MOJ

eISSN: 2381-182X

Research Article Volume 6 Issue 1

1Food Technology, University College of Technology, Osmania University, India

2Society for Energy, Environment & Development (SEED), India

Correspondence: Priyanka S, Food Technology, University College of Technology, Osmania University, Hyderabad, T.S, India

Received: July 21, 2016 | Published: January 4, 2018

Citation: Priyanka S, Ramakrishna RM, Kodandaram RD, et al. Value addition of banana (Musa paradisiaca): development and storage evaluation using osmo solar dehydration technique. MOJ Food Process Technol. 2018;6(1):1-7. DOI: 10.15406/mojfpt.2018.06.00137

Osmo Solar Dehydration Technology is an emerging technology in the food processing sector. Banana is a good source of potassium, magnesium and soluble fibre pectin; it plays a vital role in maintaining normal blood pressure, healthy digestion and eases out constipation. Therefore in this study, Osmo-solar dehydration technology was used to develop a value added Banana product using fresh banana. With this objective, the study was conducted to develop Osmo-solar dried banana (Musa paradisiaca) figs, with 13 sunny hours of drying time with a yield of 18.8%, and 14.2% moisture content in the product. The banana figs were packed into two different packaging material viz., Aluminium and Polypropylene pouches. Physico-chemical characteristics and nutritional parameters along with microbiological quality and shelf life at ambient temperature were studied. The results showed that acidity in Osmo-solar dehydrated banana was high (0.91) than the fresh fruit (0.21) due the addition of citric acid to the osmotic solution, sugar content is also observed to be high (77.23) in Osmo solar when compared to fresh fruit (11.78) due to the overnight dip in osmotic solution. The results indicated that using Osmo-solar dehydration technique many of the nutrients (vitamin C, fiber and potassium) can be retained with less energy consumption. The sensory scores showed that the samples in aluminium pouch were superior in appearance and taste when compared to polypropylene pouch samples after 60days of storage. Thus this product can be used as snack food. The value addition of Banana Figs was done by coating them with chocolate.

Keywords: banana, osmotic dehydration, solar dehydration, potassium, sensory properties

Many processing techniques can be employed to preserve fruits and vegetables. Drying and dehydration is one of the most important operations that are widely practiced because of considerable saving in packaging, storage and transportation. Osmotic dehydration has received greater attention in recent years as an effective method for preservation of fruits and vegetables. Being a simple process, it facilitates processing of tropical fruits and vegetables such as banana, Sapota, pineapple, mango, and leafy vegetables etc. with retention of initial fruit and vegetables characteristics viz., color, aroma and nutritional compounds.1,2 It is less energy intensive than air or vacuum drying processes because it can be conducted at low or ambient temperature. It has the potential advantage for the processing industry to maintain the food quality and to preserve the wholesomeness of the food. It involves dehydration of fruit slices in two stages, removal of water using as an osmotic agent (osmotic concentration) and subsequent dehydration in a dryer where moisture content is further reduced to make the product shelf stable.

Banana is a major fruit crop being grown in India with the production centers of Tamil Nadu Maharashtra, Kerala, Andhra Pradesh, Karnataka, Assam, and west Bengal. It is believed that 1000 varieties of banana sub divided in to 50 groups are cultivated in more than 150 countries with the production of about 105 million tons per year. Banana produces easily available energy, more carbohydrate and low fat. The protein level is slightly lower than cereals. Due to low sodium and high potassium contents in banana plantain fruits, it is recommended for heart and high blood pressure patients.

The aim of the study is to enhance the shelf-life of Banana by processing it into a value added dry fruit using Osmo-solar drying technology and thereby increase the shelf-life of the product.

Osmotic dehydration process was alone time consuming, laborious and the product is too sweet like candy. Hence in order to reduce process time and energy saving the new method of Osmo-solar dehydration was taken up as new method of dehydration. Partial Osmotic dehydration followed by solar dehydration is termed as Osmo-solar dehydration. In Osmo-solar dehydration fruits are initially subjected to Osmosis by dipping in sugar syrup (Osmotic agent) then the fruits are dried in a solar dryer till the acceptable moisture content is achieved.

Requirements

Raw materials: Banana fruits were procured from the local market, Sugar, Potassium metabisulphite and citric acid.

Equipment and Miscellaneous: Gas Stove with Cylinder, Flame Kettle provided with stirrer, Stainless steel utensils, stainless steel knives and peelers, Solar Dryer, Containers, Sealing Machine and Flexible packing materials (polypropylene and aluminium pouches).

Flow Chart

Process Procedure for Osmo-Solar Dehydration of Banana Figs:

Selection of Matured but not fully ripened Banana fruits

↓Sorting & Grading based on quality and physical appearance

↓Washing for 2 to 3 times to remove adhering dust, chemicals etc.

↓Peel the bananas manually

↓Slice with stainless steel Knives into small pieces

↓Transfer the slices in Sucrose solution of 70°B (1:3 Ratio) for overnight

↓Remove the Slices and wash with water quickly to remove adhering sugar syrup

↓Dry in a solar cabinet air dryer to a moisture content of 14% for 10 hours

↓Store the dried slices in air tight container for 2 to 3 days for sweating to equilibrate the moisture levels in the slices

↓Immediately pack the slices in Standby pouches (Aluminium and Polypropylene) and label

↓Store in cool and dry place (Figure 1)

Knowledge of the physico-chemical properties of food is fundamental in analysing the characteristics of food during its processing. The study of these food properties and their responses to process conditions are necessary because they influence the treatment received1 during the processing and also because they are good indicators of other properties and qualities of food. In the present investigation certain physico-chemical properties of the developed product were analysed to ensure the quality of the products.

Estimation of moisture content

Dry a petri dish beside its lid in an oven for 30 minutes at 95°C. Cool to room temperature in a desiccator for about 45 minutes and weigh the dish lid to the nearest 0.1mg (M1). Transfer the homogenized representative sample into the dish and record the weight with lid to the nearest 0.1 mg (M2). Place the dish beside its lid into the oven without draught, at ordinary pressure. Dry the whole for 5 hours at 105±2°C. Then place the lid onto the let cool to room temperature in a desiccator for 45 minutes. Weigh the closed dish to nearest 0.1mg (M3).3

Calculation:

% Moisture Content:

M1 = Mass in grams of the empty dish

M2 = Mass in grams of the empty dish + the test portion

M3 = Mass in grams of the empty dish + the test portion after drying.

Estimation of titrable acidity

It was estimated using the method of S. Ranganna, “Handbook of Analysis and Quality Control for Fruits

Estimation of Total Soluble Solids 3

Weigh about 2g of sample and macerate it by adding 10ml of distilled water. Smear on the hand refractometer and note down the reading of the soluble solids present in it in terms of 0Brix. The total soluble solids present in the sample can be calculated using the following formula:

Estimation of Reducing Sugars and Total Sugars

They are estimated using the method of S Ranganna,3 “Handbook of Analysis and Quality Control for Fruits and Vegetable Products”.

Nutritional profile was done by using the standard methods available.

Estimation of ascorbic acid

The method of Ranganna3 was followed for the estimation of ascorbic acid. Five grams of sample was extracted with 3% metaphosphoric acid. The sample was filtered and 5 ml filtrate was taken for estimation against standard dye to a pink colour. Dye was standardized taking 5 ml ascorbic acid standard (100 mg/100ml in 3% metaphosphoric acid) in a conical flask and mixed with 5 ml 3% meta phosphoric acid and titrated against the dye to a faint pink colour which persists for 15 sec and the dye factor was determined using the formula:

10g of sample was weighed and macerated with 3% metaphosphoric acid. Volume was made up to 100ml with metaphosphoric acid and filtered. 10ml of the extract was titrated against the dye in the burette to a faint pink color which persisted for 15 sec.

Estimation of Total Carotenoids

It was estimated using the method.

Estimation of Total Phenols & Total Flavonoids

They were estimated using the method.

Sensory evaluation on the basis of 9-point hedonic scale of all the prepared samples was done by taste panel. The taste panel consists of 10 members. Sensory evaluation was done to know the acceptability of the product. This sensory evaluation helped in ensuring the quality of the product. The panel members were asked to evaluate the color, appearance, flavor, taste, texture and overall acceptability by a scoring rate, 9 means like extremely, 8 means like very much, 7 means like moderately, 6 means like slightly, 5 means neither like nor dislike, 4 means dislike slightly, 3 means dislike moderately, 2 means dislike very much and 1 means dislike extremely. The different preferences were scored and subjected to statistical analysis.3

Much attention has been given to the quality of dehydrated products. Drying methods and physicochemical changes that occur during dehydration seem to affect colour, texture, density, porosity and sorption characteristics of dehydrated product. Pre-treatment by using Osmotic dehydration4-6 has been used on various food products and its main advantages are connected with retention of quality attributes, such as inhibition of enzymatic browning, retention of natural colour without addition of sulphites and higher retention of volatile compound during further dehydration. It is a water removal process, in which pieces of fruits or vegetables are immersed in a hypertonic solution. It is desirable that the Osmotic solution used has a low water activity (aw) and a good taste.

Drying Data

First, a comparative study was carried out to evaluate the best pretreatment for dehydration of banana7,8 in terms of drying time, yield obtained, nutritive and sensory properties. Solar dehydration of banana using 0.1%KMS was inferior in its quality and sensory properties when compared to the Osmo solar dehydrated banana figs using Osmotic solution (sugar syrup with 700Brix + 0.1% KMS + 0.2% Citric acid). Since the banana slices were soaked in the Osmotic solution overnight (for about 9 hrs.), 20% of the moisture content was removed, ultimately reducing the drying time in the solar drier.

The storage evaluation was carried out at two different conditions i.e., ambient storage conditions (370C, 65% RH) and accelerated storage conditions (600C, 95% RH) (Table 1) for a period of about 6 months and the product was tested for all sensory parameters.

S. No |

Name of the Product |

Drying Conditions |

Finished Product |

||||

Loading Capacity (kg/m2) |

Ambient Temp (°C) |

Cabinet temp (°C) |

Time (hrs) |

% Moisture |

% Yield |

||

1 |

Solar dehydrated banana slices |

3.4 |

27-30 |

35- 49 |

15 |

7.52 |

12.9 |

2 |

Osmo solar dehydrated banana figs |

2.7 |

27-30 |

38-50 |

12 |

14.2 |

18.8 |

Table 1 Technical Drying Data of Banana Figs

Physico Chemical Parameters

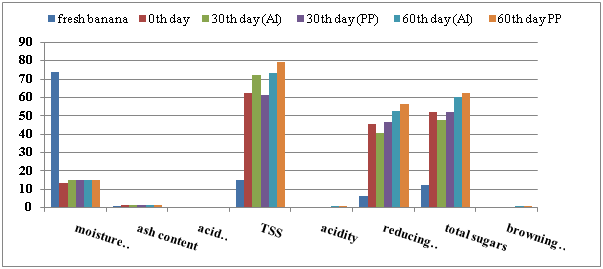

The different physico-chemical parameters Table 2 between fresh and dehydrated fruit were carried out and the study includes estimation of moisture content, acidity, brix, sugar content as well as browning index. The results showed that acidity in Osmo-solar dehydrated banana was high (0.91%) compared to fresh fruit (0.21%) due the addition of citric acid to the Osmotic solution. Sugar content was also observed to be high (77.23%) in Osmo-solar when compared to Figure 2 fresh fruit (11.78%) due to the overnight dip in Osmotic solution. The moisture content after solar dehydration of banana9-13 was less (7.52%) due to more drying hours.

S. No |

Parameters |

Fresh Banana |

0th day |

30th day |

60th day |

||||||

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

||||

1 |

Moisture content (%) |

73.35 |

13.2 |

14.9 |

14.93 |

14.72 |

14.79 |

15.12 |

15.34 |

15.02 |

15.25 |

2 |

Ash content (%) |

0.74 |

1.49 |

1.62 |

1.58 |

1.52 |

1.69 |

1.71 |

1.74 |

1.41 |

1.36 |

3 |

Acid insoluble ash (%) |

0.05 |

0.44 |

0.49 |

0.54 |

0.45 |

0.61 |

0.58 |

0.52 |

0.51 |

0.63 |

4 |

Total soluble solids (%) |

14.87 |

62.2 |

72.2 |

61.44 |

76.6 |

65.04 |

72.93 |

79.03 |

61.22 |

76.33 |

5 |

Acidity (%) |

0.21 |

0.51 |

0.65 |

0.59 |

0.71 |

0.69 |

0.91 |

0.9 |

0.84 |

0.9 |

6 |

Reducing sugars (%) |

6.24 |

45.2 |

40.9 |

46.76 |

49.09 |

45.35 |

52.35 |

56.23 |

59.02 |

68.64 |

7 |

Total sugars (%) |

11.78 |

52.1 |

47.7 |

52.17 |

53.28 |

50.9 |

60.43 |

62.25 |

65.19 |

77.23 |

8 |

Browning index (% abs) |

0.25 |

0.29 |

0.53 |

0.592 |

0.612 |

0.632 |

0.982 |

1.008 |

1.45 |

1.45 |

Table 2 Comparison between Physico Chemical Parameters of Fresh Banana and Dehydrated Banana Figs in Two Different Packaging Materials at Ambient (37°C, 65% RH) and Accelerated (60°C, 95% RH) Storage Conditions

Figure 2 Comparative Graph of Physico Chemical Parameters of Banana Figs Packed In Aluminium and Polypropylene Pouches at Ambient Storage Conditions.

Nutritional Parameters

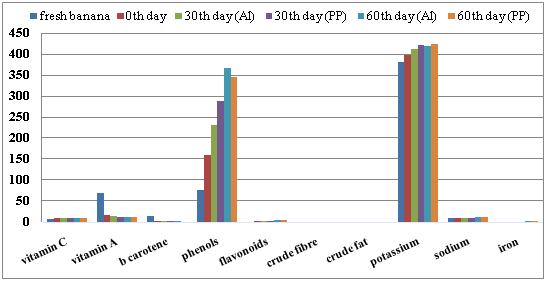

Banana is a good source of potassium, magnesium and fiber. The nutrient parameters which were analyzed Table 3 include total carotenoids, vitamin C, total phenols and flavonoids, and minerals such as potassium, sodium and iron, and crude fiber and fat. The results indicated that using Osmo-solar dehydration14 technique many of the nutrients Figure 3 could be retained with less energy consumption. The final product was acceptable in terms of nutritive value also and the results are tabulated as follows.

S. No |

Parameters |

Fresh Banana |

0th day |

30th day |

60th day |

||||||

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

||||

1 |

Vitamin C (mg/100g) |

7.25 |

11.16 |

10.7 |

10.25 |

10.43 |

10.38 |

9.84 |

9.68 |

9.75 |

9.42 |

2 |

Total carotenoids (µg/100g) |

68.34 |

16.78 |

14.3 |

13.65 |

14.76 |

14.12 |

12.54 |

11.35 |

10.51 |

9.67 |

3 |

β carotene (mg/100g) |

14.56 |

3.85 |

3.26 |

2.87 |

2.75 |

2.43 |

1.97 |

1.66 |

2.03 |

1.87 |

4 |

Total phenols (µg/g) |

76.34 |

159.55 |

230.5 |

287.45 |

308.97 |

315.86 |

366.24 |

344.7 |

351.8 |

284 |

5 |

Total flavonoids (µg/g) |

0.93 |

2.31 |

3.42 |

3.68 |

4.18 |

3.97 |

5.65 |

5.46 |

4.59 |

6.01 |

6 |

Crude fibre (g/100g) |

0.98 |

1.05 |

0.98 |

0.87 |

0.76 |

0.64 |

0.58 |

0.61 |

0.52 |

0.64 |

7 |

Crude fat (g/100g) |

0.45 |

1.24 |

1.13 |

1.54 |

1.36 |

1.65 |

1.42 |

1.32 |

1.26 |

1.94 |

Minerals |

|||||||||||

8 |

Potassium (mg/100g) |

380.3 |

398.76 |

412.4 |

420.67 |

378.98 |

390.76 |

419.67 |

424.65 |

402.68 |

427.78 |

9 |

Sodium (mg/100g) |

8.96 |

9.87 |

9.64 |

10.16 |

10.54 |

11.03 |

12.78 |

13.43 |

13.81 |

13.16 |

10 |

Iron (mg/100g) |

0.58 |

0.98 |

1.14 |

1.86 |

2.25 |

2.57 |

3.25 |

4.06 |

3.49 |

5.61 |

Table 3 Comparison between Nutritional Parameters of Fresh Banana and Dehydrated Banana Figs in Two Different Packaging Materials at Ambient (37°C, 65% RH) and Accelerated (60°C, 95% RH) Storage Conditions

Figure 3 Comparative Graph of Nutritional Parameters of Banana Figs Packed In Aluminium and Polypropylene Pouches at Ambient Storage Conditions.

Microbial Assay

Measured volumes of Table 4 different dilutions of samples were placed on suitable nutrient media, such as nutrient agar or yeast extract agar plates and the number of colonies was counted. The total viable count per milliliter or gram is calculated.

S. No |

Microbial Parameter |

Fresh Banana |

0th day |

30th day |

60th day |

||||||

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

||||

1 |

Total plate count |

1100 |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

2 |

E.coli |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Nil |

Table 4 Comparison between Microbial Parameters of Fresh Banana and Dehydrated Banana Figs in Two Different Packaging Materials at Ambient (37°C, 65% RH) and Accelerated (60°C, 95% RH) Storage Conditions

Sensory Evaluation

Mean scores of sensory evaluation are presented in the Table 5. The results showed that aluminium packed Osmo-solar dehydrated banana figs were more acceptable in terms of colour, appearance and taste when compared with the polypropylene packed Osmo-solar dehydrated banana figs. Considering the fruit embedded chocolate, it was superior to dehydrated banana figs Figure 4 in terms of all the sensory parameters, which indicates the acceptance of the product. Hence, Osmo solar dehydrated banana figs can be used as a snack food15 and also, it can be embedded into the chocolates in order to increase its acceptance. The sensory properties results are tabulated as followed in Table 5.

S.No |

Parameter |

0th Day |

30th Day |

60th Day |

||||||

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

Amb (Al) |

Amb (PP) |

Acc (AI) |

Acc (PP) |

|||

1 |

Colour |

8 |

8 |

7 |

8 |

7.5 |

8 |

7 |

8 |

7 |

2 |

Appearance |

8 |

7.5 |

7.5 |

8 |

8 |

7 |

7 |

7.5 |

7.5 |

3 |

Taste |

8 |

8 |

8 |

8 |

8 |

8 |

7.4 |

7.5 |

7.8 |

4 |

Texture |

7 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

5 |

Flavour |

8 |

8 |

8 |

8 |

8 |

7.8 |

7.4 |

8 |

7.7 |

6 |

Overall acceptability |

8 |

8 |

8 |

8 |

8 |

8 |

7 |

8 |

7 |

Table 5 Comparison between Sensory Properties of Osmo Solar Dehydrated Banana Figs Packed In Aluminium and Polypropylene Pouches and Stored At Ambient and Accelerated Storage Conditions

From the above study on dehydration of banana using two different dehydration methods like solar dehydration and Osmo-solar dehydration, based on sensory evaluation we can conclude that Osmo-solar dehydrated banana figs packed in aluminium pouch was good in all aspects like taste, appearance, texture, flavor, acceptability with an overall sensory score of 8 on a scale of 9 whereas samples in polypropylene pouch stand at 7 sensory score.

Hence Osmo-solar appears to be a good method for dehydration of banana based on sensory evaluation. Based on the microbial analysis, there is no colony count in Osmo-solar dehydrated banana figs during the storage period of 6 months. So the product was safe in microbial aspects in both the packaging materials.

Physico chemical and nutrient parameters were also analyzed in the dehydrated banana slices. These results state that more nutrient retention is observed in Osmo-solar dehydrated banana. Thus the end product is subjected to storage studies in ambient and accelerated conditions for 6 months in two different packaging materials i.e., aluminium and polypropylene pouches. It can be seen that Osmo-solar dehydrated banana in both the conditions is acceptable in all aspects (sensory, microbial, nutrient and physico chemical) and also the packaging materials. Aluminium packaging is best suitable in terms of retaining the color and appearance of the product and some of the nutritional and physico chemical properties too. Thus it can be concluded that Osmo-solar dehydrated banana is best in shelf stability for a period of 6 months with aluminium and polypropylene as a packaging materials.

I express my sincere gratitude to Prof. M. Ramakrishna Rao, Head of the organization, and Ms. R. Shyamala, General Secretary, Society for Energy, Environment and Development (SEED), Hyderabad for providing me an opportunity to carry out this project. It’s my immense pleasure to thank Dr. I. Suresh, Dr. M.M. Krishna and Dr. K. Vidyasagar for their support and guidance. I would like to thank Dr. Kavitha Waghray, Prof. Srinivas Maloo, and Asst. Prof’s. Jyotikiran Singh, V. Bhasker, Renu Pillai for extending their guidance and support to achieve this endeavour.

The author declares no conflict of interest.

©2018 Priyanka, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.