Journal of

eISSN: 2373-4310

Research Article Volume 12 Issue 2

Department of Food Engineering, Ladoke Akintola University of Technology, Nigeria

Correspondence: Abioye AO, Department of Food Engineering, Ladoke Akintola University of Technology, Ogbomoso, Nigeria, Tel 08080589890

Received: May 17, 2022 | Published: June 27, 2022

Citation: Adeyanju JA, Abioye AO, Ogunlakin GO, et al. Optimization of process variables for the production of cookies from wheat, fonio, and pigeon pea flour blends. J Nutr Health Food Eng. 2022;12(2):73-77. DOI: 10.15406/jnhfe.2022.12.00359

The purpose of this study was to optimize the incorporation of fonio and pigeon pea flours in quality attributes of cookies using a D-optimal design of response surface methodology. The impact of independent variables wheat flour (20-50), fonio flour (20-70), and pigeon pea flour (10-35) were investigated on the dependent variables (moisture content, fat content, texture, and total colour difference). Analysis of variance and regression were used to analyze the data. The moisture content ranged from 4.95 to 5.39%, oil content (15.03 to 15.55%), texture (15.50–33.00 N), and colour difference (30.95–48.54). The flour blends significantly affect moisture content, oil content, texture, and colour difference at p<0.05. The coefficient of determination (R2) generated model ranged from 0.78 to 0.99. The result of the study shows that 27.50 g of wheat flour, 62.50 g of fonio flour, and 10 g of pigeon pea flour were the optimal conditions for the production of cookies from the blend. This condition gave 4.99% moisture content, 15.1% fat content, 29.77 N texture, and 48.54 colour difference. The desirability of optimization was 0.86.cookies

Keywords: cookies, optimization, wheat-fonio-pigeon pea flour, response surface methodology, quality attributes

Cookies are popular snacks throughout the world. It is made primarily from flour, sugar, butter, and eggs. It is a sweet, crunchy dough made of wheat flour and other customary baking items. It has a soft texture and low moisture content when compared with biscuits. They are high in fat, carbohydrates, and calorie.1 Fonio (Digitaria exilis) is one of the oldest African cereals. West Africans have cultivated it across the dry savannas for thousands of years, and it was once their principal food. Fonio is also one of the most nutritious but underutilized cereals. Its seed is rich in methionine and cystine, which are amino acids vital to human health and deficient in other major cereals such as wheat, rice, maize, sorghum, barley, and rye.2

Food legumes form an essential component of people's diets in many developing countries of Africa.3 They are a cheaper source of proteins when compared to animal proteins. Pigeon pea (Cajanus cajan L.) is also called red gram or tuar (known locally in the southwest of Nigeria as ewa otili). Pigeon pea protein is a rich source of lysine but is usually deficient in sulphur-containing amino acids, methionine, and cystine; it thus supplements the essential amino acids in cereals.3 Protein-deficient foods are typical for a large portion of Nigeria's population. Protein content in carbohydrate-based foods can be increased to improve nutritional quality. Vegetable protein calories have been proposed as a solution to this problem because legume proteins are high in lysine, an essential amino acid that is limited in most cereals.4

Response Surface Methodology (RSM) is an important process and product improvement tool.5 RSM is a set of mathematical and statistical procedures that can investigate relationships between one or more responses (dependent variables) and various factors (independent variables).6 In our literature search, we discovered that no studies had been carried out using RSM to optimize cookies produced from wheat, fonio, and pigeon pea flour blends. Therefore, this study aims to investigate the effect of incorporating fonio and pigeon pea flours on the quality attributes of cookies using response surface methodology.

Materials

Pigeon pea (Cajanus cajan) seeds were obtained from a local market in Ilesa, Osun State , while fonio

(Digitaria exilis) grains were obtained from a local market in Jos, Plateau State. Other ingredients such

as eggs, baking powder, nutmeg, milk, sugar, margarine, and vegetable oil for the cookies were

purchased at a local market in Ogbomoso, Oyo State.

Processing of pigeon pea into flour

Four kilograms of each pigeon pea seed was weighed and sorted to remove dirt. It was then boiled in water for 60 min to reduce the presence of anti-nutritional factors. The seeds were dehulled with a mortar pestle and dried using a solar drier for 12 hours. The dried seeds were milled using a hammer mill, after which the flour was sieved using a 1 mm sieve size and packed in a polythene bag.

Processing of fonio into flour

Seven kilograms of fonio grains were weighed and sorted to remove dirt. The grains were washed repeatedly in portable water, dried, and milled with a hammer mill, after which the flour was sieved using one-millimeter sieve size and packaged in an airtight container until needed for analysis.7

Experimental design

The experimental design employed was the response surface methodology using a D-optimal. The design generated fourteen experimental runs. Three independent variables were used; flour ratio of wheat (35-70%), fonio (20-50%), and pigeon pea (10-35%). Four dependent variables were selected as responses representing the main parameter of cookies quality; colour difference, texture, fat content, and moisture content. The experimental data for each response variable was fitted to the quadratic model and the regression parameters for the equations were generated.

Production of cookies

The flour, salt, baking powder, egg, margarine, sugar, milk, and vanilla extract were used to make the cookie samples. For 5 minutes, an electric mixer on medium speed was used to cream margarine and sugar. After 30 minutes of mixing, the eggs and milk were added. Vanilla, flour, baking powder, and salt were thoroughly combined and added to the cream mixture; they were thoroughly mixed to form the dough. The dough was kneaded to a thickness of 0.5 cm and cut into a 5 cm circular shape. It was allowed to bake for 30 minutes at 180 °C.

Determination of the quality attributes of cookies

Moisture content

Two grams of sample were weighed and transferred into crucibles. The crucibles were placed in a 105 °C drying oven for 5 hours. They were then removed and placed in a desiccator to cool. The cooled crucibles were weighed once more. The weight loss after drying was calculated as a percentage of moisture.8

Oil content

The AOAC8 method was used to determine the oil content. The samples were ground using a grinder. A solvent extractor was used to extract fat from 5 g of sample in thimbles (SER 148, VelpScientifica, Usmate, Italy). The oil content was calculated by dividing the mass of extracted fat by the sample's dry matter.

Colour

The surface colour of the samples was measured with a colourimeter (Nippon Denshoku Σ90 colour difference meter, Japan) and expressed as Hunter L (lightness), a (redness), and (yellowness) values.9 The colour difference (Hunter ΔE) was calculated according to Equation (1):

(1)

Where , and are the L, a, and b values of cookies cut, respectively.

Texture measurement

A puncture test was used to determine the texture measurement of the cookies. The penetrometer needle was fitted and a cookie sample was placed underneath it with the tip of the needle touching the surface of the sample. The pointer shaft of the die was set to zero. The plunger of the penetrometer was released to make a free penetration on the sample for 15 sec. The penetration depth was measured by gently depressing the pointer shaft until it touched the top of the plunger again. The penetration distance was measured.10

Statistical analysis

The experiments were repeated three times, and the mean values were recorded as obtained data. Design Expert Version 6.0.1.0 (Statease Inc; Minneapolis USA, version), a commercial statistical package, was used to process the collected data. Analysis of variance (ANOVA), mathematical modeling, regression analysis, and optimization were performed using the software. For various interactions, response surface plots were generated. The process was optimised to find the levels of wheat flour, fonio flour, and pigeon pea flour that could minimize moisture content, oil content, texture, and colour. In order to determine the workable optimum conditions for the cookie process, a graphical multi-response optimization technique was used. The contour plots for all responses were superimposed, and the regions that best satisfied the constraints were selected.

Moisture content

Table 1 shows the quality characteristics of cookies made from wheat, fonio, and pigeon flour. The moisture content of the cookies ranged between 4.94 and 5.39%. This result was consistent with Omah and Okafor.11 findings on cookies made from wheat and millet-pigeon pea flour blends and Adebayo and Okoli.12 findings on flour samples made from germinated lima bean and sorghum. Because the moisture content values are less than 10%, cookies made from composite flour (wheat, fonio, and pigeon pea) have a stable shelf life. The moisture content range obtained in this study is similar to that obtained by Awolu, Omoba, Olawoye et al.13 and Adeyanju, Babarinde, Olanipekun et al.14 The analysis of variance for moisture content revealed that the quadratic model and model term, that is, the interaction between wheat and pigeon pea flour, fonio and pigeon pea flour (AC, BC), were significant. In contrast, the interaction between wheat and fonio (AB) flour was insignificant at p<0.05. The values for the coefficient of determination, R2 and adjusted R2 were 0.904 and 0.844, respectively. It indicates that the model is well-fit and suitable for predicting MC. Table 2 shows the MC response for regression coefficients and the dependent variables analysis of variance. The response surface plot of moisture content against flour blends is shown in Figure 1. The regression equation representing the effect of the variables on moisture content is depicted in Equation (2).

(2)

Runs |

A (%) |

B (%) |

C (%) |

MC (%) |

FC (%) |

T (N) |

ΔE |

1 |

35.00 |

35.00 |

30.00 |

5.06 |

15.07 |

26.00 |

40.16 |

2 |

20.00 |

50.00 |

30.00 |

5.26 |

15.40 |

25.25 |

41.32 |

3 |

27.50 |

47.50 |

25.00 |

5.19 |

15.34 |

29.75 |

34.43 |

4 |

35.00 |

45.00 |

20.00 |

5.33 |

15.43 |

15.50 |

35.65 |

5 |

27.50 |

42.50 |

30.00 |

5.14 |

15.37 |

29.16 |

34.05 |

6 |

27.50 |

62.50 |

10.00 |

4.95 |

15.03 |

33.00 |

48.54 |

7 |

23.75 |

61.25 |

15.00 |

5.39 |

15.55 |

25.50 |

41.09 |

8 |

35.00 |

55.00 |

10.00 |

5.01 |

15.09 |

18.50 |

37.05 |

9 |

20.00 |

50.00 |

30.00 |

5.26 |

15.40 |

25.25 |

41.32 |

10 |

35.00 |

55.00 |

10.00 |

5.00 |

15.09 |

18.50 |

37.05 |

11 |

20.00 |

70.00 |

10.00 |

5.19 |

15.13 |

21.50 |

30.95 |

12 |

35.00 |

35.00 |

30.00 |

5.06 |

15.07 |

26.00 |

40.16 |

13 |

27.50 |

52.50 |

20.00 |

5.39 |

15.55 |

25.50 |

41.09 |

14 |

20.00 |

70.00 |

10.00 |

5.10 |

15.13 |

21.50 |

30.95 |

Table 1 Quality attributes of composite blends from wheat, fonio and pigeon pea flour

A= wheat flour, B= fonio flour, C= pigeon pea flour, FC= fat content, MC= moisture content, T= Texture, ΔE= colour difference

Responses |

Sources of |

Sum of |

DF |

Mean |

F-value |

p-value |

MC |

Model |

0.253124 |

5 |

0.050625 |

15.10859 |

*0.0007 |

Linear Mixture |

0.060092 |

2 |

0.030046 |

8.96699 |

*0.0091 |

|

AB |

0.010666 |

1 |

0.010666 |

3.183167 |

0.1122 |

|

AC |

0.020619 |

1 |

0.020619 |

6.153497 |

*0.0381 |

|

BC |

0.179779 |

1 |

0.179779 |

53.6537 |

* 0.0001 |

|

Residual |

0.026806 |

8 |

0.003351 |

|||

Lack of Fit |

0.026806 |

4 |

0.006701 |

|||

Pure Error |

0 |

4 |

0 |

|||

|

Cor Total |

0.27993 |

13 |

𝑅2= 0.904; adjusted 𝑅2= 0.844 |

Table 2 Moisture content response for regression coefficients and ANOVA

*p<0.05 indicates statistical significance

Fat content

The cookies' fat content ranged from 15.04 to 15.55%. The fat content of cookies rises as pigeon pea flour is substituted. These values agreed with the findings of Olapade et al.7 and Okpala.15 Because of oxidative activity, the fat content of cookies affects their shelf life. 16 (Awolu et al., 2015). At p<0.05, the ANOVA result for fat content revealed that the quadratic model and model terms (AC, BC) were significant, while AB was not. The values for R2 and adjusted R2 were 0.888 and 0.818, respectively. It indicates that the model is suitable for predicting fat content and fit because R2 values closer to 1.0 provide the best fit. The response surface plot of oil content affected by flour blends is shown in Figure 2. The regression equation is depicted in Equation (3) (Table 3).

(3)

Responses |

Sources of |

Sum of |

DF |

Mean |

F-value |

p-value |

FC |

Model |

0.408925 |

5 |

0.081785 |

12.75498 |

*0.0012 |

Linear Mixture |

0.106527 |

2 |

0.053263 |

8.306824 |

*0.0112 |

|

AB |

6.13E-05 |

1 |

6.13E-05 |

0.009563 |

0.9245 |

|

AC |

0.053013 |

1 |

0.053013 |

8.267748 |

*0.0207 |

|

BC |

0.2123 |

1 |

0.2123 |

33.10975 |

*0.0004 |

|

Residual |

0.051296 |

8 |

0.006412 |

|||

Lack of Fit |

0.051296 |

4 |

0.012824 |

|||

Pure Error |

0 |

4 |

0 |

|||

Cor Total |

0.460221 |

13 |

||||

R2 = 0.888; adjusted R2= 0.818 |

||||||

Table 3 Fat content response for regression coefficients and ANOVA

*p<0.05 indicates statistical significance

Texture

The texture of the cookies ranged from 15.5 to 33 N. Increased incorporation of fonio and pigeon pea flour had a significant impact on this. It has been reported that the textural properties of food products are affected by processing conditions and raw materials.17,18 The texture results for cookies agreed with Ishiwu, Nkwo, Iwouno et al.19 on optimizing the taste and texture of biscuits made from a blend of plantain, sweet potato, and malted sorghum flour. The texture analysis of variance revealed that the quadratic model and model terms (AC, AB, and BC) were significant at p<0.05. The values for R2 and adjusted R2 were 0.866 and 0.782, respectively. Figure 3 depicts a response surface plot of texture against flour blends. The regression equation representing the effect of the variables on texture is shown in Equation (4) (Table 4).

Responses |

Sources of |

Sum of |

DF |

Mean |

F-value |

p-value |

T |

Model |

259.7443 |

5 |

51.94886 |

10.36469 |

*0.0024 |

Linear Mixture |

63.68277 |

2 |

31.84138 |

6.352905 |

*0.0223 |

|

AB |

186.3935 |

1 |

186.3935 |

37.18872 |

*0.0003 |

|

AC |

101.1906 |

1 |

101.1906 |

20.18927 |

*0.0020 |

|

BC |

55.72583 |

1 |

55.72583 |

11.11826 |

*0.0103 |

|

Residual |

40.09679 |

8 |

5.012098 |

|||

Lack of Fit |

40.09679 |

4 |

10.0242 |

|||

Pure Error |

0 |

4 |

0 |

|||

Cor Total |

299.8411 |

13 |

||||

R2= 0.866; adjusted R2= 0.782 |

||||||

Table 4 Texture response for regression coefficients and analysis of variance

*p<0.05 indicates statistical significance

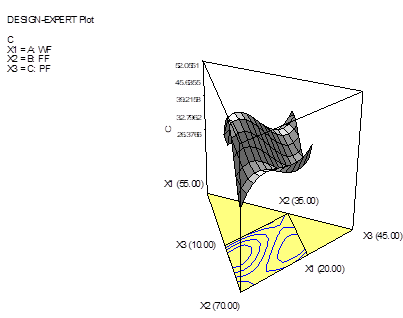

Colour difference

The result of the cookies' colour difference (∆E) ranged from 30.96 – to 48.54. It was discovered that a significant amount of brown product is formed as baking progresses. A colour change in cookies is usually caused by non-enzymatic browning at higher temperatures.19,20 obtained comparable results when vacuum frying potato chips. The cubic model and model term (AC, AB, BC ABC, AB(A-B), AC(A-C), BC(B-C)) were significant at p<0.05 in the analysis of variance for the colour difference. The values for R2 and adjusted R2 were 0.999 and 0.985, respectively. Figure 4 depicts a response surface plot of the colour difference between the variables. The regression equation is given in Equation (5) (Table 5).

Figure 4 Response surface plot showing the interaction between the variables with the colour difference.

Responses |

Sources of |

Sum of |

DF |

Mean |

F-value |

p-value |

∆E |

Model |

296.4082 |

9 |

32.93425 |

63660000 |

*0.0001 |

Linear Mixture |

11.47146 |

2 |

5.735729 |

63660000 |

*0.0001 |

|

AB |

5.867853 |

1 |

5.867853 |

63660000 |

*0.0001 |

|

AC |

5.350529 |

1 |

5.350529 |

63660000 |

*0.0001 |

|

BC |

4.726836 |

1 |

4.726836 |

63660000 |

*0.0001 |

|

ABC |

5.348712 |

1 |

5.348712 |

63660000 |

*0.0001 |

|

AB(A-B) |

3.410945 |

1 |

3.410945 |

63660000 |

*0.0001 |

|

AC(A-C) |

9.392159 |

1 |

9.392159 |

63660000 |

*0.0001 |

|

BC(B-C) |

5.564251 |

1 |

5.564251 |

63660000 |

*0.0001 |

|

Pure Error |

0 |

4 |

0 |

|||

Cor Total |

296.4082 |

13 |

||||

R2= 1.000; adjusted R2= 1.000 |

||||||

Table 5 Colour response for regression coefficients and analysis of variance

*p<0.05 indicates statistical significance

Optimization

Four appropriate solutions for the optimization process were discovered using the software package. That is, four different combinations of wheat, fonio, and pigeon pea flour could be used to minimize moisture, fat content, texture, and colour. The desirability ranged from 0.76 to 0.86. The preferred point that was of highest desirability process parameters for cookies of acceptable quality attributes were 27.5% wheat flour, 62.5% fonio flour, and 10% pigeon pea flour, which gave moisture content of 4.99%, the fat content of 15.1%, the texture of 29.78 N, and colour difference of 48.54.

The production of cookies using various ratios of wheat flour, fonio flour, and pigeon pea affects the quality of the cookies. The variance (ANOVA) analysis shows that the flour ratio influenced the moisture content, fat content, colour, and texture. Model equations were developed to accurately predict the quality attributes of cookies at any given baking temperature and time. The models' good fit was confirmed by high coefficients of determination R2 of 0.90, 0.88, 0.86, and 0.99 for moisture content, fat content, texture, and colour, respectively. The optimal process parameters are 27.5^% wheat flour, 62.5% fonio flour, and 10% pigeon pea flour, which results in a moisture content of 4.99%, fat content of 15.1%, texture of 29.78 N, and a colour difference of 48.54. The experimental data modeling generated equations that can be used to predict the quality attributes of cookies made with a wheat-fonio-pigeon pea flour blend.

None.

The authors declare having no conflict of interest.

None.

©2022 Adeyanju, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.