MOJ

eISSN: 2381-182X

Review Article Volume 2 Issue 3

Department of Food Science and Technology, Ferdowsi University of Mashhad (FUM), Iran

Correspondence: Nargess Samanian, Department of Food Science and Technology, Ferdowsi University of Mashhad (FUM), PO Box 91775-1163, Mashhad, Iran, Tel 5118 7874 30, Fax +9851 1878 7430

Received: January 01, 2016 | Published: May 31, 2016

Citation: Samanian N, Mohebbi M. Thermography, a new approach in food science studies: a review. MOJ Food Process Technol. 2016;2(3):110-119. DOI: 10.15406/mojfpt.2016.02.00041

Background: Thermography can be defined as a process of writing or printing involving the use of heat. It’s a technique for detecting and measuring variations in the heat emitted by various regions of the body and transforming them into visible signals that can be recorded photographically. Clearly it would be of great use in diagnosing abnormal or diseased underlying conditions. But in the recent years it has been suggested as a viable method in food science research both in detection and process control.

Scope and approach: We reviewed thermography as a not new method which has recently found its way into vast areas of research and practice. After discussing its history and fundamentals some practical applications of thermography such as medical, agricultural and quality control are presented. But the main focus of review is laid on its usage in food science and technology, which is provided in two main categories of process control and detection, through a series of case studies.

Key findings and conclusion: Thermography is a non invasive, non destructive and instantaneous method that makes dynamic observations feasible. It also can be used to confirm any slight gradient in temperature, suggesting it as a detection method. The most important drawback to method is being highly. Modification of the method to make it into a practical procedure in industry, heat and mass transfer studies and microbiological studies can be possible future concerns of the method.

Keywords: thermography, infrared, detecting, monitoring, microwave, heat exchangers

Thermography, which once used to be an all military method, has being used in the recent years for many different research goals. In this review paper after a short glance on different applications of the method, its usages in the food science, technology and engineering have been noticed. The most notable advantages of the method are being reliable, reproducible, non intrusive and non destructive. Besides it can provide instantaneous insight of any system involving temperature differences. The paper contains examples of case studies using the method as a monitoring or detecting method. The examples it include detecting fruits surface or internal defects, observation of the microwave drying case studies and even detecting viable bacteria.

Definition

Thermography is basically writing or printing process which involves heat transfer; to do so the matter is printed by dusting letterpress with powder and is heated to make the lettering rise. It’s both a detection and measurement technique for variations in the heat emitted by various regions of the body the so called heat is transformed into visible signals that are recordable for photography (as for diagnosing anomalies or diseased infected cases). In a typical thermography procedure infrared radiation emitted from a body is observed and registered so a real-time map of the heat distribution is depicted in the form of color visible images). This method has proved applications in not only temperature changes quantification on the surface of the objects under study, but also for uncovering internal heat intrusions and fluctuation of the thermal properties within bodies.1

It is general knowledge that every object gives off electromagnetic radiation in the form of rays from 1 to 1000 µm or infrared (IR) spectrum at a temperature above absolute zero (-273°C) about 2.5 × 10-5 mm of the object surface would suffice to emit this amount of energy .in other words, infrared thermography (IRT) is a non-contact, non-invasive technique, which maps thermal energy of different levels by a color, or a grey level.2

The energy emitted by a body basically depends on how hot its surface is, thus infrared thermography works as a two-dimensional technique for temperature quantification. This feature may be find possible uses in many applications in agriculture and ecology.3-5

Modern thermal imaging devices have resolutions that make of surface temperature measurement of moving objects feasible and its geometrical resolution is not a limitation anymore as it can be changed by using lenses with various angular fields of view.3-5

Thermodynamically speaking, an important quantity of heat, released by any (industrial) process consumes energy according to the law of entropy. As a result temperature serves as an essential parameter to assure the efficiency of the operation. Common applications include but are not restricted to: constructions, components and processes, maintenance, medicine and properties assessment.

According to the American Academy of Thermography: Thermography is the medical science that derives diagnostic indications from highly detailed and sensitive infrared images of the human body. Thermography is sometimes referred to as medical infrared imaging or telethermography and utilizes highly resolute and sensitive infrared (thermographic) cameras. Thermography is completely non-contact and involves no form of energy imparted onto or into the body.6

Thermography was first used in the 1800s; the first ‘heat picture” was produced in 1840 by Sir John Herschel. In the early 1900s, infrared research was classified by the military and unavailable for medical application. It was not until 1956 that technical information on thermography was public available, and in 1961 the first images were used in medical research to confirm that elevated skin temperatures is due cancer stricken breast. In the 1970s through the early 1980s A great number of research was done, with mixed reviews on its use. Most research was conducted on microscopically confirmed tumors and the comparison between clinical exam, mammograms and thermography in terms of their sensitivity and specificity of detecting tumors.

Applications

Like any other technique thermography has its own advantages and disadvantages. To point some:

The method has been finding new applications every day, among them; we try to offer some in this review. Two main non invasive approaches to detect anomalies in thermographic studies are: passive and active. In Passive thermography, difference in radiation temperature between studied objects and surrounding air is calculated, under conditions of natural differentiation, in active thermography however, an external source of heating of the object under study is needed.7,8

With active thermography we are capable of not only detecting defects beneath the but also of estimating their depth using heat pulse characteristics and changes in time of temperature distribution on the object. by Baranowski et al.9 took advantage of Passive thermography to locate bruises in three apple varieties, ‘Jonagold’, ‘Ligol’ and ‘Gloster’ T temperature change patterns on the surface of the bruised apples revealed with that depend on varieties, the temperature differences between bruised and intact tissue varied between 0.5 °C to1.5 °C. The experiment was performed at an ambient temperature of 25 °C. It was also found that passive thermography would be at its highest effectiveness if is done about 48 h after defect takes place. The differences in temperature are due to different firmness of the fruits with highest for ‘Jonagold’ fruit and the lowest for ‘Gloster’.9

Medical applications

Thermography has proved to be practical in breast oncology, chiropractic, dentistry, neurology, orthopedics, occupational medicine, pain management, vascular medicine/ cardiology and veterinary medicine. Thermography enables doctors to detect physiological changes in breast tissue or blood flow. Also with the advent of ultrasensitive infrared cameras any slight change in breast surface temperature may turn into an image in a process known as digital infrared thermal imaging (DIII). “hot spots” are the basis of Thermographic detection, as it is known that cancer forms these on the skin of the tumor bearing parts. Growth of malignant tumors inside a tissue requires increased blood circulation and thus temperature elevates. That’s the reason why breast cancers are hotter than their arterial supply and venous drainage. Advanced digital technology facilitates diagnosis as soon as temperature and vascular changes are ready in high resolution for analysis. Fluctuations in temperature, leads into variations in color on a thermograms of the breast’s tissue.

Regional angiogenesis, neo-vascularization and nitric oxide-induced regional vasodilatation are frequently associated with tumor initiation and progression. As thermography determines temperature variations per minute and affirms abnormal vascular patterns, it’s clearly its value in early detection and prediction of breast cancer is undeniable. These heat patterns can predict tumors much earlier than mammograms, clinical exams or self-exams.

High temperatures as the result of tumor growth can be correlated with the ultimate final diagnosis. As lesion with higher degrees in temperature turn out to be more severe cases to deal with. As research has shown that small tumors frequently exhibit greater heat increases than many of the larger ones. Long-term follow-up suggests that thermograms may provide the first indication of the presence of a malignant tumor but the tricky part is that many other abnormalities rather than cancer are also responsible for temperature elevations. For instance, unbalanced hormones which are a risk factor for some types of feminine cancers can have heat signals. Fibrocystic breasts also show increased vascularization as well as increased heat levels, so that is one case that would be easier to distinct from cancer in thermograms. IRT can also map body surface temperature remotely. Last five decades witnessed a steady increase in the utility of thermal imaging cameras to obtain correlations between the thermal physiology and skin temperature. IRT has been successfully used in diagnosis of breast cancer, diabetes neuropathy and peripheral vascular disorders. It has also been used to detect problems associated with gynecology, kidney transplantation, dermatology, heart, neonatal physiology, fever screening and brain imaging.10

Quality control applications and safety

Thermal images are an easy way to identify apparent temperature differences in industrial three-phase electrical circuits, compared to their normal operating conditions. By inspecting the thermal gradients Detecting electrical unbalance and overloads of all three phases side-by-side, technicians can quickly spot performance anomalies on individual legs due to unbalance or Overloading.

Švantner et al.11 used IR thermography heat flux measurement in fire safety applications.

Heat flux is an essential quantity for fire safety precautions. Safety distances, protective structure materials, and other fire safety arrangements are designed, first of all, based on heat flux values from a possible heat source. The heat flux to the ambient therefore has to be estimated for special technological facilities (furnaces, boilers, engines, etc.) as well as in many other branches for the event of fire hazard. This is especially important in the cases of flammable liquid tanks or large-scale stores of flammable materials or products. Proper estimation of the heat flux can help design optimized fire safety precautions leading to the minimization of fire risk or fire damage on one hand and to the decrease of the fire safety technology costs on the other hand.

Theoretical simulation of fires is often not considered as satisfactory and direct experimentation is preferred, as the experimental costs are negligible compared to possible economic and environmental damage due to a possible fire disaster. A number of experimental techniques have been developed in order to measure radiation heat flux and/or other fire diagnostics.11

Agriculture

Distinguishing soil surface crusts: Soliman et al.12 used infrared thermography as a potential technique for non-destructive characterization of soil crusts, which is a major limitation for reclamation projects in arid regions. They used a step-heating test for all samples with duration of 420 min. Temperate-time plots indicate that surface temperature reached an approximate temperature of 60 °C for all three samples after being heated for 270 min, the minimum surface temperature (58.3 °C) was obtained for the bedrock specimen because of large quartz content (64%) and weak development of pore space (1.3% of total volume).12

Evaluate crop water stress in crops: O’Shaughnessy et al.13 used digital infrared thermography and thermometry to investigate early crop water stress as a producer improved management tools to avoid yield declines or to deal with variability in crop water status. They used canopy temperature data to investigate whether an empirical crop water stress index could be used to monitor spatial and temporal crop water stress.

Methods are needed to automate the conversion of field infrared imagery to spatial maps for irrigation scheduling and site specific delivery of water. As thermal imagers become more affordable, automated digital analysis of field imagery taken at different times of the day and converted to useful and easily accessible data could provide decision support information to a producer.13

Animal science: Stabentheiner et al.14 used thermography as a mean for Assessing honeybee and wasp thermoregulation. Endothermic insects like honeybees and some wasps lose a great deal of heat due their smaller size compared to birds and mammals which calls for thermoregulation. The enormous costs of call for optimization. Thus they used thermography alongside with measuring body temperature and respiratory energy turnovers to answer questions of insect ecophysiological research. Many researchers use thermocouples for measurement of body temperature thermocouples, the difficulty of which is evident about free ranging insects. while thermography allows for repeated, simultaneous non-contact measurement of the surface temperature of several body parts, without disturbing the animal’s behavior or social interactions. By combining thermographic body temperature measurements with the measurement of operative temperature (i.e. the temperature of dead animals), the endothermic part of thermoregulation could be separated from the temperature increase caused by solar radiation in free ranging honeybee and wasp foragers.14,15

Schaefer et al.16 used thermography as a non-invasive and automated detection method for bovine respiratory disease diagnosis in receiver calves. In Bovine respiratory disease complex (BRD)- a common disease in intensely raised and newly transported calves- causes an undifferentiated fever beside other clinical signs, notably respiratory distress - the disease causes not only considerable economic forfeit to the beef industry globally but also is a potential to treat animals well being. The successful treatment of this disease depends on the early, timely and cost effective identification of affected animals. Data collected in the study demonstrated that the noninvasive, automated collection of infrared thermography data from cattle at risk of BRD is effective at identifying true positive and true negative animals. The study further demonstrated that such technology as a wireless method for collecting of biometric data is useful for bio-security and bio-surveillance purposes.16

During recent years the thermography technology has found its way in food science and technology. What comes below is a review of the relevant work, and the possibility of using the technology in related research.

Research in this field can be classified in some certain categories. Detecting defects and process control are among the most reported cases.

Process control

Cuccurullo et al.17 used the technology as a control tool to monitor apples in microwave drying test instead of a chosen slice they used infrared thermography assisted control system to monitor temperature control by detecting the instantaneous maximum temperature among the samples under study. This method can realize temperature control both in space and in time, the method was confirmed at three temperatures: 55, 65 and 75 °C.

Common properties to evaluate microwave- assisted dried fruits and vegetables are texture, and surface color, the principal sensorial parameters that affect the acceptability of dried apple. Temperature and power control in MW drying affect the final quality of the dried product, especially in highly porous foods such as apple as it changes its physicochemical and structural properties drastically. And that’s where a secure and reliable monitoring system is an essential part of the drying system. If necessary, it can automatically and continuously switch the power levels by acting on the magnetron duty cycle time in order to control the product temperature.6

The signal for realizing feedback temperature control was obtained looking inside the illuminated MW chamber by IR thermography. The latter allowed detecting the instantaneous maximum surface temperatures among the apple slices distributed randomly on the turning table while MW heating occurs. As a consequence, the feedback signal is based on the hottest pint in the whole system and not an arbitrary slice, so the temperature control position is no longer effecting the drying process.17

At the same year Albert et al used thermography to study the performance of an alginate gel with high concentration of salt as an edible susceptor. An important quality problem when cooking or warming battered and breaded foods in a microwave oven is the resulting lack of crunchiness due the way microwaves heat foods. Thus products are needed to be designed specifically for microwave heating in the first place, either by using active packaging (with susceptors) or/and by changing the batter formulation. One effect of salt in frozen food is that as it lowers the freezing point, at given temperature more water remains unfrozen. Salt also increases the ionic content and consequently the interaction with the microwave fields. During the observations, a thermovision camera was used to take thermographs after different heating periods in the microwave and to depict how heat was distributed once this new film of alginate plus salt was incorporated. The temperature histograms were also obtained from the thermographs to study the temperatures’ distribution and their evolution with heating time.18

In fact thermography has been recognized as a suitable method to monitor thermal changes while microwave processing. Arocas et al.19 used it beside theology and microstructure as a comparison between microwave- and water bath-thawed starch-based sauces. The linear viscoelasticity, microstructure and thermographic characteristics of the thawed sauces were analyzed and compared with those of freshly prepared sauces. Due to starch retrogradation, the quality characteristics of the native starch-based sauces were strongly affected by freezing and thawing, but these effects were smaller for microwave heating than for heating in a water bath.

A thermovision camera was again used to observe the samples while being stirred. Thermographic analysis using infrared thermography was carried out during the microwave- and water bath-thawing processes. It was found that in microwave thawing it was found that the heating pattern was not homogenous and did not present the concentric ring shape. All the samples began to heat up on the upper right-hand side (this heating pattern is characteristic of the microwave oven that was used and may vary between ovens). As expected, the thawing process was much faster with microwave heating.19

Kelen et al.20 have also used 3D thermography as a monitoring method to map the temperature distribution of a free flowing bulk in case of microwave drying. To get a 3D overview of a free-flowing bulk the workload was divided with Teflon layers to form cross-sectional surfaces. After dissipation of microwave energy, IR thermocartograms were taken and temperature distribution was evaluated even quantitatively. The ‘‘3D layered thermography’’ method offers reliable and workload-specific information via simple executable technique for the optimization of a microwave processes. The unique advantage of IR monitoring is that it does not disturb the drying at all and a huge quantity of data can be recorded digitally and displayed instantly.20,21

Vass & Pallai22 elaborated a method to map the 3D temperature distribution in microwave heated granular workload. Special foils with given softening temperature were placed into the workload on the surface of different layer-levels. By microwave heating the granules of the workload stick into those areas of the foils at or above the softening temperature and form a so called 3D heat map. Using foils with different softening temperatures also the exact temperatures could be determined. Quite a number of trials are needed to map the whole workload. They concluded that the ‘‘3D layered thermography’’ method offers reproducible, reliable and workload-specific information for the drying process optimization.

Mapping temperature distribution had also been used to investigate the pharmaceutical microwave vacuum drying was performed by Kelen et al.23 When drying of extremely fragile corn starch-based granules (6.3 kg) was carried out under vacuum (50T5 mbar) and accelerated by microwaves (1.2 kW, 2450 MHz) in a single/one pot unit (Collette Ultima 25 l; a high-shear granulator that incorporates vacuum and microwave drying options), local burning was experienced after 25 min of microwave heating. In the case of dielectric heating the location and temperature of hot spots are unpredictable, because of many factors, which influence the uniformity of the E-field.

They used infrared thermography as a very promising non-perturbing and non-intrusive method and make it possible to get a lot of data instantly without interrupting the drying process. The presented ‘‘3D layered thermography method’’ makes possible to map the temperature distribution in a free-flowing bulk and it also provides quantitative 3D information. Based on the known temperatures of the identified hottest areas the drying process can be regulated to keep the temperature of the endangered areas below the critical limit.20

The same process had also been used by Cuccurullo & Pierro1 to measure electromagnetic skin depth in microwave heating. They elucidated the relationship between the target skin depth and the temperature distribution and the role of the boundary conditions (providing wall heat flux linearly depending on wall temperature) was clarified. The model was validated by using infrared thermography for the can surface temperature detection and a non-invasive experimental procedure to measure the skin depth temperature dependence.24

Freund & Kabelac24 used it as a method alongside temperature oscillation to investigate the local heat transfer coefficients in plate heat exchangers. This method is contact-free and fluid independent, as it uses radiant laser heating or halogen spotlights and an IR camera to monitor temperature at surface; it allows for the rapid evaluation of the heat transfer coefficient distribution even in bigger heat exchanger areas. The IR temperature data processing includes an algorithm for temperature drift compensation, phase synchronization between the periodic heat flux and the measured temperatures, and Single Frequency Discrete Fourier Transformations. The ill-posed inverse heat conduction problem of deriving a surface map of heat transfer coefficients from the phase-lag data is solved with a complex number finite difference method applied to the heat exchanger wall. The relation between the local and the mean heat transfer coefficients is illuminated, calculation procedures based on the thermal boundary conditions are given.25

Shahraeeni & Or26 used it to quantify subsurface thermal regimes beneath evaporating porous surfaces. The spatial distribution and dynamics of non-uniform evaporative mass fluxes from porous media are quantified remotely from induced surface thermal field obtained by spatially resolved infrared thermometry. Conversion of surface thermal signatures to the estimation of evaporation fluxes hinges on knowledge of the unobservable characteristic thermal decay depth. We considered quasi-static evaporation fluxes combined with measured surface thermal fields within a surface energy balance model to obtain a general analytical approximation for the thermal decay depth. This approximation was experimentally evaluated using side view IR imagery of temperature fields beneath an evaporative surface.26

Back at Fito et al.3 tried to control the citrus surface drying by thermography image analysis. A common risk in citrus surface driers (CSD) is that due to sensitiveness of this kinds of fruits, using an higher air temperature or keeping the fruit in the drier too long, decreases both acceptability and shelf life of the final product. Nowadays, most of the new CSD use systems to control air temperature, but do not include elements to monitor the process by defining the required drying time. So they used thermography of the surface temperature distribution as a new control method. The control of fruit surface temperature during drying allows us to determine the moment when the surface drying finishes and the peel drying begins. Drying time could be well established when temperature at any point on the fruit surface exceeded this value. This possibility is relevant for improving both, heat consumption and fruit quality and may be used in the control operation.2,27

Cuibus et al.28 used infrared thermography along with dielectric spectroscopy as a control means in freezing process of raw potato. The electronic recording of plant temperature using thermocouples and examining the exothermic process damages the tissues in an irreversible way, also cell damage may lead to more ice nucleation, which makes the method even more unreliable. Dielectric spectroscopy determines the dielectric properties of a medium as a function of frequency. It is based on the interaction of an electric external field with the sample, complex permittivity (εr) is the dielectric property that describes this interaction. The real part of complex permittivity is called dielectric constant (ε′) and the imaginary part is called loss factor (ε″). The dielectric constant is related with the ability of the food to store energy, and the dielectric loss factor is related to the dissipation of the electric field energy in other kinds of energy such as the thermal one, So they monitored the temperature of potato surface to describe and quantify the water motion during the freezing process by using the infrared thermography and dielectric spectroscopy. After performing the calibration process to obtain the real value of emissivity, the samples, peeled and cut, were placed in the -20 °C freezer with specific air flow. Temperature was recorded with an infrared thermocamera, and the volume of the samples during freezing process was determined by image analysis of the pictures taken every 3 minutes. Moreover, different thermocouples would measure and register the temperature of potato surface, the internal temperature of potato and the temperature of the freezer.

They described the method as completely successful in monitoring the freezing process of potato, it made the calculation of the quantity of ice formed and the emissivity of the potato during this process.28

Detection case studies

Thermography can be used as a fast reliable method to detect the thermal differences which can be regarded as indicators. This means that the thermography is a good surveillance method to find defects ranging the viable bacteria to the bruises and dry surfaces of the fruits. What comes afterward is a review of the studies concerning the so-called applications.

Baranowski et al.29 used the pulsed-phase thermography- a kind of active method to detect early apple bruises- In apple sorting process, an important problem is how to effectively detect early bruises. In spite of the fact that bruising is the reason for rejecting the highest number of fruit in sorting lines, manual sorting is still commonly used for detecting this defect. Two basic effects of apple bruising can be distinguished, i.e. browning and softening of fruit tissue. Existing sorting systems are not capable of effectively distinguishing fruit with bruising which occurs a short time before inspection.

They based their study on the hypothesis that internal damages may change the thermal properties of the tissues. In PPT the studied object is heated with an individual thermal pulse (most frequently a rectangular pulse) and the temperature decay on the surface is analyzed on a pixel by- pixel basis as a mixture of harmonic waves, thus enabling the computation of phase and amplitude images. The fast Fourier transform was used to obtain ampligrams and phase grams of fruit heat response to defects its occurrence at different depths. The automatic segmentation procedure made it possible to select areas of bruised tissue in thermograms. A comparison of PPT results and visual inspection of bruising showed they are not even comparable as active thermography method for detecting defects is valuable up to several millimeters. With the use of PPT method it is possible to distinguish in thermogram sequences bruises reaching various depths under the skin. Linear correlation exists between the depth of bruising and frequency of the thermal response.27,29

In 2008 same authors had used the methods to detect water core in ‘Gloster’ apples. An internal physiological disorder of certain apple cultivars in which the intercellular spaces throughout the fruit are filled with fluid instead of air resulting in characteristic translucent tissue. Problem is defect is becomes visible only when damage is very serious. Therefore, they used dynamic thermography to distinguish affected and unaffected apples. The derivative of apple temperature in time per apple mass is a good parameter to evaluate the differences in thermal properties between apples with and without water core affected tissues. For apples with water core the rates of temperature increase per mass in particular initial stages of heating were considerably lower than for apples without water core affected tissue, irrespective of the part of the fruit surface from which the measurements were made9 (Figure 1).

Veraverbeke et al.30 used thermography for surface quality evaluation of apple. Apples are naturally covered with an epicuticular wax layer, which protects the fruit from stress factors, such as moisture loss, mechanical damage, and microbiological infections. This wax layer also positively contributes to the visual quality of the produce by maintaining a good surface quality. An excessive wax production or chemical and structural changes in the wax during storage and shelf life can, however, contribute negatively to the organoleptic or visual quality of the fruit. In this case the wax layer gives the fruit an unpleasant bloom or turns the surface greasy and sticky. Of some apple cultivars, such as Jonagored, it is known that they are more susceptible to the development of greasy surfaces than other cultivars, such as Elshof. differences in surface or wax quality (number of cracks, number of lenticels, level of wax smoothing,. . .) result in a different surface temperature through differences in transpiration and evaporation at the surface, Which makes thermography a good method to evaluate it.

In the absence of evaporative heat transfer, the transient temperature field inside the fruit is described by the Fourier equation.

with α the thermal diffusivity of apple (m2s-1), t the time (s), and T (°C) the temperature. At the boundary a convection boundary condition applies

with h (W/m2 °C) the surface heat transfer coefficient, n the outward normal to the surface, ρ the density (kg/m3), and T∞ the air temperature. It can be shownthat the solution of Eq. (1) subject to (2) at the apple surface is given by

with TS the surface temperature (°C), T1 the air temperature, T0 the (uniform) initial temperature (°C), C a constant, K a slope, and Fo the Fourier number, a dimensionless time defined by

with D the diameter (m). Both C and k are a function of h and D through some transcedental equation. When evaporative cooling is important, latent heat transfer at the surface and moisture diffusion in the gas or liquid phase inside the fruit becomes important as well. The corresponding model equations are complicated and no analytical solution is available. Instead, a pragmatic approach has been followed here by assuming that evaporation accelerates cooling, and, hence, causes k to increase. Further, it also causes the surface temperature to drop below the air temperature. Therefore Eq. (3) was slightly modified as

Where is the final surface temperature (°C). Note that the constant C was omitted to reduce the number of parameters to be estimated. The parameters k and should be estimated through some methods.30

Mormile et al.31 took advantage of thermography to monitor the degradation dynamics of agricultural films and proposed a novel method based on thermography vs. time which allows the degradation dynamics of agricultural films to be evaluated. Environmentally speaking. The high consumption of plastic materials in agriculture is causing serious problems. Biodegradable materials are at present the only solution to this type of problems. Research in material science is daily proposing different materials to meet this urge in different sectors. One of the challenges in this field is analyzing the degradation states of the films before their application in order to know the time and the modality of degradation.

They put some biodegradable materials of their interest on soil in an open field. The main characteristic of these materials is that they were originally liquid and they are and would immediately cross-link into a film state as soon as they’re sprayed on soil. Through an IR thermal camera the state of the films was monitored day by day and then the thermal images were analyzed in order to detect the continuous physical properties change.

Their new approach represented a valid alternative to the traditional ones, based on the visual control at different weeks. While the analysis in the visible region gives information on the effect of the ‘‘phenomenon degradation’’, the monitoring day by day through IR thermography could extend the study to the causes of the degradation their experimental results again showed that thermography can be a very good tool to monitor the degradation of a film in agriculture but also to give information on the degradation mechanism related to the soil state.31

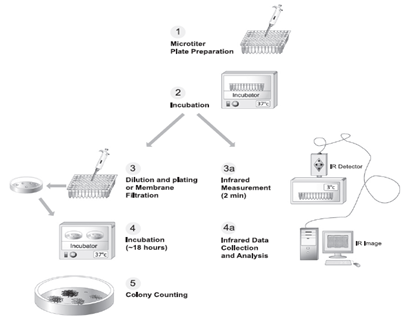

In a very recent study, Lahiri et al.32 studied detection of pathogenic gram negative bacteria using infrared thermography. Conventional methods of enumerating bacteria often need a great deal of time and labor. As all living organisms generate heat due to metabolic activities and hence, if the heat is somehow quantified, it can well represent microorganism growth. These researchers employed a non-contact and real time method - infrared thermography (IRT) for measurement of temperature variations in four clinically significant gram negative pathogenic bacteria, viz. Vibrio cholerae, Vibrio mimicus, Proteus mirabilis and Pseudomonas aeruginosa. Results indicated that the energy content, defined as the ratio of heat generated by bacterial metabolic activities to the heat lost from the liquid medium to the surrounding, vary linearly with the bacterial concentration in all the four pathogenic bacteria. As bacteria methabolism and morphology defines the convection velocity and so the heat transport (Figure 2).

Figure 2 Steps required to quantify bacteria in liquid samples using traditional colony counting methods (steps 3-5) and IRT (3a, 4a). Results from the traditional method are typically not available for 18 h or longer.

The rate of energy transfer from a liquid medium stored in a microtiter plate-well can be expressed by the following equation.

Here dE/dt is the rate of change of energy stored in the liquid medium in Watt, Et, Es and Eb are the rate of energy transferred from the liquid medium to the surrounding through the top, side and bottom of the well respectively in Watt and t is the time variable in second. In general, Es and Eb are negligible compared to Et .The time constant of temperature fall from the liquid medium to the surrounding is dependent on the thermo-physical properties of the liquid growth medium and is given by the following equation

where τ is the time constant in second, ρ is the density of the liquid medium in kg/m3, V is the volume of the liquid medium in m3, c is the specific heat of the liquid medium in J/kg K, h is the convective heat transfer coefficient between the surrounding and top surface in W/m2 K and A is the area of the top surface in m2. Presence of bacteria in the liquid medium can be considered as an additional source of heat, which is due to the metabolic activities of the bacteria. Salaimeh et al.33 provided detailed solution of the problem under this condition and defined energy content (EC) as a dimensionless quantity which is directly proportional to the heat generated by the metabolic activities of the bacteria.32

Energy content is defined by the following equation:

where is the rate of energy production by the bacteria in Watt, Ti is the initial temperature of the liquid medium in K and is the temperature of the surrounding in K. Using IRT, temperature of the liquid growth medium (with and without bacteria) can be monitored as a function of time and the corresponding EC can be derived. EC is linearly proportional to the rate of heat generated by the bacteria and hence, it provides quantitative information about the bacterial population.

They observed that energy content increases linearly with bacterial concentration for all the species and the rate of increase is species dependent. The change of EC with concentration of the pathogens is found to be dependent on their morphologies, which affect the convection mechanism. The results show that IRT could be employed as a real-time, non-contact and non-labor intensive alternative for quantification of clinically significant pathogens.

Salaimeh et al.33 have also used the infrared thermography in 2011 for Real-time quantification of viable bacteria in liquid medium. The approach used in their study was using IRT video, thermodynamics laws, and heat transfer mechanisms to directly measure, in real-time, the amount of energy lost as heat from the surface of a liquid sample containing bacteria when the specimen cools to a lower temperature over 2 min. they observed that the Energy Content (EC) of liquid media containing as few as 120 colony-forming units (CFU) of Escherichia coli per ml was significantly higher than that of sterile media (P < 0.0001), and that EC and viable counts were strongly positively correlated (r = 0.986) over a range of 120 to approximately 5 _ 108 CFU/ml.33,34

Kim et al.35 used infrared lock-in thermography and photothermal wave model for the detection of mechanical damage and estimation of damage depth and also quantitative evaluation of bruises on pears. Figure 3 shows the arrangement they used schematically. This system they used consisted of a mid-infrared camera, halogen lamps, and a controller. Thermal images of pear samples were taken with an infrared camera. The detector in the scanner unit was cooled by an integrated stirling cooler. Temperature sensitivity was 18 mK at 25 °C. A lens with a 50 mm focal distance (IFOV: 0.3 mrad, spectral band: 3.5-5 lm) was used.

Two halogen were operated by a control unit that controlled the periodic pulse on/off time and the measurement parameters. Figure 3 shows how lock-in thermography works. Periodic thermal waves propagate into the specimen and are reflected at the surface or subsurface in which the mechanical defects exist. The temperature modulation at the surface is modified by the thermal waves coming back from the inside of the material, and an oscillating interference thermal wave is produced.

The IR camera then records the oscillating temperature by picking up a series of thermal images and reconstructs a periodic wave pattern using several signals with a step of T/n (where T is a lock-in period, and n is the number of samples per lock-in period).

For the mathematical calculation of lock-in thermal signal, the digital lock-in correlation procedure was applied, product of the measured values and a set of weighting factors should be averaged. If the measurement was averaged over N lock-in periods, the digital lock-in correlation is expressed by the summation S.

This digital lock-in correlation method uses two-channel correlation which means that there are two sets of correlation functions Kj, one approximating the sine component and the other approximating the cosine component. The first channel measures the components of the signal in-phase with the sine function, and the other channel measures the component in-phase with the cosine function, which is 90° phase-shifted to the sine function. Considering the drawbacks such as demanding multiple tests for determining the range of depths at which a defect might exist, and also the possibility of obtaining different results in real condition where the bruises are the result of the environmental conditions not controlled compression force used here; results showed satisfactory accuracy. They also showed the phase of the thermal wave changes by a changed defect condition at different inspection frequencies.17,36,37

The different application of thermography method was reviewed here. Due to the simplicity of the method, it has being used in many different fields including safety studies, agriculture animal science, food science and much more. Being a non invasive, non destructive and instantaneous method, allows the researchers to perform dynamic observations. In fact wherever the changes in the state of the system involve temperature gradients, thermography can present itself as a confirmation, validation or even detecting method. The most frequently mentioned drawback of the method is being too costly due to the high prices of the thermovision cameras. In food science in special it can be more important. Although thermography is very reliable method with good reproducibility, finding more economic methods to use in the industry is very important. In scientific studies, thermography can play a very dominant role, for instance it can be well used in heat and mass transfer studies to give a deeper inside of the occurring phenomena. It can be used beside CFD studies as a suitable approving method. However for more precise applications, the importance of the calibration methods seems inevitable. Thermography has the potential to turn into a very trustable quality control method, this also includes the microbiological studies as it has been used to detect viable bacteria, Further studies are required to test the universality of this new approach and its adoptability of a wide range of pathogens or useful bacteria species. It is also a very good option for optimizing the processes which involve heat transfer.

None.

The author declares no conflict of interest.

©2016 Samanian, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.