Journal of

eISSN: 2373-4310

Research Article Volume 12 Issue 2

Department of Food, Bioprocessing and Nutrition Sciences, North Carolina State University, USA

Correspondence: S Feng, Department of Food, Bioprocessing and Nutrition Sciences, North Carolina State University USA, Tel +1 (919) - 454 -1494

Received: April 11, 2022 | Published: April 27, 2022

Citation: Feng S, Whitfield S, Ward T, et al. Analysis of a mass produced dried ready-to-use therapeutic food ingredient. J Nutr Health Food Eng. 2022;12(2):44-53. DOI: 10.15406/jnhfe.2022.12.00355

This report aims to compare quality and safety aspects of relevance to viable ready-to-use therapeutic food (RUTF) ingredients across three different cooking extrusion processes for a dried sweet potato and mealworm noodle. This noodle was created for use as an ingredient in a nutrient dense, high calorie, high protein, trail-mix like snack pack (MM) which contains roasted peanuts and dehydrated fruit in addition to the noodles. MM is intended as a treatment for moderately acute malnutrition (MAM) in disaster scenarios and regions with ongoing food shortages. Since RUTF products are typically made on an industrial scale in developed countries then shipped to places in need, the success of MM is heavily dependent upon the ability to effectively scale up production of the unique noodle formulation. In order to be viable, the product must be shelf-stable, safe, and meet or exceed nutrition guidelines for treating MAM.

The noodle, which is the focus of this project, contributes a majority of the protein and fat to MM, so its nutritional quality and consistency is very important to the success of the overall product. Three process group combinations were chosen utilizing a twin-screw cooking extruder. Each of these noodle treatments will be compared on the basis of texture, total microbial load, water activity, moisture content, total protein, total lipids, ash, and protein content with carbs determined by difference.

Texture determined by three-point bend texture analysis, is an important indicator of the final product’s variability. A product that takes more force to break will be more durable during shipping, which may be crucial in such a product. Microbial load is enumerated primarily to verify whether or not the heat processing steps are a sufficient to kill any microorganisms present. A low water activity is crucial for shelf stability, while water content is being measured to verify that the heating steps produce a fully dehydrated product. Lipid content is important in an RUTF as fat provides readily available, dense calories. Mineral and carbohydrate content are being measured for complete nutritional facts of the product. Both protein content and nutritional quality are very important to the formulation, as amino acids are the limiting factor for growth in many MAM cases. There are very specific guidelines for an RUTF regarding protein, and exceeding them is crucial for RUTF success. The data collected show an average water activity for all temperatures 0.2815, which is below the 0.65 safety target. The average fat content was 10.1365% of dry weight. The average moisture content is 1.95%.

Keywords: sweet potato, mealworm, tenebrio molitor, proximate analysis, twin-screw extruder, protein quality, amino acids, RUTF

Although food security in South Asia has been increasing over the last few decades, the percentage of children under 5 with moderately acute malnutrition (MAM) is still at an alarming 17%. Additionally, β-carotene deficiency is the leading cause of childhood blindness in South Asia.1 When a developing region in South Asia with high food insecurity is hit by a natural disaster like the 2004 Indonesian Tsunami, the results can be deadly and create millions of refugees. Temporary camps providing rehabilitation and humanitarian aid would need to be erected for these refugees.2 Thus, a Ready-to-Eat Therapeutic Food product (RUTF) would be in great demand. Thailand, for example, is considered to have a sizeable commercial market based on insect consumption because edible insects are considered a cultural norm.3 Insects are preferable to other animal proteins in RUTF applications because is a low cost investing practice with less land required for raising insects compared to typical meat sources, meaning that they can potentially be raised more cheaply, and cost has historically prevented MAM treatments with milk or other animal proteins from being successful.4

Sweet Potatoes are known to have high levels of β carotene and can be grown in a wide variety of areas, including many developing areas.5 Additionally, they are known to be high in vitamins and minerals, such as beta-carotene and vitamin C, and fiber. Therefore, an RUTF incorporated with an edible insect and sweet potatoes could be effective at treating both MAM and childhood blindness. As many of the most financially successful examples of RUTF foods are entirely vegetarian with poor protein quality.5 The use of insect protein can potentially give MM a higher protein quality content than other RUTFs. The project herein focuses on one ingredient of MM, the sweet potato and mealworm noodle, which provides the majority of the product’s protein.

Since most relief efforts for MAM are currently produced in developed countries and distributed by non-government organizations,6 the ability to produce an RUTF in a more industrial setting and scale is vital to its success as a relief option. The scope of the project involved analyzing three sets of potential pilot-scale cooking extrusion temperature parameters (75°C, 110°C , 130°C) to determine which set of barrel temperatures created a product with the greatest and least variable nutritional quality and safety. All of these extrusions required an additional dehydration step to ensure water activity was lowered below 0.65 (Farakos et al. 2014).

Edible insects

Edible insects have been eaten for a long time and have been a part of the traditional diets of many non-Western countries, but more recently, the Food and Agriculture Organization of the United Nations (FAO) has singled them out as having high potential to treat malnutrition and food shortages without requiring large amounts of land or infrastructure.4 Moreover, insects are considered as suitable alternatives to conventional animal sources such as fish, chicken, pork and beef. With land being scarce and oceans being overfished, expanding the area dedicated to farming any traditional livestock seems neither suitable nor a sustainable option. The concept of farming of insects, for food, on the other hand, is suggested to lead to lower emission of greenhouse gases and ammonia than cattle or pigs and higher efficiency in converting feed to protein. The concept of “minilivestock” or insect farming may be a low-tech activity and requires low-capital investment.4

A number of studies conducted on Tenebrio Molitor , the mealworm, have shown that larval mealworms are a very high-protein food and are also fairly high in fat, especially polyunsaturated fats.6 For example, when fed with insects, Finke et al. (1989) found that weaning rats weight increase similar to the response when fed to soy protein. Goulet et al. (1978) fed mealworms (T. molitor) to rats and found similar data as measured with soybean meal. These protein sources when compared to insect feed were equivalent or superior to soy protein, as a source of essential amino acids. Amino acids found in relatively low amounts in insects are compared to fishmeal and soybean. Histidine, lysine and tryptophan are examples of the amino acids found in these proteins (Sanchez-Muros et al., 2014). These qualities would make them an appealing food ingredient in the US based on current trends if the public could accept insect-based products, but it’s in the areas where insects are a traditional part of the diet and can easily be grown or harvested that the FAO argues they are truly valuable as emergency relief.4

Food safety of insects used for food

As edible insects are relatively novel ingredients in industrial food processing, it’s important to be aware of potential food safety hazards. Research has shown that insects can pose a significant microbiological threat when they are used for food and feed purposes; these threats have to be overcome by taking proper processing, handling, and storage measures (Rumpold and Schluter, 2013). According to the US Food and Drug Administration’s (FDA) Center for Food and Applied Nutrition, there are no special certifications needed for edible insects; the FDA requires that all food processing facilities meet the same requirements regardless of the food commodity. In this regard, the European Food Safety Authority (EFSA) (EFSA, 2015) states a similar position. However, the lack of specific regulatory guidance has caused issues for investors, farmers and entrepreneurs who are willing to build industrial-scale insect-rearing plants for food and feed.4 That said, there is not an extensive amount of research that has been done in the US regarding edible insects, and the US must rely heavily on expertise and practices that have been conducted in other countries for evidence that insects are safe to consume.

According to the European Commission's 2015 Novel Food Regulation, insects fall into the category of “novel food with a history of food use in a third country [that] has been and continues to be part of the normal diet for at least one generation in a large part of the population of a country.” Demonstration of “the history of safe use” requires documented compositional data and wide experience of use (Belluco et al., 2013). This provides us with a level of confidence as we move forward in our production of the MM noodle, especially for intended production in many of these developing countries.

The microbiota of insects includes bacteria, viruses and fungi which are present in the gut and are essential for their metabolism (EFSA, 2015). Research has shown that the main pathogens of concern with mealworms are Enterobacteriaceae and spore-forming bacteria. This bacteria was found in the fresh insects, but at levels standard for food that is freshly harvested from the soil (Klunder et al., 2012). The process of making mealworm flour involves roasting and crushing of the mealworm. Crushed mealworm larvae can have higher counts of viable bacteria, which may result from the release of microbiota from the insect’s intestines. Additionally, research has shown that Enterobacteriaceae were killed during boiling of insects, but not completely during roasting; thus roasting may not fully kill the microbiota from the insects’ intestines. A two-step kill method that includes blanching the insects in boiling water for a few minutes previous to the roasting was recommended (Klunder et al., 2012). Additionally, Salmonella spp. may be a potential concern, as Salmonella can survive in products with low water activity and high lipid content, a category the MM noodle might fall into (Farakos et al., 2014). However, EFSA (2015) states that pathogenic bacteria of insects are regarded as harmless to animals and humans due to the fact that the hosts are so phylogenetically different. For insect farming it is of utmost importance to consider rearing conditions such as substracts and feed. Most bacterial hazards (and their toxins) for humans and animals are related to insects and originate from a residential microbiota.

Malnutrition and ready-to-use therapeutic foods

There are a multitude of existing products to treat malnutrition due to food insecurity, including RUTFs, which are usually pastes or drinks that can be consumed straight out of the package; Fortified Blended Foods, powdered products mostly intended to be cooked as porridge; and other dietary supplements.7 The majority of these products, due largely to cost constraints, ease of processing, and nutritional density concerns, have fairly similar ingredients. Most are comprised of cheap vegetable protein or grains, some form of milk powder or whey protein isolate, vegetable oil, micronutrient fortifications, and sometimes sugar.7

Dairy protein is a nearly ubiquitous ingredient in these products due to the fact that multiple studies have shown that the addition of milk powder as a replacement for cheap vegetable protein like corn or soy increases weight gain in the malnourished children being treated (Hoppe et al., 2008), and that higher concentrations of milk protein compound this effect (Oakley et al., 2010). Higher-quality protein (which has a higher concentration of essential amino acids) from milk provides more of the necessary amino acids without increasing satiety by adding more overall protein, and plant products contain higher concentrations of anti-nutrients than milk does (Hoppe et al., 2008). Thus, while all-vegetable foods for treating MAM are available and cheaper to produce, milk-based products are generally regarded as the best option.

Formulation of these supplemental foods remains a focus of ongoing research, however, as the existing products and programs are far from perfect. A review of various supplemental feeding programs for treatment of MAM in children found that only 63.9% of the plans had more than 75% of participants recover from MAM, and that the number of such programs dropped to 39.3% when children who left the program before recovery were included (Navarro-Colorado et al., 2008). While some of the defaulting observed was due to availability issues in highly isolated areas, palatability of the product is also a contributor; as with any dietary intervention, consumer acceptance must be taken into consideration for success (Bechman et al., 2015).

The use of local food products to increase the acceptability of RUTFs as well as reduce costs is gaining popularity as an idea, although the predominantly distributed products are still mainly made of non-local vegetable proteins like soy, corn, and peanut with dairy, another non-local ingredient (Bechman et al., 2015).7 Often, the cheapest possible products that meet nutrient guidelines are unfamiliar and unappealing with high amounts of waste stream protein like whey isolate and oil sources (Weber and Callaghan, 2016). Existing RUTF formulations have had some success increasing acceptability for children with a sugar content as high as 28%, but the success does not extend to adults suffering from MAM. HIV patients and pregnant or nursing mothers8 also commonly suffer from malnutrition but are rarely the target audience when RUTFs are being developed because of the focus on child nutrition (Bechman et al., 2015).7

Texture is another example of the way that RUTFs are rarely developed with adults in mind. Texture is a concern, which has been studied in the formulation of paste-based RUTFs, but products are optimized for a texture, which can be squeezed out of a package without being thick enough to present a choking hazard to young children (Bechman et al., 2015).8

Rheological impact of cooking extrusion

The primary reaction that affects the structure of many extruded products is starch gelatinization, as most extruded products, which are not powders or structured meat substitutes are heavily starch-based. Since extrusion is normally a high-temperature, short-time process, starches are generally favored which have a rapid gelatinization time and will fully gelatinize so that a stable structure can be formed (Mohamed, 1990).9 There are still a wide variety of processing parameters and ingredients used for extrusion, however, so the type of starch, concentration of starch, heating time and temperature, and water feed rate all affect the degree of gelatinization and therefore the texture of the product.9 Product temperature and specific mechanical energy have been shown to affect the rheological and structural properties of the extruded product like expansion and viscoelasticity (Lei et al., 2005). The water feed rate also has a dramatic effect on these properties. Lower levels of water result in higher starch breakdown during heating, while higher levels result in gelation and a more viscous product, which dries to have a more elastic structure.10

The ingredients used in producing an extruded food affect the rate of expansion of the product as it leaves the extruder, thus affecting the formation of air bubbles and final product texture (Guy, 2001). Protein content as well as the functional properties of proteins present can have an impact on the viscosity of the material during extrusion and various structural properties of the finished product, but at higher extrusion temperatures, protein denaturation decreases the impact of functional protein properties on texture.11

Nutritional impact of cooking extrusion

Decrease of protein quality through Maillard browning is a potential concern for products with high protein and sugar contents, but cooking extrusion is typically a high-temperature short-time process, and previous papers have primarily found that typical extrusions which reach 130°C or less don’t cause significant maillard browning, although lower-moisture extrusions (with lower water feed rates) and extrusions with longer residence times are more susceptible to browning.11,12 The temperature and pressure involved in extruding protein-rich materials has been shown to affect texture of the product more than the quality of the protein (Ilo et al., 2003). Protein denaturation, however, is common in extrusion processes, especially at higher temperatures, and can be beneficial to the bioavailability of protein in extruded products. Some research has suggested that protein digestibility is also increased by the effects of shearing during extrusion (Brennan et al., 2013). Extrusion is commonly used on cereals and grains in East Africa to destroy anti-nutritional factors and gelatinize starch, which can aid in digestion.8 Whether these benefits outweigh potential loss of heat-labile micronutrients and maillard browning is dependent upon moisture content, temperature, and residence time, with low residence times, temperatures below 200°C, and moisture contents above 15% (based on feed rates) favoring good nutritional quality.13

Protein and protein quality

Protein quality is a large concern in treating malnutrition, and the current guidelines on treating MAM recommend using the minimum amount of very high-quality protein so as to reduce costs and prevent over-satiety from high protein intake. The recommended method for assessing this protein quality is by calculating the Protein Digestibility Corrected Amino Acid Score (PDCAAS),7 which adjusts the raw amino acid contents based on digestibility data acquired from a study in live rats (Darragh et al., 2000). Digestibility is also an important factor in treating malnutrition, as more protein must be present when digestibility is low, and high protein contents increase satiety and often negatively affect the amount of product a person will eat. United Nations Children's Emergency Fund (UNICEF) guidelines for RUTFs require a digestibility of at least 95% (UNICEF, 2012).

Alternatively, however, the FAO and World Health Organization (WHO) have agreed that in cases where digestibility of protein is not a concern, comparing the amino acid profile to an ideal standard is sufficient to replace an in vivo study (Albert*, 1991; FAO/WHO/UNU, 1985). There is no specific data on digestibility of mealworms, but animal proteins, mainly due to their lack of fiber, are usually very accessible to humans (FAO/WHO/UNU, 1985). Previous research on amino acids in mealworms has found that mealworm protein is completely sufficient to meet human dietary needs in this regard except in histidine, lysine and tryptophan (Li et al., 2013). However, many sweet potato cultivars are very high in tryptophan, and some have sufficient lysine to meet the FAO/WHO standards, though others do not (Bradbury et al., 1985).

Product ingredients

To produce the noodles sweet potatoes of Covington variety were used to produce the sweet potato flour (SPF) that was further mixed with mealworm flour (MWF). ‘Covington’ is an orange-fleshed, smooth-skinned, rose-colored, table-stock sweet potato, developed by North Carolina State University.14 Selected sweet potatoes were stored in a refrigerated room maintained at 15 °C. Mealworms (Tenebrio molitor) were sourced from Rainbow Mealworms (Compton, CA), and rice flour and cornstarch through local retail (Raleigh, NC).

The raw sweet potatoes and mealworms were cleaned and made into flour. Sweet potatoes were sliced into approximately 0.25” slices using a a semi-automatic slicer (Presto PS-10 Eau Claire, WI) and then dehydrated in a cabinet dehydrator Weston Pro-1000, (Gainesville, VA) for 12 hours at 60°C to achieve an 85% weight reduction due to water loss. The mealworms were roasted whole in an industrial forced-air oven at 93°C for 60 minutes to achieve about a 55% weight reduction due to water loss. Dehydrated ingredients were then ground separately in a Robot-Coupe Blixer 3 (Vincennes Cedex, FR) to a fine powder consistency.

Once all flours were produced, they were mixed by hand individually to homogenize, as each kind of flour had to be ground in small batches and there could be variability from batch to batch. This also helped to account for and distribute any variability between separate shipments of raw ingredients or dehydration batches. Homogenized flours were then stored in glass jars at -80°C in the dark to avoid enzymatic and chemical reaction, until needed.

Extrusion

Ingredient mixes were prepared the morning of extrusion to eliminate any unfavorable reactions between ingredients. The mix was made of 45 parts sweet potato flour, 35 parts mealworm flour, 15 parts rice flour, and 10 parts corn starch by weight, mixed by hand until visibly homogeneous, and then stored in a 4°C freezer in ziploc bags until time of use.

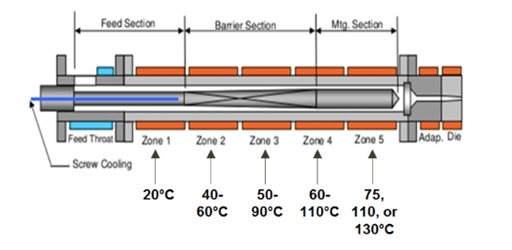

Pilot scale extrusions were conducted using a Coperion ZSK-26 (Stuttgart, Germany) co-rotating twin-screw cooking extruder with a single-screw volumetric feeder. The water feed rate was set at 4 mL/min and the powdered ingredient feed rate was calibrated to 40 g/min. Powdered ingredient feed rate had to be set by hand based upon the rotation speed of the feeder agar, and was measured by collecting powder coming out of the extruder for one minute and weighing until a setting was found which produced the correct weight twice in a row. The temperature of five different zones of the extrusion barrel could also be set individually (Figure 1), as well as the screw speed, and these were the parameters varied between treatments.

Figure 1 An example layout of the extruder, with temperature ranges shown. Exact temperature profiles for each treatment can be seen in Table 1. Image taken from Timothy W. Warner and R & B Plastics Machinery.

Three treatment groups were ran through the extruder, two with a barrel screw speed of 350 rpm (one with a final barrel temperature at 75°C and one at 110°C) and one with a barrel screw speed of 550 rpm and a final barrel temperature at 130°C. Throughout the paper, these treatment groups are mainly referred to by their final barrel temperature. These treatments were chosen to represent a wide range of extrusion parameters used for similar ready-to-eat products in the industry (Oliveira et al., 2015; Stojceska et al, 2009), in the hopes that a best set of parameters from this study could be found which could act as a prototype to be fine-tuned by further research. 130°C was chosen as the highest heat treatment because previous papers have found that 140-160°C treatments can start to experience significant maillard browning, which would negatively impact protein quality.11,12

One run used approximately 1 kg of dried ingredients. Noodles were collected on aluminum-covered sheet trays as they came out of the extruder in such a way those long, continuous straight sections could be collected for texture analysis, and were then dehydrated on the aluminum foil for 12 hours at 60°C. The whole extrusion process from creation of the mix through dehydration of the noodles was replicated three times using the same raw ingredients, which had been homogenized to minimize false variability in the data due to raw ingredient variability. Random samples from each treatment group and replication were taken for the texture analysis, water activity measurement, and microbiological plating. The remaining sample from each treatment-replicate group was ground up and homogenized for chemical analysis.

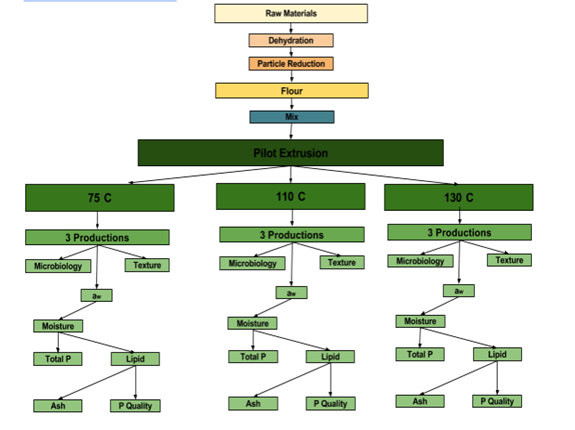

Analysis overview

The flow of experiments was designed such that the completely nondestructive water activity analysis was conducted first, followed by moisture analysis and then crude lipid analysis, as they produced dried and defatted samples, respectively, which were needed for several further analyses. Destructive analyses like crude protein, ash content, and protein quality followed utilizing primarily the defatted samples, and texture and microbiology analyses had to be run with separate noodle samples, which were not ground with the rest. The flowchart of the overall experimental design (Figure 2) summarizes all experiments.

Figure 2 A flowchart which summarizes the flow of work from preparation of raw ingredients to extrusion through all of the analyses conducted.

Unground sample from each of the three processes was pre-weighed and stored in 11g aliquots for 3 weeks at room temperature in sealed plastic bags to approximate eventual storage conditions for a shelf-stable food. Then, each 11 g sample was homogenized in a stomacher with 99 mL peptone broth and serially diluted for plating on Plate Count Agar (PCA) (Salfinger and Tortorello, 2015). Two production replicates were spread-plated at dilutions of 10--2, 10-3, and 10-4, with each dilution plated in duplicate. PCA was chosen because of the long and difficult process involved in confirmatory testing for pathogens. The hope was that if little to no growth was witnessed on the plates, then the various heat processing steps were sufficient to kill vegetative cells in naturally occurring amounts, and that if high numbers were found then later research could look more specifically at the presence of salmonella spp and enterobacteriaceae spp.

Texture

Three-point bend texture analysis was conducted using an Instron Universal Testing Machine model 5542 (Norwood, MA) with 100 N load cell and a gap length of 0.4 cm. The machine was used to quantify the peak force required to break a length of noodle as well as the distance the noodle deformed before breaking. With these values, one can also calculate the total work done on the sample, the value typically reported in a 3-point texture analysis.

The analysis was conducted as in Mariotti et al., 2011, but utilizing modified parameters on Launch Bluehill 2 Software. 13 technical replicates were tested for two true replicates of each treatment, as the analysis in general is known to be fairly variable and preliminary results based off preliminary trial with different noodles that had very high CVs.

Water activity

Water activity was measured by filling a measurement cup about halfway full of ground sample (standardized by weighing out approx. 3 grams each) and placing it into Aqua Lab Model 4TE (Decagon Devices, Pullman, WA) in a chilled mirror water activity sensor, which measures the dew point of the sample and uses it to calculate water activity (Nielsen, 2010). Three true replicates were conducted with three analytical replicates each. Further replicates could have been measured, but the data points were not highly variable.

Moisture content

Moisture content was measured gravimetrically using a vacuum oven to dehydrate ground samples at 151°C (AOAC, 2005). Around 5 g of sample were used in each metal dehydrating pan, and three true replicates were conducted with two analytical replicates.

Total lipid

Crude lipid analysis was conducted gravimetrically with a soxhlet apparatus that contains six soxhlet extractors. Samples were randomly assigned to one of the six extractors using a random number generator. Approximately 5g of sample was weighed into each thimble with the precise weights recorded, then the sample was covered in glass wool and the thimble placed in the apparatus, which runs a continuous stream of petroleum ether through the sample, conducting repeated extractions to remove all fat present in the sample. This process was allowed to run overnight before the ether was evaporated and the extracted lipids were weighed (AOAC, 2005). Three true replicates and two analytical replicate were conducted for each of the production runs in each treatment. As many other analyses required defatted sample, this was one of the first assays performed.

Soxhlet extraction was chosen because it’s an AOAC-approved method which measures the fat gravimetrically, beneficial because we needed undestroyed defatted sample for several other analyses, and because it’s much easier to conduct to completion than by-hand extraction methods that would be similar. Petroleum ether was chosen because it’s commonly used for shellfish and has also been used for mealworms in the past (Anthony et al., 1983).

Ash

Ground sample that had been dried and defatted as described above was dry-ashed in a muffle furnace for gravimetric determination of mineral content. Defatted sample was used to minimize fat splatter and prevent sample loss of very lightweight ash from the small crucibles. Ceramic crucibles were labeled with a heat-resistent pencil and fired at 525°C for 4 hours in the muffle furnace to burn any organic residue. The crucibles were stored in a dessicator to cool and then samples of approximately 1 g were weighed into individual crucibles. The samples were then ashed at 525°C for 7 hours and allowed to partially cool overnight before moving to a desiccator, where ashed samples were kept until completely cool, at which point they were weighed. Three true replicates and three analytical replicates were conducted for each extrusion treatment. Potential micro-elemental contamination during handling and grinding as well as the comparatively low ashing temperature could have been potential sources of error in the ashing process we chose, but it’s a safe method that creates no hazardous waste and was more than sufficient for rough to-the-closest-percent proximate requirements (Nielsen, 2010).

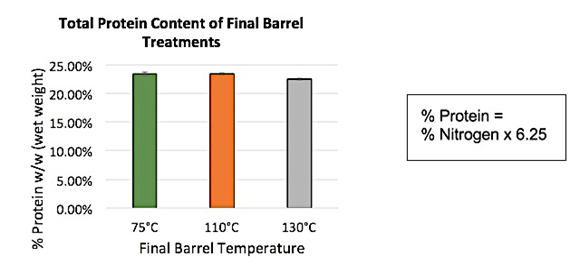

Total protein

The Dumas method was used to calculate total nitrogen for the samples. An automated micro-analyzer, the Elementar vario MICROcube was used. Samples of approximately 20-50 mg were weighed into tin capsules and deposited automatically into the combustion chamber. Standards of known nitrogen concentration were utilized to create a standard curve calculate the amount of nitrogen gas produced and the amount of nitrogen present in the initial sample from the peak area. Weights and readings of standards and samples were stored by the machine’s software as it conducted the analysis.15 Three true replicates and three analytical replicates were run for this analysis.

Total protein content was calculated by multiplying total nitrogen content by a factor of 6.25, as this is standard in the literature on mealworms6 and in sweet potato flour.16 It is also the only acceptable conversion factor to calculate the PDCAAS on a per gram of protein basis (FAO/WHO/UNU, 1985). This factor is used because most proteins contain 16% Nitrogen (Nielsen, 2010).

Protein quality

Hydrolysis with hydrochloric acid and analysis using UPLC was the chosen method for amino acid analysis. Because there is no official method for amino acid analysis when determining the PDCAAS, Protein Digestibility Amino Acid Score, the method was chosen based on available resources. Acid hydrolysis was chosen over measuring free amino acids, because that is what is required for calculating the PDCAAS for FAO RUTF standards (FAO/WHO/UNU, 1985). Hydrochloric Acid was used since it is the most common used acid in determining the PDCAAS.17 In brief, sample was first ground and defatted, then mixed with water to inject into the specially designed hydrolysis tubes. The tubes were then lyophilized overnight to remove the water. About 0.1 - 0.01 g was hydrolyzed with 500μl 6N HCl overnight, as described in Guo et al., 2015, but under vacuum instead of nitrogen-capped.18 The hydrolysis product was then neutralized with an equal amount of 6N NaOH, diluted with Borate Buffer up to a 1/200 dilution, and derivatized for HPLC, the reagents for which are purchased as a kit.19 Reverse-phase HPLC utilizing derivatized amino acid standards allowed for quantification of concentrations of each amino acid.19

Prepared standards were injected twice, to help check the precision, while the derivatization of the amino acid standards alongside the samples ensures an accurate standard curve from which to extrapolate concentrations. The PDCAAS was calculated from these numbers assuming that, as for most animal proteins, the digestibility score is 100%.

Statistical analysis

JMP statistical software (SAS Institute, Cary, NC) was used to conduct ANOVAs on the data from the analyses. All variables were additionally analyzed with a Tukey’s HSD test to determine which treatments had significantly different values from the others. Standard deviations of results for different treatments were also compared.

The final experimental design stands to measure nutritional content and texture of extruded noodle with three final barrel temperatures: 75°C, 110°C, and 130°C. See Table 1.

Microbiology

In the series of dilutions used, the plates, at 10-3 dilution experienced only very dense growth around the outer edges of the plates for all treatments. The lower dilution was too numerous to count and the higher dilution experienced no growth at all. Due to this, it can only be concluded that the microbial load on the product after 3 weeks of storage is likely in the log-4 range (10,000-100,000 CFU/g).

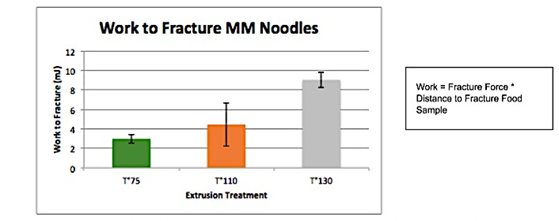

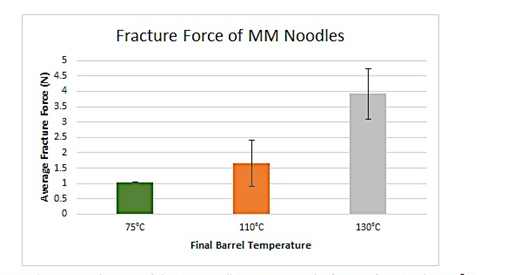

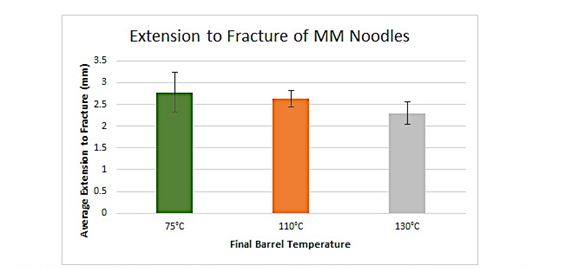

Texture

The texture results are shown in Figure 3, Figure 5, and Figure 6. A comparison of the noodles to other food samples is shown in Figure 4. The average ANOVA analysis revealed a trend (p=0.1175) of work to fracture noodles increasing as the final barrel temperature of the extruder increased. The average work to fracture the extrusion treatments was 0.088 mJ for 75°C, 0.14 mJ for 110°C, and 0.26 mJ for 130°C.

Figure 3 A trend was observed that as the final barrel temperature increased, the average work to fracture the MM noodles increased (p=0.084).

Figure 4 Average work to fracture food samples. The work to fracture the pretzel stick samples was significantly higher than the other food samples (p<0.001).

Figure 5 The average fracture of the noodle treatments. The force to fracture the 130°C treatment is significantly higher than the 75°C treatment (p=0.0414) and as a trend is higher than the 110°C (p=0.076).

Figure 6 The average distance to fracture the noodles. It appears as if the distance to fracture the noodles decreases with an increase of the final barrel temperature, however it is not significant (p= 0.429).

Water activity

The water activity is shown in Figure 7. The average water activity for all temperatures was 0.2815, with the lowest being 0.2586 for extrusion 1, 75°C and the highest being 0.3313 for extrusion 2, 75°C.

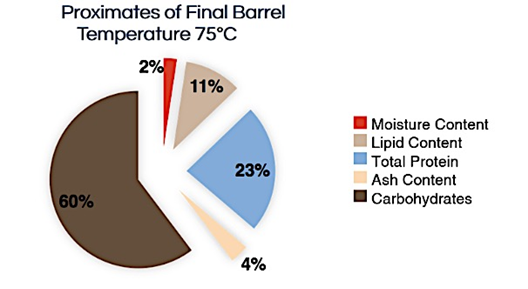

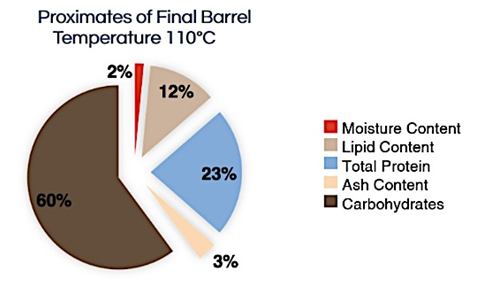

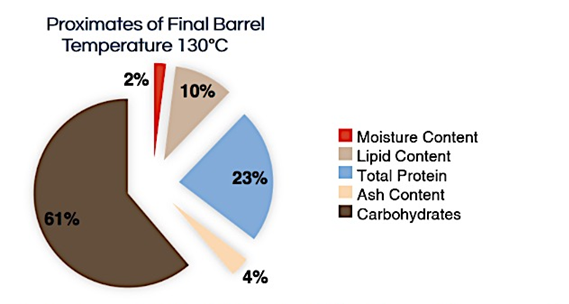

Proximates

Summary charts for the proximates of each treatment are shown in Figures 8–10. There is no statistical difference in moisture, lipid, or carbohydrate content among samples; there was however a statistically significant difference of 0.9% in total protein (p=0.0050).

Figure 8 Plot for the proximate data for the 75°C treatment. The Lipid, Protein, and Ash contents were all calculated on a wet weight basis, and the Carbohydrate content was calculated by difference.

Figure 9 Plot for he proximate data for the 110°C treatment. The Lipid, Protein, and Ash contents were all calculated on a wet weight basis, and the Carbohydrate content was calculated by difference.

Figure 10 Plot for the proximate data for the 130°C treatment. The Lipid, Protein, and Ash contents were all calculated on a wet weight basis, and the Carbohydrate content was calculated by difference.

Moisture content

The moisture content data is seen in Figure 11. Overall, there was not much variance in the numbers between treatments or extrusions. The standard deviation for extrusion 1 was closer than the standard deviation between treatments, suggesting the variance might be mechanical variance or environmental variance (moisture in the air).

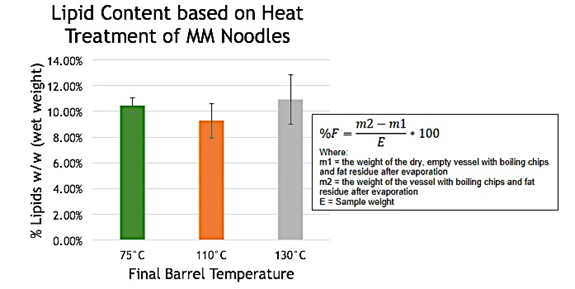

Total fat content

The fat content is shown in Figure 12. There was no statistically significant effect with extrusion treatment and total fat content in the MM noodles. The total fat content of the treatments was 10.55% for the 75°C, 9.72% for the 110°C, and 11.43% for the 130°C treatment.

Figure 12 The Percentage Fat equation used to determine the fat content of the dry content of the noodle and the average lipid content for the three final barrel treatments.

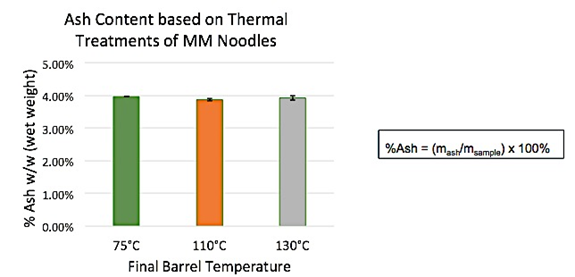

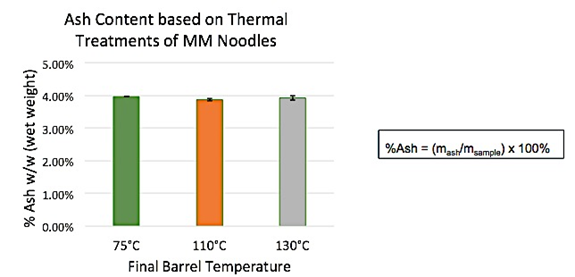

Ash

The average ash content across all treatments was 3.44%, and it did not vary significantly with treatment group (Figure 13).

Figure 13 Average ash content of all three treatment groups, shown with standard deviation between three production replicates. No significant differences were found between treatments.

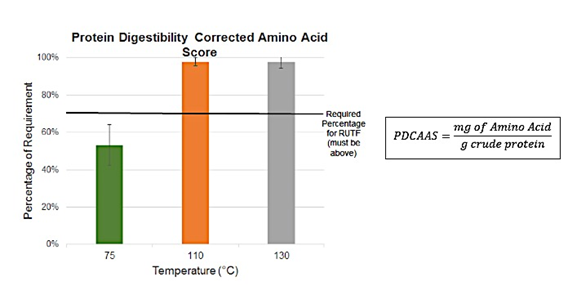

Protein quality

The protein quality is shown in Figure 14. The PDCAAS (Protein Digestibility Corrected Amino Acid Score) was calculated based on the equation in Figure15 (FAO/WHO/UNU, 1985). The amount of Tryptophan and Methionine + Cysteine was assumed to be adequate when calculating the score because the hydrolysis method used is known to destroy tryptophan and cysteine. A significant difference was found between treatment groups (p = 0.0050), with the 130°C treatment having significantly less protein content than the other two treatments

Figure 13 Average ash content of all three treatment groups, shown with standard deviation between three production replicates. No significant differences were found between treatments.

Figure 14 Protein content as a percentage of wet sample weight for all three treatment groups, shown with standard deviation between three production replicates.

Figure 15 The amount of the limiting amino acid as a percentage of the required amount for human dietary needs.

Temperature data was important to ensure that the lower heat treatment would still be sufficient to kill any internal pathogens, present in the mealworms. Mealworms took 32 minutes to reach 72°C, the desired internal temperature for inactivation of salmonella spp. (Silva and Gibbs, 2012), we could be confident that 1 hour at the reduced heat treatment would still produce an ingredient which was safe to use. Water loss was closely monitored because of an initial concern of mealworms not being fully dehydrated. However, mealworm larvae are approximately 60% moisture,6 data was consistently reaching this percentage at all time-points in runs; therefore, the issue was in fact the release of unsaturated fat during blending, not excess moisture. The fact that the average moisture loss dropped by about 5% when the actual production began is likely due to the fact that the oven was full and the crowding caused a slower rise in temperature or decreased the overall moisture loss by creating a moist environment.

Microbiology

Although the dilution scheme was comprehensive and would yield countable results, the results were not usable. We concluded the lack of results could have been due in part to our dilution scheme or due to human error while spread plating. The range of counts from those plates which could be used were within around a 1-log range of standard counts in powdered milk, which is a dried product with similar ratios of protein, fat, and carbohydrates and some similar microbiological concerns. Further research would definitely need to be done to get usable counts and to determine what microbes are present, whether they be spoilage concerns or pathogens.

Texture

It is possible that the increase of the final barrel temperature caused a greater degree of starch gelatinization which could have led to a more cohesive noodle structure which requires more work to break.9

Proximates

As noted before, there is no statistical difference between the treatments’ moisture, lipid, ash and carbohydrate content. There was a statistically significant but overall insignificant difference in protein content. From this, we can conclude that the proximate data for all treatment show no meaningful change across temperatures. These noodles are not affected by change in temperature in the range of 75-130°C or screw speed of 350-550rpm.

Water activity

The average water activity for all temperatures was 0.2815, with the lowest being 0.2586 for extrusion 1, 75°C and the highest being 0.3313 for extrusion 2, 75°C. The main concern with measuring and evaluating the water activities of our various extrusion temperatures is that they remain below 0.61. All of the samples we tested were well below this marker for shelf stability, and there was little variance between samples of the same treatment (no statistical significance). It was predictably measured that the treatment with the least application of heat (75°C final barrel temperature) had the highest water activity of around 0.3. Because all treatments were well below the limit, the water activity would not be a limiting factor in deciding which temperature is best for pilot scale extrusion.

Total fat content

There was no observable difference in the extracted fat content of the treatments. This is likely because fatty acids thermally degrade at far higher temperatures than what the noodles we subjected to. In a nitrogenous matrix, fatty acids thermally degrade into capric acid at 250°C. At 300°C, ketones and aldehydes start to be produced. In the presence of moisture, cotton seed oil can hydrolyze at 200°C.20 Therefore, the variability in the data is likely due to experimental error, not the variables in the treatment groups. The observed values were not far off of our calculated fat content, 13%. The expected total fat content was calculated by adding up the fat content of all of the ingredients and their respective parts.

Ash content

This is very close to the expected calculated value of 3.5%, which was based on reported proximate composition of individual ingredients.6,15 Since inorganic compounds that are measured by dry ashing are stable at temperatures of above 500°C, we didn’t expect to see much variation between treatments or loss during cooking compared to the raw ingredients. We were expecting that our measured value might have been further from the calculated value, however, as we assumed absolutely no moisture in the finished noodle because we had no way of calculating the amount of water added during extrusion or eliminated during dehydration. Additionally, the micronutrient composition of mealworms is known to vary pretty heavily with their diet.4The slight difference from the expected is likely due to one of these two factors, or due to rounding errors made when calculating.

Total protein

Because there has not been much research in the field of mealworms as a food ingredient and therefore little data on mealworm-containing products, total protein prediction of 21% was based on the proximate information for each ingredient and the amount of each ingredient in the product. The biggest protein contributor was the mealworms, which are estimated to have 14-25% protein (based on wet weight), and only a small amount from the sweet potatoes, 1.2% (Dansby and Bovell-Benjamin, 2003).22 In comparison to the noodle’s total protein of 23.12%, Plumpy’Nut, an already established peanut-based RUTF, has a total protein value of 13.6 of wet weight.23 While this is a good comparison for the noodle, it is important to note that the total protein of the MM sample is only looking at one part of the RUTF and would be lowered when the product meets the RUTF requirements for caloric and carbohydrate content.

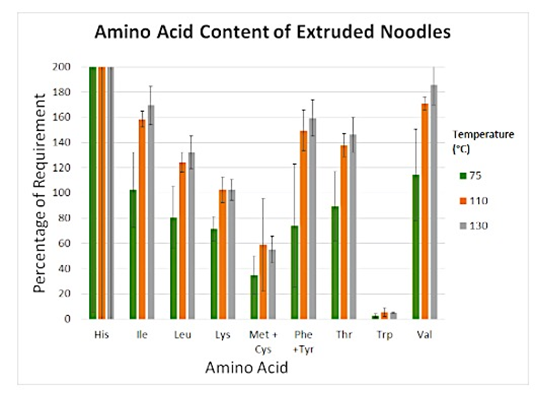

Protein quality

All of the 110°C and 130°C samples exceeded the required 70% of the PDCAAS, while none of the 75°C treatments did. The 75°C treatment had an average PDCAAS of 53.29%, the 110°C treatments had an average score of 97.76% and the 130°C treatments had a score of 97.64%. It should be noted that the calculated PDCAAS score assumed a digestibility factor of 1, as it normally is for meat products (FAO/WHO/UNU, 1985). For comparison Plumpy’nut, has a PDCAAS of 85%.8 The two higher heat treatments had significantly higher amino acid contents than the 75°C treatment (p<0.01). This is further illustrated in Figure 16, which shows the 75°C treatments having a lower amount of each amino acid shown. This may be due to the mechanism of hydrolysis used or the effect of protein and other compound breakdown with heating. If more protein was denatured in the higher heat treatments, there could be more protein opened up for the HCl to react with during hydrolysis, resulting in a higher amount. While there is not much research done of the effect of heating on hydrolysis, there has been some on the effect of heating and extruding. It has been noted in past research that protein digestibility increases with an increase in extrusion temperature in food products containing vegetable as well as some animal protein.13 This has been attributed to the inactivation of anti-nutritional factors, which can inhibit protein digestibility.

Figure 16 Amino Acid content averages for each treatment. Methionine + Cysteine and Tryptophan are not accurate of the amount present, due to destruction during hydrolysis. Histidine had well above 200% of the required amount.

Destruction of these inhibitors is shown to increase with an increase in temperature, up to 139°C.24 Other research has suggested a more complicated link between moisture flow rate, temperature, and amino acid content. Jiddere G, et al. have reported “extrusion at low temperature ranges of 100°C to 130°C” as well as a moisture “in the range of 20 to 30%” could be beneficial to retaining both reducing sugars and amino acids.25,26–37

The goal of this project was to produce a dried noodle product, which is suitable for use as an RUTF ingredient. To this end, we analyzed three different potential pilot-scale extrusion temperatures (75°C, 110°C, and 130°C) in order to assess their suitability. Texture, nutritional content, microbial load, and water activity of both products and the standard were also analyzed.

From the performed analyses, it can be determined that the 110°C and 130°C treatments are the most nutritionally viable, particularly in terms of protein quality. Based on the guidelines summarized in Table 3, all of the treatments made the requirements for total protein, moisture, water activity, mineral content; and the 110 and 130°C treatments made the requirements for protein digestibility as well. While none of the treatments contained the required carbohydrate or lipid amount, it should be understood that the noodle is only one part of the components for the RUTF final product and further formulations with inclusion of other ingredients for the finished product, could be made to hit those targets. Considering that the 110°C and 130°C treatments are statistically identical; in order to avoid further degradation of heat sensitive micronutrients, the 110°C treatment might be the most optimal treatment with regards to nutrition. Further research on the effects of extrusion parameters as well as an animal study will be needed to more clearly understand the differences in protein quality in the lower heat final temperature. With regards to safety, all of the treatments met the requirements of aw and moisture content based on guidelines summarized in Table 3. Due to the microbial experiments not yielding usable data, more research needs to be conducted to measure the microbial load of the products.

It is our recommendation that a factorial design be used to explore the ideal formulation and process of noodle production. A factorial examination of processing parameters, including those not examined in this study like water flow and screw speed, as well as raw ingredient formulation, would help to further explore effects like that seen on amino acid content, and to further optimize the process to increase protein digestibility or have other beneficial effects. We also recommend that a PDCAAS study and specific fatty acid quantification should be conducted to meet UNICEF requirements for an RUTF and to determine whether differences seen in amino acid contents are actually due to differences in protein availability. Additionally, sensory examinations will be key in the next phase to test whether locals in food insecure areas like the prototype noodle and will want to eat it. Additionally, another three-point bend should be conducted with an auditory recording device to quantify crispness and crunchiness.

None.

The author states there are no conflicts of interest.

None.

©2022 Feng, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.