MOJ

eISSN: 2381-182X

Mini Review Volume 1 Issue 2

1Department of food chemistry, Research Institute of Food science and Technology, Iran

2Department of food nanotechnology, Research Institute of Food science and Technology, Iran

3Department of food innovation, The New Zealand Institute for Plant and Food Research, New Zealand

Correspondence: Alireza Mehregan Nikoo, Research Institute of Food science and Technology, Mashhad, Iran, Tel +98 51 35425380

Received: June 06, 2015 | Published: July 17, 2015

Citation: Nikoo AM, Kadkhodaee R, Ghorani B, et al. Electrohydrodynamic atomization assisted encapsulation of bioactive compounds. MOJ Food Process Technol. 2015;1(2):37-38. DOI: 10.15406/mojfpt.2015.01.00010

Electrohydrodynamics atomization (Electrospraying) is a versatile technique to produce microspheres or beads from various materials by means of electrical forces. Electrospraying has numerous advantages over traditional methods in encapsulation: there is high encapsulation efficiency without unfavorable denaturation of bioactive molecules and an enhanced control over the size distribution of particles. This technique could be used for encapsulating bioactive molecules such as proteins, enzymes, vitamins, polyphenols, drugs and sensitive ingredients, for lots of purposes such as masking the bitter test of compounds, sustained releasing, the stability of compounds during process or shelf life of foods, etc. Living cells and spores could be encapsulated by this method for bioenvironmental purposes. Beads can be made by a wide range of food grade and natural biodegradable polymers including alginate, starch, carrageenan, chitosan zein, etc., which makes their use suitable in the development of new foods with enhanced properties and characteristics. Encapsulation by this method also achieves the ability of sustained and controlled release of bioactive compounds by foods, and increasing the effectiveness of such compounds along the time.

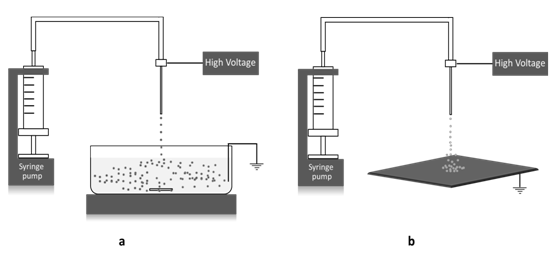

Electrospraying also known as an electrohydrodynamic atomization is a technique for atomizing liquids. The origin of electrospraying is on the base of the charged droplets theory which the interface of the droplets could be deformed by the applied electric field on a liquid droplet which egressing a capillary.1 Electrospray is a well-known phenomenon which has different applications such as fabrication of inorganic nanoparticles, thin films deposition, nanoparticles deposition, aerosolization, fabrication of micro/nano-capsules, etc.2 Electrospray could be applied in different status. Two simple systems are illustrated in Figure 1.

In Electrospray, liquid droplets are formed under a high externally applied electric field that helps the smaller sized droplets overcome the surface energy and break up into micro- or nano-sized droplets. It generates nearly monodisperse droplets with a narrow size distribution.3 There are some frequent techniques for micro or nanoparticle fabrication such as emulsification-evaporation salting-out/emulsification nanoprecipitation, ionic gelation, coacervation, and spray-drying which methods based on the emulsification are the most commonly applied for drug delivery systems formation.4

Electrospraying has several advantages compare to the mentioned frequent methods including: the use of an emulsion is optional but not required; the process have been performed in the ambient temperature or even colder rather than high temperatures which are used in spray-drying; usually there is no need for additional drying phase since particles become immediately dried in the procedure; and a higher control over the particle size distribution which they may include the semi-monodisperse particles.5 Synthesizing nano/microparticles for drug delivery with some aspects would be profitable, Like:

a. Omission of sonication or stirring to obviate the high shears;

b. Higher drug loading;

c. Higher drug distribution uniformity in the matrix;

d. Lack of residual surfactants;

e. Convenience and scalability4 and encapsulation with electrospraying could have these advantages. Moreover for obtaining the invariant biological responses it is important that the size and the uniformity of the particles be on the control. By using the electrospraying technique in the appropriate operational conditions, it is possible to fabricate polymeric particles with the controlled size compare to the traditional methods.5

Natural polymers, such as polysaccharides, are widely used in pharmaceutical applications due to their good biocompatibility and biodegradability.6 Chitosan, alginate, pectin, etc. are often used as structural components for nano and microcontainers because their Biocompatibility and non-toxicity.7 Electrospray could be a mild method for preparing nano/microcapsules by this kind of polymers. Electrospray has been applied for encapsulation of therapeutic and bioactive molecules such as antibiotics8 anti-cancer agents9 growth factors2 Enzymes.10 Also for encapsulation of adenoviruses (Ad) for the local delivery of Ad to target sites at a high concentration and subsequent enhancement of the therapeutic efficiency of Ad for cancer treatment.11 Living cells have been entrapped in microbeads by Electrospray to protect the encapsulated cells from the host’s immune system.12 To scaling up and increasing the output of the production a multiple nozzles system could be applied in parallel to overcome the low throughput of the one nozzle system.5 The current group members are working on the encapsulation of the drugs, bioactive compounds, living cells like bacteria and fern and mold spores with naturally accruing polymers by electrospraying which could be helpful in the developing of the novel food ingredients and bioenvironmental science, as well.

None.

The author declares no conflict of interest.

©2015 Nikoo, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.