Journal of

eISSN: 2574-8114

Research Article Volume 7 Issue 5

1Master in Design, Ritter dos Reis University Center (UniRitter), Brazil

2Federal Institute of Education, Science and Technology of Rio Grande do Sul (IFRS), Brazil

Correspondence: Luis Folle, Master in Design, Ritter dos Reis University Center (UniRitter), Porto Alegre, Brasil

Received: October 01, 2021 | Published: October 19, 2021

Citation: Folle LF, Theisen FC, Giuliano CP. Women’s jeans: influence of pressure in the sensation of comfort. J Textile Eng Fashion Technol. 2021;7(5):159-167. DOI: 10.15406/jteft.2021.07.00284

Jeans are considered the most democratic of garments, but some of them may be uncomfortable and, in view of this fact, the objective of this study was to evaluate the comfort obtained by women's jeans considering the influence of the pressure perceived by the users and the measured by sensor film in the interaction of the jeans with the body. By means of a quantitative research of a correlational character, the data on the perception of the comfort of the women's jeans were collected by the application of a questionnaire with students of higher and technical courses of the Federal Institute of Rio Grande do Sul - Erechim Campus, aged between 18 and 34 years. The answers were analyzed to see how the participants evaluate their bodies and the jeans available in the market. In the sequence, an experiment was carried out evaluating the perception of comfort that the users had in the use of jeans in different models and fabrics, as well as the pressure was measured by means of sensor film. The data were compared and correlated to determine pressure parameters considered comfortable by wearers during contact of the jeans with the body. It was observed that the pants with elastane presented different results in relation to the opinion of the participants and the pressure measurements shown by the sensors. That is, for both jeans with smaller sizes and those with larger sizes, participants rated jeans as comfortable, but the sensors measured higher pressure results for jeans of smaller sizes. This finding shows that by giving elasticity to the tissue, elastane may be masking excessive pressure being applied to the body and can cause health problems.

Keywords: fashion design, human factors, clothing, contact pressure

The jeans segment has grown and stood out in the market in recent years. Not always what is aesthetically attractive is comfortable and vice versa. Sometimes finding jeans that meet the psychological and physical demands of users becomes a relevant problem.

The comfort of clothing has been a fundamental necessity for the user and can be considered an attribute of product performance.1,2 However, according to Kamalha et al.1 users' preferences depend on their experiences and the social and cultural values of the environment where they are inserted that affect their perceptions of comfort. Therefore, the perception of comfort in relation to a clothing product will depend on the environment where the user is inserted and their actions when using the product. This can bring different physical, physiological and psychological sensations on different occasions. This situation highlights the complexity of assessing comfort.

According to,3 in the clothing segment, the dictatorship of the aesthetic segment that defined what people should wear is being replaced by the focus of people's health. In the same sense,2 concluded in their research that users seek to feel good and indicated the comfort and shape of clothing as the most important criteria in choosing the purchase.

For4 the good shape in a garment is an important factor that contributes to the confidence and comfort of the user. However, they point out that users have different preferences and even if they have the same biotype and have similar height and weight, when considering the shape and size of garments, their decisions for tight or loose clothing in the body may vary. In this way, the feel of the pressure applied by the garment on the body of each user may also differ.

By analogy, various authors cite clothing as a second skin3,5–7 so direct contact between the human body and the garment requires an evaluation complex to achieve satisfactory results that meet the needs of the user, which seeks to feel satisfied with the style of clothing used, as well as, to perform the body movements in a comfortable way. For this, it is fundamental to consider all aspects of the product and the user, from raw materials to the modes of use. Jeans, particularly women's jeans, are among clothing products that often present negative conditions due to the pressure that exists in the interaction with the user's body.

Many authors have focused on the study of thermophysiological comfort8–12 but others are conducting studies on the pressure of clothing products, since human interaction with clothes is constant. Commonly, clothing pressure studies are performed using sensors on the human body or manikins. Chan & Fan,13 evaluated strap pressure using balloon-type sensors and an LCD display to record pressure between the body and the strap. Subsequently,14 proposed the use of a standard mannequin to measure the pressure of the tapes. Dongsheng & Qing,15 evaluated the pressure of male suits using manikins and related the results obtained with the results measured directly in the human body. Nakahashi et al.,16 evaluated the negative effects of modeling belts on female body physiology in healthy women and examined how different materials, structure and size of a modeling strap would affect the pressure on the waist and abdomen of the wearer. Similarly, to assess the influence of the material and structure,3 measured the pressure exerted by bras on the body of Brazilian and Japanese users, by means of pressure-measuring sensors between the body and the wearer's bra. Also wearing the product on the female body,17 explored the effects of corset pressure on women's health by assessing changes in heart rate, blood flow, sweating and their metabolism during exercise. In this research it can be seen that the heart rate was decreased by up to 20% and blood flow at the fingertips by 36%, perspiration by up to 90% and energy expenditure increased by 14% compared to the control group. The results confirm the negative impacts of high-pressure clothing on women's health and the importance of knowing the consequences of wearing tight clothing in daily activities. Yan et al.,18 did a similar study but evaluated the effect of the sports bra on heart rate variation. This shows that there is a concern by researchers to understand the physiological response of these clothes and that they will impact the psychological performance of users. Because of this, there are studies that try to understand the psychological effects of pressure from clothes as in the works.19–22

Other works use numerical simulation to understand how the clothing interacts with the people as in the works of23–26 or algorithms are used to try to predict the pressure on the body as in the work of Cheng et al.27 There are efforts to scale the size of clothing using technologies such as virtual reality28 or 3D body scanning.29

In relation to these concerns about the pressure on the body, there is already a study that attempts to design a pant that relieves the pressure when performing some movement, as in the case of Bragança et al.,30 research, where the highest pressures exerted were measured on the body and in these regions were placed reliefs. This research was done with users who reported an increase in comfort after the pants were redesigned.

This experimental quantitative research aims to evaluate the effects of style and fabric on the comfort of women’s jeans. Comfort was determined by the wearer’s perception of pressure when adopting different postures and those subjective perceptions were compared with pressure directly measured by sensors in the jeans. The focus of the study was younger women. The results provide insights useful for designers and wearers of women’s jeans.

Selection and characterization of participants

Initially, questionnaires on body weight, height and shape were applied to 136 women students from the Federal Institute of Education, Science and Technology of Rio Grande do Sul – IFRS, Erechim Campus, between 18 and 34 years of age.

From the answers of this questionnaire, the participants who had an hourglass body shape were selected. This format was chosen because it represented the largest amount (56%) of the responses. This refers to the format that each user perceives her own body, that is, there was no external evaluation, only the perception of the users was evaluated.

Based on these results, it was possible to select which students would participate in the second phase of the research, since the determination of the biotype is of extreme relevance in the choice of the pant models to be produced in order to attend to the corporeal dimensions of the users. The intention in considering this variable was to know the biotype of the users who would wear the jeans and carry out the evaluations. The shapes of women’s bodies represented in the questionnaire were based on the study by Vuruskan & Bulgun,31 and are shown in Figure 1.

To define the number of jeans that needed to be made, the next step was to check the pant size with the highest frequency of use among the participants. It was verified that the greatest occurrences of use were sizes 36, 38 and 40 (these sizes are only used in Brazil). For these numbers, the highest occurring variation of weight and height was verified. Therefore, the association between the variables of weight and height with the greatest frequency and the variable of size was established. Thus, in this step, the diversity of measurements and types of bodies to be dressed with jeans for evaluation was reduced, with only 15 students remaining.

The characteristics of users who participated in the research are described in Table 1.

Size |

Minimum weight (kg) |

Maximum weight (kg) |

Oscillation Weight (kg) |

Minimum height (m) |

Maximum height (m) |

Oscillation Height (m) |

N° of Participants |

36 |

43 |

68 |

25 |

1.5 |

1.85 |

0.35 |

5 |

38 |

52 |

62 |

10 |

1.51 |

1.69 |

0.18 |

5 |

40 |

52 |

75 |

23 |

1.56 |

1.76 |

0.2 |

5 |

Table 1 Size of jeans and variation of weight and height

Definition of fabrics

The definition of the fabrics to be used in the making of the jeans was based on the properties of the fibers in the composition of the denim fabric, mainly in terms of their elasticity and touch as well as the weight, ligament type and color. Denim is a type of durable fabric made from cotton, linen or synthetic fiber in which only the warp yarns (longitudinal) are dyed with indigo dye, usually with twill ligament. The ligament is the way in which the threads that make up a fabric, the warp and the weft, intertwine.

Considering the objectives of this stage, it was understood that the elasticity of the fabric would be the most important variable, due to its capacity for greater elongation, being preferred in daily clothes to increase comfort.32 Therefore, it was decided to use fabrics with identical weight, ligament type, color and wash in the manufacture of jeans, altering only the composition variable. Thus, two denim fabrics with different properties were selected: a 100% cotton fiber fabric (Fabric 1) and another composed of cotton fiber (98%) and elastane (2%) (Fabric 2), as shown in Table 2.

|

|

Fabric 1 |

Fabric 2 |

|

Composition |

100% cotton |

98% cotton and 2% elastane |

|

Grammage |

10 OZ/yd² (339g/m2) |

10 OZ/yd² (339g/m2) |

|

Ligament |

3x1 |

3x1 |

|

Finishing |

Localized Super Stone-Used Wash |

Localized Super Stone-Used Wash |

Table 2 Characterization of fabrics

Definition of pressure gauge sensor

The pressure sensor chosen is characterized by being a flexible polyester film containing a layer of tiny microcapsules, called the Surface Profiler Film®, capable of revealing the distribution of the contact pressure between two surfaces. The thickness of the Surface Profiler Film® film is between 0.1016 mm and 1.1524 mm and is easily applied on curved surfaces and in small spaces. The amount of pressure applied to the film was defined in the pressure range between 1.4kg/cm² and 6.3kg/cm² as indicated in the product instructions, and can be observed by the color intensity of the film. The color intensity of the pressure gauge film is directly related to the amount of pressure applied to it. The more intense the color, the greater the magnitude of the pressure being applied.

Measurement chart

In the first phase of the survey, the measurements of all the 136 users who answered the first questionnaire were obtained. For this, eleven dimensions of the body that were relevant in the development of jeans modeling were verified (Table 3). Measurements were waist circumference, high hip, hip, thigh, knee, calf, hip height, thigh height, knee height, calf height (Figure 2) and button height.

|

Measurement position |

Description of the measurement |

|

Waist circumference |

The waist circumference was measured horizontally, approximately 2 cm above the navel. |

|

High Hip Circumference |

The circumference of the high hip was measured horizontally between the waist and hip line, in this case, positioned 12 cm below the waist line. |

|

Hip circumference |

The circumference of the hip was measured horizontally at the most salient point, passing the tape measure over the buttocks. |

|

Thigh Circumference |

The circumference of the thigh was measured horizontally at the most protruding point. |

|

Knee circumference |

The circumference of the knee was measured horizontally in the region located at the kneecap. |

|

Calf circumference |

The circumference of the calf was measured horizontally at the most protruding point. |

|

Hip height |

The vertical measurement from the side was taken, that is, the measurement between the waist line and the hip line. |

|

Thigh height |

The measurement between the waist line and the thigh line was measured vertically by the lateral. |

|

Knee height |

The waist line and the knee line were measured vertically by the lateral. |

|

Calf height |

The measurement between the waist line and the calf line was measured vertically by the lateral. |

|

Button height |

The distance from the waist line to the chair seat was measured vertically with the person sitting. |

Table 3 Description of the measurements taken of the jeans users participating in the research

The collection of anthropometric measurements was performed using a tape measure and adhesive labels that served to mark the height of each measured position. Thus, in order to prevent the clothes from interfering with the measurement results, a mesh pant was developed (Figure 3), which was worn by the students at the time of the measurements, without changing the shape of the body.

Of the 15 students selected, the measurements described above were obtained and an average of these measurements was made for each region of the body. With this, the measures were defined for the development of the pants to be made. These trousers resulted in 3 different sizes (36, 38 and 40). This size standard is used by Brazilian industries and was used as a reference. Table 4 shows the measurements defined for this experiment.

Size |

36 |

38 |

40 |

N° of Participants |

5 |

5 |

5 |

Waist |

67 |

72 |

77 |

High hip |

84 |

87,5 |

91 |

Hip |

93 |

98 |

103 |

Thigh |

54 |

57 |

61 |

Knee |

37 |

39 |

42 |

Calf |

34 |

36,5 |

39 |

Hip height |

20 |

22 |

24 |

Thigh height |

29 |

32 |

35 |

Knee height |

53 |

55,5 |

58 |

Calf height |

64 |

69 |

74 |

Button height |

24 |

26 |

28 |

Table 4 Average measurements of the female body, in cm, taken before the creation of the jeans

Design, fitting and manufacture of pant style

Since the idea of this research was to measure the pressure of the garment on the body and compare with the wearer’s perception of pressure, the goal was to develop jeans with a silhouette that molded the body without compressing it. The silhouette of the product is determined by the way the clothing covers the outline of the body. A close-fitting silhouette are those jeans that mold to the body without squeezing it.

The jeans initially tested showed variations in height and curvature of the button, waist circumference and leg width. It was noticed that differences in jeans style could influence the answers on the evaluation given by each user. Thus, in this work, precautions were taken to select jeans that were aesthetically similar in order to not influence the responses given by the users.

Based on the table of measurements (Table 4) and on the chosen fabrics (Table 2), the pattern was defined, observing the shrinkage of each fabric after washing, as the jeans would pass through finishing processes when laundered after being made. Thus, from the measurements of table was added the shrinkage predicted in the processes of washing and movement gap in each of the models. According to Osorio,33 the movement gap is the smallest gap that is increased in the fabric in specific points of the body in order to allow its movement. The added movement gap varied between the modeling due to the characteristics of the fabrics used and also to test the influence of the modeling in different dimensions.

Among the two patterns tested, the close-fitting type is characterized by smaller dimensions when compared to the traditional fit. The close-fitting jeans are 4 cm shorter in circumference measurements, 1.5 cm shorter at the front button height and 0.7 cm shorter in the back rise than the traditional fit, with different requirements due to the fabrics of the jeans. As mentioned, the fabrics used are different only in the composition, being called as Cotton Fabric, which is 100% Cotton and Mixed Fabric which has 98% Cotton and 2% Elastane.

Based on the definition of the fabrics and modeling, the jeans used in the experiment were characterized as Jeans 1, Jeans 2, Jeans 3 and Jeans 4, as described in Table 5.

Jeans |

Type |

Jeans 1 (style 1) |

Close-fitting and Mixed Fabric |

Jeans 2 (style 1) |

Close-fitting and 100% Cotton |

Jeans 3 (style 2) |

Traditional fit and 100% Cotton |

Jeans 4 (style 2) |

Traditional fit and Mixed Fabric |

Table 5 Types of jeans tested in the research

Based on the predicted shrinkage for Fabric 1 (100% cotton) and Fabric 2 (98% cotton and 2% elastane) and on the measurements defined for this research, the design of the base size 38 was developed manually by two-dimensional design.

Then, the adjustment of base size 38 for sizes 36 and 40 was performed using the CAD system. For this, the two jeans patterns were scanned and imported into the Audaces Molds software (Audaces is CAD software used for creating and developing garments. In the specific case of pattern-making and adjustments, it is possible to quickly create and scale patterns with the tool, which ensures very sensitive precision indexes), where the necessary corrections were made and the patterns adjusted. The adjustment measurements were determined by the differences between each size, verified in the table of measurements. Later, the jeans were fitted using the Audaces Fitting software and plotted for delivery to the jeans production industry.

The industry developed the spread manually, employing the zigzag spreading mode, and the fabric was cut using a 5” vertical blade cutting machine. The sewing procedure was divided into stages, initially with the front and back parts prepared, then the assembly and finishing of those parts made. The entire process used proper industrial machines for making Jeans, for instance, a Single Needle Lock Stitch and a Double-Lock Stitch machines, Overlock machines, a Flatlock Sewing machine, a Bartack machine, a Waistband Attaching machine, a Button Hole machine, a Button Attaching machine, and a Riveting machine. With the sewing completed, residual threads were removed from the clothing, the measurements were checked and the garment was delivered for washing.

It is important to note that sizes 36, 38 and 40 are the mean of the wearers' body measurements, not the pants. With body measurements, two styles of pants were developed, one close-fitting and other traditional fit for each numbering (36, 38 and 40) as shown in Figure 4. In total, 12 trousers with an association of different fabrics and models were made, three in each style and one in each size. Between each test with the participants, the jeans were washed so that the elasticity of the fabric returned to normal.

Position of sensors

The pressure sensors were placed in regions of the body where the jeans usually applied high pressure. These regions were defined based on questioning done with the 136 female students during the first phase of this research. These locations were positioned at the upper (PS1) and lower (PS2) waist, front (PS3) and rear of the thigh (PS4) and front (PS5) and side of the knee (PS6) (Figure 5).

Sensor positioning mode

In order to avoid interfering with the wearer's sensitivity and the elasticity of each pair of jeans, a thin and smooth mesh fabric was used. This fabric was sewn on the pants so that the sensors could be fitted between the jeans and this fabric, in positions PS 1, PS 2, PS 3 and PS 4 (Figure 6). The stitching of the fabric on the jeans was performed manually with long stitches and no lashing at the beginning and at the end of the seam to avoid interfering with the elasticity of the pant fabric.

Figure 6 Fabric sewn on the jeans, identifying the points and the shape of the insertion of the pressure sensors.

In positions PS 5 and PS 6, an elastic was prepared with the same stitched mesh fabric used in the jeans and folded into an "envelope" into which the sensors were fitted (Figure 7).

Figure 7 Tailored fabric forming an envelope into which the pressure measuring sensors were inserted in the knee region. Instrument used to position the sensors in the knee.

Fitting of the jeans

As the pressure sensor is very sensitive, it could register a pressure the moment the pants were worn. This would mean that the recorded pressure was not that of the actual use in certain anatomical positions, but rather the pressure the user would make to wear the pants, which was not the purpose of this study.

To avoid this, a side opening with a zipper was placed on one of the legs from the hem to just below the knee height of 85 cm in length. The trousers were dressed with the zipper fully open, thus favoring the placement of the sensors on the leg.

Anatomical Positions for Evaluations

The positions chosen to evaluate comfort were defined from tests in which the pants would bring difficulty to the user's movement. Thus, movements of the lower limbs were performed, interfering with the pressure between the jeans and the wearer's body. During the tests it was noticed that, even if the jeans were aesthetically pleasing in the erect position, it would be important to know the perceptions of the users in that same position to compare with other anatomical positions. In Table 6, the four movements are described to reach the predicted positions. The sitting position was not tested because it was considered that AP4 would be more severe than the sitting position and would simulate this condition more effectively. Positions were measured only once because the pressure sensor records the maximum pressure detected for that position.

|

Positions |

Description of movements |

|

Anatomical Position 1 – AP1 |

Maintaining the body erect. |

|

Anatomical Position 2 – AP2 |

Maintaining the body straight, the user flexes the left hip and knee at an angle of approximately 90º and positions the left foot on a bench. |

|

Anatomical Position 3 – AP3 |

Maintaining the position of the lower limbs according to AP2, the user flexes the body forward to place her hands together with the left foot on the bench. |

|

Anatomical Position 4 – AP4 |

The user crouches on the side of the seat while flexing the lower limbs to the maximum and resting her hands on the bench for better balance. |

Table 6 Description of the positions for experiment with jeans

According to the movements described in Table 6, the positions are represented in Figure 8.

Evaluation of the tightness of the pants felt by the participants

During the experiment, the users answered to a questionnaire which was intended to evaluate the comfort that the participants feel when they used each pants for each test position.

They answered their perceptions of tightness in the regions of waist circumference, high hip, hip, thigh and knee. The evaluators rated their satisfaction levels for comfort on a five-choice Likert scale, with 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight as an option.

Perception of comfort by users regarding anatomical positions, jeans and body regions

Each pant was evaluated by the user in the four anatomical positions established for the experiment. Thus, in the AP1, AP2, AP3 and AP4 positions, the respondents answered the same questions, which sought to understand the feelings of comfort and discomfort caused by the jeans, especially regarding the pressure between jeans and the female body in those positions.

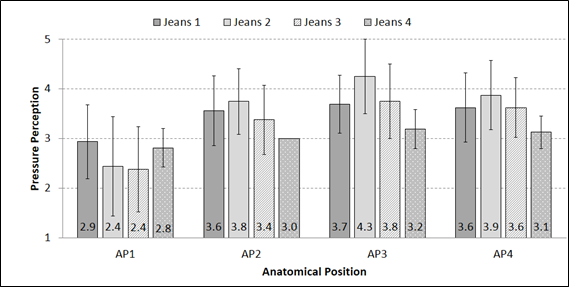

Waist circumference

Regarding the waist circumference, when checking the perceptions observed by the users for each pair of jeans, it was noted that in AP1, jeans 1 and 4 were described as the tightest, but in this position, all jeans were loose with averages less than 3, that is the answer option that represents the perception of comfort. In AP2, AP3 and AP4, jeans 2 presented the highest levels of pressure to the users. Jeans 4 were the ones in which there were lower pressure levels in AP2, AP3 and AP4, close to or very close to the ideal comfort range (3) (Figure 9).

Figure 9 Perceived pressure by wearers in the waist region of each pair of jeans at different anatomical positions (AP). The pressure perception in the y-axis is 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight.

Considering the average pressure obtained in each anatomical position, regardless of the evaluated jeans, it was found that for the waist line, AP3 reached the highest pressure levels, making the jeans less comfortable or even unwearable. On the other hand, because it is the position in which the body remains in the upright form without moving the jeans fabric, AP1 resulted in the lowest pressures and the greatest level of comfort for users among the four positions tested.

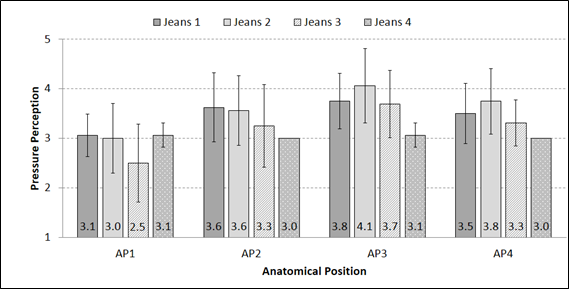

High hip circumference

Analyzing the average comfort provided by each pair of jeans in each anatomical position, it is observed that in AP1, jeans 1 and 4 were considered tighter but very close to the average considered comfortable. In AP2, jeans 1 and 2 were judged to be the tightest and jeans 4 as being the least tight. In AP3 and AP4, jeans 2 were considered the tightest, followed by jeans 1 and 3, while jeans 4 again showed the greatest comfort and the least amount of variation in the users' scores, obtaining the lowest standard deviation (Figure 10).

Figure 10 Pressure perceived by the users in the region of the high hip in each pair of jeans in the different anatomical positions (AP). The pressure perception in the y-axis is 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight.

In relation to the average recorded for all APs, regardless of the jeans worn, AP3 recorded the highest mean, i.e., the greatest tightening sensation, followed by AP2, AP4 and AP1. For the hip region, it is observed that all the anatomical positions presented some degree of superiority to the value assigned as comfort, that is, they were tighter. Thus, this indicates that the patterns used in this position should be readjusted to the point of resulting in greater comfort for the user than those observed in this study.

Hip circumference

By analyzing the feeling of tightness in the hip region for each pair of jeans and every AP, it was possible to note that in AP1, jeans 1 and 2 were judged as those with the highest pressure. Jeans 3 was considered the most comfortable in AP1 and jeans 4 were the most comfortable for the other positions (Figure 11). With the exception of jeans 4 in AP2, AP3 and AP4, the feeling of tight in the hip region was evident in the evaluated jeans, as they interfered with the movement of the users.

Figure 11 Pressure perceived by the users in the region of the hip circumference in each pair of jeans in the different anatomical positions (AP). The pressure perception in the y-axis is 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight.

In relation to the average recorded in all APs, regardless of the jeans worn, AP3 registered the highest mean, that is, the greatest tightening sensation, followed by AP2, AP4 and AP1. For the hip region, it is observed that all the anatomical positions presented some degree of superiority regarding comfort, that is, they were tighter. This indicates that the patterns used in this position should be readjusted to the point of resulting in greater comfort for the user than those observed in this study.

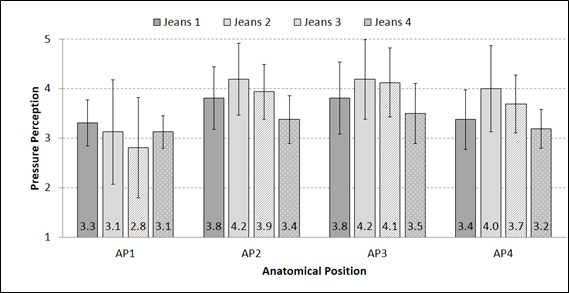

Thigh circumference

When assessing the pressure between the thigh and the jeans, the perception indicated refers to the position in the upper thigh, where another pressure gauge sensor was later positioned for posterior correlation.

In the interaction of each pair of jeans with the thigh region, the means of users’ perception indicated that in AP1, jeans 1 obtained the highest levels of pressure, while in the other APs, it was jeans 2. The lowest perception of pressure (greater comfort) during AP1 was obtained with jeans 3, while in the other APs it was jeans 4 (Figure 12).

Figure 12 Pressure perceived by users in the thigh region for each pair of jeans in the different anatomical positions (APs). The pressure perception in the y-axis is 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight.

The results indicated the following order of interference: AP3, AP2, AP4 and AP1 when evaluating the APs that most interfered with the sensations in the thigh region, independent of the jeans.

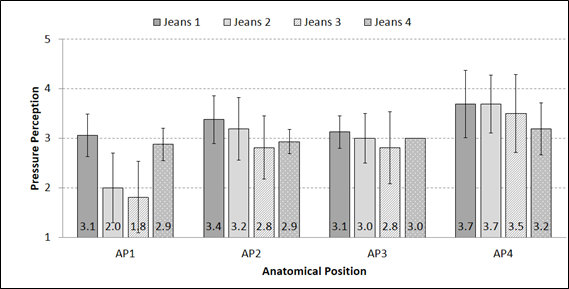

Knee circumference

When analyzing the averages of each pair of jeans in each AP, it was observed that, in AP1, AP2 and AP3, jeans 1 were perceived as having greater pressure, whereas in AP4, jeans 1 and 2 were the same on average. This AP also had a higher pressure index when the responses for all jeans were observed in all the anatomical positions (Figure 13). Additionally, in the evaluation of the lower pressure, it was noted that jeans 4 were judged to be less tight in AP4, while in the other APs, jeans 3 generated lower levels of pressure.

Figure 13 Pressure perceived by users in the knee region in each pair of jeans in the different anatomical positions (APs). The pressure perception in the y-axis is 1-very loose, 2-loose, 3-comfortable, 4-tight and 5-very-tight.

The means of perceived pressure during anatomical positions were lower in the knee region than in the other regions (waist, high hip, hip and thigh). Regardless of the jeans, the highest interference was found in positions 4 and 2. Considering that the jeans styles were not adjusted in the knees, the pressure perceived by the users suggests a high interference with the movements and the permanence of the user in AP4.

Measurements through sensors

The Sensor Surface Profiler Film® – SPF B had good flexibility and adequate thickness to assess the pressure between the jeans and the body. The results obtained through its use, as well as its measurement capacity of 1.4kg/cm² up to 6.3kg/cm² were evaluated in order to assess the range of pressure that marks the change between comfort and discomfort in the user.

Sensor 1, positioned at the top of the waistband (Figure 5, PS1), stood out as the one with the highest pressure and the highest pressure and widest range of pressures in all tested jeans, ranging from 3.5kg/cm² in jeans 4 to 5.7kg/cm² in jeans 1 (Figure 14). Half of this sensor was positioned under the pants and half past the waistband; thus, the recording occurred at the end of the fabric. Normally, in this position, the existing pressure can be easily perceived. In addition, this process facilitates standardization at the place of positioning between the pants and the user, because regardless of the user's biotype that influenced the position of the other sensors, this sensor always remained at the end of the tissue with a portion below the tissue.

Figure 14 Pressure measured by sensor film in wearers of jeans in different jeans and sensor positions on the body.

Regarding the comparison with the users' responses and the pressure measurement, it is possible to verify some situations of pressure perception. In the knee, for example, the users' perception was, on average, comfortable; however, the sensors measured high pressures toward the front. In the waist, the highest pressure measurement for all the jeans was registered. However, jeans 1 registered the highest pressures, and in the testimonials of the users, on average, there was a sensation of comfort. This may show that the elastane masks the sensation in the users and could be harmful to their health. However, if the style is in the correct size, the elastane can act as a pressure relief, because jeans 4 registered the smallest pressures on the body.

In the front and upper thigh, the pressures were on average similar, which shows that when performing a squat (AP4) or upper-body movement (AP3), all jeans will generate tightness. In this sense, designers should pay attention to the choice of fabrics and the use of correct style (looser in this region) to allow greater comfort, well-being and safety in the execution of the movements. It is important to note that the pressure sensors measure the maximum pressure that has been imposed, which does not mean that the pressures will be high in all positions.

Another important observation is that the measured pressure is relatively high (2 to 6 kg/cm2), that is, at the lowest recorded pressure, there will be 2 kg of force per cm2, which, over a whole day, can be harmful to health.

The study by Chan & Fan,13 evaluated which pressure strap that shaped the body was comfortable according to the perception of the users. Through an experiment, they compared the subjective perception of the users felt in the tightness of the straps with the pressure measured by the sensors positioned between the straps and the body of the users. Based on the results, they suggested an average pressure considered ideal at each point of the body so that the brace would be able to shape the body and also be comfortable. However, the largest measured pressure was approximately 30 mmHg (0.04 kg/cm²); i.e., the pressure measured by Chan & Fan,13 is approximately 150 times less than the highest pressure measured in this study (6kg/cm²).

Recently, a case was reported worldwide of an Australian woman who, after wearing slim-fit skinny jeans while squatting and organizing closets, began to feel difficulty when walking and swelling in the legs. The next day, she had a sudden illness in the street and her feet became numb. She had to be rescued and referred to a hospital where she stayed for four days until she rehabilitated her muscular and neurological functions.34 This situation exemplifies the adverse effects that constrictive clothing, such as some jeans, can cause in users, and that some users may be unaware of these potential problems or may disregard them in favor of the appearance of the product.

Considering the perceptions of the users, it was noticed that the jeans with smaller size (style 1 or close-fitting) when made in 100% cotton fabric (jeans 2) in the interaction with the body cause a greater sensation of tightness. On the other hand, the larger size (style 2 or traditional fit) jeans with elastane resulted in a more favorable interaction according to users (jeans 4).

It was also noticed that, among the four anatomical positions evaluated, the AP3 was the one that the users said had a greater sensation of tightness in the regions of waist, high hip, hip and thigh. Only in the knee region did the pressure increase for the AP4 when the participant crouched. In AP1, there were the smallest interferences. In relation to the pressure measured by the sensors, the smaller size of the trousers with elastane (jeans 1) was the one that registered the most pressure, and the trousers with larger size and elatano were the ones that measured the lowest pressure values (jeans 4). The evaluation of jeans 4 was consistent in the two forms of evaluation, indicating less pressure associated with greater comfort. The higher pressure measured by the sensors in jeans 1 was not perceived by the users. Probably the explanation is the composition of the fabric of this jeans, because it contains elastane mixed with cotton, the fabric becomes more malleable and follows the movements of the users even when the pants are tight without causing a sensation of discomfort.

Considering what has been said above, it has been noticed that the use of an elastane pants, with a small size (style 1 or close-fitting), causes that the users are being subjected to an excessive pressure without they even notice. Due to this, the excess pressure of the product on the body during daily activities impairs the movements, does not allow the user to remain in some positions, or even cause damage to health, since this too great pressure can promote a lack of circulation of the blood in regions where pant pressure is higher.

It is important to note that elastane alone is not responsible for excessive pressure on the body but rather the use of it in pants with a smaller size (style 1 or close-fitting). If not too tight pants is used, the elastane will help to maintain the comfort of the garment over the body, regulating the pressure according to the movements.

Although the pressure sensor measures the maximum pressure that has occurred during use, the Film Sensor Surface Profiler Film® – SPF B can be used between the body and the jeans without interfering in the pressure results during the interaction, allowing measurement of the average pressure range considered comfortable for most users in the waist, thigh and knee regions.

Above all, based on the results, it is important to evaluate the comfort of women's jeans considering the influence of the pressure perceived by users and the pressure measured by sensors in the interaction of jeans with the body, since comfort depends on many variables, among them pressure.

Finally, it is important to emphasize that this study was limited in the analysis of hourglass body type. For the other body types, similar analyzes would have to be done to see if the results are the same. Another limitation of the study was the sitting position analysis, which was not evaluated as well. Since this position is practiced in many situations because of work, for example, it is likely that the pressures in this position are as high as the measures in this study.

This study was supported by the Federal Institute of Education, Science and Technology of Rio Grande do Sul (IFRS).

None.

The authors declare there is no conflict of interest in publishing the article.

©2021 Folle, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.