Journal of

eISSN: 2373-4310

Research Article Volume 10 Issue 1

Department of Food Science and Technology, Osun State Polytechnic, Iree, Nigeria

Correspondence: Adedeji T.O, Department of Food Science and Technology, Osun State Polytechnic, Iree, Nigeria, Tel 08066514332

Received: April 16, 2020 | Published: August 18, 2020

Citation: Olosunde OO, Adedeji TO, Amanyunose AA, et al. Development and quality evaluation of a typical flour blend from Orange –fleshed Sweet potato (Ipomea batatas) and Soy-bean (Glycine max L). J Nutr Health Food Eng. 2020;10(1):23-29. DOI: 10.15406/jnhfe.2020.10.00341

The study investigated the functional, pasting properties, proximate composition and sensory evaluation of sweet potato –soy flour blend mixed in the ratio of 100:0; 90:10; 80:20 and 70:30 sweet potato: soy flour blend. The proximate composition revealed that the crude protein, crude fibre and ash content of the flour blends increased with increased inclusion of soy flour. The swelling index and oil absorption capacities of the blends increased as SP increased except for sample SP70SF30 while the water absorption capacity and the bulk density decreased down the trend. Water absorption characteristics ranged between 2.40 to 2.46g/ml. The peak, setback, and final viscosities increased with increased inclusion of soy flour while pasting temperature and time of the flour blends decreased with increased inclusion of soy flour. The peak viscosity ranged between 70.42 to 131.00Rvu 20% soy flour inclusion was most preferred among the composite blends though all samples were acceptable by the panellists in all the sensory attributes evaluated. Thus, the flour is highly nutritious and may ensure the growth of infants and therefore, can help to reduce malnutrition in developing countries like Nigeria.

Keywords: sweet potato, soy flour, blend, samples

Malnutrition and food insecurity are among the most serious problems facing tropical African countries today.1 It has been estimated that 800 million malnourished people live in some of the least developed countries.2 High prices of available staple foods and policy constraints on food imports are also contributing factors that have been worsening the food situation in developing countries.3,4 Also contributing to this problem is the underutilization of most of the crops found in this part of the world. These crops include legumes, root crops and cereals which have been investigated and found to be inexpensive and possess good nutritive value for the solution of protein-energy malnutrition.5 The potential of roots and tubers for addressing the food insecurity situation in West African countries comes only next to cereals, but the utilization of these crops remains under exploited. Although several root crops are available on the market, in most cases production rate compared with consumption has mostly remained unmet.6

Sweet potato (Ipomea batatas) is a root crop that is grown in many countries.7,8 It is grown predominantly for human food in Africa, whereas it is produced primarily for animal feed in China.9 Sweet potato roots vary in color, with orange-fleshed types being particularly rich in β-carotene, the most important provitamin A carotenoid.10 Irrespective of their color, all sweet-potato are low in protein quantity and quality.11 Some orange-fleshed varieties are found naturally, while others have been developed through conventional breeding. Sweet potato varieties improved through modern biotechnology have also been developed.12 In both cases, selected orange-fleshed varieties are being further developed through participatory breeding initiatives with local farmer communities to incorporate agronomic traits that farmers want.13

Soy protein is a protein that is isolated from soybean. It is made from soybean meal that has been dehulled and defatted. Dehulled and defatted soybeans are processed into three kinds of high protein commercial products: soy flour, concentrates, and isolate. Recently, soy protein popularity has increased due to its use in health food products, and many countries allow health claims for foods rich in soy protein. Soy protein is generally regarded as being concentrated in protein bodies, which are estimated to contain at least 60–70% of the total soybean protein.12 Upon germination of the soybean, the protein will be digested, and the released amino acids will be transported to locations of seedling growth. Soy protein is used in a variety of foods, such as salad dressings, soups, meat analogues, beverage powders, cheeses, non-dairy creamer, frozen desserts, whipped topping, infant formulas, breads, breakfast cereals, pastas, and pet foods. Soybean protein is a "complete protein" since it provides all of the essential amino acids for human nutrition. Soybean protein is essentially identical to that of other legume pulses and is one of the least expensive sources of dietary protein. For this reason, soy is important to many vegetarians and vegans. Soybean flour contains 50% protein. The digestibility of some soy foods is as follows: steamed soybeans 65.3%, tofu 92.7%, soy milk 92.6%, and soy protein isolate 93–97%.12 This research work, if adopted, will improve utilization of orange-fleshed sweet potato to produce a nutritionally superior product for nutritionally vulnerable groups among infant and adult group. The aim of the research study is to develop a typical flour blend from orange fleshed sweet potato and soy flour and to evaluate the proximate composition, organoleptic, functional and pasting properties of the flour blend.

Materials

Orange fleshed sweet potato roots tubers, soya beans and other ingredients (sugar and salt) used in this study for the preparation of the flour blend were obtained from a supermarket market in Iree, Osun state.

Development of Sweet potato –Soy Flour Blend

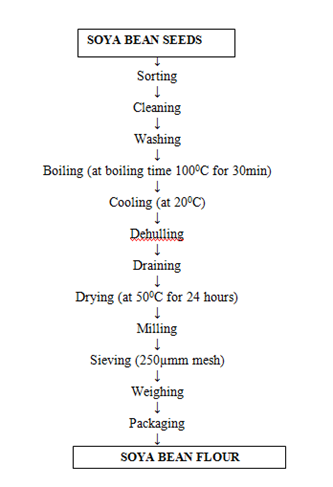

Figure 1 and 2 shows the process flow diagram for the development of the orange fleshed sweet potato and soy bean flours. Huang et al.,14 method was adopted with some modifications for the production of both flours.

Figure 1 Flow chart for the production of orange fleshed sweet potato flour

source: huang et al.14

Figure 2 Flowchart for the production of soya bean flour

source: huang et al.14

Preparation of Sweet potato –Soy Flour Blend

Table 1 shows the sample codes and designation of sweet potato-soy flour. It was prepared by mixing sweet potato and soy flour in varied proportions of 100:0; 90:10; 80:20; 70:30 with other dry ingredients at ambient temperature. The flour was made to pass through 250 μm sieve (USA standard testing sieve; A.S.T.M.E.-11 specification). The samples were then cooked in a pre-heated heat exchanger tank 220°C for 15 minutes and stored in sealed polyethylene pouches for further analyses.

Sample Codes |

SP100SF0 |

SP90SF10 |

SP80SF20 |

SP70SF30 |

SP:SF(g) |

100:0 |

90:10 |

80:20 |

70:30 |

SP (g) |

100 |

90 |

80 |

70 |

SF(g) |

0 |

10 |

20 |

30 |

Salt (g) |

0.5 |

0.5 |

0.5 |

0.5 |

Sugar (g) |

2.0 |

2.0 |

2.0 |

2.0 |

Table 1 Sample code and designation of sweet potato –Soy Flour Blend

Keys: SP100SF0 stands for 100% SP: 0% SF; SP90SF10 stands for 90% SP:10% SF; SP80SF20 stands for 80% SP:20% SF; SP70SF30 stands for 70% SP: 30% SF; SP – orange fleshed sweet potato; SF – soybean flour

Analyses

Sensory evaluation of sweet potato –soy flour blend meal

Preference tests were conducted with 10 untrained panellists in a large-scale consumer acceptability test to determine relative preferences for the various sensory attributes of the flour blend samples using the nine-point hedonic scale as described by Mridula et al.15 A score of 9 represented like extremely with 1 indicating dislike extremely. Taste, aroma, texture, crust colour, mouth feel and overall acceptability were the attributes considered in the preference test. The test was carried out by administering a semi-structured questionnaire to randomly selected and willing respondents at Osun state polytechnic Iree. The samples were served in disposable plates to panelists in a systematic order to eliminate positional biases in assessment (i.e., were presented to consumers using a complete random design). The panelists were provided with disposable cups with water to rinse their mouths between samples. The questionnaire was explained to the panelists to orient them on what was expected of them. In situations where the respondent could not fill out the questionnaire independently, sensory assistants were available to help them write out their responses in a language of mutual understanding as accurately as possible.

Proximate analysis of sweet potato –soy flour blend samples

Moisture content, protein content, crude fat, ash content and crude fibre were determined using the method as outlined in the AOAC.16 Carbohydrate content was determined by difference.

Functional properties of sweet potato –soy flour blend

This was determined according to the method of Burke et al.17

The pasting properties of the sweet potato –soy flour blend

This was determined according to the method of Shuey and Tipples, 2002.

Statistical analysis

All determinations from the laboratory experiments were done in replication. The statistical analyses were subjected to ANOVA procedures depending on the experimental design. Significant statistical differences in samples were tested at p < 0.05, and least significant differences (LSD) method was used for the post-hoc multi comparison test. All the analyses were done with Statistical Package for Social Scientist (16.0) software.

Results

Discussion on functional properties of sweet potato –soy flour blend

Table 2 shows the functional properties of the flour blend samples produced from orange fleshed sweet potato and soya bean flour. The results was comparable to that reported by Lisa et al.18 who worked on chemical and protein quality of soya bean (Glycene max) banana (Cycerus esculentus) based weaning food. The bulk density of the flour blend samples ranged from 0.50 g/ml to 0.55 g/ml. These show that the flour blend sample SP70SF30 has the lowest bulk density (0.50 g/ml) followed by sample SP100SF0 (0.55 g/ml), followed by sample SP90SF10 and SP80SF20 that has the same bulk density (0.53 g/ml). Bulk density gives an indication of the relative volume of packaging material required and high bulk density is a good physical attribute when determining the mixing quality of a particulate matter.19 The bulk density is a reflection of the load the flour samples can carry, if allowed to rest directly on one another. The density of processed products dictates the characteristics of its container or package product density influences the amount and strength of packaging material, texture or mouth feel. According to Soison et al.20 higher bulk density is desirable for greater ease of dispersibility of flours. Also, high bulk density limits the caloric and nutrient intake per feed of a child which can result in growth faltering. However, low bulk density would be an advantage in the formulation of complementary foods. This is because lower BD values lead to higher amounts of flour particles which can stay together and thus increasing the energy content of such diets. Therefore, more of the samples could be prepared using a small amount of water yet giving the desired energy nutrient density and semi-solid consistency which can easily be consumed by both infants and adults.

Samples |

W A C (g/ml) |

O A C (g/ml) |

B D (g/ml) |

S I |

SP100SF0 |

2.67 |

1.48 |

0.55 |

3.00 |

SP90SF10 |

2.48 |

1.57 |

0.53 |

3.90 |

SP80SF20 |

2.46 |

1.55 |

0.53 |

4.08 |

SP70SF30 |

2.40 |

1.39 |

0.50 |

2.92 |

Table 2 Functional properties of sweet potato –soy flour blend

Keys: SP100SF0 stands for 100% SP: 0% SF; SP90SF10 stands for 90% SP: 10% SF; SP80SF20 stands for 80% SP:20% SF; SP70SF30 stands for 70% SP: 30% SF; SP – orange fleshed sweet potato; SF, soybean flour

The water absorption capacity (WAC) of the flour blend ranged from 2.40g/ml to 2.67g/ml. This shows that sample SP100SF0 (2.67g/ml) has the highest WAC followed by sample SP90SF10 (2.48g/ml), SP80SF20 (2.46g/ml) and SP70SF30 (2.40g/ml) respectively. WAC is the ability of product to associate with under a condition where water is limited. It is also the amount of water taken up by flour to achieve desired constituency or optimal and result. WAC indicates the volume of water required to form gruels with suitable consistency for infant feeding. Carbohydrates have been reported to influence water absorption capacity of foods.21 The ability of protein to bind water is indicative of its water absorption capacity. The observed variation in water absorption among the flour blend samples may be due to different protein concentrations, their degree of interaction with water and their conformational characteristics. On the other hand, Prinyawiwatkul et al.,21 reported that lower water absorption capacity is due to less availability of polar amino acids in flours. This effect could be due to the loss of native granules structure of starch association. With respect to water absorption capacity, Giami & Bekeham,22 reported that the microbial activities of food products with low water absorption capacity would be reduced, thereby extending the shelf-life of the product. Therefore, lower water absorption capacity diets are desirable for making thinner gruels hence sample SP80SF20 (2.46g/ml) is more suitable in formulation of various diets. Water absorption is important in bulking and consistency of products.

The solubility index influences the product to be soluble in which Nnanemere,23 reported that difference in solubility capacity was due to variation in granular association coupled with amylase – amylopectin ratio of starches from various flows. Solubility index of a sample is also the possibility to determine to what extent a pure sample can be dissolved in a solvent.24 The Water Absorption Capacity and Swelling Index are important parameters which ultimately determine the sample consistency (that is solid, semi-solid, or liquid). Flours with both high WAC and SI values hold large amounts of water during their preparation into gruels and thus become voluminous with a low energy and nutrient density. The values obtained in this study were lower than those obtained by Ikpeme et al., 2000 for formulated diets based on taro and soy bean. Samples with the least Swelling Index value such as sample SP80SF20 (2.92) would provide more nutrient density food for an infant.

The Oil Absorption Capacity (OAC) ranged from1.39g/ml to 1.57g/ml, this shows that sample SP90SF10 is the highest (1.57g/ml), followed by sample SP80SF20 (1.55g/ml), SP100SF0 (1.48g/ml) and SP70SF30 (1.39g/ml) respectively. The Oil Absorption Capacity decreased with increased inclusion of soy-bean flour. This shows that the flour blend may be useful in formulation of weaning food. Generally the water absorption capacities of the flour blend formulations were higher than their oil absorbance capacity, implying that samples with high WACs tend to have low OACs due to the fact that there are more hydrophilic interactions in flour blends with high WACs. Oil gives soft texture and flavour to food and the absorption of oil by food products improves mouth feel and flavour retention. The high absorption capacity suggests lipophilic nature of the flour constituent since oil absorption is attributed to the physical entrapment of the oil.25

Discussion on proximate analysis of sweet potato –soy flour blend

Table 3 shows the proximate analysis of the flour blend formulated from Orange Fleshed Sweet potato Flour and Soybean Flour. The moisture content of the flour blend samples ranged from 6.80% - 6.99%. Sample SP100SF0 (6.80%) has the lowest moisture content, while the increase in moisture content of the sample SP100SF0 (6.8%), SP90SF10 (6.85), SP80SF20 (6.96%), SP70SF30 (6.99%) increased with increased inclusion of soy flour, respectively. Sample SP90SF10 (6.85%) can be used as an index for their storage stability. The higher the moisture content, the shorter the shelf life. Product moisture is significant to shelf life, packaging and general acceptability.

Sample |

Moisture Content |

Ash Content |

Fat Content |

Crude Protein |

Crude Fibre |

Carbohydrate Content |

SP100SF0 |

6.80 |

1.54 |

3.62 |

5.22 |

1.10 |

81.72 |

SP90SF10 |

6.85 |

1.56 |

3.72 |

5.38 |

1.15 |

81.35 |

SP80SF20 |

6.96 |

1.65 |

3.85 |

5.65 |

1.17 |

80.72 |

SP70SF30 |

6.99 |

1.66 |

3.87 |

5.66 |

1.18 |

80.69 |

Table 3 Proximate analysis of sweet potato –Soy Flour Blend

Keys: SP100SF0 stands for 100% SP: 0% SF; SP90SF10 stands for 90% SP: 10% SF; SP80SF20 stands for 80% SP:20% SF; SP70SF30 stands for 70% SP: 30% SF; SP – orange fleshed sweet potato; SF, soybean flour

The ash content of flour blend ranged from 1.54% – 1.65%. Sample SP70SF30 (1.66%) has the highest ash content, whereas sample SP100SF0 (1.54%) has the lowest ash content which is the control sample.

Crude fat of the flour blend ranged from 3.62% - 3.87%. Sample SP70SF30 (3.87%) has the highest crude fat content followed by sample SP80SF20 (3.85%). This establishes the fact that soybean is rich in fat content. It helps in growth and development of infant and in mature body cell. The fat contents of the formulated diets corresponded to the recommended fat level for weaning foods which should be less than 10%. The fat content of a food sample can affect its shelf stability. This is because fat can undergo oxidative deterioration, which leads to food spoilage. Hence, a food sample with high fat content is more liable to spoilage than one with a lower fat content. Furthermore, high intake of fat especially saturated fatty acids has been shown to increase the level of cholesterol in the blood; however, this is not the case with unsaturated fats such as fat found in soybean and orange fleshed sweet potato. Hence the formulated diets are suitable for formulation of foods which cut across all group of people including those with health related problems.

The crude fibre content of the flour blend ranged from 1.10% - 1.18% which compared favourably with crude fibre content reported by Altima et al. 2007. Sample SP70SF30 (1.18%) reported as the highest value was as a result of the high amount of SF present in the formulation. Fibre containing food, help in the nutritional and metabolic implication for the populace. The daily intake of fibre should gradually be increased to 5g per day. Fibre is an important dietary component in preventing overweight, constipation, cardiovascular disease, and diabetes and colon cancer. High dietary fibre content has been reported to impair protein and mineral digestion and absorption in human subjects. Some fibre related fractions such as polyphenols and non-starch polysaccharides, bind minerals such as Calcium, Zinc and Iron, making them unavailable for human nutrition. Hence low-fibre diets are suitable for weaning foods.

The protein content of the flour blend sample SP70SF30 (5.66%) was the highest while SP100SF0 (5.22%) was the lowest. Soybean is good source of protein for human consumption and in infant food formulation. Soybean protein helps in building and repairing body tissue. According to FAO/WHO Codex Alimentarius Standards for weaning foods, the protein content should range from 14.52 to 37.70 g/100 g for maximum complementation of amino acids in foods and growth. Thus, the protein content of the flour blend did not meet up, however other sources of protein like milk can be added to further enhance the protein demands of the flour blend.

Carbohydrate content of the flour blend ranged from 80.69% - 81.72%. Sample SP100SF0 (81.72%) has the highest carbohydrate content while sample SP70SF30 (80.69%) has the least carbohydrate content because of high amount of SF contained in its formulation. Carbohydrate is a source of energy and it helps in the regulation of blood glucose.26 Plate 1, 2 and 3 show the picture of soy-bean flour, sweet potato flour and sweet potato –soy flour blend.

Discussion on pasting properties of sweet potato –soy flour blend

The pasting characteristics of the flour blend are shown in Table 4. Peak viscosity is the maximum viscosity developed during or soon after the heating. The peak viscosity of the flour blend sample ranged from 70.42 to 131.00 RVU which increased with increased SF inclusion. The peak viscosity seen in flour blends indicates that the flour blends without modifications may be suitable for the preparation of complementary foods

Sample |

Peak Visc. (Rvu) |

Trough Visc. (Rvu) |

Breakdown Visc. (Rvu) |

Final Visc. (Rvu) |

Setback Visc. (Rvu) |

Pasting Time (Min.) |

Pasting Temp. (0c) |

SP100SF0 |

70.42 |

58.25 |

53.17 |

78.33 |

22.92 |

7.00 |

89.58 |

SP90SF10 |

111.25 |

101.58 |

62.58 |

85.25 |

24.88 |

6.18 |

83.63 |

SP80SF20 |

129.71 |

117.71 |

90.42 |

133.42 |

35.25 |

5.37 |

81.93 |

SP70SF30 |

131.00 |

118.58 |

95.38 |

140.88 |

40.29 |

4.50 |

80.02 |

Table 4 Pasting properties of sweet potato –Soy Flour Blend

Keys: SP100SF0 stands for 100% SP:0% SF; SP90SF10 stands for 90% SP:10% SF; SP80SF20 stands for 80% SP:20% SF; SP70SF30 stands for 70% SP: 30% SF; SP – orange fleshed sweet potato; SF, soybean flour

Trough viscosity measures the ability of the paste or gel formed to withstand breakdown during cooling. The trough viscosity of the flour samples ranged from 58.25 to 118.58 RVU which increased as the percentage inclusion level of SP increased. This may be due to the swelling capacity of the starch granules in SP.

Breakdown viscosity measures the ability of the flour to withstand heating and shear stress during cooking. The breakdown viscosity of the flour samples ranged from 53.17 RVU to 145.38 RVU.

Final viscosity (FV) measures the ability of the starch to form starch and viscous paste or gel after cooking and cooling. Final viscosity of the flour blend samples ranged from 78.33 to 140.88 RVU which increased as the percentage inclusion of SP increased. This may be attributed to high carbohydrate content in SP.

Setback viscosity (SV) gives an idea about retrogradation tendency of starch in flour sample. The Setback viscosity of the flour blend samples ranged from 22.92 to 40.29 RVU which increased as the percentage inclusion of SF increased. This indicates reduction in the textural characteristics of the samples since setback has been correlated with texture.

Peak time is the time at which the peak viscosity occurred in minutes and it is a measure of the cooking time of the flour. Peak time of the flour blend samples ranged from 4.50 min to 7.00 min which decreased as the inclusion of SF increased.

Pasting temperature is the temperature at which the first detectable increase in viscosity is measured and it is an index characterized by the initial change due to swelling of starch. A high pasting temperature usually indicates the flour has high water absorption capacity. The pasting temperature of the flour blend samples ranged from 80.02°C to 89.58°C which decreased with increased inclusion of soy flour.

Sensory characteristics of sweet potato –soy flour blend meal

Consumer sensory score of the flour blend meal is shown in Table 5 below. Samples were scored in terms of colour, aroma, taste, texture/sponginess, crust, mouth feel and overall acceptability using the nine-point hedonic scale. With respect to the sensory attributes evaluated, all samples were acceptable by the panellists. Sample (SP100SF0) being the control was rated very low in all the sensory attributes evaluated followed by sample (SP90SF10). Sample (SP80SF20) was rated higher in terms of colour, flavour, taste and overall acceptability. Colour is a very important parameter in judging food quality. It does not only reflect the suitability of raw materials used for production but provides information about the formation and quality of the products. It also influences consumer’s choice and preferences.27,28 The colour of the flour blend was brighter than that of the control sample. This might be due to the fact that the quantity of soy-flour inclusion.

Sample Codes |

Colour |

Aroma |

Taste |

Texture |

Crust |

Mouthfeel |

Overall acceptability |

|

SP100SF0 |

6.13±0.01 |

6.08±0.05 |

5.98±0.02 |

5.27±0.02 |

5.58±0.01 |

5.67±0.05 |

5.52±0.04 |

SP90SF10 |

6.08±0.05 |

6.03±0.03 |

6.57±0.07 |

5.18±0.04 |

6.02±0.02 |

6.01±0.06 |

6.42±0.02 |

SP80SF20 SP70SF30 |

6.88±0.14 6.27±1.01 |

6.40±0.10 5.90±0.02 |

6.28±0.11 5.70±0.05 |

6.10±0.03 6.12±0.09

|

6.22±0.03 6.25±0.04 |

6.25±0.01 6.27±0.03 |

6.78±0.08 6.65±0.03 |

|

|

|

|

|

|

|

|

Table 5 Mean values of sensory scores of sweet potato –Soy Four Blend Meal

Keys: SP100SF0 stands for 100% SP: 0% SF; SP90SF10 stands for 90% SP: 10% SF; SP80SF20 stands for 80% SP: 20% SF; SP70SF30 stands for 70% SP: 30% SF; SP – orange fleshed sweet potato; SF, soybean flour

Sample (SP70SF30) was rated higher in terms of texture, crust and mouthfeel by the panellists. Overall acceptability is another important criterion in the flour blends; all the samples were acceptable to the panelists. However, the mean scores (5.52-6.65) of the samples increased slightly with increase in the level of inclusion of SF to SP. The order of the score for the overall acceptability was SP80SF20 > SP70SF30> SP90SF10 >SP100SF0. The result of overall acceptability for the sweet potato –soy composite meal revealed that the flour samples had the best rating and the control had the least rating.

A recent survey showed that the choice of food by the consumer is a complex phenomenon determined by sensory pleasure among several other factors, although taste is considered to be the fundamental determinant of food choice,29 color is the primary factors that motivates a consumer to try a product in the first place.30 In addition, flavor- one of the most important determinants of selection or choice of fruit-based food material by consumer.31 Generally, sample (SP80SF20) had the best overall acceptability among other flour blend samples.

Conclusion

From the result above, it was observed that sample with 20% soy bean inclusion was most nutritious and preffered by the panelists among the flour blends. This showed that sweet potato–soy flour blend can be incorporated in formulation of various foods and diets in Nigeria. The proximate composition, functional, and pasting properties of sweet potato–soy flour blend was cheaply enhanced. The crude protein, crude fibre and ash content of the flour blends increased as the SF level increased. The swelling index and oil absorption capacities of the blends increased as SP increased except for sample SP70SF30 while the water absorption capacity and the bulk density decreased down the trend. The peak, setback, and final viscosities increased as SF inclusion increased while pasting temperature and time of the flour blends decreased as the percentage SF level increased. The colour of the flour blends was light orange which showed a predominance of orange colour. Furthermore, the other quality attributes of the flour blend showed that they could be used in the preparation of complementary foods and as substitute raw materials for wheat in production of pastas, puddings and biscuits. The study paves way for enhanced utilization of orange flesh sweet potato and soybean in the country. Thus, the highly nutritive flour blend was satisfactory to ensure the growth of infants and therefore, can help to reduce malnutrition in developing countries like Nigeria.

Recommendations

None.

None.

©2020 Olosunde, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.