it is also correct to take into account that for smaller fish, their leathers must show a more homogeneous thickness than the leathers of larger fish, since throughout their growth, there is a superposition of collagen fibers layers, which may uneven in different leather regions. According to Alla et al.,14 the dermis thicknesses the is mainly determined by proportion of collagen fibers. Thus, it would an explanation for fact that the thickness is variable, in the different cutting leather directions.23

Paiche leather in the head region showed significantly lower 7.07 N mm-2 tensile strength compared to central and tail regions, and these did not differ between them, whose average value was 11.00 N mm-2. Leathers demonstrated greater strength in the longitudinal direction 12.05 N mm-2, while the transversal and diagonal did not differ (Table 2). Cavali et al.3 evaluated the characteristics of paiche leather tanned with plant extracts in place of chromium salts. The authors used specimens of paiche leathers with an average thickness 1.79 mm to 2.82 mm, around the thickness of the leathers used in this study. He reported that leathers tanned with chromium salts showed differences in tensile strength and stretching in the leather direction. The longitudinal direction showed lower strength 4.68 N mm-2 to traction in relation to other directions 6.66 and 7.64 N mm-2. These traction results contradict the results obtained in current study regarding the direction, because in this the better leather strength was in the longitudinal direction. Sstrength values obtained in the leather in current study were higher than those reported by Listat et al.23 This may be related to tanning formulation used, especially regarding the amount of chromium salts or oil content applied in the fat liquoring stage.

Oliveira et al.24 tanning paiche skins with vegetable tannins, reported that paiche leather demonstrated averages 1.91 for thickness, 311 for maximum strength, 16.76 for traction and 57% for stretching. In the leather direction (14.5 N mm-2 longitudinal, 19.1 N mm-2 transverse and 52% transversal and 62% longitudinal) there was no significant difference for traction and stretching, respectively. These values showed in terms of tensile strength were higher than those obtained in current study, due to tanning technique applied and the animal's skins size, which is a function of the (greater weight of the animal) used in the tanning process. The weight variation according to authors was 5 to 43 kg, while in current study it was around 12.61 kg. The skin size must have influenced the results, as they are smaller compared to higher weights reported by Listrat et al.23 and Oliveira et al.24 for the leathers of fish 5 to 43 kg.

Paiche leathers in the central region showed (p <0.05) the highest value (38.13mm) of deformation, although did not differ from head region (31.80mm). In the head region, the leather demonstrated lowest elasticity (52.80%), while in the tail region the highest (71.47%). When analyzing the deformation and stretching of paiche leather, in terms of direction, the transversal one showed the highest deformation value (36.93mm) and stretching (83.33%), shown to more elastic in this direction (Table 2). Elasticity is directly related to traction, as the paiche leathers in the head region showed lower strength and likewise lower elasticity, while these results were higher in the central and tail regions. A similar result was obtained by Cavali et al.,3 who reported that the elasticity (60.79%) was higher in the transverse direction of paiche leather, shown that paiche leather is more elastic in the transverse direction.

The fact that the collagen fibers are easier to slide between themselves, which determines the elasticity in the leather, this makes it difficult to break them due to this ease of movement between them, increasing the striation in relation to length of specimen of the test, which occurs in cm. In this case, it was 3.81 for the specimens in the central region and 3.69 for the transverse leather direction. It will also normally require less force in the application of the test to perform the leather specimen rupture (Table 2). For the paiche leathers, the same occurred in the progressive tear test, where in the central and tail regions the leather resistance was greater compared to head region of the same leather, although in this the maximum force applied in the test did not shown any difference between the regions.

There was no significant difference for force applied in the performance of the traction and stretching test regarding leather regions. Although as for the directions, the force applied to leather in the longitudinal expressed a significantly higher value 301.80 N, while in the transversal the lowest 167.20 N. Thus, with greater force required in this test, even with low elasticity, the leather demonstrated greater strength in the longitudinal direction. This can only be explained by histological structure of collagen fibers. The number of fine fibers and the intertwining between them provide a fibers binding and consequently a greater strength to leather.2,13

The force applied in the progressive tearing test showed no difference for region and direction of the leather. Leathers showed a significant difference only in the regions when the tear was evaluated, with the head region shown less strength (39.60 N mm-1) and the central and tail regions did not differ between them, whose average value was 51.47 N mm-1.

Studies to evaluate the mechanical strength carried out in the laboratories of IPT (Franca city, São Paulo state, Brazil), and BASF (Sapucaia do Sul city, Rio Grande do Sul state, Brazil) proved that fish leathers, tanned in the same thickness as bovine leather, showed greater strength due to intertwining of collagen fibers25,26 and that these fibers are chains of amino acids that give rise to secondary structure in the form of a helix that interacts with other chains through cross-links, giving a high strength.23 Briefly, analyzing paiche leathers tanned with chromium salts, whose thickness ranged 1.96 to 2.77 mm, these leathers showed high tensile strength (12.05% in the longitudinal direction), elasticity (83% in the transverse direction) and tear (51.74% in the central region). Since mammalian leathers tanned with chromium salts according to Souza et al.27 presented values of 9.80N mm-2 for traction for these same parameters, a stretching to rupture of at least 60%, and progressive tearing of 14.72 N mm-2.

They were used as croaker skins with an average weight 2.82 kg and 79.53 cm. The skins have 6.32% of skin over the weight of the fish, whose skins weighed an average of 0.147 g. After the skin’s transformation into leather, they had an average thickness 0.75 to 1.32 mm. Evaluating croaker leathers strength, there was an interaction between the region and the direction of the leather in traction parameters and the force applied in this test. With the interaction unfolding, the highest strength for observation in tail region in the longitudinal direction (25.12 N mmm-2), while the lowest strength was in leather diagonal direction in the head region (7.38 N mm-2) and central (7.87 N mm-2, although it is longitudinal (8.73 N mm-2) of the head region, it did not differ from the diagonal (Table 3).

When analyzing directions within each region, the longitudinal was significantly superior (head 73.16 N; central 158.50 and tail 333.50 N) than the other directions. Therefore, the longitudinal direction of the tail region showed significantly greater strength and the smallest was in the diagonal direction of the head region (54.16 N) and central (60.33 N) (Table 3). It is important to explain the superiority of the longitudinal direction in terms of resistance in relation to the other directions because there is greater interweaving of collagen fibers. And this is an adaptation of the fish to optimize the body hydrodynamics.3

There was a significant difference for region and direction of the leathers regarding deformation and stretching. Leathers in the central region showed greater deformation, that is, 5.17 cm longer, per specimen, in the traction test, corresponding to 86.27% of elasticity or stretching. However, the tail region showed the lowest value 4.16 cm of deformation and 69.11% of leather stretching in the test execution. When analyzing leather directions, the transversal showed the highest value 6.84 cm and 114.6% of elasticity. The longitudinal and diagonal directions did not differ between them for deformation and stretching. However, there was no significant difference regarding regions and directions of the leathers in the determination of progressive tearing (Table 3), whose average value for the region was 99.21 (N mm-1) and 99.21 for direction.

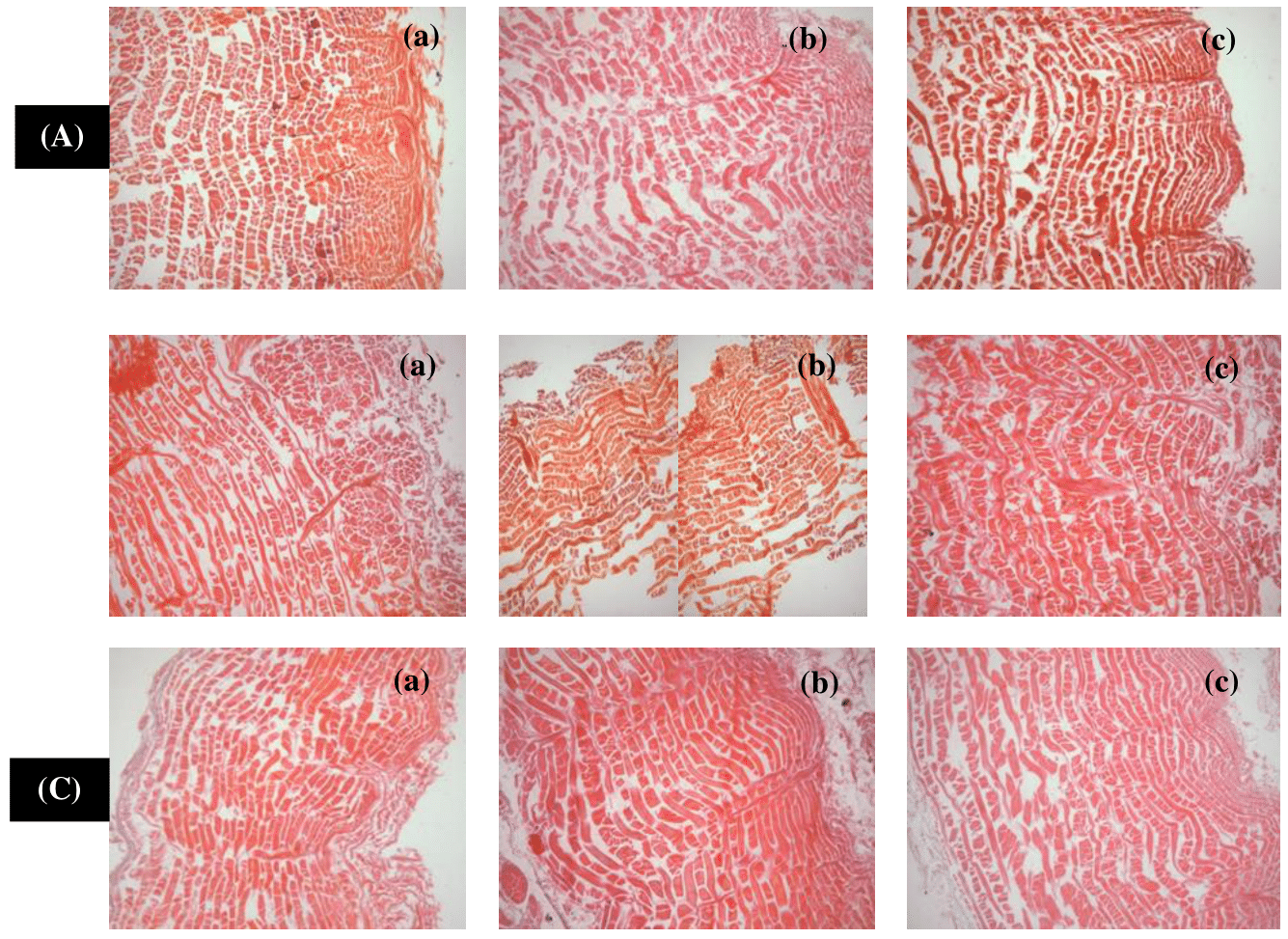

In three species of fish leathers, it is possible to observe the dermis, which is formed by superimposed, intercalated, and organized layers of collagen fiber bundles, with the fiber layers being thinner near the surface (epidermal region) and thickening to average approaching the hypodermis region (Figures 1A–1C). The layers thickness of collagen fibers and the intertwining of these fibers in the direction perpendicular to skin surface is what differentiates the fish leathers.

Figure 1 Photomicrographs (A) Histology of O. niloticus (Nile tilapia) leathers, (a) longitudinal direction, (b) transverse feeling, (c) diagonal feeling;

(B) Histology of A. gigas (paiche) leathers, (a) longitudinal direction, (b) transverse feeling, (c) diagonal feeling;

(C) Histology of C. virescens (croaker) leathers, (a) longitudinal direction; (b) transverse feeling; (c) feeling diagonal.

Nile tilapia leather strength is due to histological structure of the skin as a architecture function of collagen fiber bundles in the deep dermis. According to Souza et al.28 the skin dermis is formed by arrangements of layers of collagen fibers superimposed parallel to surface of the skin and interspersed perpendicularly to it, forming a tie between these collagen fibers (Figure 1A). In general, this provides greater strength to leather after tanning, with the tanning agent’s reaction to collagen fibers and the addition of fat liquoring oils that lubricate them for greater slippage between them, determining greater softness in the leather.

The dermis is composed of a thick crisscross arrangement of collagen fibers that wrap helically around the fish's body,23 sustaining the transmission of force along the spine, providing locomotion through undulating movements. With this arrangement characteristic of collagen fibers existing in the skin, after tanning and transformation of this skin into leather (putrescible material), the leather shows high strength, mainly in the direction transverse to fish length due to this histological structure that is formed to help in swimming, as well as to support the fish's own internal structure.21

If we compare the three fish species in terms of size, paiche and croaker were slaughtered with greater weight, consequently shown greater skin size, and if we analyze the results obtained from leather stretching and deformation, which corresponds to elasticity and how much the specimen length in the test performed, is the transverse direction that demonstrated greater elasticity and deformation, shown that this leather direction must have more histological structure prepared to support the swimming movements, as it is a larger fish, as well as the organs internal. If compared with Nile tilapia leathers, due to their smaller size, there is no significant difference for leather directions and also for regions. As for the regions, for the croaker leathers, deformation and stretching were greater for the central region and may also associated with movement and support, while the paiche is larger and requires more agility in swimming, especially to perform air breathing mandatory, must have a more developed histological structure in the tail region to assist in this movement in swimming to come up to surface to breathe. So much so that the stretching of the leather in the tail region was significantly higher (71.47%) compared to other regions.

Comparing the three species leathers studied (small, medium and large) in terms of strength parameters, it was notable that the leathers of the larger paiche, the leathers regions and directions influenced the tensile strength, deformation and stretching. Medium-sized fish, the region and direction, influenced only the leather deformation and stretching test, for traction there was interaction, while smaller Nile tilapia there was interaction for deformation and stretching, since the traction was influenced only by the direction removal of specimens (Tables 1–3).

In Figure 1B of the paiche leather longitudinal section, the leather surface can observe, shown the protective lamellae scales and insertion, where the difference in histological tissue is clearly observed, as a function of the thickness, disorganization in the collagen fibers, unlike organization, arrangement and orientation of collagen fibers in the dermis. In Figure 1B, which shows the paiche leather cut in the transverse direction, it can be observed that the collagen fibers are in layers parallel to leather surface and from space-to-space transverse fibers cross the parallel ones, which are thicker, providing a tighter binding on the leather. The distribution of collagen fibers is observed to thinner and closer together and as they move away from the surface, they increase in thickness and spacing between them.

Listat et al.23 reported that the dermis demonstrates a structural arrangement of collagen fibers, allowing the skin to have great strength to different traction forces. For this reason, the skin of some species of fish can used commercially in the manufacture of leather goods. Analyzing SEM images and histology (Figure 1C), where the interlacing architecture, arrangement and orientation of collagen fibers, as well as the superimposed layers of these fibers can observed, confirm physicomechanical results obtained from leathers tanned in the longitudinal, transversal and diagonal directions of Nile tilapia, 'paiche and croaker leathers.

Test 2: Tanned leathers strength

After the process of tanning the three fish species skins, the flower design can be observed (Figures 2A–2C). This flower design of the leathers refers to design formed by lamellae protecting and inserting the scales, where they are inserted when on the animal. The flower design is characteristic of each species of scale fish, forming unique and inimitable mosaics. For those who have knowledge about each species of fish, through the leather after tanning, the species of fish can be identified by the design formed and lamellae depending on their opening and length.15

Figure 2 Photomicrographs (A) Flower drawing of O. niloticus (Nile tilapia) leather shown protective lamellae (a, b) and scale insertion (c);

(B) Drawing of A. gigas (paiche) leather flower shown protective lamellae (a, b) and scale insertion (c);

(C) Flower drawing of C. virescens (croaker) leather shown protective lamellae (a, b) and insertion of the scales (c);

(D) Surface of A. gigas (paiche) leather, resistance measurement (a) and leather scale space (b).

More descriptions: (A) flower design; (B) opening or diameter of protective lamellaes and insertion of fish leather scales, (*) junction point between three lamellaes; (C) place of measurement of the lamellae of insertion and protection of the scale.

With the fish skinning that is with the skin’s removal, depending on how the scales are inserted in the skin, scales size, depth or length of the lamellae (dermal tissue that overlaps the head portion of the scale), they come out very easily, while in other species it becomes more difficult to remove the scales, requiring an efficient gutter to open the fibrous structure and remove the scales.3,8

Flower leathers design of the three species is extremely different, and the croaker has a smaller opening (space referring to place where the scale was) of the lamellae, as well as the length (dermal tissue that overlaps the head scale portion) the same Nile tilapia leather is intermediate to skin of the two other species. Removal of scales is very easy compared to very small gills like the croaker or very large ones like paiche. The paiche leathers lamellae are more open and longer compared to other species (Figure 2B). As the depth of lamellae is very great, the difficulty of removing the scales is also greater, as they are better inserted into the dermal structure even in a lime solution, which opens the dermal structure, it is not enough to easily remove all the scales (Figure 2B).

In Figure 2B, it can see in the croaker, a scale incorporated in the coverslip that did not come off during the tanning process. There is often a need to activate more hours in the solution to completely remove the many scales from the skin. In the scalp, it is defined as a longitudinal scale’s protection and scalp length.

These lamellae are positioned in the fish lateral line, shown scales of larger size and differentiated from the skin rest. These are more difficult to remove during the tanning process. Requiring greater action to achieve removal. In Figures 2A–2C, it is possible to notice the lamellae much more developed and larger compared to rest of the leather. In Nile tilapia leather this is not observed.

The pattern of organization of protective lamellae scales and insertion is observed, being elongated (1.5 to 2.5 cm) and deep (3.5 to 4.5 cm), as well as the diameter or opening between them 1.5 to 4.0 cm, that is, where the scales are inserted (Figures 1A–1C). The coverslips thickness varies 0.45 to 1 mm, this being for the point (*) of junction between the three coverslips (Figures 2A–2D). Therefore, the lamellae form a unique design, species fish characteristic shown commercial importance for its beauty. However, in addition to beauty observed for this type of leather, its strength quality can still be associated, which differs in relation to different species, and within the same species it can vary in relation to regions (head, central or tail) or direction (longitudinal, transverse and tail).

Cavali et al.3 when evaluating the skins regarding design to flower design, they reported that the paiche skin provides a leather with a more defined flower design characteristic and difficult to imitate, due to greater size of the protective lamellae and scale insertion. The same authors mention that the design is a characteristic of each species after tanning, constituting a definition of each type of skin, depending on the species. Therefore, it can be identified which species of fish the tanned leather is from, just by observing this visual feature of the surface of this leather. Matiucci et al.2 reported that pacu skin shows these very small and triangular lamellae, providing, after tanning, a leather with a delicate design, with well-opened lamellae.

Also, a very visible feature in paiche leather are the holes referring to lateral line of the fish, they are small and positioned between the junction of the three parts of the lamellae (Figures 2A–2D). In the leathers of the other fish species, despite knowing the existence of these holes, it was not possible to visualize them, perhaps due to size being much smaller than those observed in the paiche leathers.

In Figure 3A and 3B, the fleshy side of the leather can observed, after tanning the three species skin shown the layers of collagen fibers intertwined with each other. With the paiche leather SEM, in this same place, this organization of the collagen fiber bundles interweaving can observed with better clarity. The lamellae showes in the three fish species leathers are also made up of much finer collagen fibers, together and disorganized in relation to leather rest. Note that in the paiche leather, because the flap is thicker, the collagen fibers are also thicker and separated between them, giving the appearance of a more spongy tissue (Figures 3C–3E).

Figure 3 Photomicrographs (A) Flesh side of A. gigas (paiche) leather after tanning with vegetable tannin, shown arrangement of collagen fiber bundles;

(B) SEM shown arrangement and orientation of collagen fiber bundles on flesh side of paiche leather in superimposed layers;

(C) SEM of O. niloticus (Nile tilapia) leather shown superimposed layers of collagen fiber bundles of the dermis;

(D) SEM of paiche leather shown superimposed layers of collagen fiber bundles in the dermis;

(E) SEM of C. virescens (croaker) leather shown superimposed layers of collagen fiber bundles of the dermis.

After the leathers tanning, species regardless, it was observed that the vegetable tannin (1.35 mm) provides an increase in the leathers compared thickness to those tanned with chromium salts (1.23 mm). Evaluating leathers thickness of fish from different species, it is noted that there was a significant difference between them, with the paiche leathers shown the greatest thickness (2.38 mm), while the croaker leathers thickness (0.95 mm) and Nile tilapia leathers (0.96 mm) were similar (p >0.05), despite the difference in slaughter weight between these two species. It was expected that croaker leather would thicker be due to its larger size compared to Nile tilapia, as happened with paiche leathers (Table 4).

When the leathers were evaluated according to species and tanning agents, the Nile tilapia (14.18 N mm-2) and croaker (13.30 N mm-2) leathers showed similar strength values, although higher than paiche leathers strength (10.43 N mm-2). Therefore, even the paiche leather, being thicker, was less strength. Nile tilapia leather is 26.45% more strength than paiche leather and 21.5% croaker leather for the traction parameter. The three species leathers showed no difference in the tensile test tanning agent regardless (chromium salts or vegetable tannin) used in the process. Therefore, more use of vegetable tanning is recommended, as it is more ecological and does not interfere with strength.

Croaker leather showed higher elasticity (77.59%) and strength to progressive tearing (102.81 N mm-1) compared to paiche leathers (65.26% and 46.83 N mm-1, respectively). Therefore, croaker leather was 15.89% more elastic than paiche leather. As for tear strength, croaker leather is more strength for this parameter 54.45%. Nile tilapia leathers demonstrated elasticity similar to leathers of the two species. The tanning agents do not influence the determination of tearing and elasticity of the leathers of the three species of fish. While the paiche leathers needed more force 105.44 N and 244.69 N, respectively, to perform the progressive tearing and traction tests, while Nile tilapia leather required the lowest (64.23 N mm-1 and 135.38N). The tanners influence force applied to continue the leathers tearing, and the tannins tanned required significantly greater force (89.27 N mm-1) and those with lower chromium salts (78.53 N mm-1).

Oliveira et al. 24when analyzing paiche leather tanned with vegetable tannin achieved superior results for maximum strength (365.6%), progressive tearing (82.80%), and traction (19.1%), where the technique used and the time of exposure to tanner can influence strength. Eires et al.29 when tanning in a static way, where the product stayed longer in contact with the leather, it achieved results of strength that were also superior, the leather of Cynoscion acoupa, a species of large fish, obtained a maximum strength 513.1%. As we can see, the time of exposure to vegetable tannin tanning agent provides greater strength. Although it does not change the result of stretching the species leather, which were at the same average in this study.

Alla et al.14 and Hilbig et al.30 state that when chromium is used as a tanning agent, the stretching strength is affected, as chromium makes the leather softer and more elastic. In current study, the stretching of leathers tanned with chromium salts was only higher for Nile tilapia (71.40%) and croaker (82%), with no significant difference.

Result obtained from chromium oxide in Nile tilapia, paiche and croaker leathers were 3.11, 2.85 and 2.94%, respectively. This percentage refers to amount of chromium oxide (tanning agent) attached to collagen fibers. The minimum value of chromium oxide fixed in the semi-finished leather must 3.0%,31 according to BASF32 the value of chromium oxide in the leather must above 2.5%. In this way, the three leathers tanned with chromium salts have an adequate amount of chromium salts. The value obtained in current study averages that leathers were able to withstand high temperatures, without shrinking, that is, there is no shrinkage of collagen fibers when the boiling or shrinkage test performed during the tanning process is performed (Table 5).

There was interaction between species and tanning agent for the deformation parameter. Croaker leather demonstrated the highest value regardless of the tanning agent used, so that the elasticity was lower (77.59%) for leathers of this species. The leather that showed the least deformation was that of paiche, tanned with chromium salts and the elasticity of this leather was evaluated and it was less elastic (65.25%). The substances soluble in dichloromethane varied 11.84 to 25.10% among the analyzed leather samples of the three species. This analysis refers to substances that are extractable from the sample by the solvent. This analysis indicates the content of oils and greases in the leather. BASF32 reports that the values must at most between 16 to 18% for leather to used in clothing.

In fat liquoring, collagen fibers must be coated with oil, to provide a better feel and strength to progressive tearing, wettability with water, impermeability to water and permeability to air and water vapor, due to the lubrication fibers effect, avoiding their agglutination.30,31 In current study, leathers tanned with chromium salts showed higher values of extractable substance in dichloromethane compared to leathers tanned with vegetable tannin. Final pH of the leather is usually acidic, to provide better fixation of retanning agents, dyes, and oils. The aqueous extract pH of the ground leather was determined by potentiometer and measures the solution ionic concentration. In current study, the pH value ranged 3.77 to 4.20 for leathers tanned with corm salts and 5.43 to 5.53 for those tanned with vegetable tannins. The differential figure was not detected; therefore, it averages that it was below 0.4, being considered good, due to fact that there is very little acidity between the collagen leather fibers after its tanning process. Excessive acidity causes the protein chain degradation, by acid hydrolysis, decreasing the leather strength.33,34 The minimum pH value in semi-finished leather should 3.5.31

The pH values obtained for three species are much higher than the value reported by Neu et al.31 and Baldi et al.34 This pH variation is due to the lower amount of formic acid added in the variation pH stage, where for tanning with chromium salts this pH should be 3.0, while for vegetable tannin it should be 4.0, so that the tanning agents absorbed by the dermis and subsequently fixed.32,33 In current study, as the same percentages of chemical products were used during the other stages, and the pH correction was not carried out at the end of the tanning process, in the fixation stage, whose pH should be at 3.5.

Due to these higher pH values that occurred in the tanning with vegetable tannin (5.43 for Nile tilapia, 5.53 for croaker and 5.49 for paiche), there was less fixation of oils in the final process of tanning, being noticeable in values of extractable substances in dichloromethane, which were 11.84 for Nile tilapia leathers, 15.24% for croaker and 17.51% for paiche), while those that showed better fixation were the values 15.64, 21.97 and 25.10%, respectively for the same species when tanned with chromium salts. Fixation is very important both in the fat liquoring and dyeing stages, since in the leather pH range of around 3.5 there is no release of dye and oils, with higher proportions of these remaining in the leathers.

The tannin-tanned leathers had higher calcium contents ranging 0.10 to 0.54%, while the chromium salt-tanned leathers had values 0.05 to 0.09%. The lower the calcium content shows in the leather, the softer it is, since the amount of calcium tends to make the leather more cardboard, depending on the calcium used in the initial stages of the process (liming). The values were lower for leathers tanned with corm salts, as a pH required function for tanning with corm salts, which must pH 3.0, while for vegetable tannins it must 4.0, thus enabling the greater calcium retention in the tanning process. According to BASF32 and Baldi et al.,34 Oliveira-Filho et al.,35 the pH value below 3.5 makes the leather less strength and can cause damage to quality of the product, especially in the leather structure.

Tanning agents can influence the force applied in the tests and the leather thickness with better results for leathers tanned with vegetable tannin, while for other strength parameters, either of the two tanning agents evaluated can used. The regions and leather directions influence leathers strength as a function of each parameter evaluated. Nile tilapia leather shows higher tensile strength in the longitudinal direction and lower in the diagonal direction, with no differences being observed in the leather regions of this species. It tears more easily in the tail region and in the head region, probably because it has less reticulin fibers. Elasticity is greater in the longitudinal direction of the head region and smaller diagonally for the same region. Croaker leather shows greater tensile strength in the transverse direction of the head region and in the longitudinal tail region direction. It is a leather with greater elasticity in the transverse direction of the head and central region. While paiche leather demonstrates greater strength in the longitudinal direction of the central and tail regions. Leather is more elastic in the transverse direction and in the tail region. It has less tear strength in the head region. As for physicochemical tests, the results were similar for leathers of the three species. It can be observed that in the Nile tilapia skins, the collagen fibers were thick, parallel, however, with large bundles of collagen fibers arranged in the transverse skin direction. Comparing leathers of the three species of fish, the paiche leather, despite the greater thickness and the distribution of collagen fibers intertwined with these fibers’ transverse to surface of the leather, demonstrated lowest tensile strength, progressive tearing and less elastic, compared to others. Analyzed leathers croaker and Nile tilapia leathers showed similar results in terms of tensile strength and elasticity, being only less strength to progressive tearing.

Tanning with vegetable tannin is recommended for the skins of the three fish studied. Leathers become high quality products, being the raw material for making various artifacts such as clothes and shoes. In addition, it is more environmentally friendly than conventional chemical tanning agents. The quality characteristics of leathers have varied with the commercial dynamics of the new market niches, especially for the numerous purposes for which they are applied. Years ago, only strength and durability were prioritized, nowadays the priority is the participation of fish leathers in new foreign market niches, with leathers that expand in terms of flexibility, visual characteristics, representativeness, and rusticity. Also, the labeling of these leathers comes from the use of organic products. Therefore, fish leathers express important physicomechanical characteristics in relation to traditional bovine leather and have their added value when subjected to organic products and processes that maintain the natural characteristics of the product, guaranteeing the fixation of the color and/or collagen fibers characteristics of the such as the use of organic tanning and natural dyes. They have added market value to leather accessories and artifacts with an appeal of sustainable origin.

This study was supported by the Universidade Estadual de Maringá and also by Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

The authors declare that there are no conflicts of interest.

None.

©2024 Corrêa, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.