MOJ

eISSN: 2381-182X

Review Article Volume 12 Issue 1

1Department of Food Science and Technology, Joseph Sarwuan Tarka University, Makurdi, Nigeria

2Department of Food Science and Technology, University of Nigeria, Nsukka

3Nutrition Innovation Center for Food and Health (NICHE), Ulster University, NI, United Kingdom

4Department of Nutrition and Food Science, University of Rhode Island, United States

Correspondence: Stephen Sule, Department of Food Science and Technology, Joseph Sarwuan Tarka University, Makurdi, Nigeria, Tel +2347036148455

Received: February 28, 2024 | Published: March 22, 2024

Citation: Sule S, Okafor GI, Momoh OC, et al. Applications of food extrusion technology. MOJ Food Process Technols. 2024;12(1):74-84. DOI: 10.15406/mojfpt.2024.12.00301

This review explores applications of food extrusion technology. Extrusion cooking, a thermal processing method, applies high heat, pressure, and shear forces to uncooked masses, yielding a broad spectrum of food products like snacks, ready-to-eat cereals, confectioneries, weaning foods, crisp bread, dairy products, pasta, meat analogs and extenders. The characteristics and working operations of the extruded as well as materials used in extrusion processing have been highlighted. Raw materials undergo grinding, conditioning, and extrusion, leading to significant changes in starch, proteins, vitamins, lipids, and fibre. The process not only enhances sensory and nutritional aspects but also reduces lipid oxidation, enhances shelf life, reduces production cost and eliminates anti-nutritional factors. Applications span human and animal foods, value-added products from waste, rice bran stabilization, and oil expelling. Recent advancements in extrusion technology include hot melt extrusion, supercritical carbon dioxide extrusion, 3-D printing, and other innovative applications, making extrusion technology a sustainable and versatile method for meeting evolving market demands, contingent upon specialized knowledge.

Keywords: food extrusion, food processing, applications, nutritional changes, quality

Extrusion technology, well known in the plastic industry has now become a widely used technology in the agri-food industry where it is referred to as food extrusion or extrusion cooking.1 It is a complex and complicated technological process, but very flexible and provides the possibility for processing a range of different raw materials.2 It involves the application of high heat, high pressure, and shear forces to an uncooked food mass in an extruder to obtain a wide range of products including snacks, ready-to-eat (RTE) cereals, confectioneries, and crisp bread.3 It may also be described as a process by which a set of mixed ingredients are forced through an opening in a perforated die with a design specific to the food and is then cut to a specified size by blades.4

Generally, the technology can be carried out either as cold extrusion or hot extrusion (extrusion cooking). To prevent oxidation and moisture absorption during storage, packaging plays a vital role in preserving the quality of both cold and hot extruded products. Because extrusion involves the combination of heat transfer, mass transfer, pressure changes, and shear, it causes a large number of complex changes to foods including hydration of starches and proteins, homogenization, gelation, shearing, melting of fats, denaturation or re-orientation of proteins, plastification and expansion of the food structure.5 Thus, careful control must be observed if product quality is to be maintained.

Extruded foods are composed mainly of cereals and other starch food sources. The major roles of these ingredients are structure, texture, mouth feel, bulk, and many other characteristics desired for specific finished products.3 The two factors that most influence the nature of the extruded product are the physicochemical properties of the food and the operating conditions of the extruder. The physicochemical properties considered are; the type of feed materials, their moisture content, the physical state of the materials, their chemical composition (amounts and types of starches, proteins, fats, and sugars), and the pH of the moistened material. On the other hand, some of the most important operating parameters in an extruder are temperature, pressure, the diameter of the die apertures, and shear rate.6 Extrusion technology has been applied in the production of confectionery products, snack foods, breakfast cereals, dairy products, infant foods, meat analogs, and extenders as well as in oil expelling and recycling food waste.

Extrusion technology excels in adaptability, swiftly responding to consumer demands by adjusting ingredients and conditions.7 It yields diverse products with unique characteristics, meeting varied market preferences.8 Notably energy-efficient, it reduces operational costs and space requirements, aligning with eco-friendly practices. The ability to modify food materials allows for innovative snack production, catering to evolving tastes.9 Its minimal environmental impact, coupled with high productivity and automated control, ensures an efficient and responsible manufacturing process.10

The extrusion process

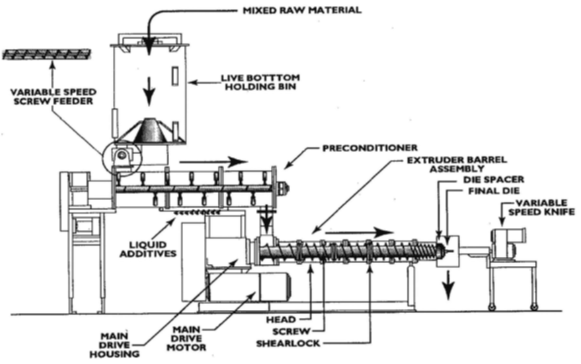

The extrusion process commences with the milling of the selected raw materials to achieve the appropriate particle size, typically resembling coarse flour. Subsequently, the dry mixture undergoes mixing and preconditioning, during which additional ingredients like liquid sugar, fats, dyes, meats, or water are incorporated, depending on the intended product. Steam is introduced to initiate the cooking process, and the preconditioned mix is then propelled through an extruder. During the extrusion process, the extruded product often undergoes puffing and textural changes due to the reduction of forces and the release of moisture and heat, termed the expansion ratio.11 The product generates its friction and heat under pressures ranging from 10 to 20 bars resulting in protein denaturation and starch gelatinization, contingent upon various inputs and parameters. At the output of the extruder, blades rotating around the die openings cut the extrudate to the desired length. The cut products are then dried and cooled to achieve rigidity while retaining porosity (Figure 1). The dried extruded product may further be subjected to surface treatments such as seasonings, coatings and polishing. They may also undergo additional processing such as cooking, baking or frying to enhance flavour and improve nutritional characteristics.

Numerous food extrusion processes involve high temperatures over a short duration.11 Critical factors influencing the extrusion process include the composition of the extrudate, the length and rotational speed of the screw, barrel temperature and moisture content, die shape, and the speed of the blades' rotation. These parameters are meticulously controlled based on the desired product to ensure the uniformity of the output.9

The extruder

The extruder is a specialized device for extrusion. It performs multiple unit operations simultaneously, including mixing, shearing, starch gelatinization, protein denaturation, texturization, enzyme inactivation, thermal cooking, pasteurization, dehydration, shaping, and size reduction.12 Comprising five main parts - pre-conditioning system, feeding system, screw, barrel, die, and cutting mechanism, extruders are chosen based on raw materials and desired products.

Pre-conditioning with steam or water is crucial for uniform hydration and reduced extruder retention times, prolonging equipment life.7 The feeding system ensures a consistent flow of raw materials, utilizing mechanisms like vertical feeding screws or vibrating troughs.13 The screw, a vital component, determines cooking degree, gelatinization, and protein denaturation. Mono-piece or multi-piece screws, with distinct elements, convey, compress, degas, and promote kneading and shear.9 The barrel, solid or jacketed, allows temperature control with steam, oil, water, or air circulation.14 The die shapes the product and increases internal pressure, coming in various designs and orifice numbers. The cutting mechanism, either horizontal or vertical, determines the final product's size based on blade rotation speed (Figure 2).

Figure 2 General view of an extruder system.15

Extruders vary in shape, size, and operation- piston, roller, or screw. Piston extruders, the simplest, use a piston or battery to force material through a nozzle. Ideal for viscous, shear-sensitive materials, they deposit fillings in confectionery. Roller extruders with counter-rotating drums shape products like crackers and cookies. Screw extruders, the most complex, use rotating screws in a stationary barrel for material conveyance through a die. Based on their mode of operation, extruders are divided into cold extruders and hot extruders (extrusion cooking). While based on their mode of construction, they are divided into single-screw and twin-screw extruders.

Cold extruders

In cold extrusion, food materials are heated below 100 oC, maintaining the temperature for shaping and mixing various foods, like batter, meat, and pasta. The low temperature and consequent low-pressure extrusion reduce issues associated with high cooking temperatures.16 Preservation of cold extruded products involves chilling, baking, or drying. Packaging is crucial to prevent oxidation and moisture absorption. Cold extruders suit small-scale and household use, while costly extruder cookers are for large-scale industries.17

Hot extruders (extrusion cooking)

Hot extrusion involves heating food above 100 oC, using frictional heating to rapidly increase temperature. The heated food passes through barrel sections with small flights to enhance shear and pressure.7 After shaping, rapid cooling removes moisture in the form of steam. Various shapes like shells, rods, doughnuts, and spheres are formed. Extrusion cooking creates new products such as puffed cereals and expanded snack foods.

The choice between cold extrusion and hot extrusion in food processing depends on the desired product characteristics, processing requirements, energy considerations, and equipment capabilities (Table 1). Both techniques offer unique advantages and are utilized in creating a wide range of food products with diverse textures, shapes, and functionalities.

|

S/N |

Characteristic |

Cold extrusion |

Hot extrusion |

|

1 |

Temperature |

This process is carried out at or near room temperature. |

Involves heating food materials to higher temperatures usually above 100 oC. |

|

2 |

Material Properties |

Suitable for stable solid or semi-solid foods that can maintain their structure without significant heating. |

Used for materials that require cooking or other thermal modifications to achieve the desired texture or consistency. |

|

3 |

Effect on nutrients |

Increased vitamin retention, reduced protein denaturation, minimal impact on starch, fiber, and fats, thus lowering the risk of oxidation and rancidity. |

Reduced vitamin retention, increased impact on protein texture, carbohydrate and fiber structure changes, and higher risk of lipid oxidation. |

|

4 |

Product Characteristics |

Generally results in products with denser and firmer texture. |

Allows for the creation of expanded and porous products. |

|

5 |

Equipment |

Pasta machines, dough extruders, and specialized molds or dies for shaping various food items. |

Extruders that heat and cook food under controlled conditions. Dies and molds may also be used to shape the extruded product. |

|

6 |

Energy Consumption |

Generally consumes less energy since it doesn't involve significant heating processes. |

Requires energy for heating the food material. Energy may vary depending on the product and processing requirements. |

|

7 |

Product Variety |

Well-suited for producing products like pasta, noodles, certain snacks, dough-based items, and some confectionery items. |

Allows for diverse products like expanded snacks, breakfast cereals, meat analogs, textured vegetable proteins, and other thermally processed food products. |

|

8 |

Cooking and Gelation |

Doesn't involve cooking or significant gelation. Post-extrusion cooking or further processing may be required for certain products. |

Can involve cooking, gelatinization, or partial denaturation of proteins leading to cooked or partially cooked products with specific textures and properties. |

Table 1 Comparison between cold and hot extrusion

Single-screw extruders

Single-screw extruders feature a lone rotating screw within a metal barrel, available in various patterns, with a common design having a constant pitch. Raw materials in granular form are introduced through the hopper in the feed section. The screw's rotation moves the material to the transition section, where the screw channel becomes shallower, compacting the material. Significant mechanical energy dissipation occurs, raising the material's temperature and causing starch gelatinization, enhancing cohesion. The material proceeds through the metering section ultimately pushed through the die opening. Barrels of single-screw extruders typically incorporate helical or axial grooves on inner surfaces to facilitate more effective material conveyance and mixing.9,18 Categories of single-screw extruders include cold-forming (pasta-type) extruders, high-pressure forming extruders, low-shear cooking extruders, collet extruders, and high-shear cooking extruders.

Twin-screw extruders

Twin screw extruders feature two parallel screws of equal length rotating inside the same barrel, typically with a smooth internal surface. More complex than single screw extruders, they offer increased flexibility and superior control. These extruders are suitable for high-moisture applications, products with higher component quantities like fibres and fats, and more intricate products.19 Four configurations are possible based on screw position and rotation direction: (i) co-rotating intermeshing screws; (ii) co-rotating non-intermeshing screws; (iii) counter-rotating intermeshing screws; (iv) counter-rotating non-intermeshing screws.20 Intermeshing screws increase material residence time, while non-intermeshing screws induce greater shear, especially when rotating in opposite directions.

Twin screw extruders offer versatile handling of viscous, oily, sticky, or wet materials up to 25% fat content. They experience reduced wear in smaller machine parts compared to single-screw extruders. Additionally, they accommodate a broad particle size range from fine powder to grains, unlike the limited range of single-screw extruders. Their self-wiping characteristics make clean-up exceptionally easy (Figure 3).

Materials used in extrusion processing

Extrusion cooking utilizes diverse raw material combinations, including cereals, grains, starches, tubers, oilseeds, legumes, and meat and proteins.21 Key characteristics defining these materials include type, physical state, moisture content, pH, and chemical composition (starch, proteins, fats, and sugars). They are categorized by functional roles, such as structure-forming materials, dispersed phase fillers, plasticizers, lubricants, nucleating agents, coloring materials, flavoring substances, and preservatives.14

Structure-forming materials, like maize starch and flour, form the primary ingredient group. Cereals, pseudocereals, and tubers are used for extruded food. Rich in starches, these ingredients vary in amylose and amylopectin proportions, influencing texture. Dispersed phase fillers, the second-largest group, include plant and animal proteins, legume and pulse proteins, meat, marine proteins, and plant fibre. Proteins generally act as fillers, contributing to structure formation, as in textured vegetable protein.7

Plasticizers and lubricants (water, oils, emulsifiers) reduce mechanical energy by altering properties like melting points, viscosity, hardness, and shear. Water acts as a plasticizer, reducing interactions exponentially. Oils and fats lubricate the compressed polymer mix and affect eating qualities. Emulsifiers, with higher melting points than triglycerides, behave as oils, providing lubrication.

Nucleating agents enhance bubbles in extrudates, refining textures. Ideal nucleates, like baking powder or chalk talc, improve cell number and texture. Color comes from natural materials or post-reaction colors like the Maillard reaction. Flavoring substances (salt, sugars, spices, animal digest, natural, artificial flavors) are added during extrusion or post-treatment. Post-extrusion flavoring has drawbacks like uneven application, contamination risk, stickiness, and additional cost. Other additives include preservatives, antioxidants, vitamins, and minerals, with compounds serving specific purposes.14

Quality changes in foods during food extrusion

Extrusion, known for its efficiency and high-volume production of textured foods, also introduces significant quality changes. These changes, affecting structural, textural, and nutritional aspects, can be both positive and negative. The process may enhance nutrient bioavailability but poses a risk of degradation, especially for heat-sensitive vitamins and proteins. Managing these changes is vital for ensuring nutritional quality. Additionally, the Maillard reaction during extrusion contributes to flavor, color, and aroma development, enhancing taste and visual appeal.22

Effect on physical and sensory characteristics

Extrusion variables such as temperature, moisture, and screw speed have been reported to affect expansion ratio, bulk density, water absorption index, water solubility index, and hardness of extruded foods.23–26

The production of characteristic texture is one of the main features of extrusion technology. The HTST conditions in extrusion cooking have only minor effects on the natural color and flavor of foods. Fading of color due to product expansion, excessive heat or reactions with proteins, and reducing sugars or metal ions may be a problem in some extruded foods.27 The process conditions used in extrusion cooking such as high barrel temperatures and low feed moistures favor the Millard reaction and also decrease the nutritional availability of lysine.28 Increasing protein content at constant feed moisture content causes an increase in brittleness, hardness, and crispness but decreases the color intensity. Flavors are therefore more often applied to the surface of extruded foods in the form of sprayed emulsions or viscous slurries, however, this may cause stickiness in some products and hence require additional drying.

Effect on chemical properties

Effect on starch

Inherent to all cereals, pseudocereals, fruits, vegetables, and legumes, carbohydrates constitute the predominant components, ranging from simple sugars to complex structures like starches and fibres. The primary raw materials for extrusion and bakery-based products often involve milled cereal flour and starchy materials. Starch, typically comprising 50% to 80% of dry solids, significantly influences the physical characteristics of the extruded melt, impacting expansion, hardness, and degree of cooking.14

Extrusion cooking induces gelatinization at lower moisture contents (12-22%), where the combination of heat, shear forces on starch granules, and water content disrupts the molecular structure, leading to molecular hydrolysis. Starch polymers undergo dispersion and degradation, forming a continuous fluid melt during extrusion. This fluid polymer continuum traps water vapor bubbles, stretches during extrudate expansion, and stabilizes the structure until the cell ruptures. Upon cooling, the starch polymer cell walls recoil and stiffen, contributing to the final extrudate structure. As moisture is removed, the starch polymer adopts a glassy state, resulting in a hard and brittle texture.29,9 Factors such as increased temperature, screw speed, and pressure during extrusion can accelerate gelatinization, while lipids, sucrose, dietary fibre, and salts may retard this process.

Effect on fibre

Extrusion cooking induces transformative effects on the structural characteristics and physicochemical properties of foods. The primary impact involves a shift from insoluble fibre to soluble fibre, driven by the disruption of covalent and non-covalent bonds between carbohydrates and proteins associated with the fibre. This rupture leads to the formation of smaller molecular fragments that exhibit increased solubility.30,9 The resulting alterations in fibre structure contribute to enhanced functional properties, encompassing elevated gelatinization temperature, greater solubility, improved swelling and solvent retention capacity, heightened apparent viscosity and consistency coefficient, reduced flow behavior index, and enhanced foam ability.31

Effect on protein

Proteins, as biopolymers with numerous chemical groups, exhibit heightened reactivity compared to polysaccharides, leading to various changes during extrusion, primarily denaturation. Comprising chains of amino acids, proteins in native raw materials possess diverse physical sizes and forms. The extrusion process involves the breakage and potential reformation of disulfide bonds, resulting in improved protein digestibility by exposing enzyme-sensitive areas and inducing denaturation.9 Strong shear during extrusion significantly influences protein structure and conformation. The breakdown and denaturation of proteins contribute to increased protein solubility in extruded meat-based foods.32 Electrostatic and hydrophobic interactions promote the formation of insoluble aggregates, and while the creation of new peptide bonds remains controversial, high molecular weight proteins can dissociate into smaller subunits.33 Enzymes, being proteins, lose their activity due to high temperatures and shear during the extrusion process.

Extrusion finds a significant application in high-protein foods for protein texturization. Texturization processes through extrusion are utilized to produce products mimicking the texture, taste, and appearance of meat or seafood, providing high nutritional value.34 In extrusion, globular proteins from oilseeds (soybeans, sunflower seeds, common beans, peas, and cottonseed) and cereals, especially wheat gluten proteins, have been identified to form a continuous structure.35,36

Effect on lipids

In the extruder, fats and oils become liquid at temperatures above 40°C. They are mixed with other materials and are rapidly dispersed as fine oil droplets. The presence of lipids in quantities lower than 3% does not affect expansion properties, however, in amounts above 5%, the reduction in expansion rate is considerable. Lipids have a powerful influence on extrusion cooking processes by acting as lubricants because they reduce the friction between particles in the mix and between the screw and barrel surfaces and the fluid melt.9 Extrusion results in increased metal chelating activity as well as 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging activity probably due to the formation of novel compounds such as melanoidins during thermal processing.37 Maillard reaction products are found to have strong antioxidant properties comparable to those of commonly used food antioxidants.38 Extrusion cooking has shown a significant decrease in reducing power.39

The onset of oxidation in extruded foods can be postponed through several mechanisms, including the denaturation of oxidative enzymes like lipase and other enzymes. Additionally, the formation of lipid-amylose complexes reduces the availability of both starch and lipids, contributing to extended shelf life for extruded products. Moreover, the extrusion process facilitates the release of endogenous antioxidants in granules, offering protection against oxidation.40 Polyunsaturated fatty acids (PUFA)-3 and -6, vital for human health, are more susceptible to oxidation due to their higher degree of unsaturation. Consequently, there is a growing preference for extrusion and other alternative food processing methods over traditional processing to mitigate nutrient loss and minimize oxidation.

Effect on micronutrients

Vitamins can be destroyed by the action of temperature or by oxidation. Since extrusion mostly involves thermal treatment at higher temperatures of 100 oC, some loss of vitamins in the processed material is expected, especially of the temperature-sensitive and water-soluble vitamins such as vitamin C.41 However, because of the HTST-type shock treatment, the extent of losses is lower than with conventional methods such as static long-term cooking. Thiamine being the most sensitive to temperature, is damaged during extrusion depending on the processing conditions, temperature rise, and screw speed. Riboflavin losses are much lower (about 94% retention after extrusion) and decrease with increasing water content in the mixture.42 Vitamins A and E reveal high stability in extruded products, much higher than in the case of raw materials. According to researchers, it is associated with an increased susceptibility to the extraction of fat-soluble vitamins after baro thermal processing.43

Minerals, characterized as inorganic, heat-stable, solid, crystalline chemical elements, are naturally occurring and cannot be decomposed or synthesized through ordinary chemical reactions. Their heat stability allows for pre-processing fortification without the risk of subsequent damage. Extrusion enhances mineral absorption by mitigating factors that inhibit absorption, including phytates, polyphenols, and other antinutrients. The increased solubility of fibre (which may influence the gastrointestinal tract's mobility and potentially interfere with mineral absorption) as a result of extrusion is also beneficial.14

Effect on anti-nutritional factors

Anti-nutritional factors (ANFs) are natural compounds found in edible seeds that, upon ingestion, interfere with the body's utilization of nutrients, particularly proteins, vitamins, and minerals. They bind to these nutrients, reducing their absorption in the gastrointestinal tract.44 Common ANFs in edible seeds include phytate, phenolic compounds (like tannins), lectin, enzyme inhibitors (such as trypsin and amylase inhibitors), saponins, and oxalates. These ANFs can have adverse effects, but various processing techniques, including extrusion cooking, can help mitigate these effects by lowering or removing harmful compounds before consumption.45

Extrusion cooking, a highly effective technology, has been shown to reduce tannins and haemagglutinins in foods.46 Shear forces generated during extrusion also eliminate trypsin and protease inhibitors.2,47 Other researchers have reported the mitigating impact of extrusion on phytates, oxalates, saponins, and polyphenols.48,24

Effect on anti-oxidant properties

While reactive oxygen species (ROS) play a crucial role in maintaining normal physiological functions, their accumulation can lead to oxidative damage and increase the risk of diseases like cancer and cardiovascular issues.49 Natural phenols and flavonoids can counteract initial free radicals, reducing ROS concentration and preventing chain reactions.

The impact of extrusion on the antioxidant properties of food products can be both positive and negative. Positive effects may result from the thermal disruption of cell walls and subcellular compartments during extrusion, releasing confined phenolics and enhancing their radical scavenging activities.50 In some cases, extrusion increases antioxidant capacity, possibly influenced by the presence of ingredients like proteins or aromatic compounds. Alternatively, extrusion may promote the formation of Maillard reaction products, which also enhance antioxidant activity.51 Conversely, extrusion may deplete bioactive compounds due to thermal and shear stress on the product.

It's important to note that the antioxidant activity of fibre-rich by-products during extrusion is significantly influenced by feed moisture and temperature. Therefore, optimization of these parameters should be considered to maximize antioxidant benefits.52,53

Effect on micro-organisms

Extrusion technology as with other high-temperature processing techniques is capable of inhibiting microbial activity within the food material. As a result, most conventional extruded products such as snack foods and breakfast cereals are safe to eat. The high-temperature processing and shear results in lower water activity (0.1 and 0.4), suggesting a longer shelf life of the product.13 Suitable packaging then becomes an important factor to consider if the status of microbial quality is to be maintained.

Fraiha et al.54 in their studies using Bacillus stearothermophilus spores, reported that shear stress may be involved in microbial load reduction during the extrusion process, predicting that mechanical forces might cause cell rupture. They opined that heat was not the sole phenomenon to explain cell death during extrusion, mechanical damage of cells might be involved.

Extrusion processing at low barrel temperatures (80-100 oC) resulted in injury to spores of B. globigii. Extrusion at the higher barrel temperatures in zone 2 (120 and 180 oC) resulted in extensive spore destruction.55 Okelo et al.56 observed that most pathogenic organisms would be inactivated by extrusion cooking by selecting extruder conditions within the experimental variable ranges that maximized spore destruction of thermophilic bacteria. This reduction would also likely include members of mesophilic Bacillus cereus group.

Extrusion cooking has been identified as one of the most effective ways to reduce mycotoxin levels in processed products, especially if glucose or other additives such as ammonia or sodium bisulphite are included as ingredients. This is especially important since extruded products are highly popular in the food and feed market.14

Application of extrusion technology in food processing

Extrusion technology plays a pivotal role in the food processing industry, contributing significantly to the production of extruded foods for human consumption, pet foods, and the value addition of food wastes and by-products. This innovative method not only offers an efficient and cost-effective means of producing a diverse range of extruded food items but also facilitates the reintegration of food processing by-products and residues into the overall food stream, emphasizing its economic and sustainable contributions to the field of food processing.

Foods for human consumption

Extrusion technology serves as a versatile and pivotal method employed in the production of an extensive array of food products. This includes but is not limited to, the manufacturing of snacks, breakfast cereals, analogues for meat and cheese, supplementary foods, infant foods, and various textured food items, showcasing the adaptability and widespread application of this innovative process.

Breakfast and whole cereal products

The increasing emphasis on healthy eating and evolving lifestyles has elevated the demand for cereals, especially in the form of extruded foods. Ready-to-eat cereals undergo various cooking and modification processes, such as flaking, toasting, puffing, shredding, or extruding, making them suitable for human consumption with low apparent densities.57 Additionally, cold extruded products such as pasta make up the diets of many individuals.58

In the production of directly expanded extrusion-cooked breakfast cereals, flours and/or grits, along with additional ingredients, are processed at low moisture content, typically below 20%, using single or twin-screw extruders. The configurations and operating characteristics of these extruders predominantly lead to mechanical cooking, with a focus on achieving expansion and texture. Conversely, pellet-to-flakes extrusion-cooked breakfast cereals involve cooking cereal flours and/or grits with ingredients at a moisture level ranging from 22 to 26%. Twin-screw extruders, preferred for this process, reduce the mechanical component of cooking, emphasizing the thermal aspect compared to the former processing conditions.13

The evolution of twin-screw extruders has significantly contributed to the advancements in extrusion cooking. This innovation addresses the excessive shear forces applied to the grain formula during extrusion cooking in single-screw extruders. The ability to customize the setup of screw elements in a twin-screw extruder, coupled with greater flexibility in screw speed and heat input, enables precise control over the extrusion cooking process.59

Breakfast cereals (BCs) can be crafted from composite flours containing legumes to compensate for the lack of essential amino acids. Additionally, when made with whole grain flour, BCs become sources of fatty acids and fibres. Grains in BCs provide B-group vitamins, tocopherols, and minerals such as iron, zinc, and copper. Emerging BC products strive for functional appeal, integrating antioxidants (tocopherol, lycopene) and fibres (Beta-glucans, gums, oats, wheat, passion fruit brans) to enhance nutritional benefits.22,60

Confectionary and snack products

Extrusion cooking, specifically High-Temperature Short-Time (HTST) extrusion, is a versatile method employed in creating a chewy and gelatinized product, such as fruit gums and licorice. The process involves a mixture of sugar, glucose, and starch, where heat plays a crucial role in gelatinizing the starch, dissolving the sugar, and vaporizing excess water, which is then vented from the machine. To enhance the product, colorings, and flavors are introduced to the plasticized material.7 This technology allows for a high degree of customization. The product's texture, ranging from soft to elastic, can be adjusted by carefully controlling the formulation and processing conditions. Additionally, alterations in shape are achievable by changing the die, providing a dynamic aspect to the production process. A myriad of flavors and colors can be incorporated, offering a broad spectrum of potential products. This includes popular items like crispbread, licorice, boiled sweets, creams, toffee, fudge, and chocolate.10 Lower pressure/larger die apertures create preforms from pre-gelatinized cereal doughs, expanded into the final product by frying, toasting, or puffing, using residual moisture for rapid expansion.

The production of snacks, on the other hand, has progressed swiftly, dividing into three generations. First-generation snacks involve processing whole grains with moisture, cooking, and drying. Second-generation snacks, often marketed as high-fibre, low-calorie, high-protein products, result from extrusion processing of materials like flours, cereals, starches, and proteins. The continuous mass produced is cut, dried, flavored, and stored. Third-generation snacks, termed "half products," exit the extruder in die form and expand through frying or heating later, offering low moisture, high density, and extended shelf life.61,62 Supercritical fluid injection in twin-screw extrusion cooking unlocks possibilities for innovative processing in cereals, confectioneries, pasta, flavorings, pharmaceuticals, snacks, and beyond.59Top of Form

Meat analogues and extenders

Meat analogues and extenders, also known by various terms such as meat substitute, mock meat, faux meat, or imitation meat, aim to replicate specific aesthetic qualities and chemical characteristics of meat.7 Their popularity has increased in the past few decades due to the high demand for alternative and cheap sources of protein to cover the nutrition gap. They can be produced using various techniques including extrusion technology and they closely mimic the fibrous structure of meat from animal protein.63

Meat extenders, produced at low moisture contents (20-35%), and meat analogues, created at high moisture contents (50-70%), have distinct characteristics. Defatted soy flour and soy protein concentrate (SPC) are commonly used for meat extenders, while meat analogues rely on soy protein concentrate (SPC) and soy protein isolate (SPI). Primary vegetable proteins, such as those from soybeans, common beans, peas, and cereals like wheat proteins responsible for gluten network formation, are utilized in the production of meat analogues.36

Denaturation, melting, and alignment are some of the changes that occur in the extrusion of high-protein raw materials. Denaturation during the extrusion process of proteins results in reduced protein solubility, improved digestibility, and inactivation of antinutritional factors. Additionally, the extrusion of soy protein helps eliminate or reduce the bitter taste and undesirable aroma and volatiles associated with this protein.13

Dairy products

Milk protein possesses health benefits and desirable functional properties. When protein is subjected to mechanical shear as in extrusion, considerable changes in the molecular structure of the protein are seen. These changes (texturization) lead to the formation of new protein-based food products. Texturization stretches and shears the protein to form a new fibre bundle-like structure that withstands hydration, cooking, and other procedures.64 Extrusion technology plays a crucial role in the production of various milk products. It is also employed for stretching and forming operations in cheese making as well as in the production of functional powders with excellent hydration properties.65

Low-temperature extrusion (LTE) has emerged as an innovative technology for achieving the highest quality in dairy products, including butter and ice cream. Sangeetha66 investigated the feasibility of utilizing a twin-screw system at low temperatures (2, 6, and 10 oC) and various linear screw speeds (0.03, 0.05, 0.08, 0.10 & 0.13 m/s) for cooling and working operations in butter manufacturing. Subsequently, an improved version of the refrigerated conjugated intermeshing twin-screw extruder was developed for the continuous production of butter on a commercial scale.67 According to Wildmoser68, low-temperature extrusion (LTE) of ice cream is conducted after freezing in a conventional scraped surface freezer. This process aims to enhance the microstructure and other quality characteristics of ice cream. In LTE, the frozen product undergoes shear treatment in a single or twin-screw low-temperature extrusion system within the temperature range of approximately -10 to -20 oC.

Extrusion cooker systems serve as continuous chemical reactors for converting acid casein into sodium caseinate. The neutralization of acid casein occurs using sodium bicarbonate in a twin-screw extruder at barrel temperatures of 65-160 oC, screw speeds of 150 rpm, moisture content ranging from 19-30%, and a mean residence time of 40 seconds.68

Foods for pet and animal consumption

Extrusion technology extends its application beyond human consumption, finding utility in the preparation of semi-moist and dry-expanded pet foods, aquatic feeds, and diets for laboratory animals. Specifically, pet foods for cats and dogs are subjected to direct extrusion followed by drying. The versatility of extrusion extends to the production of specialized feeds, catering to the nutritional needs of ornamental fish, high-grade complete feeds essential for maintaining the health of various species, and diets tailored for exotic creatures housed in aquariums.9 This broadened application of extrusion technology serves to enhance the efficient utilization of available cereal grains, vegetable resources, and animal proteins in the formulation of diverse and nutritionally balanced animal diets.

Initially, single-screw extruders were common, but modern practices favor twin-screw co-rotating extruders with modular structures and varied geometry.33 In the feed industry, extrusion competes with pelleting, especially for the thermal treatment of raw materials and agglomeration of feeds with higher moisture content (>30%). Extrusion-cooking inactivates antinutritional components, enhancing digestibility, and making it suitable for young animals.

Value-added products from food waste and by-products

Food processing wastes encompass residues from diverse processing operations, including fruits, vegetables, dairy, meat, grain, bakery, sugar, confectionery, fat, oil, beverages, and other food preparation residues.69 These by-products are rich in antioxidants, essential fatty acids, dietary fibre, minerals, vitamins, and phytochemicals such as polyphenols, carotenoids, phytosterols, and hesperidin.7 Extrusion cooking, known for its cost-effectiveness and versatility, has found applications in utilizing these industrial by-products and residues to develop a diverse range of extruded foods. This utilization naturally influences the textural, functional, sensorial, physical, and nutritional characteristics of the products3,70 Extrusion processing serves as a valuable tool for handling various raw materials, offering a means to incorporate unconventional, under-utilized nutrient sources, and food processing residues into food systems. Under-utilized cereals, pseudo-cereals, and food materials with low economic or processing value have been successfully integrated into consumer markets.71,72,4

Other applications

Extrusion also finds application in rice bran stabilization just after milling. This helps reduce the free fatty acid of rice bran oil. Generally, temperatures between 120 and 130 °C for about 20 s with a screw speed of 140 rpm are sufficient to inactivate rice bran lipase. This stabilized rice bran can be used in human food and animal feed.73

Extrusion can also be used in oil expelling by cooking the seeds and breaking down the oil-bearing tissues in a fraction of the time required for conventional conditioning methods. The oil seed remains in the extruder system for less than 30 seconds at a temperature of approximately 1350C. The short cooking time at high temperatures is adequate to satisfactorily destroy anti-nutritional agents such as the trypsin inhibitor and not so long as to damage important nutritional components such as protein.74,75

Recent developments in food extrusion technology

Hot melt extrusion (HME)

Hot-melt extrusion (HME), initially used in plastics, has been extended to cereal food production. It efficiently forms solid dispersions, enhancing stability and bioavailability in food and drug products. In food processing, HME is established for improving solubility, starch gelatinization, and protein denaturation, enhancing digestibility, and neutralizing anti-nutritional factors.76

A fundamental HME setup includes a platform, extrusion barrel, rotating screw on a shaft, and an extrusion die shaping the product (Figure 4). The shape of the extrudate can vary (rods, pellets, tablets) based on specific needs. Twin screw extruders are commonly used in the hot melt extrusion process. They typically consist of feed, compression, and metering zones. The feed zone ensures consistent feeding and mixing, while the compression zone employs special screw elements for additional mixing, melting, homogenizing, and shearing of the extrudate. The metering zone further melts and mixes the food particles at a uniform temperature, resulting in food with an even composition.77 In food, HME's versatility is explored in dietary supplements and insect-based pellets for protein sources. Studies show improved solubility, stability, and dispersion properties, promising applications in meat replacements, feedstuffs, cheese creams, and drugs.78

Neutraceutical foods with encapsulated bioactive compounds are developed using HME, fostering interactions between wall materials and bioactive compounds. The solvent-free method ensures excellent throughput and reduced particle size, increasing solubility and antioxidant capacity. However, further research is needed to assess toxicity and bioaccessibility in HME products for potential food industry applications.

Extrusion using supercritical carbon dioxide

The concept underlying supercritical fluid-assisted extrusion involves the utilization of a supercritical fluid, typically CO2, injected as a blowing agent into a cooked feed mixture that contains volatile micronutrients, flavorings, and colorants. Water is incorporated into the ingredients to serve as a plasticizer, while steam aids in heating the ingredients for cooking.79 Following cooking, steam helps prevent product puffing and reduces the product's temperature through water flash-off in the cooling zone. Additionally, the cooling zone decreases the temperature to below 100 °C, gradually increasing the pressure to supercritical levels. Supercritical carbon dioxide is then introduced to the feed in the subsequent zone. The shear forces generated by the mixing screw break down the supercritical carbon dioxide into tiny bubbles, resulting in the expansion of the extrudates upon exiting the die (Figure 5).

Supercritical carbon dioxide (SC–CO2) extrusion enhances end-product uniformity with smoother surfaces. It surpasses steam in expansion, serving as a leavening agent and reducing processing time for leavened dough. Supercritical fluid-assisted extrusion employs CO2 as a blowing agent for cooked feed, enhancing physico-chemical properties, appearance, expansion, and antioxidant features.79 Lohani and Muthukumarappan80 reported a 12% improvement in phenolic and antioxidant activity using cornflour, hydrodynamic cavitated sorghum flour, and apple pomace. Bashir et al.81 successfully produced nutritious rice-soy chips using SC–CO2, exhibiting enhanced nutrient retention and sensory acceptance.

Paraman et al.82 utilized fruit pomace and whey in SC–CO2 extrusion to create low-density, fibre-rich snacks rich in dietary fibres, polyphenols, and vitamin C. Yoon and Rizvi83 improved the functional and nutritional properties of milk concentrate-based extruded snacks using Greek acid whey. SCF extrusion reduced browning in whey protein-based snacks.84 Balentić et al.85 used SC–CO2 as a blowing agent to develop corn snacks, improving physical and sensory properties. Nitrogen injection during extrusion enhanced the microstructure of red lentil puffed snacks, making them suitable for nutritional programs like mid-day meals due to palatability, shelf stability, and economic feasibility.86

Extrusion-based 3‐D printing

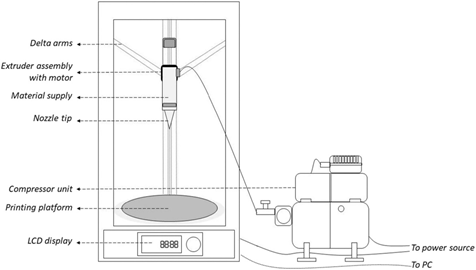

Extrusion-based 3-D printing is a cutting-edge technique for creating computer-designed food products layer by layer.87 Initially patented by Yang et al.,88 it has been applied in making chocolates, cake frosting, processed cheese, and sugar cookies.89 This digital extrusion process allows precise customization of food products with intricate designs, geometries, and internal structures.90 Based on findings from Derossi et al.,91 3-D food extrusion mimics fused deposition technology. Here, a syringe-type extruder deposits high-viscosity food paste along a computer-controlled path. The robotic construction process, guided by computer control, involves loading food materials and extruding them along a predetermined path, leading to the gradual layer-by-layer deposition (Figure 6). Essential parameters for quality include rheological properties of inks, extrusion temperature, printing time, and post-processing. Successful applications range from chocolates to meat products.

Figure 6 Diagram of a typical extrusion type 3D food printer.92

When printing food via extrusion, important factors such as composition, nutritional value, rheological properties, thermal stability, deposition ease, and structural retention after deposition must be considered. Food extrusion can occur at room temperature or in a molten state. Successful 3-D printed products encompass chocolates, cereal-based cookies, cakes, pasta, sugar powder items, meats, and processed cheeses. Ongoing research explores fruit and vegetable-based matrices and multi-material printing, offering potential benefits for dysphagia patients. Challenges include ensuring uninterrupted temperature control for meat extrusion. Despite complexities, the field holds promise for mass production and novel business opportunities globally, pending further investigations.87,91

Food extrusion technology has emerged as a highly versatile and efficient method with extensive applications spanning various industries. This innovative process is known for its ability to create a wide array of food products featuring unique textures and shapes, made possible by advanced extruder designs and the utilization of specialized materials. While food extrusion can lead to notable quality improvements in foods, such as enhanced digestibility, prolonged shelf life, and enriched nutritional profiles, its reach extends to both human and animal consumption.

Extruded foods encompass a diverse range, from direct-expanded snacks and breakfast cereals to texturized proteins, confectionery items, meat substitutes, ready-to-eat pasta, and functional foods. Recent advancements in food extrusion, including techniques like hot melt extrusion, supercritical CO2 extrusion, and 3D printing, have significantly broadened the scope and potential of this technology.

These developments hold considerable promise for elevating product quality, promoting sustainability, and driving innovation within the food industry. With ongoing evolution, food extrusion is poised to play an integral role in meeting evolving consumer preferences for healthier, convenient, and customized food offerings in the years to come.

None.

The authors report that there are no competing interests to declare.

None.

©2024 Sule, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.