MOJ

eISSN: 2381-182X

Research Article Volume 8 Issue 1

Department of Food Science and Technology, Federal University of Technology, Nigeria

Correspondence: Oluwajuyitan Timilehin D, Department of Food Science and Technology, Federal University of Technology, Akure, P.M.B. 704, Nigeria, Tel +234806-645-4937

Received: January 30, 2020 | Published: February 26, 2020

Citation: Akinyede AI, Oluwajuyitan TD, Dada JB, et al. Influence of substitution on amino-acid profile, physicochemical and sensory attributes of breakfast cereal from millet, soycake, rice bran and carrot pomace blends. MOJ Food Process Technol . 2020;8(1):19?27. DOI: 10.15406/mojfpt.2020.08.00237

Background: Breakfast is often referred to as the most important meal of the day; however some have limited amount of protein and carotenoid. Hence, this study is aimed to evaluate the amino acid profile, physicochemical and sensory qualities of breakfast cereals from millet, soycake, ricebran, carrot pomace flour blends. The breakfast cereals were formulated using Nutri-survey with respect to 50% Recommended Daily Allowance (RDA) of protein and fibre for adult and were formulated as follows; MS [Millet+Soycake (70:30) %]; MSR [Millet+Soycake+Ricebran (65:25:10) %]; MSC [Millet+Soycake+Carrot pomace (60:30:10) %] and MRCS [Millet+Ricebran+Carrot pomace+Soy cake (60:30:5:5) %]. The protein content ranged from 2.05-22.37g/100g; crude fat 9.34-22.05g/100g; crude fibre 2.19-3.78g/100g; total ash 3.21-5.43g/100 g; moisture 4.83-6.34g/100g; and carbohydrate 40.59-77.43g/100g respectively. An increase in protein content was observed with an inclusion of soycake into the flour blends. The mineral content ranged from 23.72-34.23mg/100g (P), 0.77-5.59 mg/100g(Fe), 0.03-0.04 mg/100g(Cu), 2.25-3.00mg/100g(Zn) and 0.80-2.71mg/100g(Ca) respectively. The phosphorous was the highest while copper was the least mineral in concentration. The breakfast cereals contained substantial amount of essential amino acid higher than the recommended value for children and adult, having glutamic acid as the most abundant and tryptophan with the least value. The functional properties ranged from; 0.78-0.81g/mL, 1.51-2.42g/mL, 1.66-3.89g/mL, 13.18-15.91g/mL, 12.00-16.00% and 59.44-199.40% for bulk density, oil absorption capacity, water absorption capacity, foam capacity, least gelation and swelling capacity respectively. The values for total carotenoid ranged from 0.0041-1.75mg/100g respectively. Based on the sensory evaluation, sample made from Millet and Soybeans (MS) blend was ranked best and most preferred by the panelist although all the breakfast cereal samples recorded high acceptability by the panelists.

Keywords: breakfast cereal, pear millet, carrot pomace, amino acids, physicochemical, sensory attributes

Breakfast is often referred to as the most important meal of the day and in recent years has been implicated in weight control, cardio-metabolic risk factors and cognitive performance.1 Epidemiological study conducted by the American Heart Association on “Breakfast Timing and Frequency: Implications for Cardiovascular Disease Prevention” shows that 74% of breakfast skippers did not meet two thirds of the Recommended Dietary Allowance for vitamins and minerals compared with 41% of those who consumed breakfast.1,2 Guenther et al.3 and Vieux et al.4 also report on young adults (age, 20–39 years) who skipping breakfast and had overall daily diets that were less than optimal in terms of nutrient intake as measured by indices of total daily diet quality. Meanwhile breakfast cereal is a type of aforementioned that is increasingly gaining acceptance in most developing countries Nigeria inclusive, and gradually displacing most traditional diets that serve as breakfast due to its convenience, nutritional values, job demands and less expensive especially amongst urban dwellers4–6 Breakfast cereals have also been endorsed as the principal source of breakfast’s carbohydrates7,8 and allow the consumers to vary their breakfast meal with several different cereal-based products. Among these, breakfast cereals are nowadays available in numerous formulations and have been associated with the reduction of the risk of several chronic diseases in both adults and adolescents.8,9

However, they contain limited amount of protein and carotenoid which are linked with proper body development as a result of repairs and building body tissues10 and proper functioning of the eyes, enhancing immune system against diseases11 respectively. For these reasons, breakfast cereal from blends of millet, rice bran, carrot pomace and defatted soybean will play an important role in helping consumer of all ages move towards a balanced diet and healthy lifestyle. An important cereal used in tropical and subtropical regions of world in the production of breakfast cereal is Pearl millet (Pennisetum typhoides) and is considered as a staple crop for many regions of Asia and Africa due to its high content of carbohydrate. India leads the world in pearl millet production with 8.59 million tones.12

Rice bran constitutes around 10% of total weight, obtained as a by-product of rice milling from outer layer of the brown (husked) rice kernel.13 Rice is a staple food crop consumed by 50% of population of the world and contains 20% oil (fat) and 15% protein, 50% carbohydrate (majorly starch) dietary fibres such as beta-glucan, pectin, and gum.14,15 Rice bran is also rich in antioxidant compounds namely polyphenols, carotenoids, Vitamin-E, gamma oryzanol, and tocotrienol which help in preventing the oxidative damage of body tissues and DNA. Bran is an industrial residue of cereal from milling process. It consists of pericarp, aleurone and subaleurone fractions.16

Soybean (Glycine max) contains 40-50% crude protein and about 20% fat. It contains very little of starch (4.66-7%) and quite a lot of hemicellulose and pectins. Protein of soybean products characterized much quantity of lysine, tryptophane, isoleucine, valine and threonine however sulphuric amino acids are less than in protein of rape products.17,18

Carrot (Daucus carota) is a root vegetable, usually orange, purple, red, white or yellow in colour, with a crisp texture when fresh. It is a rich source of β carotene and contains other vitamins, like thiamine, riboflavin, vitamin B-complex and minerals.19 Schweiggert20 reported carrot pomace is a rich source of valuable bioactive and functional compounds. Yoon et al.21 reported on enzymatic production of a soluble-fibre hydroxylase from carrot pomace and its sugar composition. However, the present study was carried out to determine the amino acid profile, physicochemical and sensory quality of breakfast cereal produced from blends of pearl millet, soycake, rice bran and carrot pomace.

Sources of materials

Freshly harvested matured pear millet yellow variety (Pennisetum typhoides) and carrot were purchased from Erekesan market, Akure, Nigeria. Rice bran and defatted soycake (Cyperus esculentus) were obtained from Ile-Oluji Rice Processing Industry, Ondo, Nigeria and Rom Mill factory, Ibadan, Nigeria, respectively.

Pear millet processing

Pearl Millet was processed into flour using a modified method of Gull et al.22 with a slight modification. Pearl millet grains were cleaned from soil particles and debris, milled with a laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and passed through a 60 mm mesh sieve (British Standard) to obtain pear millet flour. The flour was packed in air tight polyethylene bags, sealed and stored at -4°C until further uses.

Carrot pomace preparation

Fresh carrots were washed in running tap water several times to remove extraneous material. Trashes were removed with stainless steel knife and trimming was done. An electrical juice extractor was used to extract carrot juice and the pomace was collected separately after juice extraction, it was then spread uniformly and oven dried at 60°C for 4 h using a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK). The dried pomace was grinded with a laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and passed through a 60 mm mesh sieve (British Standard) to obtain carrot pomace flour.22 The flour was packed in air tight polyethylene bags, sealed and stored at -4°C until further uses.

Rice bran stabilization

The rice bran was stabilized using the method described by Iqbal et al.23 Stabilization was done by microwave oven heating maintained at 120°C for 10 min to inactivate lipase enzyme. Stabilized rice bran was allowed to cool to room temperature and was packaged in air tight polyethylene bags and stored at -4°C until further uses.

Formulation of blends

The breakfast cereals were formulated using Nutri-survey with respect to 50% Recommended Daily Allowance (RDA) of protein and fibre for adult12 as shown in Table 1. Developed flour samples was packed in air tight polyethylene bags, sealed and stored at -4°C until analysis.

Sample code |

Millet(%) |

Soybean(%) |

Rice bran(%) |

Carrot pomance(%) |

M |

100.00 |

0.00 |

0.00 |

0.00 |

MS |

70.00 |

30.00 |

0.00 |

0.00 |

MSR |

65.00 |

25.00 |

10.00 |

0.00 |

MSC |

60.00 |

30.00 |

0.00 |

10.00 |

MSRC |

60.00 |

30.00 |

5.00 |

5.00 |

Table 1 Formulation of Flour Blends

Production of breakfast cereals

The method described by Mbaeyi-Nwaoha and Uchendu24 was modified for the production of breakfast cereals. The composite flour was mixed together with small quantity of water, to serve as binding effect, one gram of salt and ten gram of sugar were added to improve the taste, the mixture was partially heat treated for 10 min to gelatinized the starch. The dough was then cut into small shapes with table knife and toasted in an oven at 120°C for 1h after which the toasted breakfast cereals was allowed to cool under room temperature and packed in air tight polyethylene bags, sealed and stored at -4°C until analysis.

Determination of proximate composition flour blends

Proximate compositions, that is, moisture content, total ash, crude fiber, crude fat and crude protein content of flour blends and breakfast cereal were determined using the standard methods.25 Carbohydrate content was determined by difference as follow:

Determination of mineral compositions

Calcium(Ca), iron(Fe), copper(Cu) and zinc(Zn) were determined using Atomic Absorption Spectrophotometer (AAS Model SP9) and Phosphorus was determined using Vanado-molybdate method in accordance to the method describe by AOAC.25

Determination of amino acid composition of processed flour blends

The amino acid profiles of the experimental samples were determined according to the method described by AOAC.25 The experimental samples were digested using 6N HCl for 24 h. Amino acids were determined using the Beckman Amino Acid Analyzer (model 6300; Beckman Coulter Inc., Fullerton, Calif., USA) employing sodium citrate buffers as step gradients with the cation exchange post-column ninhydrin derivatization method. The data were calculated as grams of amino acid per 100 g crude protein of flour sample.

Determination of functional properties of the flour blends

Determination of bulk density: Bulk density was determined according to the method of Asoegwu et al.26 Samples were placed in a 25 mL graduated cylinder and packed by gently tapping the cylinder on the bench top 10 times from a height of 5 cm and the volume of the sample was recorded. The procedure was repeated three times for each sample and the bulk density was computed as (g/mL) of the sample.

Water absorption capacity (WAC) and oil absorption capacity (OAC): The method described by Onwuka27 was used. One gram of the flour sample was weighed into a 15mL centrifuge tube and suspended in 10mL of water or oil. It was shaken on a platform tube rocker for 1 min at room temperature. The sample was allowed to stand for 30 min and centrifuged at 1200 x g for 30 min. The volume of free water was read directly from the centrifuge tube.

Least gelation (LG): The least gelation concentration was determined by a modification of the method of Sathe et al.28 The samples dispersions of 2, 4, 6, 8, 10, 12, 14, 16, 18 and 20% (w/v) were prepared in 5 mL distilled water in test tubes, which were heated at 90 oC for 1 h in water bath (Gallenkamp). The heated dispersions were cooled rapidly under running tap water and then at 4 oC for 2 h. The least gelation concentration was determined as that concentration when the sample from the inverted tube did not slip or fall.

Determination of β-carotene

The carotene was determined by the method described by AOAC.25 One gram of the sample was dissolved with 10 mL of acetone in a 50 mL conical flask and stood for 20 min and shook gently at 4 min interval to extract the colour substance in the sample. A 10 mL of water and 5 mL of hexane were added after agitation, allowed to settle to form two layers and the upper layer of the clear solution was separated into a test tube using separating funnel. This upper layer obtained was used for β carotene analysis; 2 mL of the solution was pipetted into a glass curvet and read off the absorbance at 436 nm.

Breakfast cereal colour determination

Colour properties (l*, a*, b*) of the breakfast cereal was determined by using a chroma meter CR-4 (Konica Minolta Inc., Japan) as described by Omran and Hussien.29 A standard white tile was used to calibrate the instrument. The breakfast cereal was uniformly packed in a clean petri plates with lid. The instrument head was placed and exposures conducted. Readings were displayed l*, a* and b* as colour parameters according to the CHELAB system of colour movement. The l values ranged from 0 (black) to 100 (white), a values from -80 green to +100 (red), while the b ranged from -80 to +70 yellow.

Breakfast cereal sensory attributes evaluation

All sensory analyses were conducted in a sensory laboratory with adequate lighting and no aroma environment. Panelists were selected based on familiarity with control samples, recognition and perception of common aroma. The breakfast cereal samples were prepared by stirring flour in boiling water 1:4 (v/v) of flour to water dispersion at 100°C for 30 min. The reconstituted formulated breakfast cereal and the control samples were coded and presented to 30 untrained panelists. The panel members were assigned individually to well illuminate laboratory booths and the breakfast cereal prepared were served at 40°C coded with random three digits. Water at room temperature was provided for mouth rinsing in between successive evaluation. Sample attributes (colour, texture, taste, aroma, etc.) were rated on a scoring scale of 1 to 9, where 1=dislike extremely and 9=like extremely. Panelists made their responses on score sheets which were designed in line with the test procedures.30

All data were expressed as mean±standard error of mean (SEM) using the Statistical Package for Social Sciences (SPSS version 21). Significant differences among the means were determined using Duncan Multiple Range Test (DMRT) with significant at p<0.05

Proximate composition of composite flour blends and breakfast cereal

The proximate composition of the composite flour ranged from (6.83–9.09; 3.44–5.60; 2.53-3.99; 6.57–24.20; 2.31–23.93; 35.59–73.27)g/100g for moisture, total ash, crude fiber, fat, protein and carbohydrate content respectively. The moisture content was significantly lower (p>0.05) than 10 g/100 g FAO12 recommendation for cereal flour which implies that the composite flour will be chemically and microbiologically stable during storage and will therefore give the product a long shelf life.31 Pearl millet (M) had lower protein content (2.31 g/100g) compared with other studies32–34 which may be due to difference in source of raw material and processing method used. Comparatively, the protein content shows an appreciable increase and significantly higher (p<0.05) than (12.00 - 13.90 g/100 g) reports of Onyango et al.35 and this could be due to the inclusion of rice bran, carrot pomace and defatted soybeans cake respectively. This finding is similar to the report of Khetarpaul et al.36 who observed a significant increase in protein content of pear millet with the inclusion of wheat and defatted soybeans flour in production of chapattis. Oluwajuyitan and Ijarotimi10 also affirm the increase in protein content of food materials with inclusion of legumes such as soycake. However, there is no significantly difference (p>0.05) between the crude fiber content of the samples. The fat content was slightly higher (p<0.05) in comparison with other findings.37,38 These differences can be attributed to the differences in the growing conditions, soil properties and the origin of cultivars. The proximate composition of the composite flour was significantly higher (p<0.05) than the proximate composition of the developed breakfast cereal products especially the protein content. However, an increase was observed in the carbohydrate content of the breakfast cereal compared to the composite flour, this can be due to the effects of processing conditions which involves high temperature during toasting which may be responsible for moisture loss and denaturation of protein. Comparatively, a similar result was obtained by Agugo and Onimawo39 for toasting mung bean flour which showed that toasting significantly increase carbohydrate content (Table 2).

Sample |

Moisture |

Total ash |

Crude fibre |

Crude fat |

Protein |

Carbohydrate |

Developed Composite Flour Blends |

||||||

M |

6.83±1.46b |

3.44±0.49b |

2.73±2.23a |

10.72±0.99b |

2.31±2.00c |

73.27±6.94a |

MS |

7.69±0.22a |

4.13±0.75a |

2.53±1.79a |

24.20±3.30a |

23.73±2.00ab |

37.72±3.61c |

MSR |

6.65±0.32b |

4.43±0.03ab |

3.99±3.0a |

6.57±2.98c |

19.94±2.01b |

58.42±7.13b |

MSC |

9.09±0.79a |

5.37±0.03ab |

2.80±2.42a |

22.08±0.97a |

23.35±2.00ab |

37.38±5.52c |

MSRC |

8.70±0.11a |

5.60±0.99a |

3.00±2.53a |

23.36±1.52a |

23.93±2. 00a |

35.59±6.08c |

Developed Breakfast Cereal Products |

||||||

M |

4.83±0.16c |

3.21±0.11c |

2.39±0.89ab |

9.34 ±0.16c |

2.05±2.00c |

77.43±1.43a |

MS |

6.34±0.22a |

4.09±0.23b |

2.19 0.12b |

21.76±2.93a |

21.97±0.17a |

43.63±1.21c |

MSR |

5.02±0.32bc |

4.39±0.08b |

3.78±0.56a |

4.73±0.86d |

17.99±1.34b |

62.73±1.41b |

MSC |

5.10±0.79b |

5.12±0.42a |

2.92±1.65ab |

16.56±0.12b |

21.85±0.25a |

46.68±2.43c |

MSRC |

6.06±0.11a |

5.43±0.31a |

3.09±0.57ab |

22.05±0.49a |

22.37±1.21a |

40.59±3.12d |

Table 2 Proximate Composition (g/ 100 g) of the Flour Blends

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M, 100% millet; MSR, millet soycake ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %.

Mineral composition of developed breakfast cereal

As shown in Table 3, developed breakfast cereals (MS, MSR, MSC and MSRC) are rich in mineral and contain more than 100% pear millet (M). A significant increase (p<0.05) was observed among the samples for Calcium (Ca), Iron (Fe) and Phosphorus (P). However, there was no significant difference (p>0.05) between the samples for Copper (Cu). The mineral contents ranged from 0.80 mg/100g(M) to 2.71mg/100g (MSRC); 0.77mg/100 g(M) to 5.59mg/100g (MSC) and 23.72mg/100g(M) to 34. 23mg/100g (MSC) for Ca, Fe and P respectively. A significant decrease (p>0.05) was observed for Zinc (Zn) which ranged from 3.00mg/100g (M) to 2.25mg/100g(MS). Statistically, the concentration of P, Ca and Fe were significantly higher (p<0.05) in other samples than 100% millet but the concentration of Zn was lower when compared to 100% millet product of the breakfast cereals. Previous studies reported high contents (6.56 39.63 and 211mg/ 100g) of Ca in pearl millet than in present study.40–42 The present findings reported maximum iron (5.59 mg/100 g), zinc (3.0mg/100 g) and copper (0.4mg/100 g) in composite pearl millet. Hama et al.43 also reported (4.51mg/100g) Fe content in pearl millet which is comparable to the findings in this study. On the contrary, Abdalla et al.44 and Chaudhary45 reported higher Fe contents in pearl millet varieties ranging from (17.88-18.65 and 10.30-11.49) mg/100g, respectively. Results of Zn in this study are comparable to those reported by Hama et al.43 who obtained (1.80-2.02mg/100g) Zn in pearl millet whereas Sridevi et al.46 reported low value of Zn (0.73mg/100g). On the contrary, Abdalla et al.44 and Chaudhary45 documented high content of Zn (6.7-7.29 and 4.47-5.29mg/100g) respectively in pearl millet varieties. Results of Cu are in agreement to results reported by Sridevi et al.46 and Thilagavathi et al.,41 Abdelrahaman et al47 reported high range (0.85-1.46 mg/100g) of copper content in pearl millet cultivars. This mineral has linked with several benefits as they enhance proper functioning of the body system. However, variation in mineral content may be due to genotypic, season effect and extraction method.

Samples |

Ca |

Zn |

Cu |

Fe |

P |

M |

0.80±0.02d |

3.00±0.09a |

0.03±0.00a |

0.77±0.03e |

23.72±0.13d |

MS |

1.76±0.09c |

2.25±0.09d |

ND |

3.00±0.02d |

32.21±0.09a |

MSR |

1.86±0.09c |

2.75±0.09b |

0.03±0.01a |

4.56±0.01b |

31.66±0.04c |

MSC |

2.7±0.11a |

2.50±0.09c |

0.04±0.01a |

5.59±0.08a |

34.23±0.90a |

MSRC |

2.25±0.05b |

2.75±0.09b |

0.03±0.00a |

4.13±0.03c |

34.05±0.31b |

Table 3 Mineral Composition (mg/ 100 g) of Developed Breakfast Cereal

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M, 100% millet; MSR, millet soycake ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %; ND, not detected.

Amino acid profile of developed breakfast cereal

The result of the amino acid profile of developed breakfast cereal and 100% millet is presented in Table 4. The most abundant amino acid is glutamic acid which are 8.61, 9.39, 6.21, 9.08 and 8.63g/100g protein for samples M (control), MS, MSR, MSC and MSRC respectively. The least abundant is tryptophan and their values are 0.00, 0.94, 0.79, 0.84 and 1.15g/100g protein MS, MSR, MSC and MSRC. Although tryptophan was not detected for control sample (M). The breakfast cereal food under study has a good essential amino acid profile of between 21.25, 25.83, 27.10, and 28.62g/100 g protein while the control has 26.32g/100g protein. These values are higher than the total essential amino acid value of 26.8 g/ 100 g recommended for children under two years.48

Parameters |

M |

MS |

MSR |

MSC |

MSRC |

*(12,48) |

Essential amino acids (EAA) |

||||||

Valine |

4.95±0.03a |

3.51±0.03c |

2.51±0.03e |

3.62±0.02b |

3.27±0.02d |

3.5 |

Threonine |

3.21±0.02c |

3.38±0.02b |

3.00±0.02d |

3.55±0.01a |

3.22±0.01c |

3.4 |

Isoleucine |

3.14±0.03c |

3.34±0.03a |

3.01±0.03d |

3.14±0.03c |

3.21±0.03b |

2.8 |

Leucine |

6.87±0.04a |

6.83±0.04a |

4.32±0.05d |

6.59±0.03b |

6.19±0.03c |

6.6 |

Lysine |

2.04±0.02e |

3.34±0.02a |

3.07±0.03c |

3.18±0.02b |

3.02±0.02d |

5.8 |

Methionine |

1.29±0.02a |

1.20±0.02bc |

1.07±0.02d |

1.23±0.01b |

1.17±0.01c |

2.2 |

Phenylalanine |

3.31±0.03d |

4.80±0.03a |

2.39±0.03e |

3.72±0.02b |

3.37±0.02c |

2.8 |

Histidine |

1.42±0.01a |

1.28±0.01b |

1.09±0.02d |

1.23±0.01c |

1.23±0.01c |

1.9 |

Tryptophan |

N. D |

0.94±0.01b |

0.79±0.01d |

0.84±0.01c |

1.15±0.01a |

1.1 |

ƩTEAA |

26.23c |

28.62a |

21.25e |

27.10b |

25.83d |

26.8 |

Non-essential amino acids (NEAA) |

||||||

Arginine |

4.21±0.03c |

4.99±0.08a |

3.35±0.08d |

4.47±0.07b |

4.21±0.07c |

2.0 |

Alanine |

4.31±0.02b |

4.47±0.03a |

3.79±0.02e |

4.17±0.02c |

4.10±0.02d |

- |

Serine |

3.34±0.03b |

3.67±0.02a |

2.65±0.02e |

3.19±0.02c |

3.02±0.02d |

- |

Proline |

3.97±0.04a |

3.45±0.02b |

2.24±0.02e |

3.35±0.02c |

3.05±0.02d |

- |

Glutamate |

8.61±0.01c |

9.39±0.08a |

6.21±0.07d |

9.08±0.07b |

8.63±0.07c |

- |

Glycine |

3.20±0.02b |

3.42±0.03a |

3.00±0.02c |

3.23±0.02b |

2.99±0.02d |

- |

Tyrosine |

3.18±0.03b |

3.44±0.02a |

2.24±0.01d |

3.44±0.01a |

3.10±0.01c |

- |

Aspartate |

6.82±0.01b |

7.01±0.04a |

5.58±0.05e |

6.08±0.04d |

6.33±0.04c |

- |

Cysteine |

1.02±0.01a |

0.97±0.00b |

0.85±0.01d |

1.03±0.00a |

0.91±0.00c |

- |

ƩTNEAA |

38.66b |

40.81a |

29.91e |

38.04c |

36.34d |

- |

Predicted Nutritional Qualities |

||||||

TAA |

64.89c |

69.43a |

51.16e |

65.14b |

62.17d |

- |

TEAA/ TNEAA |

0.68c |

0.70b |

0.71a |

0.71a |

0.71a |

- |

ƩSAA(Meth+Cys) |

2.31a |

2.17c |

1.92e |

2.26b |

2.08d |

- |

ƩArAA(Phe+Tyr) |

6.49c |

8.24a |

4.63d |

7.16b |

6.47c |

- |

Lysine/ Arginine |

0.48d |

0.67c |

0.92a |

0.71b |

0.72b |

- |

Table 4 Amino acid profiles (g/100 g of protein) of breakfast cereal

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M, 100% millet; MSR, millet soycake ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %. *FAO/ WHO12; TAA, total amino acid; TEAA, total essential amino acid; TNEAA; total non-essential amino acid; SAA, sulphur amino acids; ArAA, aromatic amino acids; ND, not detected.

Amino acid content of the breakfast cereal foods is a particular relevant issue in both infant and adult feeding, where Protein-Energy-Malnutrition (PEM) has continued to pose challenges in the research area. This, according to other researchers, is due to poor feeding practices and low quality protein commonly associated with plant-based single diets.49–51

Functional properties of developed breakfast cereal

The results of the various functional properties carried out are shown in Table 5. Bulk Density (BD) is an important criteria used as an index for packaging material and transportation. The lower the bulk density, the higher the amount of flour particles that can bind together leading to higher energy value. The bulk density of developed breakfast cereal ranged from 0.78 to 0.81g/mL. There is no significant difference (p>0.05) between the samples. The findings of this study are similar to (0.87-1.27g/mL) reported by Akinola et al.52 And this implies that lesser packaging material will be required for packaging of developed breakfast cereals which is more economical for food processing industries. Oil Absorption Capacity (OAC) of the breakfast cereal ranged from 1.51g/mL (MSC) to 2.42g/mL (MSRC) and there is a significant difference (p<0.05) between the samples. The findings of the present study are comparably higher than (0.87g/mL) report of Thilagavathi41 and this is desirable and may enhance its organoleptic properties. However, variation in findings may be due to difference in sources of raw materials and end use of material. Water Absorption Capacity (WAC) is the ability of flour to absorb water and swell for improved consistency in food and it is desirable in food systems to improve yield and food consistency Osundahunsi et al.53 WAC of developed breakfast cereal ranged from 1.66g/mL (M) to 3.89g/ml (MSRC) with a significant difference (p<0.05) between the sample. The findings of the present study are comparably higher than (0.74g/mL) report of Thilagavathi.41 Foaming Capacity (FC) had the values ranged from 13.18g/mL (MSC) to 13.91g/mL (MSRC)g/mL with no significant differences (p<0.05) between the samples. The findings of this present study are low comparably to the report (0.72-3.38%) of Akinola et al.52 This is desirable as it will enhance the protein quality of the breakfast cereal meal. Least Gelation (LG) is the ability of proteins to form gels, and it’s defined as the minimal protein concentration required for inverting a tube without producing sliding of the gel in the walls. The values ranged from 12.00% (M)–16.00% (MSRC) with a significant difference (p<0.05) between the samples. The results of these findings are comparable with the report (8-18%) of Fasasi54 for raw, roasted and germinated pear millet flour. These variations in the gelling properties of different legume flours may be due to variations in the ratios of different constituents such as carbohydrates, lipids and proteins that make up the samples. Also similar values of gelation capacity have been reported for other legumes for raw (16.00%) and heat processed (18.00%) cowpea flour (Abbey and Ibeh,55 Swelling Capacity (SC) values of the developed breakfast cereal ranged from 59.44% (M) to 199.40% (MSRC) with a significant difference (p<0.05) between the samples. The findings of this study is comparably higher when compared with1.25-4.47% of Akinola et al.52

Samples |

Bulk density |

Oil absorption |

Water absorption |

Foaming capacity |

Least gelation |

Swelling capacity |

M |

0.81±0.01a |

1.79±0.06b |

1.66±0.03c |

13.18±0.21a |

12.00±0.00b |

59.44±0.41c |

MS |

0.81±0.01a |

1.86±0.01b |

1.98±0.05b |

13.43±0.52a |

12.00±0.00b |

159.50±0.11b |

MSR |

0.78±0.01a |

1.91±0.02b |

1.98±0.05b |

13.66±0.10a |

16.00±0.00a |

129.50±0.23b |

MSC |

0.81±0.02a |

1.51±0.03b |

3.86±0.04a |

13.61±0.15a |

12.00±0.00b |

169.63±0.21a |

MSRC |

0.78±0.02a |

2.42±0.55a |

3.89±0.04a |

13.91±0.05a |

16.00±0.00a |

199.40±0.04a |

Table 5 Functional Properties of Developed Breakfast Cereal

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M, 100% millet; MSR, millet soycake ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %.

Variation in results could be due to differences in the processing method used. Swelling capacity is an important factor used in determining the expansion accompanying of solvent. According to Kinsella,56 swelling causes changes in hydrodynamic properties of the food sample, thus imparting characteristics such as body, thickness and reduced viscosity of the food, plasticity and electricity. Hence, these properties are desirable for a good breakfast cereal meal.

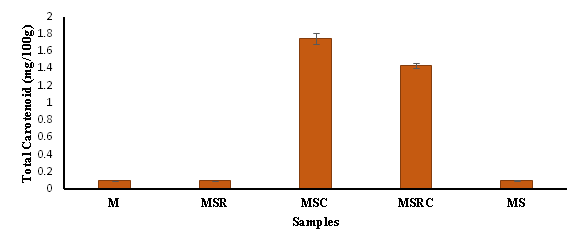

Total β-carotene content: The β-carotene of developed breakfast cereal ranged from 0.0041mg/100g (M) to 1.75mg/100g in (MSRC) (Figure 1) respectively, the total carotenoid content increase with increased carrot pomaces which may be as a result of carrot pomance is a by-product rich in β-carotene, a precursor of vitamin A. This increased content of β-carotene is beneficial as this may reduce the risk of night blindness and poor immune system. However, the finding of this present study is low compared to 100% carrot pomance value reported by Alam et al.57 and this may be due to low proportion of the carrot pomace added to the flour used in developing breakfast cereal meal.

Figure 1 Total Carotenoid of Developed Breakfast Cereal.

M, 100% millet; MSR, millet Soycake Ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %.

Colour of breakfast cereal

The colour characteristics of the breakfast cereals is presented in Table 6. There were significant differences (p<0.05) in the l*, a* and b* values. Due to substitution of various flour level MSR, MSC, MSRC and MS, there was a considerable difference in colour among different breakfast cereals. The lightness l* value of the breakfast samples decreased slightly from 53.19 to 32.85. The a* values of the breakfast cereals has lower values compare to l* and b* values, this may be due to creamish white colour of pearl millet flour. The b* value of the breakfast cereals decrease from 21.14 to 14.83 this may be due to the carotenoid pigment present in carrot pomace. Difference in the colour characteristics of the breakfast cereals samples may be attributed due to differences in the colored pigments of different flours.

Samples |

l* |

a* |

b* |

c |

h |

M |

53.19±0.36a |

11.13±0.08b |

21.42±0.15a |

24.14±0.16a |

62.54±0.15a |

MS |

39.73±0.09e |

10.66±0.11c |

14.84±0.13e |

18.30±0.19d |

54.38±0.16a\d |

MSR |

48.35±0.78b |

10.30±0.04cd |

18.18±0.08b |

20.90±0.05b |

60.46±0.21b |

MSC |

32.85±0.26a |

11.59±0.08a |

15.64±0.09d |

19.33±0.14c |

53.15±0.07e |

MSRC |

45.05±0.45d |

10.17±0.27d |

16.87±0.31c |

19.61±0.32c |

59.40±0.26c |

Table 6 Colour of Breakfast Cereal

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M: 100% Millet; MSR: Millet Soycake Ricebran (65:25:10) %; MSC: Millet Soycake Carrot pomace (60:30:10) %; MRCS: Millet Ricebran Carrot pomace Soy cake (60:30:5:5) %; MS: Millet Soycake (70:30) %.

Sensory evaluation of the breakfast cereals

It could be deduced from the Table 7 that there was no significant difference (p<0.05) among the samples for the aroma and overall acceptability while significant difference existed among the samples for taste, appearance and texture. Sample MS had the highest score for aroma, taste and overall acceptability of 6.50, 6.50 and 5.65 scores respectively while sample MSRC had the least score in texture and overall acceptability of 5.25 and 5.80 score. Sample M had the highest score in texture and appearances of 6.4 and 6.55 respectively while sample MSC had the lowest in taste and appearance with 5.00 and 5.65 score respectively. With respect to the non-significant differences in the aroma and overall acceptability of the breakfast cereal has mentioned earlier, all the breakfast cereals samples were generally acceptable by the panellists but sample MS is the most preferred sample.

Sample |

Aroma |

Appearance |

Texture |

Taste |

Overall acceptability |

M |

6.10±0. 36a |

6.55±0.28ab |

6.4±0.32ab |

5.7±0.38ab |

5.45±0.59a |

MS |

6.50±0.32a |

6.25±0.38ab |

5.95±0.34ab |

6.5±0.30a |

5.65±0.59a |

MSC |

6.35±0.39a |

5.65±0.41b |

5.55±O.35ab |

5.00±0.37b |

4.85±O.55a |

MSRC |

5.80±0.43a |

5.70±0.39b |

5.25±0.45b |

5.50±0.44aab |

4.70±0.59a |

CONTROL |

6.20±0.16a |

6.19±0.20a |

5.87±0.16a |

5.74±0.16ab |

5.28±0.24a |

Table 7 Sensory Evaluation of the Breakfast Cereals

Means (±SEM) with different alphabetical superscripts in the same row are significantly different at P<0.05

M, 100% millet; MSR, millet soycake ricebran (65:25:10) %; MSC, millet soycake carrot pomace (60:30:10) %; MRCS, millet ricebran carrot pomace soy cake (60:30:5:5) %; MS, millet soycake (70:30) %.

The combination of millet, rice bran, soybean and carrot pomace can be utilized into breakfast cereal production with improved nutritional composition, mineral and organoleptic properties. Hence, it consumption may be recommended for both young and old people. However, further studies such as animal and clinical trials should be carried out to authenticate the potency of these breakfast cereal.

None.

None.

The Authors declare that there was no conflict of interest.

©2020 Akinyede, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.