Journal of

eISSN: 2373-4310

Research Article Volume 10 Issue 1

Department of Food Science and Technology, University of Agriculture Makurdi, Nigeria

Correspondence: Aondoakaa Philip Ityotagher, Department of Food Science and Technology University of Agriculture Makurdi, Benue State, Nigeria, Tel 07031294545

Received: July 10, 2020 | Published: July 22, 2020

Citation: Ityotagher AP, Julius A. Physiochemical composition, sensory properties and keeping quality of functional yoghurt produced from milk-soy flour blends. J Nutr Health Food Eng. 2020;10(1):5-12. DOI: 10.15406/jnhfe.2020.10.00339

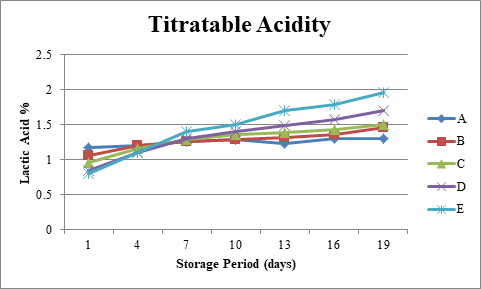

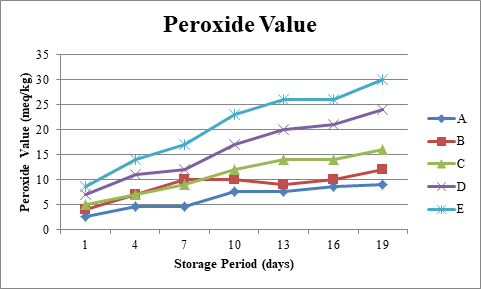

Present study was aimed to investigate the potential of utilizing milk powder in combination with whole soybean flour for the production of functional yoghurt. Yoghurt samples A (control), B, C, D and E were produced at 0%, 10%, 20%, 30% and 40% of milk (nunu) substitutions with whole soybean flour. The physico-chemical properties, sensory evaluation, and keeping quality of the different yoghurt samples were investigated using standard methods. All data were statistically analysed and significance difference was accepted at 5% probability level. The physico-chemical analyses results obtained showed a decrease in total solids (21.71-9.98%), total solids-not-fat (20.13-6.19%), titratable acidity (1.17-0.80%) and viscosity (10.65-0.97 Pa.S) with an increase in pH (4.10 - 5.01) and peroxide value (2.50 – 8.50meq/kg). Proximate values increase remarkably for moisture (78.20-86.23%), Ash (0.19-1.20), protein (2.98-9.14%), fat (1.02-3.42%) and fibre (0.00-2.37%). A reverse trend was observed for carbohydrate (16.60-1.02%). pH, titratable acidity, viscosity and peroxide value of yoghurt samples evaluated during 19 days of storage at 50C revealed a decreasing trend in viscosity throughout the storage period and in pH up to 16th day. Conversely, titratable acidity and peroxide value increased in all samples but higher titratable acidity values and peroxide value values were recorded for whole soybean enriched yogurts compared to the control (all milk yoghurt) after the 4th day and throughout the storage period respectively. The sensory evaluation result showed no significant difference (P > 0.05) between the control and sample B in aroma and appearance but a significant difference (P<0.05) between the control and the enriched samples was recorded for taste, mouth-feel and overall acceptability. It was concluded that the blend containing 90% milk powder and 10% whole soybean flour had the bestpotential for the production of yoghurt which would be acceptable.

Keywords: milk-soy-yoghurt, physiochemical, sensory, keeping, enrichment, functional

Functional foods refer to processed foods which positively affect one or more target functions such as reduction of diseases in the body along with its nutritional effects.1 The relationship between diet and health is not a new concept. The opinion “let food be thy medicine and medicine be thy food”, which is credited to Hippocrates, the father of medicine, in many literatures was proposed about 2500 years ago.2 This food as medicine philosophy fell into relative obscurity in the 19th century with the advent of modern drug therapy.2,3

However, nowadays, Consumer interest in disease prevention and health promotion is shifting towards the potential health benefits of functional foods. This recent trend of moving away from chemical based remedies, towards more nature-based prevention and treatments is gaining momentum mainly as a result of the increasing cost of healthcare.4,5 and comparatively less residue effect associated with functional foods.6

Whole soybean has a good potential for application in the functional food industry as it contains many components that are beneficial to health, such as fiber (which is not naturally found in yoghurt), essential fatty acids, isoflavones, proteins, oligosaccharides etc.7 It has been reported that consumption of Soy protein decreases hyperfiltration in diabetic persons and may reduce urine albumin excretion (proteinuria).8 Protein content of soybeans is about 4 times that of egg and 12 times that of milk9 and contains all amino acids essential to human nutrition, which makes soy products almost equivalent to animal sources in protein quality. Soy protein is characterized by less saturated fat and no cholesterol10 with biological value of 74, whole soybean 9611 and protein digestibility value of 9812 and rich in polyunsaturated fats, the iodine value ranges from 125 to 132 gI2/100 g.13

Yoghurt is a type of dairy product produced from milk or milk products by lactic acid fermentation through the action of probiotics Streptococcus salivarius subsp. thermophilus and Lactobacillus dellbruekii sub-spp. Bulgaricus.14 It is one of the most famous fermented dairy products widely consumed in many countries including Nigeria. Yoghurt is a healthy food for both adult and children. For children, it is a balance source of protein, fats, carbohydrates, and mineral while for the elderly who are usually characterized by more sensitive colons, Yoghurt is also a valuable food.15

Nowadays food is increasingly refined leading to greatly reduced fiber content16 and consequently reduced fiber intake by consumers which pose the risk of colon cancer and other gastrointestinal diseases. Biological ageing and antibiotic therapy result in physiological and pathological changes that make older people to become more prone to age-related diseases.17 These factors also result in declining level of beneficial bacteria in the intestine.18,19 which allow the growth of toxin producing and cancer causing bacteria.20 This can lead to gastrointestinal disorders such as bloating, flatulence, abdominal pain and altered bowel habits.21

Since yoghurt is highly consumed in our modern society and is relatively less expensive, whole soy enriched yoghurt can therefore serve as an important vehicle to supply fiber and other health promoting components to consumers and thus reduced the risk of gastrointestinal and cardiovascular diseases. Thus this present study was aimed at investigating the potentials of producing functional yoghurt enriched with whole soybean flour and to determine the variation of some physicochemical properties of the product during storage.

Raw material procurement

The soybean seeds, commercial powdered (Nunu) milk and freeze-dried starter culture were obtained from Gboko main market in Benue State, Nigeria. Portable water was used throughout the experiment.

Preparation of whole soybean flour

Whole soybean flour was prepared according to the method described by Bolarinwa et al.22 with modifications. The procured soybean seeds were thoroughly sorted and washed to remove dirt and other extraneous materials such as sands, sticks, leaves and debris. It was then oven dried at 60°C for 6 h. The soybeans were roasted at 150°C for 30 min and milled into fine flour using milling machine (hammer mill, model EU 5000D) and sieved through 45 μm mesh size sieve. The flour was packed and sealed in polyethylene bags (55μm thick) until it was used.

Blend formulation

Four different blends were formulated based on the chemical composition of powdered (Nunu) milk purchased and the prepared whole soybean flour in the ratios of 90:10, 80:20, 70:30 and 60:40, respectively (Table 1).

Samples |

Milk Powder (g) |

Whole Soybean Flour (g) |

A (Control) |

100 |

0 |

B |

90 |

10 |

C |

80 |

20 |

D |

70 |

30 |

E |

60 |

40 |

Table 1 Blend ratio for whole soybean incorporated yoghurt

KEY:

Sample A: 100% milk powder (Nunu)

Sample B: 90% milk powder (Nunu) and 10% whole soybean flour

Sample C: 80% milk powder (Nunu) and 20% whole soybean flour

Sample D: 70% milk powder (Nunu) and 30% whole soybean flour

Sample E: 60% milk powder (Nunu) and 40% whole soybean flour

Production of enriched whole soybean yoghurt

Yoghurt was produced from the powdered (Nunu) milk (control) purchased and each of the four blends (90:10, 80:20, 70:30 and 60:40) according to the method described by Ndife.9 The yoghurt samples were coded with letters A (100:0), B (90:10), C (80:20), D (70:30) and E (60:40) corresponding to the control and the various blends, respectively.

Physico-chemical evaluation of different yoghurt samples

The total solids, total solid-non-fat and titratable acidity of the yoghurt samples were determined by the official methods of AOAC.23 Viscosity and pH were measured by the methods described by Jeremia et al.24 and Igbabul et al.15 respectively while peroxide value was determined by the method described by Onwuka GI.25 The proximate analysis (moisture, ash, fat and crude fiber) of the samples was also determined by the official methods of AOAC:23 the moisture by oven drying method; ash by muffle furnace ignition method; fat by ether extraction method. The protein content was determined by formol titration method as described by Shagufta,26 while carbohydrate was determined by difference method as described by Olagunju et al.27

Keeping quality of different yoghurt samples

The yoghurt samples were stored at 50C over a period of 19days. The pH, titratable acidity, viscosity and peroxide value of the yoghurt samples were also measured during storage as previously described every 3 days until day 19. Yogurt without any added soybean (control) was also used to evaluate the nutritional changes that may be caused by addition of whole soybean into yogurt.

Sensory evaluation of different yoghurt samples

The samples were coded and sensory evaluation of the coded yoghurt samples was carried out by 20 trained panalists. They tested the samples based on the following attributes; appearance, aroma, mouth-feel, taste and overall acceptability of the sample using a 9 point Hedonic scale, where 9 indicates extremely like and 1 extremely dislike as described by Ihekoronye and Ngoddy.28

Statistical analysis

Analysis of variance (ANOVA) was carried out on the data obtained to detect statistical differences at 5% level of significance, while the Ducan’s multiple range test was used to separate the means. All statistical analyses of data were performed using SPSS (version 20.0) software.

Physico-chemical properties of different yoghurt samples

The physico-chemical properties of the yoghurt samples are presented in Table 2. There were significant differences (p<0.05) between the control (sample A) and the enriched samples (sample B, C, D and E) for total solids, total solid-non-fat and pH, while significant differences (p<0.05) were observed among all samples for titratable acidity, viscosity and peroxide value.

|

Parameters |

A (100:0) |

B (90:10) |

Samples C (80:20) |

D (70:30) |

E (60:40) |

|

Total Solids (%) |

21.71a±1.24 |

18.93b±1.16 |

17.02b±1.13 |

13.01c±1.04 |

9.98d±0.56 |

|

Total Solids Not-Fat (%) |

20.13a±1.42 |

15.53b±0.02 |

13.49b±0.03 |

9.52c±0.05 |

6.19d±0.82 |

|

pH |

4.10d±0.01 |

4.50c±0.00 |

4.60b±0.00 |

5.00a±0.00 |

5.01a±0.01 |

|

Titratable Acidity (%) |

1.17a±0.05 |

1.05b±0.03 |

0.96c±0.02 |

0.84d±0.03 |

0.80e±0.04 |

|

Viscosity(Pa.s) |

10.65a±0.02 |

8.24b±0.02 |

5.81c±0.02 |

3.39d±0.01 |

0.97e±0.02 |

|

Peroxide Value (meq/kg) |

2.50e±0.02 |

4.00d±0.01 |

5.00c±0.01 |

7.00b±0.02 |

8.50a±0.04 |

Table 2 Effect of whole soybean flour inclusion on the physico-chemical properties of yoghurts

Values are means ± SD triplicate determinations. Values with different superscript within the same row are significantly different (P < 0.05)

KEY:

Sample A: 100% milk powder (Nunu)

Sample B: 90% milk powder (Nunu) and 10% whole soybean flour

Sample C: 80% milk powder (Nunu) and 20% whole soybean flour

Sample D: 70% milk powder (Nunu) and 30% whole soybean flour

Sample E: 60% milk powder (Nunu) and 40% whole soybean flour

The total solids and total solid-non-fat of the yoghurt samples ranged from 9.98% in sample E to 21.71% in sample A and from 6.19% in sample E to 20.13% in sample A, respectively. Total solids are an indication of the dry matter content and total solid-non-fat indicate the fraction of the total solids that is not fat. The relatively high values of the total solids and total solid-non-fat of the control compared to those of the enriched yoghurt samples agree with the findings of Ndife et al.9 who also observed a similar trend in yoghurt samples enriched with coconut-cakes.

The pH value of the yoghurt sample increased as the concentration of whole soybean flour increased. The value ranged from 4.10 to 5.01 and was lowest with the control. This could be due to more availability of lactose to the fermenting bacteria in the control sample. The pH values of the yoghurt samples were comparable with the pH of five commercial yoghurt samples evaluated by Igbabul et al.15 Unlike pH, the result for titratable acidity (expressed as lactic acid %) decreased as the concentration of whole soybean flour increased and ranged from 0.80% in sample E to 1.17% in sample A. These values are above the minimum titratable acidity of 0.6% required by Food Standard Code for plain yoghurt.29

The viscosities of the yoghurt samples were low compared to the viscosities of commercial yoghurt samples as reported by Igbabul et al.15 who further stated that the viscosity of commercial yoghurt is usually enhanced by the addition of stabilizers and thickeners which can also be included in the different yoghurt samples investigated in this study but at permissible levels as given by Codex Alimentarius standards, FDA and other bodies that are known and have been established internationally in setting standards for food and food additives.

Peroxide value measures the amount of peroxide or hydroperoxide groups (initial products of lipid oxidation) present in oil or fat.30 It serves as a useful indicator of the extent of oxidation of lipids, fats, and oils and has been associated with the rancidity in lipid-containing food products.31 Peroxide values of the yoghurt samples increased as the concentration of whole soybean flour increased and range from 2.50 meq/kg in sample A to 8.50 meq/kg in sample E. According to Onwuka GI.,25 a rancid taste begins to show up when the peroxide value is between 20 and 40meq/kg.

Keeping quality of different yoghurt samples

Figure 1 shows the variations of some physico-chemical properties of different yoghurt samples during the storage period. The pH value of all yoghurt samples was inversely correlated to the storage period; it decreased with the passage of time up to 16th day and started to slimly increase thereafter. Vahedi et al.,32 Ranadheera et al.33 and Kumari et al.34 reported that pH values of fruit yoghurt decreased during storage and slimly increased at the latter part of storage. Decrease in pH value in the current study may be attributed to increase in lactic acid production by lactic acid bacteria. While the slight increase in pH at the latter part of storage may be due to biochemical metabolism caused by microorganism; as sugar sources are used up, microorganisms start to utilize proteins thereby producing products such as peptides which may cause slight pH increase. The results for pH of the samples during storage were similar to the findings of Kumari et al.34 who also reported the same trend in rice incorporated yoghurts.

(i)

(ii)

(iii)

(iv)

Figure 1 Variations of some physico-chemical properties of plain and whole soybean incorporated yogurts during storage: (i) pH, (ii) Titratable Acidity, (iii) Viscosity and (iv) Peroxide Value.

Titratable acidity of all the yogurt samples increased with the passage of time during storage period. Many authors also reported similar trend, increase in titratable acidity with time, for fermented dairy foods.32,34,35 It is widely documented that lactic acid bacteria usually convert lactose into lactic acid. Therefore the reason for the trend observed could be due to the activity of S. thermophilus and L. bulgaricus cultures used in the present study. Higher titratable acidity values were recorded for whole soybean enriched yogurts compared to plain yogurt after the 4th day. Fiber improved the growth and survival of lactic acid bacteria during incubation and refrigerated storage.36,37 Fiber in whole soybean might have impacted positively on the growth and activity of lactic acid bacteria in the whole soybean enriched yogurts and thereby higher lactic acid production in whole soybean enriched yogurts than in plain yogurt might be possible.

A decreasing trend in viscosity of the yogurts samples with passage of time was observed in the present study. All the whole soybean incorporated yogurt samples exhibited lower viscosity values throughout the storage period compared to the plain yoghurt. Lower total solid contents in whole soybean enriched yogurt samples could be suggested as a reason for decreased viscosity in whole soybean enriched yogurt samples in the present study. Tamime and Robinson38 and Kumari et al.,34 reported that, decreasing total solid content in yogurt could result to lower consistency and viscosity values.

Peroxide values for all the yoghurt samples increased with days of storage. Peroxide values for the whole soybean incorporated yoghurt samples (B, C, D and E) were higher than that of the all milk yoghurt sample (A) during storage. Sample E with 40% whole soybean flour recorded the highest peroxide value (30 meq/kg fat) due to its high unsaturated fat content. Peroxide values of sample A, B and C were within safe limit during storage as the values were below 20 meq/kg. A rancid taste begins to show up when the peroxide value is between 20 and 40 meq/kg.25 Sample D and E which contained 30 and 40% whole soybean flour respectively were more susceptible to lipid oxidation, leading indirectly to the formation of compounds responsible for rancid and off-flavors in the product.

Proximate composition of different yoghurt samples

Results for effect of whole soybean flour inclusion on the proximate composition of the yoghurt samples are presented in Table 3. There were significant differences (p<0.05) between the control and the other yoghurt samples for all the proximate parameters (moisture, ash, protein, fat, fibre and carbohydrates). Significant differences (p<0.05) were observed among all samples for fiber and carbohydrate values. The moisture content of the yoghurt samples ranged from 78.20% in sample A to 86.23% in sample E and was dependent on the proportion of powdered milk to whole soybean flour used. The moisture content of food gives an indication of its microbial stability and keeping qualitie.39-41 The moisture content results for all the samples fell within the moisture content range (78.2 to 87.1%) of nine commercial yoghurt samples evaluated by Olugbuyiro and Oseh.42 The ash content of the samples increased as the concentration of whole soybean flour increase and range from 0.19% in sample A to 1.20% in sample E. This may be attributed to the relatively high mineral content of soybean. The mineral content of whole soybean is reported to be 4.90%43 while that of powdered milk (Nunu) is 4.39%.27 Like moisture and ash, the content of protein, fat and fibre increased with the increase in the whole soybean flour in the yoghurt samples. Conversely, the carbohydrate content of the yoghurt samples decreased considerably from 16.60% in the yoghurt sample produced from 100% milk to 1.02% in the yoghurt samples produced from 40% whole soybean flour. The protein content of the yoghurt sample produced from 100% milk was 2.98% as compared to 4.79, 6.03, 6.68 and 9.14% for the yoghurt samples produced from 10, 20, 30 and 40% whole soybean flour, respectively. The trend was the same for fat and crude fibre content of the yoghurt samples. This is a reflection of the superiority of whole soybean flour27,44 over powdered (Nunu) milk in protein, fibre, fat and ash properties and it suggest their mutual supplementation effect. The crude fiber values compared favourably with results on other whole soybean substituted products such as biscuits as documented by other researchers.45

|

Parameters |

A (100:0) |

B (90:10) |

Samples C (80:20) |

D (70:30) |

E (60:40) |

|

Moisture (%) |

78.20d±1.24 |

81.07c±0.98 |

81.96c±0.12 |

83.88b±1.43 |

86.23a±0.06 |

|

Ash (%) |

0.19d ±0.63 |

0.28c ±0.05 |

0.34b±0.02 |

0.37b±0.02 |

1.20a±0.04 |

|

Crude Protein (%) |

2.98d±0.03 |

4.79c±0.09 |

6.03b±0.05 |

6.68b±0.09 |

9.14a±0.05 |

|

Fat (%) |

1.02c±0.34 |

2.76b±0.06 |

3.00ab±0.09 |

3.12ab±0.04 |

3.42a±0.12 |

|

Crude Fibre (%) |

0.00e±0.00 |

0.65d±1.03 |

1.13c±1.20 |

1.65b±0.95 |

2.37a±1.24 |

|

Carbohydrate (%) |

16.60a±1.85 |

11.01b±2.00 |

8.67c±0.95 |

6.04d±1.02 |

1.02e±1.98 |

Table 3 Effect of whole soybean flour inclusion on the proximate composition of yoghurt

Values are means ± SD triplicate determinations. Values with different superscript within the same row are significantly different (P < 0.05)

KEY:

Sample A: 100% milk powder (Nunu)

Sample B: 90% milk powder (Nunu) and 10% whole soybean flour

Sample C: 80% milk powder (Nunu) and 20% whole soybean flour

Sample D: 70% milk powder (Nunu) and 30% whole soybean flour

Sample E: 60% milk powder (Nunu) and 40% whole soybean flour

Sensory properties of different yoghurt samples

While significant differences (p <0.05) were observed between the control and the different yoghurt samples for taste, mouth-feel and overall acceptability, there was no significant difference between the control and sample B in terms of appearance and aroma (Table 4). The differences between the control and the other yoghurt samples for taste, mouth-feel and overall acceptability may be attributed to the beany flavour of the soybean. Osaili46 reported that soybean products have had limited consumer acceptance because of its undesirable beany after taste but this attribute can be improved with processing and product formulation skills such that the whole soybean supplemented yoghurt samples will have little or no detectable beany after taste while at the same time still enhancing the nutritional and functional properties of the Yoghurt samples.

|

Parameters |

A (100:0) |

B (90:10) |

Samples C (80:20) |

D (70:30) |

E (60:40) |

|

Appearance |

8.50a |

7.54ab |

7.20bc |

6.50bc |

6.35c |

|

Aroma |

7.60a |

6.50abc |

5.55b |

4.20cd |

3.65d |

|

Taste |

7.15a |

4.90bc |

5.15b |

4.00cd |

3.60d |

|

Mouth-feel |

6.25a |

5.20b |

5.15b |

4.40bc |

4.15c |

|

Overall acceptability |

6.85a |

5.25b |

5.20b |

4.15c |

3.60c |

Table 4 Effect of whole soybean flour inclusion on the sensory properties of yoghurts

Means with different superscript within the same row are significantly different (P < 0.05).

KEY:

Sample A: 100% milk powder (Nunu)

Sample B: 90% milk powder (Nunu) and 10% whole soybean flour

Sample C: 80% milk powder (Nunu) and 20% whole soybean flour

Sample D: 70% milk powder (Nunu) and 30% whole soybean flour

Sample E: 60% milk powder (Nunu) and 40% whole soybean flour

Based on the findings of this study, it can be concluded that, Whole soybean flour inclusion imparted positively on the nutritional value of yoghurt. Protein, fibre, ash, fat and moisture of the enriched yoghurt samples were significantly higher than those of the control (all milk yoghurt). Conversely, the carbohydrate contents of the enriched yoghurt samples were significantly lower than those of the control, hence an excellent diet source for obese, diabetes and colon cancer patients. The physiochemical properties of the control were superior to those of the enriched samples. Susceptibility to lipid oxidation increased more at 30% and 40% level of substitution of whole soybean flour into the fermented milk during storage. In terms of sensory composition, the control received the highest ratings in all sensory properties evaluated.

The physiochemical and sensory properties of sample B compared favorably with those of the control. Therefore the blend containing 10% whole soybean flour had the best potential for the production of functional yoghurt which would be acceptable and is recommended. However, for high acceptability further research is needed to improve on the sensory properties by the modification of the production process, genetic engineering of varieties of soybeans devoid of lipoxyganase activity and use of flavourings.

None.

There is no conflict of interest.

©2020 Ityotagher, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.