Journal of

eISSN: 2574-8114

Mini Review Volume 7 Issue 1

1Faculty of Textile Engineering, Technical University of Liberec, Czech Republic

1Faculty of Textile Engineering, Technical University of Liberec, Czech Republic

2Faculty of Technology and Design, Khmelnytskyi National University, Ukraine

2Faculty of Technology and Design, Khmelnytskyi National University, Ukraine

Correspondence: Lubos Hes, Faculty of Textile Engineering, Technical University of Liberec, Czech Republic, Tel +420 720 515 964, Tel +420 720 515 964

Received: December 24, 2020 | Published: January 27, 2021

Citation: Hes L, Manákova M, Paraska O. The effect of long time wear on thermal comfort properties of various parts of denim trousers. J Textile Eng Fashion Technol. 2021;7(1):12-14. DOI: 10.15406/jteft.2021.07.00262

In this paper, thermal comfort parameters of various parts of selected standard denim trousers subject to 2 years of daily wearing are experimentally investigated, both under dry and wet state. The study is based on the use of fast testing instruments, which require small testing samples and quick measurement. From the study, it is inferred that wearing of denim trouser really changes the properties, some of them negatively, but the affected areas are small.

Keywords: denim trousers, wearing, zones, thermo-physiological comfort, wet state

Denim garments manufactured from densely woven using cotton yarns became very popular in the last couple of decades, as they offer excellent sensorial comfort when worn, due to low bending rigidity of the used yarns and good moisture sorption.1 At low sweating level, the absorbed moisture does not deteriorate substantially thermal properties of the garments and hence the total comfort properties are very good. However, denims, as well as other fabrics are often used also as the sports and outdoor clothing, where they can be exposed to higher levels of moisture, due to sorption of rain water or in case of intensive sweating.2 In this case, unfortunately, these garments in wet/moist state may exhibit low thermal resistance, cool contact feeling and low water vapour permeability (WVP), as wetted cotton fabrics can swell and hence block big pores in the structure. Research reports on thermal comfort properties of denim fabrics in wet state are few,2,3 as standard testing instruments, due to long time of measurement of samples, do not allow reliable determination of their comfort properties in wet state (the measured sample gets dry when the testing time is longer than 10 minutes). That is why in this study, special PC evaluated commercial ALAMBETA and PERMETEST testers were used to provide reliable non-destructive measurement of thermal insulation and thermal contact properties of fabrics in dry and wet state as well as their WVP respectively, in a very short time of measurement.2 Both instruments are non- destructive testers, and the required minimum size of the sample is just 14x14mm, which enabled to measure thermal properties of different zones of real trousers. In this paper, thermal conductivity λ, thermal absorptivity b (in dry and wet state) and evaporation resistance of various parts of 600 days used standard denim trousers were determined. The test results thus obtained are presented along with the inferences.

Thermal resistance ‘R’ and thermal conductivity ‘λ’ are the basic parameters of thermal comfort of fabrics and the former depends on fabric thickness ‘h’:

(1)

For the purpose of this study, it is important to note, that thermal conductivity of liquid water is taken as 0.61W/m/K whereas thermal conductivity of dry textile fabrics lies in the range 0.033–0.09W/m/K. That is why, the amount of the moisture absorbed in the fabric should not exceed certain threshold level, otherwise thermal comfort properties of the denims would get reduced.

Thermal absorptivity ‘b’ of fabrics was introduced by Hes4 to characterise thermal contact feeling during short contact of human skin with the fabric surface. Here ‘ρc’ [J/m3] is thermal capacity of the fabric.

(2)

The ‘b’ values under approx. 250 [Ws1/2/m2/K] presents warm and dry feeling, whereas the ‘b’ values over approx. 400 [Ws1/2/m2/K] means dry and cold feeling, and the wet & cold feeling is felt at the ‘b’ values over 500 [Ws1/2/m2/K].5

Thermal absorptivity of fabrics, as well as their thermal resistance and thermal conductivity were in this study determined by the new ALAMBETA tester displayed on the Figure 1. New tester employs the same measuring principle as the previous model, but the new the device is smaller, lighter (7kg) and enables easier calibration of all the measured thermal parameters.

Figure 1 Alambeta computer interfaced commercial non-destructive tester of thermal properties of textile fabrics.5

Water vapour permeability was measured using PERMETEST instrument6 which measures the parameter in the form of relative water vapour permeability ‘P’ [%], or preferably as evaporation resistance ‘Ret [m2 Pa/W], as per international standard ISO 11092. The lower is the ‘Ret’, the more permeable is the tested fabric for water vapor. According to this standard, fabrics with ‘Ret’ values below 6 [m2 Pa/W] are considered as well permeable, and fabrics with ‘Ret’ lower than 13 [m2 Pa/W] still offer acceptable water vapour permeability.7

Testing of fabrics

Samples were cut from standard blue twill denim trousers worn daily for 2 years. The original square mass was determined from a piece of fabric protected against wear under the unused pocket. It was 405g/m2, and the same square mass was found at the sample from thigh zone. A bit lower was the mass of the sample from the limb zone, 404g/m2. However, due to the wear, the mass of a fabric around the zipper was reduced to 397g/m2, and the sample mass from the knee zone was logically the lowest one, 392g/m2. As the biggest mass difference was found for samples from pocket and knee, these 2 samples were used for the evaluation of the wear effects. As mass effects were still quite low, the thickness of these 2 fabrics was practically the same. That is why in the study, changes of thermal resistances were not evaluated, only differences in thermal conductivity, as these may reflect the changes in compactness and porosity, caused by the wear were measured.

The samples in dry state were measured for the thermal conductivity values for 3 times, the wetted samples were tested only one time, as adjustment of the same moisture content is not feasible. Relative humidity U of the samples is given by mass of the wet sample minus mass of the “ultra–dry” sample divided by the mass of the ultra–dry sample (achieved after drying the samples in the hot air oven for 20mins.). The result thus obtained was multiplied by 100. To obtain relative humidity/moist percentage. The samples were kept in water for more than 12 hours and then stepwise mechanically dried. Due to relatively high thermal conductivity of water, ‘λ’ of wet fabric exceeds the level 0.09 [W/m/K] (Table 1).

|

Denim trousers |

Ret |

λ dry |

λ U=20% |

λ U=40% |

‘b’ dry |

‘b’ U =20% |

‘b’ U=40% |

|

|

[m2Pa/W] |

[W/m/K] |

[W/m/K] |

[W/m/K] |

[Ws½/m2/K] |

[Ws½/m2/K] |

[Ws½/m2/K] |

|

Zipper |

6.1 (6.6) |

0.0610 (1,4) |

0.11 |

0.13 |

210 (4,5) |

490 |

570 |

|

Thigh |

6.4 (4.0) |

0.0616 (1,9) |

0.107 |

0.119 |

195 (6,9) |

470 |

625 |

|

Knee |

6.2 (6.4) |

0.0522 (7,2) |

0,109 |

0.127 |

175 (2,8) |

530 |

579 |

|

Free calf |

6.5 (4.5) |

0.0604 (0,9) |

0.111 |

0.125 |

180 (3,1) |

505 |

590 |

|

|

4.7 (4.8) |

0.0584 (6,7) |

0.09 |

0.12 |

214 (2,6) |

475 |

665 |

Table 1 Thermal comfort parameters of denim fabric from trousers worn daily within approx. 600 days. Numbers in parentheses present levels of the related Variation Coefficient (%). This coefficient cannot be determined for samples in wet state, as preparation of samples with the same moisture level (for the repeated measurements) is very uneasy.

From the results follow, that the sample protected against abrasion - considered as new fabric, exhibits surprisingly the lowest evaporation resistance or highest water vapour permeability. It can be attributed to the highest inter–yarn porosity, as the cotton fibres fibrillation (hairiness) is still low, due to missing fabric surface and inter–yarn friction (low dislocation of fibres).

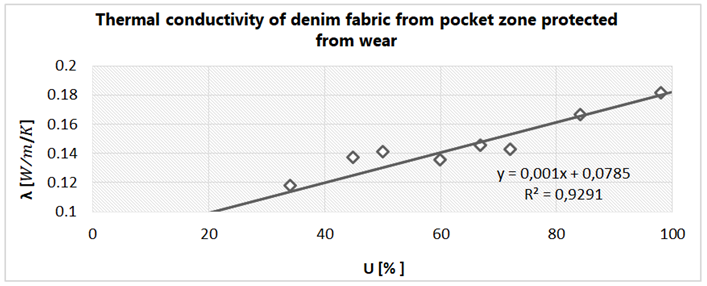

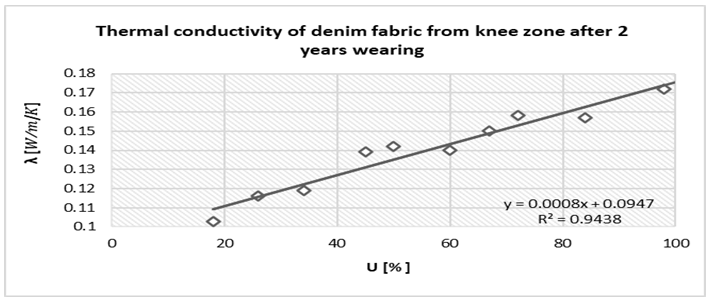

As regards dry thermal conductivity, the lowest value or highest thermal resistance was found at the knee sample due to the most intensive wear effect resulting in internal yarn fibrillation and hairiness. On the contrary, in wet state the finer internal structure causes higher levels of this parameter (Figure 2) (Figure 3).

Figure 2 Thermal conductivity of denim sample protected from wear as function of its relative moisture content.

Figure 3 Thermal conductivity of denim sample from the knee zone as function of its relative moisture content.

The determined thermal absorptivity ‘b’ reveals similar behaviour as that for thermal conductivity. In dry state, the knee sample exhibited the lowest ‘b’ value, due to the lowest level of thermal conductivity (see the mutual effects from the Equation 2), but in wet state, the knee samples exhibited the highest thermal absorptivity. However, the highest wet thermal absorptivity level was found for the pocket, wear–free sample, with the lowest surface hairiness (lowest portion of air in the contact layer).8

From the presented investigation of the effect of long-time wear of denim fabrics (trousers) on their thermal comfort properties follows, that wearing really changes these properties, both in dry and wet state. The reduced water vapour permeability of worn sample may reduce thermo-physiological comfort of a wearer, but the effective water vapour area (knee zone) is small. In wet state caused by sweat and rain moisture, thermal insulation properties of worn parts of the trousers are lower than these of the (simulated) new denim fabric. Regarding wet thermal absorptivity level, the worn zones of trousers indicate even dryer thermal contact feeling. The study confirmed the importance of experimental research based on simulation of real wearing conditions of fabric by means of special fast working testing instruments.

None.

None.

There is no conflict of interest in publishing articles according to the author’s declaration.

©2021 Hes, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.