Journal of

eISSN: 2373-4310

Mini Review Volume 8 Issue 3

Medical and Pharmaceutical Biotechnology, Center for Research and Applied Technology in Jalisco, Mexico

Correspondence: Padilla Camberos Eduardo, Medical and Pharmaceutical Biotechnology, Center for Research and Applied Technology in Jalisco, ciatej, Normalistas 800, Guadalajara, Jalisco, Mexico, Tel 3333455200

Received: April 18, 2018 | Published: May 11, 2018

Citation: Eduardo PC, Emmanuel VFJ. Encapsulation of food active ingredients in liposomes. J Nutr Health Food Eng. 2018;8(3):238-239. DOI: 10.15406/jnhfe.2018.08.00276

Liposomes are microscopic vesicles composed of phospholipid bilayers entrapping one or more aqueous compartments. Their properties have permitted numerous applications in several fields, including the food industry. The controlled release of active ingredients can be achieved using liposomes. In this mini-review we briefly introduce various aspects of liposomes preparation and their application in food technology.

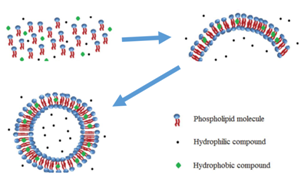

Liposomes are colloidal aggregates formed by one or more closed bilayers, which include in their interior a small fraction of the aqueous medium.1 They form spontaneously when the lipid molecules (mostly phospholipids) generate the membrane that encloses an active agent, and are dispersed in the aqueous medium giving rise to suspensions of vesicles with diameters that can have a size from nanometers to microns (Figure 1).2 Liposomes have particular characteristics and have been studied in many fields as medical, environmental and food, some studies are based in models of cell membranes helping to elucidate the physical and chemical behavior, organization of cell compartments and the structures of cell transport.3

Figure 1 Liposome formation. modified from Emami et al.12

Liposomes are classified according their structure, taking account the type of layers formed at the moment of producing the membranes of the vesicles. They surround the active medium that is intended to be encapsulated and the size they have at the end of the encapsulation.4

There are different methods for obtaining liposomes, by example

The lipid double layer structure presented by liposomes are suitable for a correct permeability towards plasma membranes of certain eukaryotic cells and microorganisms.6 Liposomes in addition, provide a way to deliver hydrophobic agents, and can also improve the properties of the encapsulated active agent by increasing circulation time.7

The liposomal encapsulation allows protection to the content from enzymatic degradation, which is very common in natural compounds that undergo a rapid degradation as it is the case of the essential oils.7 Some articles report that the encapsulation of essential oils trough liposomes has allowed a chemical stability of them, as well as an efficient activity as antimicrobial agent for food preservation.8

Liposomes have the ability to increase the antimicrobial activities of encapsulated ingredients. For example, liposomes loaded with pure carvacrol and thymol were effective as preservative and conserving agents in food industries.9

Another use of liposomes is encapsulation of vitamins to protect and increase the absorption, enhance the bioavailability; for example vitamin C encapsulated in liposomes retains 50% of its activity even after 50 days of storage in refrigeration, whereas non-encapsulated vitamin loses its activity after 19 days.

Liposomes have been used in the food industry to improve the flavor of ripened cheese by synergistic delivery of ascorbic acid and tocopherols. Another example of the application is the encapsulation of calcium lactate in lecithin liposomes to fortify the soymilk with levels of calcium equivalent to those found in cow’s milk.10

Liposomal encapsulation was used to retain the antioxidant activity of resveratrol and recent studies reported a faster rate and better absorption of encapsulated curcumin, a natural polyphenolic phytochemical.11

None.

Author declares there is no conflict of interest.

©2018 Eduardo, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.