MOJ

eISSN: 2381-182X

Research Article Volume 7 Issue 1

1Food Engineering Department, University of Batna, Algeria

2Mechanical Department, University of Batna, Algeria

Correspondence: Radhia Ferhat, Food Engineering Department, University of Batna, Algeria, Tel +213 560015966

Received: May 15, 2018 | Published: February 28, 2019

Citation: Siabdallah N, Ferhat R, Lahbari M, et al. Convective solar drying of spinach leaves. MOJ Food Process Technol. 2019;7(1):22-25. DOI: 10.15406/mojfpt.2019.07.00214

The drying on of the means is usually used which allows the conservation of the food products by lowering of the activity of water. This paper presents the results of an experimental spinach (Spinacia oleracea) drying study in a new solar dryer. It is an indirect solar dryer with forced convection was developed and improved at the Food Science laboratory. Drying spinach leaves to a final moisture content of 2% from 93.2% (wet basis), with an air-drying speed equal to 1m/s. This study made it possible to determine the drying kinetics of spinach leaves, the evolution of the temperature profile and the influence of drying air recycling (0, 50 and 90%) on drying time. The curves of drying obtained show that the drying rate increased marginally with the increase in fraction of air recycled. It is reduced 3 to 4 hours, by increasing the fraction air recycled from 50 to 90 % respectively, with a significant profit of thermal energy. The drying temperature is higher and stable in the drying chamber of the order of 55 to 65°C (90% air recycled).

Keywords: water content, solar drying, performance, spinach leaves, air recycles

Solar energy is an important alternative source of energy. It is relatively preferred to other sources because it is free, abundant, and inexhaustible and non-pollutant in nature compared with higher prices and shortage of fossil fuels. Solar energy is very abundant in Algeria, in particular in the south of this country. As an alternative to open sun drying, the solar drying system is one of the most attractive and promising applications of solar energy systems. It is a renewable and environmentally friendly technology that is also economically viable is most developing countries. Drying is one of an important post handling process of agricultural production. It can extend shelf life of harvested products, improves the quality and reduces post-harvest losses. Solar crop drying has been demonstrated, to be cost effective and could be an effective alternative to traditional and mechanical drying systems, especially in-locations with good sunshine during the harvest season.1 The purpose of this process is to remove moisture from a product to achieve the desired moisture content. The amount of heat supplied to the product by air heated with natural or artificial means causes the movement of moisture from inside the product to the surface.2

The temperature of the drying air must be kept below the recommended values for the intended use of the product, as the excessive temperature of the drying air can cause physical and chemical changes and deterioration of the product quality. To maintain the quality of the product and avoid damaging its constituents, especially essential oils and vitamins that are sensitive to heat, it must be dried at a low temperature. The problem of drying at low temperature is that it takes a lot of time. Many studies have led to a mastery of the solar drying process, and the design of dryers thus reducing drying times, improving the quality of dried products, and eliminating losses due to poor drying of products. This work was also carried out both at the kiln3‒6 and at the level of the drying process.7–13 However, it is clear that the practice of drying has remained strongly traditional. In this work, we are interested in improving the performance of an indirect forced convection solar dryer. To reduce the drying time and preserve the organoleptic quality of the products to be dried.

Drying system

The indirect solar dryer with forced convection (Figure 1) is used in this study. It designed and realized by the LESEI laboratory.14 Figure 2 shows a photograph of this solar dryer. It consists of mainly a solar air heater, a centrifugal blower and drying chamber.

Measurement instruments and equipment

The following measurement instruments were used:

Vegetal product

Spinach is an herbaceous plant, vegetables grown for the consumption of their leaves, used first as a medicinal plant. It is very recognizable by its long green leaves, curly or flat depending on the variety.15 The spinach leaves used in this Spinacia oleracea variety study, were collected in the area of Batna in June 2015.

Experimental methods

The drying experiments, were carried out in a solar drier with forced convection for the periods (May-July 2015), under the climatic conditions of the city of Batna. Each experiment starts at 9 am to 5pm. The leaves of spinach to be dried of initial moisture content is approximately 93,2 %, drying occurs until a final moisture of 2%; by taking the loss of moisture using a balance starting from an initial mass of 500g/tray, each thirty minute.

During this process, the air velocity setting in the drying chamber was fixed at 1 m/s. Air temperature (ambient temperature and the air temperature at the inlet, middle, and outlet of the collector), solar radiation, and wind velocity were measured. The temperatures of air inlet, inside and outside the drying chamber, were also measured each thirty minute. Relative humidity sensors were installed in the middle of the drying chamber. Air temperature was measured by a K-type thermocouple, and the intensity of solar radiation was measured by a pyranometer. The solar dryer improvement involves the addition of a drying air recycling system, connecting the drying chamber outlet with the solar collector inlet.

The study of the influence of the different fractions of recycled air (0, 50 and 90%) on the kinetics of drying and the effect of drying on the quality of product to dry was carried out. During the drying operation, there is a double transfer: thermal and mass. To illustrate these transfer movements, there are several characteristic curves called "drying curves".16 To know:

Experimental conditions

Drying tests of spinach in the forced convection indirect solar dryer were carried out during the period of May-July 2015. Figure 3 shows the variation of ambient conditions with time of day during the experimental drying. This period is characterized by sunny days. Figure 3A presents the change in global solar radiation for the day considered. It varied between 843 and 950W/m2, the intensity of solar radiation reached its maximum around noon hours. The variation in sunshine during drying implies a variation in the ambient air temperature of 23.0 and 31.9°C. In addition, the relative humidity varied between 17.5 and 43.6% and the maximum wind velocity is 3.6m/s are shown in Figure 3B.

Study of drying kinetics

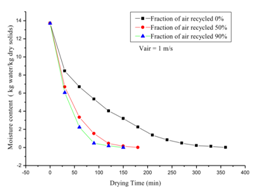

The spinach leaves were dried to a final moisture content of 2% from 93.2% (wet basis) in 6 hours with an air-drying speed equal to 1m/s. The drying curves of spinach are decreasing (Figure 4). They admit the same pace in the three experiments, but with a time gain of 3 to 4 hours of the drying time for the second and third experiments respectively, when increasing the fraction of recirculated air by 50 to 90%.

Figure 4 Variation of mean moisture content with drying time at different fractions of air recycled.

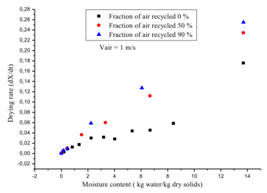

It is obviously observed from the Figure 4, that the moisture content is decreased faster at the initial stages of drying and thereafter became slower as drying proceeds. It is seen from the Figure 5 that the drying rate increased marginally with the increase in fraction of air recycled.17,18

Figure 5 Drying rate according to function of the reduced water content at different fractions of air recycled.

There is a significant difference between the value of the ambient temperature and the temperature at the output of the solar collector (Figure 6), this temperature difference varies from 10 to 33.9°C during the day of the experiment. Knowing that the ambient temperature is between 24 and 32°C for the day considered. The difference is due to the influence of solar radiation on the absorber and to the greenhouse effect, which has results among the absorber and the glass cover, playing an important role in the heating of the air flowing through the air inside the solar collector.

The drying temperature is higher and stable in the drying chamber of the order of 55 to 65°C, under the effect of recycle exhaust air (90% air recycled). However, in the drying recirculation of exhaust air, it is more disturbed and variable of the order 26 to 43°C (0% air recycled) are shown in Figure 7. This is the simultaneous action of reheating the exhaust air recycled, causing the temperature stability in the drying chamber, and then a significant decrease in drying time. An essential factor in the drying process is the air relative humidity; the variation of the exhaust air relative humidity with drying time at different fractions of air recycled (up to 90%), is shown in Figure 7. It is seen from the figure that the relative humidity of the exhaust air is higher in the beginning of drying and decreased with drying time as drying proceeds and became constant in the final stage of drying. This is because the higher drying rate of the spinach leaves during initial stage of drying results in release of more moisture in the drying air. It is also observed from the figure that the relative humidity of the exhaust air increased, with the increase in fraction of air recycled.

The solar forced convection dryer operated well for dehydration of spinach leaves for the controlled conditions of drying air temperature, relative humidity and drying air velocity. The dryer is also facilitated with recirculation of exhaust air. The spinach leaves were dried to a final moisture content of 2% from 93.2% (wet basis) in 6 hours with an air-drying speed equal to 1m/s. The drying curves of spinach are decreasing. They admit the same pace in all experiments. The drying rate increased marginally (3 to 4 hours) with the increase in fraction of air recycled (50 to 90%). with a significant profit of thermal energy.

None.

The author declares that there is no conflict of interests regarding the publication of this paper.

©2019 Siabdallah, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.