Research Article Volume 5 Issue 2

Impact of processing steps on physicochemical and rheological properties of tomato paste (cold-break)

Adel Abu Bakr Shatta,

Regret for the inconvenience: we are taking measures to prevent fraudulent form submissions by extractors and page crawlers. Please type the correct Captcha word to see email ID.

Khaled Mohamed Youssef, Abdullah Saleh Al Sanabani, Salah Kamel El Samahy

Department of Food Technology, Faculty of Agriculture, Suez Canal University, Egypt

Correspondence: Adel Abu Bakr Shatta, Department of Food Technology, Faculty of Agriculture Suez Canal University, Ismailia 41522, Egypt, Tel +20-111-717-3478

Received: August 31, 2016 | Published: November 7, 2017

Citation: Shatta AAB, Youssef KM, Sanabani ASA et al. Impact of processing steps on physicochemical and rheological properties of tomato paste (cold-break). MOJ Food Process Technol. 2017;5(2):263-271. DOI: 10.15406/mojfpt.2017.05.00122

Download PDF

Abstract

Tomato paste is used for color and taste of food preparations. Tomato pastes are potentially rich sources of dietary phytonutrients might contribute important health benefits to consumers. Twenty one samples from five processing steps were collected in-line processing of tomato paste (cold-break) to follow-up the changes of some quality attributes of tomato juice to paste and to investigate the relationship between some rheological properties and pectin fractions, as well as the relation between the Hunter color readings, beta-carotene and lycopene contents. The results showed that, the rheological values, pectin fractions, lycopene and beta-carotene contents were increased significantly during concentration of tomato juice to paste. Lycopene and total carotenoids contents were well correlated with Hunter color parameters (

= 0.80-0.93). During concentration process, the studied rheological properties of tomato juice had positive correlations with total and pectin fractions contents. Exponential regression produced a better fit with total, oxalate soluble and water soluble pectins (

= 0.83-0.94), while linear regression with acid soluble pectin content produced a good correlation (

= 0.93-0.95).This investigation is useful for whom concern with tomato paste processing (cold-break).

Keywords: tomato paste, rheological properties, color, lycopene, pectins, cold break

Abbreviations

WIS, water insoluble solids; AOAC, association of official chemists; TSS, Total soluble solids; ANOVA, analysis of variance; OSP, oxalate soluble pectins; WSP, water soluble pectins

Introduction

Tomato (Solanum lycopersicum L.) belongs to the family Solanaceae. It is one of the most popular a horticultural crop of great interest, being widely consumed either fresh or processed such as tomato juice, soup, paste, puree, ketchup, sauce and salsa.1 In 2015, Egypt is ranked the world's fifth largest producer of tomato. Egypt produces about 8,533,803 tons of fresh tomatoes per year, accounting 1.15% of the total world production.2 Of Egypt's output of 8.5 million tons of fresh tomato per year, only 252000 tones are processed.3 Global processing tomato production this year is expected to increase 6% to reach 42.24 million tons, according to the latest estimate by the World Processing Tomato Council.4 Besides its economic importance, the nutritional value of its fruits, the tomato, one of the most important worldwide agricultural crops, is rich in a plethora of natural antioxidant compounds. The regular consumption of tomatoes or tomato products has been related epidemiologically to a lower incidence of cardiovascular diseases, prostate, gastrointestinal and epithelial cell cancers.5 Tomatoes do not lose their health benefits as they are processed or cooked. In fact, lycopene in cooked and processed tomatoes (sauce, paste, salsa, canned tomatoes) is more easily absorbed than fresh tomatoes. In the United States, about 57% of daily lycopene intakes come from processing tomato products and only 12% from fresh tomatoes.6 Also, in western countries, tomato-based products comprise 85% of dietary lycopene.7

Since tomato paste is the main ingredient in the final products, maintaining the quality of the paste is crucial for the tomato processing industry. The characteristics quality factor of tomato paste depends on the quality of starting raw materials (variety and ripening stages), processing conditions (process design, time, temperature and process pressure), storage time and conditions.8 These factors introduce great variation in the quality of the paste.9 These variations pose difficulties in achieving a consistent paste quality during production. As a quality control routine for pastes included: color, soluble solids content, pH, acidity and consistency.10

Color is an important quality factor in processed tomato concentrates, since it influences consumer acceptability. Many reactions can take place during thermal processing and affect color. Among them, the most common are pigment degradation, especially lycopene.11,12 Also, viscosity of tomato paste is one of the main quality attributes that should be considered to determine the overall quality and consumer acceptability of many tomato products. Tomato paste contains both water soluble materials and insoluble components. The consistency of a tomato paste is mainly controlled by the amount of pectin, total soluble solids, and size distributions of insoluble constitute.13 Viscosity is an important technological factor that is related to the content of substances insoluble in alcohol, protein, pectins and polysaccharides.14 Furthermore viscosity is the combined effect of liquid soluble material, insoluble in suspension that contribute to the overall consistency of tomato paste.15 Different empirical models have been used to characterize the flow behavior of tomato concentrate.16 Many of them relate to solid concentration, particle size and processing conditions, like breaking temperature, finishing, concentration and homogenization of both tomato juice and tomato paste.16-18 In fact, these processing conditions have an indirect effect on the apparent viscosity and flow parameters, by influencing the physicochemical characteristics of the water insoluble solids (WIS) particles and serum viscosity.16 Several researchers have shown that difficulties in quality control arise from the great variation in flow behavior in commercial tomato paste caused by different agronomical and processing conditions.16 Tomato paste exhibits complex rheological behavior, i.e. it is a non-Newtonian, shear-thinning and time dependent fluid that shows an apparent yield stress.15,19,20 One of the problems facing the companies for exporting tomato pastes is variation in color and consistency of their products. An in-line process measurement of tomato paste properties, especially the consistency, is very valuable for improving the quality of products and minimizing production cost.21

Therefore, the objective of this study was to follow-up the changes of physiochemical properties of tomato juice during the tomato paste processing and to study the relationship between some rheological characteristics (apparent viscosity, yield stress, consistency coefficient) and pectin fractions, as well as the relation between the Hunter color readings, beta-carotene and lycopene contents of tomato paste during the processing.

Materials and methods

Materials

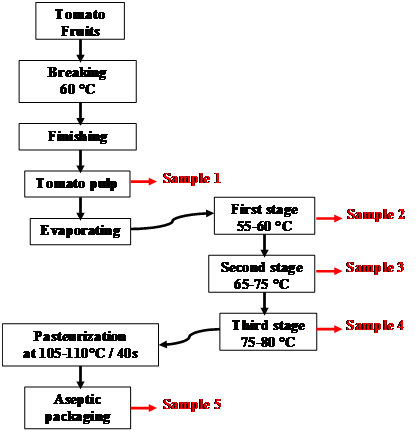

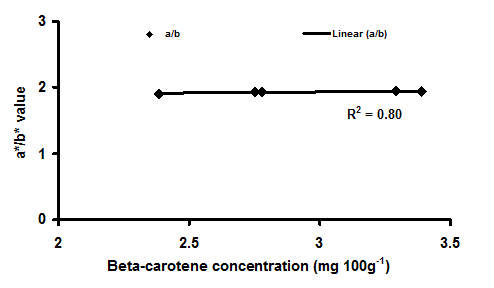

Samples from the different processing steps in-line plant and the resultant tomato paste were collected from Ismailia National Company for Food Industries “Foodico”, Ismailia, Egypt. The plant used a Castle rock tomato variety and cold-break rupture process. Samples from five processing steps from independent processing events using different independent tomato batches (twenty one samples from each processing step) were collected during cold-break processing during two years. Figure 1 shows the tomato paste production scheme (arrows outward indicate the sampling steps of the study).

Figure 1 Flowchart of tomato paste production (arrows outward indicate the sampling steps of the study).

Chemicals and reagents: Sodium hydroxide and calcium chloride were purchased from Fluka. Ammonium oxalate and anhydrous Na2SO4 were obtained from Sigma-Aldrich CO. Petroleum ether, acetone, acetic acid and hydrochloric acid (analytical grade) were from Scharlab (Barcelona, Spain).

Methods

Preparation of tomato paste: Fresh tomato fruits were washed and sorted prior to entry into the breaker. The tomato fruits were crushed and extracted at 60 °C and strained by three refiners with diameters of 1.2, 0.8 and 0.4mm to remove seeds, skin and large pieces of tomato, followed by holding for periods ranging from seconds to minutes during which the enzymes liberated as result of crushing catalyzed the breakdown of pectins. The concentration process passed through three stages, the first at 55-60 °C, the second at 65-75 °C, the last at 75-80 °C under vacuum, followed by flash pasteurization at 105-110 °C for 40s and filling in aseptic bags. The final concentration reached about 36 °Brix.

Physicochemical analysis: The moisture content and titratable acidity (%, as citric acid) were determined according to the methods of Association of Official Chemists.22 Total soluble solids (TSS) content of the samples was determined using a digital refractometer (Model A 131769, ATAGO, Tokyo, Japan) and were expressed as degrees °Brix according to the AOAC22method. All the readings were performed at 20 °C after filtration through hydrophilic cotton. The pH value of the samples was measured using a pH-meter (model 3305 Jenway Ltd, UK) at 20 °C.

Determination of tomato chlorophylls, β-carotene and lycopene: Chlorophyll a and b, β-carotene and lycopene contents of tomato samples were determined with the method described by Barros et al.23 with some modifications as follows: Two hundreds mg of sample was vigorously shaken with 10 ml of acetone-hexane mixture (4:6) for 5 min and filtered through glass wool. The extract was adjusted to 10 ml with volumetric flask. The absorbance of the extract was measured at 453, 505, 645 and 663 nm using a spectrophotometer (6505 UV/ VIS, Jenway LTD, Felsted, Dunmow, UK). Contents of lycopene, β-carotene, chlorophyll a and b were calculated according to the following equations:

(1)

(2)

(3)

(4)

Where A is the absorbance at the mentioned wavelengths and further expressed in mg per 100 g dry weight.

Total pectic substances: Total pectins (water-soluble, ammonium oxalate 0.2 % and 0.05NHCl fractions) were determined according to the AOAC.22

(5)

Where:

WS =water-soluble fraction

OS = ammonium oxalate-soluble fraction

AS = acid-soluble fraction.

Color measurements: Color attributes; lightness (

), redness (

) and yellowness (

) of tomato juice and paste were measured in a cylindrical sample cup (5-cm diameter × 2-cm high) filled to top using a Labscan Model LSXE (Hunter Associates Laboratory, Reston, VA, USA). Standard color plate No. 400 with reflectance values of

= 25.70,

= 33.60 and

=14.70 was used as a reference. The tomato paste samples were diluted to 12 °Brix before measuring.24 The red-yellow ratio (

) was reported to indicate the redness of tomato paste.25 To determine the overall color changes, a numerical total color difference (∆E) was calculated according to Park et al.26 using the following equation:

(6)

The color intensity (C*) was calculated as: C*= (a*2 + b*2)0.5

Furthermore, the hue angle (hab) was calculated as: hab = tan-1 (b*/a*)

Where hab= 0°C for a red hue and hab= 90°C for a yellow hue.27

Rheological measurements: Rheological properties of tomato juice or paste were carried out with Brookfield Digital Rheometer model DV-III+ (Brookfield Engineering Lab., INC., Middleboro, USA) at 20 °C. The Brookfield small sample adapter and Sc4-14 and Sc4-21 spindles were used. Data were analyzed using the Casson (Eq. 7) and Power law (Eq. 8) mathematical models.28 These models are:

(7)

(8)

where:

;= shear stress (N m-2)

= Yield stress,

(N m-2)= shear stress at zero shear rate

= plastic viscosity (mPa s)

= shear rate (s-1)

= consistency coefficient (mPa sn)

= flow behavior index.

The apparent viscosity (mPa s) of the samples was measured at 10 rpm at 20 °C.

At least three replicates of each test were performed. All samples had the same recent thermal history.

Activation energy and the effect of temperature on viscosity: Activation energy and effect of temperature on viscosity were calculated using Arrhenius-type equation as mentioned by Ibarz et al.29 The equation is:

(9)

Where:

is the viscosity

is a constant

is the activation energy

is the gas constant

is the absolute temperature in °K.

Statistical analysis: The data are presented as the mean of the determinations ± standard deviation. Analysis of variance (ANOVA) was performed using CoStat under windows program (CoStat program ver. 6.311, 2005). Duncan’s multiple range test was used to establish the multiple comparisons of the mean values at p = 0.05.

Result and discussion

Effect of processing steps on some quality attributes of the resultant tomato paste

Some quality attributes of tomato juice during concentration are presented in Table 1. Upon concentration from 4.48 to 35.88 °Brix, the moisture content significantly decreased from 94.17 to 63.13 g 100 g-1. The pH values not significantly decreased from 4.29 to 4.23, while the titratable acidity contents significantly increased during processing from 0.447 to 3.001 g 100 g-1 as citric acid, respectively. Because the classification of tomato products, e.g., paste or puree, is done according to its soluble solids content, it is a key characteristic of tomato products. During evaporation, the real-time value of the soluble solids helps to determine the end point of the processing. In addition, the flavor of tomato paste is closely associated with the soluble solids content and titratable acidity. These results are within the limit specified by Egyptian Standard, Codex Standard, and the results obtained by Shatta & Youssef.30,31

|

Parameter

|

Tomato Juice

|

First Stage

|

Second Stage

|

Third Stage

|

After Pasteurization

|

|

Moisture content

|

94.17a±1.68

|

93.04a±1.61

|

89.61b±2.65

|

63.90c±2.09

|

63.13c±2.47

|

|

TSS (°Brix)

|

4.48c±0.62

|

5.48c±0.88

|

8.35b±1.27

|

35.27a±2.96

|

35.88a±0.59

|

|

pH value

|

4.29a±0.15

|

4.22a±0.13

|

4.26a±0.17

|

4.25a±0.07

|

4.23a±0.07

|

|

Titratable acidity (%, as citric acid)

|

0.447b±0.081

|

0.525b±0.084

|

0.582b±0.070

|

3.079a±0.235

|

3.001a±0.259

|

Table 1 Changes in physicochemical characteristics (mean ± SD, n= 21) during processing of tomato paste (cold-break)

Data are an average (±SD) of triplicate

SD: Standard Deviation

N: Number of the samples

Means having the same letter within each row are not significantly different at p= 0.05.

|

Item

|

Tomato Juice

|

First Stage

|

Second Stage

|

Third Stage

|

After Pasteurization

|

|

Beta-carotene

|

2.386d±0.092

|

2.750c±0.081

|

2.777c±0.080

|

3.389a±0.090

|

3.291b±0.060

|

|

Chlorophyll a

|

1.180c±0.081

|

1.044d±0.060

|

1.426b±0.072

|

1.485b±0.071

|

2.220a±0.089

|

|

Chlorophyll b

|

2.067d±0.616

|

2.496c±0.297

|

3.245b±0.734

|

3.192b±0.545

|

4.857a±0.932

|

|

Lycopene

|

1.953d±0.089

|

2.674c±0.249

|

3.099b±0.205

|

3.596a±0.222

|

3.710a±0.217

|

|

Color Attributes

|

|

L*

|

26.42b±1.49

|

26.98a±0.88

|

26.67b±0.81

|

24.64c±1.09

|

24.06d±1.09

|

|

a*

|

26.92c±1.43

|

27.14c±1.09

|

28.32a±0.82

|

27.80b±1.61

|

27.28c±1.66

|

|

b*

|

13.78d±0.86

|

14.30b±0.50

|

14.65a±0.52

|

14.36b±0.57

|

14.12c±0.55

|

|

a*/b* ratio

|

1.93a±0.11

|

1.90a±0.10

|

1.94a±0.07

|

1.94a±0.09

|

1.93a±0.09

|

|

C*

|

30.24c

|

30.68bc

|

31.88a

|

31.29ab

|

30.72bc

|

|

hab

|

27.11c

|

27.78a

|

27.35b

|

27.32b

|

27.37b

|

|

ΔE

|

-

|

0.8

|

1.17

|

2.07

|

2.41

|

Table 2 Changes in pigments content (mg 100 g-1, wet basis) and color attributes (mean ± SD, n= 21) during processing of tomato paste (cold-break)

Data are an average (±SD) of triplicate.

SD: Standard Deviation

N: Number of the samples

Means having the same letter within each row are not significantly different at p= 0.05

Maintaining the natural color in processed and stored foods has been a major challenge in food processing. In the case of tomato products (i.e. paste), an important reaction is the degradation of the red pigment lycopene, originally in the trans form, that isomerizes to the cis structure during heating, resulting in changes of color.12 Table 2 shows that, the beta-carotene lycopene contents of the tomato juice were 2.386 and 1.953 mg 100 g-1 (wet basis), respectively. The beta-carotene and lycopene contents significantly increased during the concentration process to 3.291 and 3.710 mg 100 g-1 (wet basis) in the pasteurized paste, respectively. These results are in agreement with those obtained by Shatta,30 Marković et al.32 and Youssef.31 Also, the contents of chlorophyll a and b significantly increased during concentration process. Seybold et al.33 found that, due to the loss of water during thermal processing of tomato, contents of lycopene and carotenoids on a wet weight basis increased. On a dry weight basis, contents of lycopene increased or decreased depending on the origin of the tomato fruits used, whereas the β-carotene contents decreased or were quite stable.

Lightness and

ratio reported as the indicative and quality parameters for the color of tomato products34 of the samples were measured to quantify the extent of the color difference between tomato pastes samples. A one unit difference in

value of two samples can be detected by the human eyes. Hunter color parameters; lightness (

), redness (

) and yellowness (

) changed significantly during tomato processing (p = 0.05). The L* value decreased from 26.42 for the juice to 24.06 (the darkest) for the resultant tomato paste. The

value not significantly increased from 26.92 to 27.28, but

value significantly increased from 13.78 to 14.12 for juice and pasteurized tomato paste, respectively. The red-yellow (

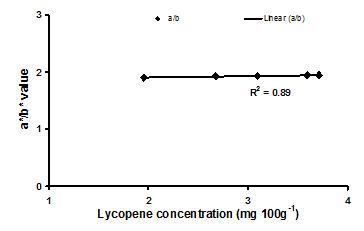

) ratio, indicates the redness of tomato products.

An ratio of 1.90 or greater represents a top quality product in terms of color and an

ratio of less than 1.80 means that the tomato products may be unacceptable for inclusion in the products, where

bright red color is desired.34 The

value of the tomato juice was not significantly changed during processing steps enclosed to 1.93, indicating a top quality product. The color intensity (C*) value and red hue angle (hab) changed during processing steps with range around 31.00 and 27.00, respectively. The arithmetic total color difference (∆E) showed that the color difference gradually increased during processing, from 0.80 at the first concentration stage to 2.41 for the pasteurized paste (Table 2). This factor, which summarized the effect of the thermal process on the color during concentration process, was low.

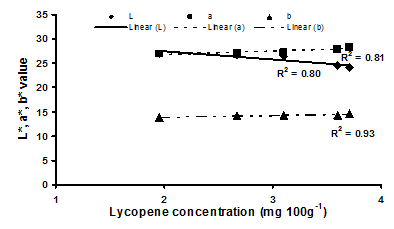

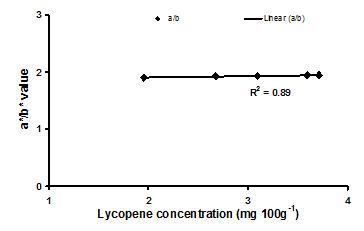

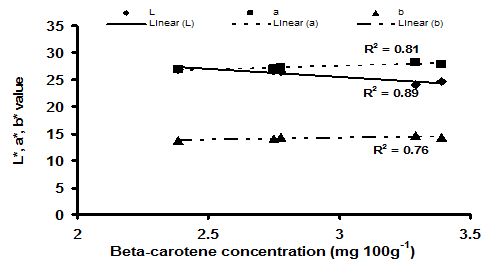

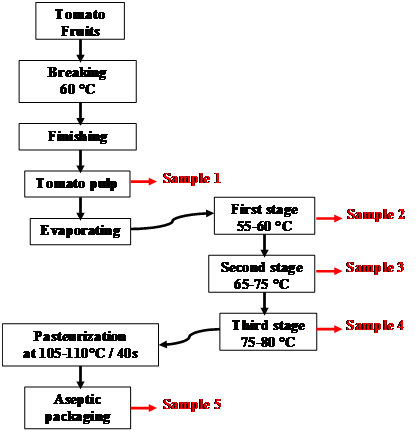

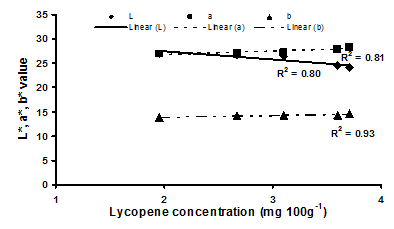

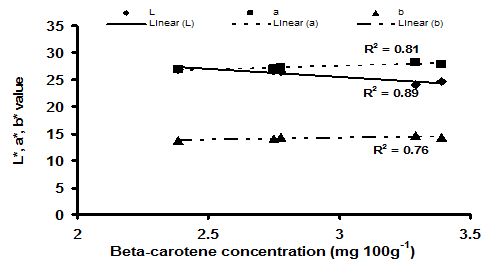

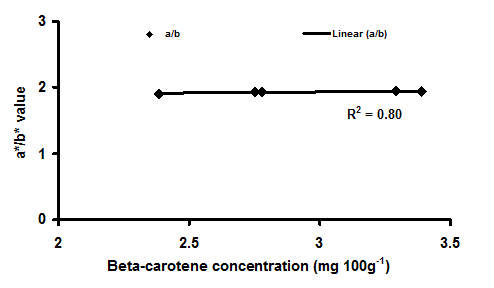

The relationships between lycopene, beta-carotene contents and

,

,

and

ratio values are shown in Figure 2 & Figure 3. Apparently, lycopene and beta-carotene contents were well correlated with Hunter color parameters, indicating that the contents of these pigments significantly influenced the color of tomato paste.35 D’Souza et al.36 Thompson et al.37 and Raffo et al.38 have achieved highly linear regression (

close to 1) between lycopene content and the

,

,

chromatic coordinates (especially with the

ratio) obtained from reflectance readings on tomato.

Figure 2 Linear regressions of the lycopene concentrations with the Hunter color parameters and

ratio during processing of tomato paste.

Figure 3 Linear regressions of the beta-carotene concentrations with the Hunter color parameters and

ratio during processing of tomato paste.

The arithmetic correlations between lycopene (Lyco), beta-carotene (Caro) contents and

Hunter color parameters and ratios were linear as seen from the following equations:

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

Arias et al.38 reported that

or

value is well related to lycopene concentration; however, the

ratio of provided the best relation.

Effect of processing steps on pectin fractions content and rheological properties of the resultant paste

Table 3 shows that, the total and fractions of pectin significantly increased during tomato paste production. Pectin significantly influences the textural and rheological properties of tomato products, because of its great thickening and gel-forming capabilities. Many investigators proved that the colloid materials i.e. pectins were the main constituents affecting the rheological behavior of tomato juices. With this in view it could be expected that the higher the pectin the higher the rheological values.40,41

The yield stress (

) value significantly affected by tomato juice concentration it significantly increased from 1.33 N m-2 of the juice to 442.30 N m-2 of the pasteurized tomato paste (Table 3). The consistency coefficient (k) values significantly increased from 97.23 mPa sn of the tomato juice to 45268 mPa sn of the tomato paste. Also, apparent viscosity significantly increased during concentration process from 202.89 to 108176 mPa s (Table 3). These results are in agreement with those obtained by.20,31,42,43

Figure 4 shows that, the rheological characteristics (apparent viscosity (

) at 10 rpm, consistency coefficient (k) and yield stress (

)) of tomato juice during concentration had positive correlations with total and pectin fractions contents. Exponential regression produced a better fit with total (

), oxalate (

) and water soluble (

) pectins, while linear regression with acid soluble pectin content was obtained as shown from Figure 4 and the following equations:

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

(29)

In fact, as shown from the obtained equations, the highly positive correlation was between rheological properties and oxalate, acid and total pectin contents, where the determination coefficient (

) values exceeded 0.92. A very well correlation was between the apparent viscosity and pectin fractions. These results were in agreement with those found by Youssef.31

Regarding the activation energy (

) of the flow, results presented in Table 4 show that, the

values changed significantly during concentration process. They ranged between 3057.54 and 6959.32 KJ/ K mol. The temperature had an effect on the viscosity of the tomato juice during concentration process, which was very well correlated with the Arrhenius equation. Where, the coefficient of determination (

) values were between 0.981 and 0.993.

|

Item

|

Tomato Juice

|

First Stage

|

Second Stage

|

Third Stage

|

After Pasteurization

|

|

Total pectin

|

7.84c±1.87

|

8.32c±2.22

|

9.20bc±1.53

|

10.59ab±2.66

|

11.68a±2.42

|

|

Water soluble pectin

|

2.28b±0.97

|

2.71ab±1.10

|

2.90ab±1.20

|

3.18ab±1.65

|

3.62a±1.59

|

|

Ammonium oxalate-soluble pectin

|

3.60c±0.99

|

3.81c±1.10

|

4.36bc±1.20

|

5.10ab±1.65

|

5.63a±1.17

|

|

Acid soluble pectin

|

1.96b±0.64

|

1.80b±0.55

|

1.94ab±0.55

|

2.31a±0.68

|

2.43a±0.74

|

|

Yield stress (Nm-2)

|

1.33d±0.97

|

1.61d±1.06

|

34.03c±4.32

|

389.01b±13.36

|

442.30a±18.74

|

|

Consistency coefficient (mPa sn)

|

97.23e±0.87

|

160.49d±1.96

|

607.86c±3.64

|

42843b±99.24

|

45268a±102.56

|

|

Apparent viscosity(mPa s)

|

202.89e±16.57

|

609.63d±55.87

|

8298.40c±208.87

|

101365b±262

|

108176a±254

|

Table 3 Changes in pectin fractions content (g 100 g-1, wet basis) and rheological properties (mean ± SD, n= 21) during processing of tomato paste (cold-break)

Data are an average (±SD) of triplicate

SD: Standard deviation

n: Number of the samples

Means having the same letter within each row are not significantly different at p= 0.05.

|

Item

|

Tomato Juice

|

First Stage

|

Second Stage

|

Third Stage

|

After Pasteurization

|

|

Activation energy (Ea, KJ/ K mol)

|

3837.54d

|

6236.63b

|

6959.32a

|

4277.09c

|

3057.54e

|

|

Viscosity constant (η∞, mPa s)

|

44.66d

|

40.8d

|

468.95c

|

17590.25b

|

31007.98a

|

|

R2

|

0.936

|

0.981

|

0.992

|

0.973

|

0.993

|

Table 4 Changes in Arrhenius equation parameters (n= 21) during processing of tomato paste (cold-break, temperature range 5-80 °C)

N: number of the samples, R2: correlation coefficient of determination.

Means having the same letter within each row are not significantly different at p= 0.05.

Conclusion

Concentration process had significant effect on the quality attributes of the resultant tomato paste (cold break). The characteristics of tomato juice are significantly changed during process to paste. The rheological characteristics and Hunter color parameters of tomato juice during processing to paste had good correlations with pectin fraction contents and pigment concentrations, such as lycopene and beta carotene. Tomato paste processing can be controlled by these correlations and understanding and solving many problems arising during processing in the flow behavior or the color.

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

The author declares no conflict of interest.

References

- Ray RC, El Sheikha AF, Panda SH, et al. Anti-oxidant properties and other functional attributes of tomato. An overview. Int J Food Ferm Technol. 2011;1(2):139–148.

- FAOSTAT. Viale delle Terme di Caracalla 00153 Rome, Italy; 2015.

- WPTC (World Processing Tomato Council). USA: University of Colorado; 2015.

- WPTC (World Processing Tomato Council). Portugal: IEEE; 2016.

- Donkor S, Agyekum AK, Akuamoa F, et al. Antioxidant potentials of tomato paste extracts found on major markets in Accra Metropolis. Amer J Appl Chem. 2015;3(5):158–163.

- Chug-Ahuja JK, Holden JM, Forman MR, et al. The development and application of a carotenoid database for fruits, vegetables, and selected multicomponent foods. J Amer Dietetic Assoc. 1993;93(3):318–323.

- Fraser PD, Bramley PM. The biosynthesis and nutritional uses of carotenoids. Prog Lipid Res. 2004;43(3):228–265.

- Farahnaky A, Majdinasab M, Majzoobi M, et al. A Comparative study of physicochemical and rheological properties of Iranian tomato pastes. Int J Food Eng. 2010;6(1):1–14.

- Anthon GE, Diaz JV, Barrett DM. Changes in pectins and product consistency during the concentration of tomato juice to paste. J Agric Food Chem. 2008;56(16):7100–7105.

- Egyptian Standards No ES (132-1). Arabic: Preserved tomato products: part 1 Tomato concentrates. Egyptian Organization for Standardization and Quality, Egypt; 2005. p. 1–12.

- Barreiro JA, Milano M, Sandoval AJ. Kinetics of colour change of double concentrated tomato paste during thermal treatment. J Food Eng. 1997;33(3-4):359–371.

- Rodrigo D, Jolie R, Van Loey A, et al. Thermal and high pressure stability of tomato lipoxygenase and hydroperoxidelyase. J Food Eng. 2007;79(2):423–429.

- Luh BH, Kean CE. Canning of vegetables. In: JG Woodroof editor. Commercial Vegetable Processing. New York, USA: Van Nostrand Reinhold; 1998. p. 195–285.

- Gallais A, Bannerot H. Amelioration des especes vegetales cultivees: Objectifs et criteres de selection. France: INRA; 1992. p. 379–391.

- Sobowale SS, Olatidoye OP, Odunmbaku LA, et al. A comparative study on physicochemical and rheological properties of imported tomato paste in Nigeria. Sustain Agric Res. 2012;1(2):51–56.

- Sánchez MC, Valencia C, Gallegos C, et al. Influence of processing on the rheological properties of tomato paste. J Sci Food Agric. 2002;82(9):990–997.

- Xu SY, Shoemaker CF, Luh BS. Effect of break temperature on rheological properties and microstructure of tomato juices and pastes. J Food Sci. 1986;51(2):399–402.

- Yoo B, Rao M. A Creep and dynamic rheological behavior of tomato concentrates: effect of concentration and finisher Screen Size. J Texture Stud. 1996;27(4):451–459.

- Abu-Jdayil B, Banat F, Jumah R, et al. A comparative study of rheological characteristics of tomato paste and tomato powder solutions. Int J Food Prop. 2004;7(3):483–497.

- Bayod E, Willers EP, Tornberg E. Rheological and structural characterization of tomato paste and its influence on the quality of ketchup. LWT- Food Sci Technol. 2008;41(7):1289–1300.

- Zhang L, Schultz MA, Cash R, et al. Determination of quality parameters of tomato paste using guided microwave spectroscopy. Food Cont. 2014;40:214–223.

- AOAC. Official methods of analysis of AOAC international. In: W Horwitz editor. 17th ed. Gaithersburg, MD: USA: AOAC International; 2002. 2200 p.

- Barros L, Cabrita L, Boas MV, et al. Chemical, biochemical and electrochemical assays to evaluate phytochemicals and antioxidant activity of wild plants. Food Chem. 2011;127(4):1600–1608.

- Gomez R, Varon R, Amo M, et al. Differences in the rate of coloration in tomato fruit. J Food Qual. 1998;21(4):329–339.

- Min S, Zhang QH. Effect of commercial-scale pulsed electric field processing on flavor and color of tomato juice. J Food Sci. 2003;68(5):1600–1606.

- Park SJ, Lee JL, Park J. Effects of a combined process of high pressure carbon dioxide and high hydrostatic pressure on the quality of carrot juice. J Food Sci. 2002;67(5):1827–1834.

- Røra AMB, Einen O. Effects of freezing on quality of cold smoked Salmon based the measurements of physicochemical characteristics. J Food Sci. 2003;68(6):2123– 2125.

- Hegedusic V, Lovric T, Parmac A. Influence of phase transition (freezing and thawing) on thermo physical and rheological properties of apple puree-like products. Acta Alimen. 1995;22:337–349.

- Ibarz A, Garvin A, Casta J. Rheological behavior of sloe (Prunvs spinosa) fruit juices. J Food Eng. 1996;27(4):423–430.

- Shatta AA. Some quality attributes of tomato paste (cold-break) in relation to the concentration process. Ann Agric Sci Moshtohor. 2000;38:2259–2268.

- Youssef KM. The relationship between rheological properties, color and structural characterization of tomato paste (cold-break) during processing. J Agric Sci Mansoura Univ. 2009;34:6299–6309.

- Marković K, Hruŝkar M, Vahĉic N. Lycopene content of tomato products and their contribution to the lycopene intake of Croatians. Nutr Res. 2006;26(11):556–560.

- Seybold C, Frohlich K, Bitsch R, et al. Changes in contents of carotenoids and vitamin E during tomato processing. J Agric Food Chem. 2004;52(23):7005–7010.

- Hayes WA, Smith PG, Morris AEJ. The production and quality of tomato concentrates. Crit Rev Food Sci Nutr. 1998;38(7):537–564.

- Patras A, Brunton N, Da Pieve S, et al. Effect of thermal and high pressure processing on antioxidant activity and instrumental colour of tomato and carrot purées. Inn Food Sci Emer Technol. 2009;10:16–22.

- D’Souza MC, Singha S, Ingle M. Lycopene concentration of tomato fruit can be estimated from chromaticity values. Hort Sci. 1992;27(5):465–466.

- Thompson KA, Marshall MR, Sims CA, et al. Cultivar, maturity and heat treatment on lycopene content in tomatoes. J Food Sci. 2000;65(5):791–795.

- Raffo A, La Malfa G, Fogliano V, et al. Seasonal variations in antioxidants components of cherry tomatoes (Lycopersicon esculentum cv. Naomi F1). J Food Comp Anal. 2006;9(1):11–19.

- Arias R, Lee TC, Logendra L, et al. Correlation of lycopene measured by HPLC with the L*, a*, b* color reading of a hydroponic tomato and the relationship of maturity with color and lycopene content. J Agric Food Chem. 2000;48(5):1697–1702.

- Mac Dougall AJ, Needs PW, Rigby NM, et al. Calcium gelation of pectic polysaccharides isolated from unripe tomato fruit. Carbohydrate Res. 1996;923(2):235–249.

- Narayanan J, Deotare VW, Bandyopadhyay R, et al. Gelation of aqueous pectin solutions: A dynamic light scattering study. J Colloid Inter Sci. 2002;245(2):267–273.

- Juszczak L, Fortuna T. Viscosity of concentrated strawberry juice: effect of temperature and soluble solids content. E-J Polish Agric Univ. 2003;6(2):1–7.

- Hsu KC. Evaluation of processing qualities of tomato juice induced by thermal and pressure processing. LWT-Food Sci Technol. 2008;41(3):450–459.

©2017 Shatta, et al. This is an open access article distributed under the terms of the,

which

permits unrestricted use, distribution, and build upon your work non-commercially.