Journal of

eISSN: 2373-4310

Research Article Volume 13 Issue 2

1Federal Altai Scientific Center of Agro biotechnologies, Russia

2Polzunov Altai State Technical University, Russia

Correspondence: Olga N Musina, Federal Altai Scientific Center of Agro biotechnologies, Barnaul, Russia, Tel 8-3852-56-45-45

Received: July 11, 2023 | Published: August 16, 2023

Citation: Musina ON, Nagornyh EM. Collagen in processed cheese technology. J Nutr Health Food Eng. 2023;13(2):49-51. DOI: 10.15406/jnhfe.2023.13.00370

Hydrolyzed collagen has proven itself well in the food industry in terms of improving the structural and mechanical properties of products (soups, beverages, meat and dairy products). In the dairy industry, collagen is mainly used in the formulation of beverages, information about the use of hydrolyzed collagen in the formulation of processed cheeses has not been found.

The relationship between the introduction of hydrolyzed collagen into the formulation of processed cheese and changes in its structural and mechanical properties has been studied.

It was found that the sample of cheese with collagen has significantly more viscous and adhesive properties compared to the control sample. The absence of peaks of tensile strength throughout the experiment was revealed when immersed at a speed of 10 mm/s in samples of processed cheese of a straight horizontal indenter to a depth of 50 mm. The increase in effort on the indenter goes smoothly enough. The resistance to immersion of the indenter in the samples under study varies with the progress depending on the degree of structure formation in the cheeses. Organoleptic studies of cheese samples confirmed these patterns.

The introduction of hydrolyzed collagen into the formulation improves the structural and mechanical properties of processed cheeses. Hydrolyzed collagen is recommended for use in the formulation of processed pasty cheeses.

Keywords: processed cheese, hydrolyzed collagen, rheology, structural and mechanical characteristics

The concept of this work is based on the hypothesis of a positive effect of hydrolyzed beef collagen on the rheological and microstructural characteristics of processed cheese.

Collagen is a valuable secondary protein-containing raw material in the meat and poultry processing and fishing industries. Collagen is the result of the hydrolysis of the skins, then a purified acid purification process to obtain pure collagen.

In humans and mammals, about a third of all proteins are made up of collagen. The amino acid composition of collagen is unique and unique-such amino acids as hydroxyproline and hydroxy-h are found only in collagen peptides, and collagen is also rich in such amino acids as glycine (33%), proline +hydroxyproline (22%).1,2

A typical collagen molecule (tropocollagen) consists of three polypeptide α-chains twisted in a triple helix, each of which contains about 1000 amino acids. Mature collagen consists of tropocollagen molecules combined into fibrils, is stabilized by covalent bonds, and is practically insoluble. Under normal conditions, collagen is a very stable protein, but as a result of heating above 40 °C, it loses its triple helix structure and turns into a water-soluble mixture of polypeptides.3

Hydrolyzed collagen is a mixture of low-molecular-weight peptides that can be produced by enzymatic action at a certain incubation temperature in acidic or alkaline media.1 Collagen plays an important role in the human body, but the decrease in its synthesis is noted at a young age, and by maturity, the production of collagen is only a quarter compared to young people.4–8

Hydrolyzed collagen has proven itself well in the food industry in terms of improving the structural and mechanical properties of products (soups, beverages, meat and dairy products).2,3

Various domestic and foreign studies have shown that hydrolyzed collagen has antioxidant and antimicrobial properties,1,3,9,10 beef and sheep hydrolyzed collagen can increase the bioavailability of calcium due to the addition of its ions.3,11,12 A natural result is the widespread use of hydrolyzed collagen in the composition of functional, enriched and specialized products, including for dietary and herodietic nutrition.1,3,13–17

In the dairy industry, collagen is mainly used in the formulation of beverages;16–18 in the available scientific and technical literature, information on the use of hydrolyzed collagen in the formulation of processed cheeses is not found.

Taking into account the potentially enriching effect of using hydrolyzed collagen in dairy products, as well as data on its high thermal stability, solubility, antioxidant and rheological properties, the question of studying the behavior of collagen-containing mixtures in processed cheese technology is of great scientific and practical interest.

The aim of this work is to evaluate the relationship between the introduction of hydrolyzed коcollagen in the formulation of processed cheese and changes in its structural and mechanicalх properties.

Processed cheese in the course of experiments was produced from rennet cheeses, cottage cheese, butter, cream, skimmed milk powder and hydrolyzed collagen, with the addition of melting salts, acidity regulators, salt and water. Cheeseлis produced by grinding, mixing and melting the prepared raw materials using melting salts on the Thermomix TM5 device.

The main raw materials used in the work are: semi-hard rennet cheeses according to GOST 32260 with a mass fraction of dry matter 56%, fat in dry matter 45%; cottage cheese according to GOST 31453 with a mass fraction of dry matter 25%, fat 5%; sweet and creamy peasant butter according to GOST 32261 with a mass fraction of dry matter 75%, fat 72.5%; cream according to GOST 34355 with a mass fraction of dry matter 41%, fat 35%; skimmed milk powder according to GOST R 52791 with a mass fraction of dry matter 96%; food salt according to GOST R 51574 of the first class; citric acid food monohydrate according to GOST 908; drinking water according to GOST R 51232, sodium orthophosphate according to GOST 31725; sodium pyrophosphate according to GOST R 55054; sodium triphosphate и and sodium polyphosphate - according to GOST 31686.

Hydrolyzed beef collagen of the "Athletic Food" brand obtained by enzyme hydrolysis, manufactured by SMT-Group LLC, Russia.

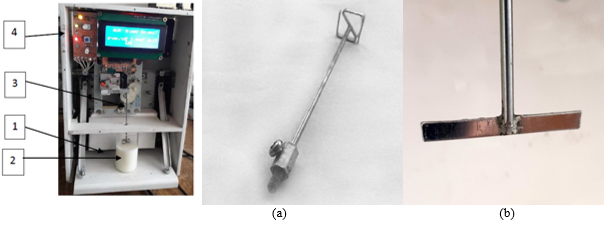

The rheological properties of processed cheeses were studied in the laboratory of the Siberian Research Institute of Cheese making (a division of the Federal State Budgetary Research Institution of the Russian Academy of Sciences) on the basis of the processes and equipment sector under the supervision of Professor A. A. Mayorov using the author's method, which provides for immersion of the indenter to a given depth and measurement of the loading force on the indenter.19,20 The description of the "Reokon" and its appearance are given inах,20,21 as well as in Figure 1. The method is based on determining the loading force on the indenter when it is immersed in a sample of processed cheese to a given depth at a given speed.

"Reocon" consists of a measuring device with a mechanical system and a control unit connected to a data recording computer (Figure 1). The container with the sample (2) is installed on the base of a moving mechanism (1) designed to raise the sample to the required level. The working part of the device is an easily removable indenter (3). The movement of the indenter ("up" and "down") at a distance of 50 mm is carried out by an electric drive. The speed of the indenter is 10 mm/s. The force generated as a result of the indenter movement is recorded via an analog-to-digital converter and fed to the USB input of the computer, where it is displayed in tabular form. Data processing is performed using an Atmei GA 328 microprocessor. The control unit (4) contains power supply devices for the electric drive, an indenter movement system ("up" and "down"), and an analog-to-digital converter.21

Figure 1 The appearance of the device (a) and the indenter (b): 1 - the base of the moving mechanism, 2 - the sample container, 3 - the indenter, 4 - the control unit.

The principle of operation of the device is based on measuring the tensile strength of a processed cheese sample when the indenter is immersed. The measurement results, converted to grams, are displayed on the monitor screen. Thus, this method of studying the structural and mechanical properties of processed cheese is based on measuring the resistance that a cheese sample exerts to an indenter immersed in it to a depth of 50 mm.

The final result is taken as the arithmetic mean of the results of three definitions.

Rheology examines the processes associated with irreversible residual deformations and the flow of various viscous and plastic materials, rheometry studies the structural and mechanical properties of bodies using special devices and devices. The most important properties плавленого of processed cheese are rheological (fluidity, viscosity, strength, elasticity), while from the point of view of rheology, cheese is a viscoplastic-elastic body.20 Preliminary experiments have shown that it is more appropriate to use ножевой a straight horizontal knife indenter. The measurements were carried out at 20 о C. The experiments were performed in 3-4 repetitions.

Recipes for the control and experimental samples of processed cheese are given in Table 1. For collagen the percentage of 3.1 was chosen as a result of a preliminary experiment to study the possibility of introducing different doses of collagen into the formulation of processed cheeses and evaluating their organoleptic properties.22

Raw material name |

Consumption for making a cheese sample, kg |

|

Control sample |

Test sample |

|

Semi-hard cheese |

309.6,6 |

357.0 |

Cottage cheese |

102.0 |

102.0 |

Butter |

239.1 |

284.1 |

Cream |

122.4 |

61.2 |

Powdered milk |

10.6 |

21.8 |

Table salt |

1.0 |

1.0 |

Melting salt |

20.4 |

20.4 |

Citric acid |

1.0 |

1.0 |

Collagen |

0.0 |

3.1 |

Water |

186.9 |

168.4 |

Total |

1020.0 |

1020.0 |

Yield |

1000.0 |

1000.0 |

Table 1 Composition of processed cheese

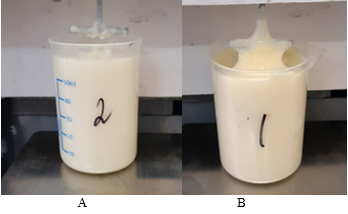

The interaction of processed cheese samples with the indenter is shown in Figure 2. It can be seen that the sample with collagen has significantly more viscous and adhesive properties compared to the control cheese sample, which is visually expressed in a greater degree of sticking to the indenter.

Figure 2 Typical interaction of processed cheese samples with an indenter in the measurement process (a - control sample, b – test sample).

The value of the resistance that processed cheese exerts to the indenter immersed in it is studied. It is established that there are no peaks of ultimate strength both at the time of the beginning of the experiment (contact of the cheese surface with the indenter), такand during the entire course of the experiment when the indenter is submerged to a depth of 50 mm. Throughout the experiment, the increase in force is quite smooth, and there is no sharp drop in force after exceeding the strength limit in the samples не наблюдается. The resistance to immersion of the indenter in the test samples varies depending on the degree of structure formation in the cheeses.

Evaluation of the organoleptic properties of the control and experimental cheese samples also confirmed that the sample with collagen has a higher viscosity and adhesion, which is a positive result in optimizing the structural and mechanical properties of processed cheeses. Hydrolyzed collagen is recommended for use in the formulation of processed pasty cheeses.

The relationship between the introduction of hydrolyzed collagen into the formulation of processed cheese and changes in its structural and mechanical properties was studied.

A sample of cheese with collagen has significantly higher viscosity and adhesive properties compared to the control sample. It was found that there were no peaks of ultimate strength throughout the experiment при погружении when a straight horizontal indenter was immersed at a speed of 10 mm/s in samples of processed cheese to a depth of 50 mm. The increase in force on the indenter is quite smooth. The resistance to immersion of the indenter in the test samples varies depending on the degree of structure formation in the cheeses. Organoleptic studies of cheese samples confirmed these patterns.

Thus, it was found that the introduction of hydrolyzed collagen into the formulation improves the structural and mechanical properties of processed cheeses. Hydrolyzed collagen is recommended for use in the formulation of processed pasty cheeses.

This work was supported by the project 075-00316-20-01 (FZMM-2020-0013, mnemocode 0611-2020-013) from the Ministry of Science and Higher Education of the Russian Federation.

The author declares that there are no conflicts of interest.

©2023 Musina, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.