MOJ

eISSN: 2381-182X

Research Article Volume 11 Issue 1

1Department of Agricultural & Bioenvironmental Engineering, Federal Polytechnic Bida, Nigeria

2Department of Agricultural & Bioresources Engineering, Federal University of Technology Minna, Nigeria

Correspondence: Gana I M, Department of Agricultural & Bioenvironmental Engineering, Federal Polytechnic Bida, Niger State, Nigeria

Received: December 12, 2022 | Published: January 5, 2023

Citation: Gana IM,Gbabo A,Hassan A M, et al. Effects of operating speed, cutter bar cutting speed and forage plant moisture content on performance of a forage harvester. MOJ Food Process Technols. 2023;11(1):1-7. DOI: 10.15406/mojfpt.2023.11.00271

Many researchers have advocated for the establishment of grazing zones and pasture farming as one method of reducing conflict between farmers and herders. In most developing countries, pastures are harvested using manual means, which is tedious and time-consuming. As a result, a self-propelled forage harvester was developed. This research looks into the effects of forage plant moisture content, cutter bar cutting speed, and operating speed on the cutting and field efficiencies of the forage harvester. The experiment was based on a central composite rotatable design (CCRD). The machine's testing revealed that a combination of an operating speed of 2.4 km/h, a cutting speed of 55 m/min and forage plant moisture content of 55% yielded the highest cutting efficiency and field efficiency of 94.42% and 89.95%, respectively. The cutting efficiency was significantly (P≤0.001) affected by the cutting speed and the forage plant moisture content, whereas all the parameters significantly (P≤0.001) affected the field efficiency. The desirability function method in rsm was used to optimize the machine settings via numerical optimization. This resulted in a combination of 2.33 km/hr operating speed, 54 m/min cutting speed, and 67% plant moisture content (wb) that offered optimal values of cutting efficiency of 94.36% and field efficiency of 91.3%. The study's findings were used to establish harvester settings that would produce the best machine performance.

Keywords: cutting, efficiency, forage, harvester, moisture content

Globally, the agricultural sector is being weighed down by a number of challenges that impact the sector's contribution to feeding the world and the growth of the world economy. Some of the challenges include population growth, climate change, violent conflicts, poor and inadequate technologies, among others. The global human population could grow to 9.7 billion people by 2050. According to the United Nations, there were nearly 821 million people in 2018 (2017: 804 million) who regularly do not have enough food to eat. Nigeria was ranked 103rd out of 119 nations on the 2018 Global Hunger Index by the International Food Policy Research Institute (IFPRI), indicating a severe degree of hunger there. Nigeria's present population of 196 million is expected to increase by no less than 202 million between 2018 and 2050. By 2050, the nation is anticipated to overtake the third-most populous nation in the world-the United States-which is now (SDG 2017.1 As Nigeria's population continues to grow, it is becoming increasingly challenging for food supply to meet demand. On the other hand, nomadic herdsmen pushing southwards in search of grazing fields and water for their cattle (due to desertification and water depletion in the north) resulted in violent conflicts with crop farmers. According to Ojelade2 the relationship between the two parties to the conflict is hostile and contentious, which has had a significant influence on food security, particularly food for immediate consumption.2 Claim that in order to feed an expanding population, livestock products including meat, milk, and eggs are always in demand at higher and higher levels. The establishment of grazing zones and pasture farming, which involves growing grasses and legumes (forages) for animals to graze, have both been suggested as potential solutions to this problem by several researchers. The cost of harvesting has reportedly been quite high, and the harvesting procedure has an impact on the end feed's quality because it's important to seek out enough feed quality to support milk production.3 In the majority of developing countries, including Nigeria, forage is currently harvested manually with sickles. The farmer risks injury and exhaustion when using this harvesting technique. According to Tian et al.4 harvesting forage plants and straw feed crops (silage maize) was time-consuming, energy-intensive, labour-intensive, and led to significant nutritional loss. On the other hand, the imported harvesters are only suitable for large farms; they cannot be used on tiny fields. Recently, some academics have been looking at the development of forage and silage harvesters to increase operational effectiveness and cutting efficiency. Their drawbacks, however, are the machinery's imperfections, a lack of adaptability and dependability, and the expense of importation. An elf-propelled forage harvester was developed to address all these issues. The objective of this presentation is to investigate the interactions between its independent and dependent variables and to optimize its operational parameters.

Forage plot preparation

Five forage plots at the experimental field of the National Cereal Research Institute in Badeggi, Niger State, Nigeria with varying moisture content; 25%, 35%, 45%, 55%, and 60% measuring 10 meters squared each were used for this study. They were subdivided into 1-meter squared plots. Each plot was subsequently harvested using a developed forage harvester based on the design matrix shown in Table 1.

Equipment

This research used a forage harvester (Plate I) developed at the Department of Agricultural & Bioenvironmental Engineering, the Federal Polytechnic Bida, Nigeria. The machine harvests forage plants. Chain and sprocket, eccentric wheel, connecting arm, crop cutting unit consisting of a ledger and a knife section, crop supporting frame, machine transportation unit, and the frame are the major components of the machine. With the help of the divider, the machine collects the standing plant and then chops it with the sickle and ledger blades.

Design of experiments

The experimental was designed as a function of machine functional parameter of forward speed of the harvester (A), cutting speed of the cutter bar (B) and forage plant moisture content (C) (independent variables) using central composite rotatable design (CCRD) of response surface methodology (rsm). In order to obtain the required data, the range of values of each of the three variables (k) were determined as reported Gana et al.5,6 and is presented in Table 1. For three variables (k=3) and the five levels (-α, -1, 0, 1 and + α) experiments, the total number of runs was determined by the expression; 2k (23= 8 factorial points) + 2k (2 × 2 = 6 axial points) + 6 (center points: six replications)7 and the design is shown in Table 1.

Experiments set up

Based on the design of the experiment five forage field with varying forage plant moisture content of 25%, 35%, 45%, 55%, and 60% were prepared. Twenty plots of 1 m square each were marked, these comprised of 1 plot each from farm with 25% and 60% forage plant M.C., 4 plots each from farms with35% and 55% forage plant M.C., and 10 plots from farm with forage plant of 45% M.C. The operating speed was varied at speed of 1.3 km/hr, 1.6 km/hr, 2 km/hr, 2.4 km/hr and 2.7 km/hr. The cutting speed was varied at speed of 15 m/min, 25 m/min, 40 m/min, 55 m/min and 65 m/min. The experiment was conducted on the experimental field of the National Cereal Research Institute in Badeggi, Niger State, Nigeria, on April 6th and 21th, 2021.

Statistical analysis

Analysis of variance (ANOVA) was carried out to estimate the influence of main variables and their likely effects on the responses.

Optimisation technique

Design expert ® 7.0.0. Software was employed using numerical technique for the optimisation of independent variables and the dependent variables in this study. By applying the desirability functions method in RSM, number of solutions were obtained for the optimum covering criteria with desirability close to 1 and the first solution with desirability closest to 1 was selected.

Determination of effects of the independent variable on the machine performance

The overall performance of the harvester was evaluated on the basis of cutting efficiency and field efficiency by varying forward speed, cutting speed and the forage plant moisture content.

Cutting efficiency

The cutting efficiency of the harvester was determined as the ratio of total number of cut plant to the total number of plant present before cutting operation of the plot as reported by Imrul et al.8 and is given as

(1)

where, Ceff is the cutting efficiency (%), N1 is the total number plant before cutting, N2 is the total plants left after cutting.

Field efficiency

The field efficiency was determined as reported by Ashraful Alam et al.9 and is given as

(2)

(3)

(4)

where, Feff is the field efficiency (%), Ca is the actual field capacity (ha/hr), Cth is the theoretical field capacity (ha/hr), W is the width of the harvester cutter bar assembly (m), S is the operating forward speed (km/hr), Act is the actual operating time (hr), Tt is the total operating time (hr)

The results of the effects of the operating speed, cutting speed, and moisture content of the machine are shown in Table 1. The value of cutting efficiency ranged from 51.78% to 90.12%. The highest value of 94.42% was obtained from the combination of operating speed of 2.4 km/h, cutting speed of 55 m/min and forage plant moisture content of 55%, while the interaction between operating speed of 2 km/h, cutting speed of 15 m/min and forage plant moisture content of 45% yielded the lowest value of 50.23%. The values of the field efficiency ranged from 53.82% to 89.95%. The highest value of 89.95% was obtained from an interaction between an operating speed of 2.4 km/h, a cutting speed of 55 m/min and a forage plant moisture content of 55%. while the lowest value of 53.82% was obtained from the interaction between operating speed of 2 km/h, cutting speed of 15 m/min and forage plant moisture content of 45%.

Std |

Run |

Speed of operation (km/h) |

Cutting speed (m/min) |

Moisture content (%) |

Actual cutting efficiency (%) |

Predicted cutting efficiency (%) |

Actual field efficiency (%) |

Predicted field efficiency (%) |

3 |

1 |

1.6 |

55 |

35 |

83.6 |

84.02 |

60.43 |

60.25 |

13 |

2 |

2 |

40 |

25 |

67.45 |

68.05 |

55.76 |

55.61 |

20 |

3 |

2 |

40 |

45 |

86.16 |

86.12 |

80.87 |

80.91 |

6 |

4 |

2.4 |

25 |

55 |

69.33 |

68.55 |

67.7 |

67.23 |

11 |

5 |

2 |

15 |

45 |

51.78 |

52.23 |

53.82 |

54.26 |

17 |

6 |

2 |

40 |

45 |

85.12 |

86.12 |

79.57 |

80.91 |

15 |

7 |

2 |

40 |

45 |

85.5 |

86.12 |

81.19 |

80.91 |

19 |

8 |

2 |

40 |

45 |

86.64 |

86.12 |

82 |

80.91 |

18 |

9 |

2 |

40 |

45 |

85.5 |

86.12 |

81.28 |

80.91 |

1 |

10 |

1.6 |

25 |

35 |

68.21 |

66.98 |

40.89 |

40.65 |

2 |

11 |

2.4 |

25 |

35 |

60.6 |

61.01 |

64.34 |

64.46 |

10 |

12 |

2.7 |

40 |

45 |

87.88 |

86.12 |

75.52 |

75.65 |

4 |

13 |

2.4 |

55 |

35 |

83.6 |

82.69 |

73.05 |

73.08 |

5 |

14 |

1.6 |

25 |

55 |

68.4 |

68.95 |

46.02 |

45.34 |

7 |

15 |

1.6 |

55 |

55 |

91.63 |

90.86 |

79.39 |

78.62 |

9 |

16 |

1.3 |

40 |

45 |

88.96 |

89.4 |

45.65 |

46.45 |

16 |

17 |

2 |

40 |

45 |

87.88 |

87.95 |

80.7 |

80.91 |

14 |

18 |

2 |

40 |

60 |

80.24 |

80.15 |

72.31 |

73.39 |

8 |

19 |

2.4 |

55 |

55 |

94.24 |

95.11 |

89.95 |

89.53 |

12 |

20 |

2 |

65 |

45 |

88.83 |

88.89 |

89.02 |

89.5 |

Table 1 Results of effects of operating speed, cutting speed and forage moisture content on cutting and field efficiency

Effects of independent variables on cutting efficiency

The result of the statistical analysis of variance (ANOVA) of the cutting efficiency presented in Table 2 showed that the model is significant with an F-value of 258.43 and a P-value probability > F less than 0.0500. In this case, it was only the cutting speed and plant moisture content that had an effect on the cutting of the forage plants. The R-square value of 0.9957 was very close to 1 as recommended. The lack of fit F-value of 1.11 implies that the lack of fit is not significant relative to the pure error. There is a 45.56% chance that a Lack of Fit F-value this large could occur due to noise. A non-significant lack of fit is good because if it is significant, then the model will not be able to predict the response.10

Source |

Coefficient estimate |

Standard error |

F-value |

p-value |

|

Model |

86.12 |

0.4247 |

258.43 |

< 0.0001 |

Significant |

A-Speed of operation |

-0.431 |

0.2818 |

2.34 |

0.1571 |

|

B-Cutting speed |

10.9 |

0.2818 |

1496.1 |

< 0.0001 |

|

C-Moisture content |

3.6 |

0.2818 |

162.81 |

< 0.0001 |

|

AB |

1.16 |

0.3681 |

9.95 |

0.0103 |

|

AC |

1.39 |

0.3681 |

14.33 |

0.0036 |

|

BC |

1.22 |

0.3681 |

10.96 |

0.0079 |

|

A² |

0.9035 |

0.2743 |

10.85 |

0.0081 |

|

B² |

-5.5 |

0.2743 |

402.24 |

< 0.0001 |

|

C² |

-4.25 |

0.2743 |

240.03 |

< 0.0001 |

|

Lack of Fit |

|

|

1.11 |

0.4556 |

not significant |

C.V. % |

1.30 |

||||

R² |

0.9957 |

||||

Adjusted R² |

0.9919 |

||||

Predicted R² |

0.9773 |

||||

Adeq precision |

58.2351 |

||||

Table 2 Regression analysis of response of cutting efficiency

The coefficient of variation (C.V) of 1.3% obtained was low, below the threshold value of not greater than 10%. This indicated that the deviation between experimental and predicted values was low, as reported. The coefficient of determination R value of 0.99785 indicated that the model was able to predict 99.785% of the variance and only 0.212% of the total variance was not explained by the model. The coefficient of correlation R-Squared value of 0.9957 was very close to 1 as recommended by Xin and Saka.11 But as further reported, a large value of R2 does not always suggest that the regression model is a good one because it will increase when a variable is added regardless of whether the additional variable is statistically significant or not. Hence, predicted and adjusted R2 were suggested to be used to check the model adequacy. It was also observed that the predicted R–Squared of 0.9773 was in reasonable agreement with the adjusted R–Squared of 0.9919, which indicated that the experimental data fitted well. The value of adequate precision of 58.2351 obtained was above the minimum value of 4 reported. This indicated an adequate signal, which showed that the model can be used to navigate the design space.

The regressed cutting efficiency model is given as

(5)

where,CEf is the Cutting efficiency (%), A is the operating speed (km/h), B is the cutter blade cutting speed (m/min), C is the forage moisture content (%).

The model equation was improved by removing the insignificant model terms. Values greater than 0.1000 implies that the model terms are not significant (that is A is not were not significant) and since the term is insignificant the fitted model is presented:

The fitted cutting efficiency model is given as

(6)

It is important to add that the variables B and C in the model have positive co-efficient implying a direct proportionality. That is independent increase in B and C increased the cutting efficiency.

Simulation and validation of cutting efficiency model

The model equation obtained was simulated and the cutting efficiency was observed to be within the experimental range. From Table 1, the actual value of cutting efficiency was observed to be in close agreement with the predicted value. This is ascertaining to close agreement between the predicted value and observed value, validating the need for the model equation to be used to determine the optimum cutting efficiency at various operating conditions.

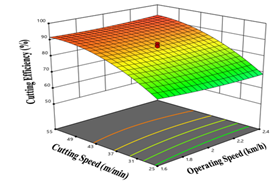

Effects of operating speed and cutting speed on cutting efficiency

From Figure 1 & 2, the effects of cutting speed on cutting efficiency revealed that increasing the cutting speed from 25 to 43 m/min increased cutting efficiency from 65% to 88% at a constant plant moisture content of 23%, and then remained constant to 92% with subsequent increases to 55 m/min. This could be attributed to an increase in reciprocating speed causing an increase in impact force, cutting, and shearing actions of the blades. This is in line with the findings of a study published, which found that a harvester's field efficiency increases when the cutter bar reciprocating speed increases. On the other hand, the cutting efficiency remains constant with a variation in operating speed from 1.6 km/h to 2.4 km/h. There are insignificant effects on the cutting efficiency.

Figure 1 Response surface for effects of cutting speed and operating speed on the cutting efficiency.

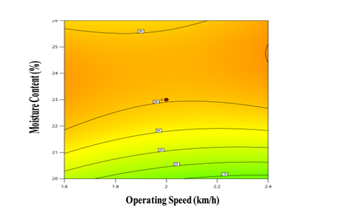

Effects of forage plant moisture content and operating speed on cutting efficiency

From Figure 3 & 4, the impacts of forage plant moisture content on cutting efficiency revealed that raising the moisture content from 40% to 55% increased cutting efficiency from 77% to 84% at a constant cutting speed of 40 m/min, and then remained constant with a further increase in moisture content to 70%. Plants shatter and lodge at lower moisture levels, making it difficult for the reaper to cut them. The plant also shows resistance to the cutter bar's cutting impact at higher moisture content. The moisture content of the rice plant had a significant impact on cutting efficiency. This is consistent with the findings of comparable investigations by Helmy et al.12 who found that a fall in plant moisture content leads to a loss in cutting efficiency, as does much higher plant moisture content.

Figure 3 Response Surface for Effects of plant moisture content and operating speed on the cutting efficiency.

Figure 4 Contour plot for effects of plant moisture content and operating speed on the cutting efficiency.

Effects of independent variables on field efficiency

The result of the statistical analysis of variance (ANOVA) of the field efficiency presented in Table 3 showed that the model is significant with an F-value of 661.97 and a P-value probability > F less than 0.0500. In this case, all the three variables had an effect on the field efficiency. The Lack of Fit F-value of 1.18, coefficient of variation (C.V) of 1.2%, coefficient of determination R value of 0.99915, The coefficient of correlation R- Squared value of 0.9983, predicted R – Squared of 0.9920, adjusted R – Squared of 0.9968 and adequate precision of 82.19 are all satisfactory and validated the model.

Source |

Coefficient estimate |

Standard error |

F-value |

p-value |

|

Model |

80.91 |

0.3431 |

661.97 |

< 0.0001 |

significant |

A-Speed of operation |

8.68 |

0.2276 |

1454.29 |

< 0.0001 |

|

B-Cutting speed |

10.48 |

0.2276 |

2118.25 |

< 0.0001 |

|

C-Moisture content |

5.29 |

0.2276 |

539.22 |

< 0.0001 |

|

AB |

-2.74 |

0.2974 |

85.12 |

< 0.0001 |

|

AC |

-0.4787 |

0.2974 |

2.59 |

0.1385 |

|

BC |

3.42 |

0.2974 |

132.34 |

< 0.0001 |

|

A² |

-7.02 |

0.2216 |

1004.22 |

< 0.0001 |

|

B² |

-3.19 |

0.2216 |

207.39 |

< 0.0001 |

|

C² |

-5.8 |

0.2216 |

685.63 |

< 0.0001 |

|

Lack of fit |

1.18 |

0.429 |

not significant |

||

C.V. % |

1.2 |

||||

R² |

0.9983 |

||||

Adjusted R² |

0.9968 |

||||

Predicted R² |

0.992 |

||||

Adequate precision |

82.19 |

||||

Table 3 Regression analysis of response of field efficiency

The regressed field efficiency model is given as

(7)

where,FEf is the Field efficiency (%), A is the operating speed (km/h), B is the cutter blade cutting speed (m/min), C is the forage plant moisture content (%.)

The model equation was improved by removing the insignificant model terms. Values greater than 0.1000 implies that the model terms are not significant (that is AC is not significant) and since the term is insignificant the fitted model is presented equation 8

The fitted field efficiency model is given as

(8)

It is important to add that the variables A, B and C in the model have positive co-efficient implying a direct proportionality. That is independent increase in A, B and C increased the cutting efficiency.

Simulation and validation of cutting efficiency model

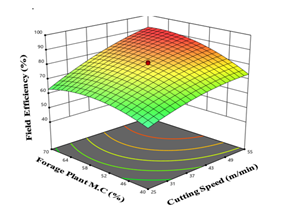

The model equation obtained was simulated and the field efficiency was observed to be within the experimental range. From Table 1 the actual value of field efficiency was observed to be in close agreement with the predicted value. This is ascertaining to close agreement between the predicted value and observed value validating the need for the model equation to be used to determine the optimum field efficiency at various operating conditions. From Figures 5 & 6, the impacts of cutting speed on field efficiency revealed that raising the cutting speed from 25 m/min to 55 m/min enhanced cutting efficiency from 43% to 74% at a constant moisture content of 40%.

This could be attributed to an increase in reciprocating speed causing an increase in impact force, cutting, and shearing actions of the blades. This is in line with the findings of a study published, which found that a harvester's field efficiency increases when the cutter bar reciprocating speed increases. Also, the field efficiency increases from 73% to 89% as the operating speed increases from 1.6 km/h to 2.2 km/h and remain constant with further increase in operating speed to 2.4 km/h.

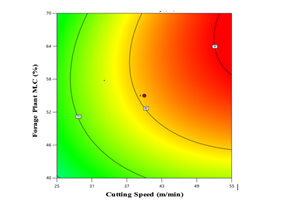

Effects of forage plant moisture content and operating speed on cutting efficiency

From Figures 7 & 8, the impacts of forage plant moisture content on field efficiency revealed that raising the moisture content from 40% to 64% increased field efficiency from 73% to 92% at a constant cutting speed of 55 m/min, and then remained constant with a further increase in moisture content to 70%. The forage plants lodge at lower moisture levels, making it difficult for the cutter bar to cut them. The plant also shows resistance to the cutter bar's cutting impact at higher moisture content. This could be due to the plant's susceptibility to mechanical shear, which makes them easier to cut at higher moisture content, increasing the harvester's field efficiency. However, once the moisture level rose above 64%, the cutter bar became clogged, reducing the harvester's field effectiveness even more. The moisture content of the forage plant had a significant impact on field efficiency. This is in line with the findings of Ojomo et al.13 who observed that weeds (plants) become turgid at increasing moisture content, making them more sensitive to mechanical shear. Field efficiency, on the other hand, went from 62% to 73% as the cutting speed increased from 25 m/min to 45 m/min.14,15

Figure 7 Response Surface for Effects of plant moisture content and operating speed on the field efficiency.

Figure 8 Contour plot for effects of plant moisture content and operating speed on the field efficiency.

Optimization analysis

The numerical optimization methodology was used to optimize the machine settings, and the desirability function method in RSM was used. This resulted in optimal cutting efficiency of 94.36% and field efficiency of 91.3%, with an operating speed of 2.33 km/hr, a cutting speed of 54 m/min, and plant moisture content of 67%. The ramp for the optimization is shown in Figure 9.

The result of this investigation gives the standard machine input parameters capable of improving the performance of the developed harvester. The cutting speed and the forage plant moisture content had significant effects (P 0.001) on the cutting efficiency, while all the parameters had significant effects on the field efficiency.

None.

The author declares no conflicts of interests.

©2023 Gana, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.