Journal of

eISSN: 2574-8114

Research Article Volume 4 Issue 3

Department of Wet Process Engineering, Bangladesh University of Textiles, Bangladesh

Correspondence: Kawser Parveen Chowdhury, Assistant Professor, Department of Wet Process Engineering, Bangladesh University of Textiles, Address: 92, Shaheed Tajuddin Ahmed Avenue, Tejgaon, Dhaka-1208, Bangladesh, Tel 8801716167777

Received: May 25, 2018 | Published: June 6, 2018

Citation: Chowdhury KP. Process intensification of fluorocarbon-free and fluorocarbon-based water repellent finishes on cotton knit fabrics. J Textile Eng Fashion Technol. 2018;4(3):199-207. DOI: 10.15406/jteft.2018.04.00146

The capabilities of the fluorocarbon-free alkyl urethane based resin, was analyzed on cotton fabric. In this study, both single jersey and double jersey knit structured fabrics were taken to evaluate the performance of different water repellent finishes on fabrics properties. The performance of the fluorocarbon-free alkyl urethane based resin and fluorocarbon based water repellent chemicals were evaluated and compared at different formulations. The effectiveness of water repellency of the finished fabrics were evaluated by AATCC 127 hydrostatic head test method and by ISO 4920:2012 spray rating test method. To assess the performance of water repellent finished knit fabrics, GSM, bursting strength test, stiffness, color fastness to wash, color fastness to sea water, color fastness to saliva, color fastness to rubbing, color fastness to light were done according to ISO and ASTM method. The results showed that the fluorocarbon-free alkyl urethane based resin treated fabrics exhibited competitive result on water repellency, other physical and chemicals properties. The water repellent finish type and concentration were very important criteria to obtain good water repellency. Environmental friendly fluorocarbon-free water repellent chemicals could be a good alternative than fluorocarbon based water repellent chemicals.

Keywords: water repellent finish, water repellency, single jersey fabric, double jersey fabric, environmental friendly finishing, fluorocarbon

FC, Fluorocarbon based water repellent chemical; AU, Alkyl urethane based water repellent chemical; Conc, Concentrations; FC+D, Fluorocarbon with dendrimer water repellent chemical; PFOS, perfluorooctanesulfonate; PFOA, perfluorooctanoic acid; PP, polo pique

Water repellency is one important property that is needed on protective clothing like apparel, home and technical textiles without deteriorating the comfort ability of the cotton fabric. Water repellency is increasingly becoming the focus of interest for protective clothing. This repellency can be achieved by implementing water repellent chemicals on textile fibres with minimal effects on other functional properties like strength, flexibility, breathability, softness etc.1 There are various methods that have been used to achieve water repellency on cotton. The modification process route, the application of chemicals from renewable resources, the use of non-toxic chemicals and solvents are some of the requirement of green chemistry. Among different chemicals, fluorocarbon based chemicals are mostly used to impart water repellency along with oil repellency on textile without much affecting air permeability and hand feel.2−6 Fluorocarbons consists of perfluorinated carbon chains with a polymer backbone with perfluoro groups as its side chains.7,8 Some fluorocarbons are made with C8 carbon backbone chains that can release perfluorooctanesulfonate (PFOS) and perfluorooctanoic acid (PFOA) and other toxic and hazardous materials. C6 based fluorocarbons were introduced to minimize the release of toxic chemicals. C6 based fluorocarbons showed decreased water repellency than C8 based fluorocarbons ones. Recently some cross-linkers like alkyl urethane, were introduced which is fluorocarbon free and obtained from renewable resources. Both fluorocarbons based and alkyl urethane chemicals are usually available as water emulsions and are applied on fabric by the pad-dry-cure method.2−5

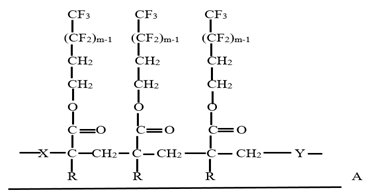

The first water repellent chemical is dispersion of fluorine compounds, namely fluorocarbon (FC). FC was applied on fibre, after curing process should form a structure that presents a dense CF3 outer surface to provide maximum repellency. A typical structure is shown in Figure 1. The length of the perfluorinated side chains is about 8–10 carbons. Co-monomers are X,Y, for example are stearyl- or lauryl-meth-acrylate, butyl-acrylate, methylol- or epoxy-functional acrylates.

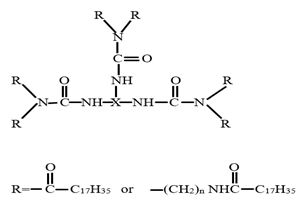

The second water repellent chemical is fluorocarbon resin with polymeric, hyperbranched dendrimers in a hydrocarbon (FC+D). It is called bio-nic finish as it is a novel FC development inspired by nature. Fluorocarbon polymers are applied together with dendrimers (Figure 2). Dendrimers are highly branched oligomers with non-polar chains. The length of the perfluorinated side chains is about 6 carbons which is lower amounts of fluorocarbon compared to dendrimer-free FC finishes. It forms a starbrush structure to force the polar parts of the FC polymers to form the surface structure. The final polar and non-polar sandwich arrangements are highly ordered, resulting better repellency effects.

The third water repellent chemical is poly alkyl urethane resin (Figure 3). It is a renewably sourced fluorocarbon free water repellent chemical. It is environmental friendly as it contains 63% renewably resourced material obtained from different plant-based sources. It efficiently repels water and water based liquid like curry stain, fruit juice, tea, hot coffee, red wine etc. from cotton and blend fabrics.

In the literature, a significant number of researches on variety of water repellent chemicals, their application procedure, improved water repellency and their durability and various wash fastness have been reported.9−10 But, there are almost insufficient work on the comparison of fluorocarbon based and fluorocarbon-free of water repellent finishes on both single jersey and double jersey knit fabrics properties. The purpose of this study was to comparison and evaluates the performance of what chemicals on which concentration (conc.) affected which knit structure’s fabric properties after finishing.

Fabrics

100% cotton both single jersey and double jersey knit fabrics (scoured and bleached) are used to finish different types of water repellent chemicals by pad-dry-cure method. The fabrics are supplied by Micro Fibre Group, Bangladesh. Four types of knit structures are used here, two of them are single jersey derivatives such as polo pique (PP) and single jersey (S/J) and other two of them are double jersey derivatives such as 1×1rib (Rib) and interlock (Int). Fabric specifications are given in Table 1.

Name of fabric |

Knit structure |

GSM |

Count |

Composition |

Single jersey |

Polo pique |

160 |

30 Ne |

100% cotton |

S/J |

160 |

30 Ne |

100% cotton |

|

Double jersey |

Rib (1×1) |

160 |

30 Ne |

100% cotton |

|

Interlock |

160 |

30 Ne |

100% cotton |

Table 1 Types of fabrics with their specification

Supplied fabrics have excellent hydrophilic character. Fabrics are then processed in Micro Fibre lab with three different water repellent chemicals. Two of these chemicals are fluorocarbon based and another one is alkyl urethane based. These three water repellent chemicals are applied on cotton knit fabrics in three different concentrations (70g/L, 90g/L and 100g/L) to investigate the effect of water repellent chemicals and their concentrations (conc.) on water repellency and other physical properties of the fabrics. Moreover, fabrics are dyed by using a general recipe (Table 2) in Micro Fibre lab and finished with different water repellent chemicals in 100g/L conc. as it showed excellent water repellency to evaluate different fastness properties of the fabrics.

Dyes and chemicals |

Polo pique fabric (Turquise color) |

Shade |

S/J fabric (orange color) |

Shade |

Rib fabric (black color) |

Shade |

Interlock fabric (red color) |

Shade |

|

Dyestuff |

Reacto bond Turquise Blue G 133% |

4% |

Reacto bond Orange 2RX |

0.50% |

Reacto bond Black DN |

8% |

Reacto bond Red HW |

0.50% |

|

Auxiliaries |

Jinlev ECO CL 225 (Levelling agent): 25g/l |

||||||||

Jintexy Ec SQ 117CA (Sequestering agent): 25g/l |

|||||||||

Jingen Lub CBA (Wetting agent): 50g/l |

|||||||||

Basic Chemicals |

Polo pique |

S/J |

Rib |

Interlock |

|||||

Glauber’s salt |

60g/L |

16g/L |

80g/L |

16g/L |

|||||

Soda ash |

20g/L |

9g/L |

20g/L |

9g/L |

|||||

Temperature |

80˚C |

60˚C |

60˚C |

60˚C |

|||||

Time |

90 min |

||||||||

M:L |

1:10 |

||||||||

After treatment |

Cold wash |

||||||||

Acid wash 2cc/L for 4-5min (Green acid) |

|||||||||

Hot wash at 95˚C for 7 min |

|||||||||

Soap wash 2g/L for 7 min (Soaping agent Jingen SP AW5045) |

|||||||||

Hot wash at 95˚C for 7 min (2 times) |

|||||||||

And then dry. |

|||||||||

Table 2 Dye application bath are listed for fabrics

Water repellent chemicals

Three types of water repellent chemicals are used for this experiment. Two of these chemicals are fluorocarbon based and third one is alkyl urethane based. First is fluorocarbon (FC) (trade name Nuva TTC, fluorocarbon based water repellent finishing agent, weakly cationic, dispersion of fluorine compound, Clariant), second is fluorocarbon with dendrimers (FC+D) (trade name Rucostar EEE6, fluorocarbon based water repellent finishing agent, weakly cationic, fluorocarbon (C6) resin with polymeric, hyperbranched dendrimers in a hydrocarbon, Rudolf chemie) and third is alkyl urethane based water repellent chemicals (AU) (trade name Zelan R3, alkyl urethane based water repellent finishing agent, weakly cationic or non ionic, poly alkyl urethane compound, Huntsman).

Water repellent application bath

Different structured knit fabrics are finished with three different water repellent chemicals at three different conc. (70g/L, 90g/L and 100g/L) from a separate bath with same bath condition. First is fluorocarbon (FC), second is fluorocarbon with dendrimers (FC+D) and third are alkyl urethane (AU) water repellent chemicals which solutions are prepared and applied on different knit fabrics. The process parameters are adopted as recommended by the supplier. The finishing recipe is given in Table 3. Horizontal Pad-Mangle machine (Rapid, Xiamen Rapid Co Ltd, China) is used for padding with 4.5rpm fabric speed and 2.3kg/cm2 padding pressure. Channel precision oven machine (china) is used for drying and Labtec Steamer machine (Newave Lab equipments Co Ltd, Taiwan) is used for curing.

Finishing bath set up |

Fluorocarbon |

FC+ dendrimers |

Alkyl urethane |

|

Name of chemicals |

Resin |

70, 90, 100g/L |

70, 90, 100g/L |

70, 90, 100g/L |

Acetic acid |

01ml/L as required for pH 4-5 |

01ml/L as required for pH 4-5 |

01ml/L as required for pH 4-5 |

|

Phobol XAN g/L (booster) |

-- |

-- |

10g/L |

|

Invadine PBN (wetting agent) |

-- |

-- |

5g/L |

|

Application Parameters |

Padding |

80% pick up |

||

Drying |

120˚C for 3min |

|||

Curing |

160˚C for 2min |

|||

Padder Pressure |

1bar |

|||

Table 3 Water repellent application bath

Phobol XAN: a booster, dispersion of oxime blocked isocyanate, cationic, pH 2.5-4.5 and dissolve in cold water.

Invadine PBN: a wetting agent, surface active preparation of ethyoxylated fatty alcohol and aliphatic ether alcohol, anionic, pH 7.5-9.5, dissolve in cold water.

Methods

Water repellent evaluation test: There are two types of water repellent evaluation test are used.

Physical and chemical testing: Each sample is tested in the standard atmosphere, 25±2˚C temperature and 65% RH after conditioning 24hrs.

GSM test: GSM test is done by GSM cutter from James H. Heal & Co. Ltd. Halifax, England according to ASTM (D 3776-79) method.

Bursting strength test: It is done by bursting strength tester from SDL Atlas according to ASTM (D 3786-87) method

Stiffness test: It is done by fabric stiffness tester from J. K. King Ltd, USA according to ASTM D4032.

Color fastness to wash: Color fastness to wash is measured with ISO 105-C06-C2S method.

Color fastness to sea water: It is done by ISO 105-E02 method.

Color fastness to saliva: It is done by DIN 53160-1:2010-10 method.

Color fastness to rubbing: The resistance of color against rubbing of dyed fabrics (dry and wet) is evaluated with ISO 105X 12 methods.

Color fastness to light: It is done by ISO 105-B02 method.

Water repellent evaluation test

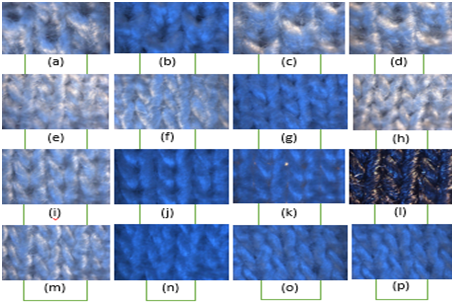

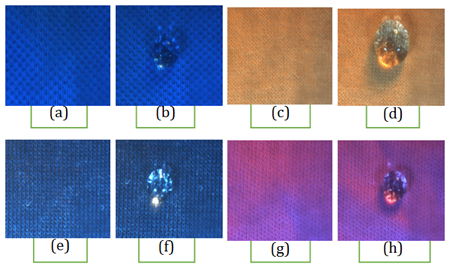

Drop test: Three types of water repellent solutions (trade name Nuva TTC, Rcostar EEE6, & Zelan R3) are prepared in 70g/L, 90g/L and 100g/L conc. and applied this conc. on different single jersey and double jersey knit dyed fabrics. Four different knit fabrics are used in this study, two of them are single jersey derivatives (S/J, polo pique) and another two are double jersey derivatives (rib, interlock). This is the visual test to evaluate the water repellency. When a water droplet is placed on water repellent material then the drop will rest up on it without penetration. Here are some physical appearances of untreated and treated fabrics (Figure 4) (Figure 5), showed that treated fabrics are water repellent.

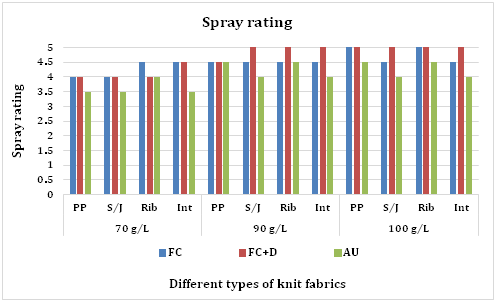

Spray rating test

Fluorocarbon (FC), FC+dendrimers (FC+D) and alkyl urethane (AU) water repellent chemicals solutions are prepared in three different conc. (70g/L, 90g/L and 100g/L) and applied on single jersey (S/J, PP) and double jersey derivatives knit fabrics. These treated fabrics are then evaluated by using ISO 4920:2012 method and spray rating are expressed in Table 4 and Figure 6. Schindler and Hauser discussed that after finishing by pad-dry-cure process, the heat treatment (drying and curing) changes perfluoro side chains to almost crystalline structures to achieve optimal water repellency.9 Compared with the untreated fabric, the finished fabrics had good water repellency with around 3-5grades.

Conc. (g/L) |

Fabric |

FC |

FC+D |

AU |

70 |

Polo pique |

4 |

4 |

3-4 |

S/J |

4 |

4 |

3-4 |

|

Rib |

4-5 |

4 |

4 |

|

Interlock |

4-5 |

4-5 |

3-4 |

|

90 |

Polo pique |

4-5 |

4-5 |

4-5 |

S/J |

4-5 |

5 |

4 |

|

Rib |

4-5 |

5 |

4-5 |

|

Interlock |

4-5 |

5 |

4 |

|

100 |

Polo pique |

5 |

5 |

4-5 |

S/J |

4-5 |

5 |

4 |

|

Rib |

5 |

5 |

4-5 |

|

|

Interlock |

4-5 |

5 |

4 |

Table 4 Spray rating of different fabrics treated with water repellent chemicals at 70g/L, 90g/L and 100g/L conc

It is shown from Figure 6 and Table 4 that by applying different water repellent chemicals in 70g/L conc., water repellency rating varies with different knit fabric. FC water repellent chemical showed better result comparatively than others. Moreover, rib fabric gave better result for its compactness. In 90g/L conc., water repellency rating has found better for FC+D water repellent chemical for both single jersey and double jersey derivatives. Among the fabrics, S/J, rib and interlock fabrics showed the best rating for FC+D water repellent chemical by that conc. Particularly for 100g/L conc., FC gave the best result for all fabrics rather than others and in high conc. all the chemicals show better result for all fabrics.

Hydrostatic head test: This test is done according to AATCC 127 method on different types of knit fabrics after water repellent finish at various conc. which are stated below in Table 5 and Figure 7.

Fabric Name |

Hydrostatic head test (cm of water) (Unfinished) |

Conc. (g/L) |

FC |

FC+D |

AU |

Polo pique |

14 |

70 |

16 |

16 |

16 |

S/J |

15 |

17 |

16 |

17 |

|

Rib |

14 |

16 |

17 |

16 |

|

Interlock |

15 |

16 |

18 |

16 |

|

Polo pique |

14 |

90 |

18 |

18 |

17 |

S/J |

15 |

18 |

17 |

18 |

|

Rib |

14 |

17 |

20 |

18 |

|

Interlock |

15 |

18 |

21 |

20 |

|

Polo pique |

14 |

100 |

19 |

20 |

19 |

S/J |

15 |

20 |

18 |

20 |

|

Rib |

14 |

18 |

21 |

18 |

|

Interlock |

15 |

20 |

22 |

21 |

Table 5 The hydrostatic head test of different fabrics treated with water repellent chemicals at 70g/L, 90g/L and 100g/L conc

From the above chart it has seen that the more pressure required forcing water through the fabric and with the conc. increases from 70g/L to 100g/L, the pressure requires more. An increase in repellent conc. caused an improvement in wetting times of the fabric after finishing. Because the water repellent chemicals form a coating on the fabric and the more conc. of chemicals leads the higher density of the coating resulting increased water repellency. It is shown from Figure 7 and Table 5 that by applying different water repellent chemicals in different conc., hydrostatic head test rating varies with different knit fabric. FC+D water repellent chemical showed better result comparatively than others for both single jersey and double jersey derivatives.

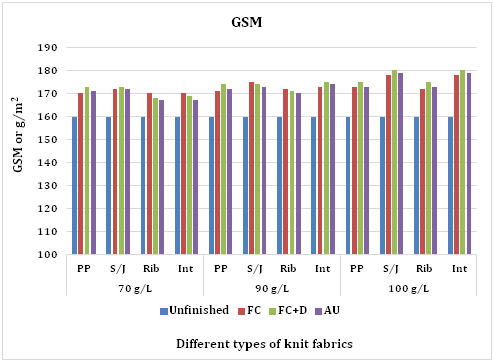

Analysis of GSM

The GSM tests are done according to ASTM (D 3776-79) method for all fabrics with different conc.

After chemical implementation of the different knit fabric with various concentrations from Figure 8 and Table 6, GSM has increased because chemical has covered up all the pores of the fabric and a chemical coating is created on the fabric. Therefore, the water is not allowed to penetrate into the fabric.

Fabric Name |

GSM (Before) |

Conc. (g/L) |

FC |

FC+D |

AU |

Polo pique |

160 |

70 |

170 |

173 |

171 |

S/J |

160 |

172 |

173 |

172 |

|

Rib |

160 |

170 |

168 |

167 |

|

Interlock |

160 |

170 |

169 |

167 |

|

Polo pique |

160 |

90 |

171 |

174 |

172 |

S/J |

160 |

175 |

174 |

173 |

|

Rib |

160 |

172 |

171 |

170 |

|

Interlock |

160 |

173 |

175 |

174 |

|

Polo pique |

160 |

100 |

173 |

175 |

173 |

S/J |

160 |

178 |

180 |

179 |

|

Rib |

160 |

172 |

175 |

173 |

|

Interlock |

160 |

178 |

180 |

179 |

Table 6 GSM of different fabrics treated with water repellent chemicals at 70g/L, 90g/L and 100g/L conc

Bursting strength test

Bursting strength plays a vital role after water repellent finish. It was done according to ASTM (D 3786-87) method. In here, in the chart the bursting strength of the cotton knit fabric shows slight detoriation occurs and it is obviously taken into account as resin cross links in amorphous region of cellulose leading lower flexibility and harsh hand feel. Though it is marginal for the fabric to go for the next proceedings.

From the above chart in Figure 9 and Table 7, it is clear that after water repellent finish the fabric strength is decreased and it’s reasonable. The fabric strength is decreased by increasing of water repellent chemical conc. The bursting strength of knit fabric is reduced because of effect of the cellulosic fiber during cross linking process. When the water repellent chemicals form cross link with the cotton free O-H group in the amorphous region, it makes stiff of the fabric and moreover, cross linking reaction is done mainly in acidic condition which are also responsible for the loss of the fabric bursting strength.

Fabric Name |

Bursting Strength (kpa) (before) |

Conc. (g/L) |

FC |

FC+D |

AU |

Polo pique |

285.1 |

70 |

250.3 |

249.5 |

255.7 |

S/J |

292.8 |

262.8 |

279.9 |

270.5 |

|

Rib |

265.1 |

246.8 |

262.6 |

230.2 |

|

Interlock |

309.7 |

288.8 |

278.6 |

277.1 |

|

Polo pique |

285.1 |

90 |

235.4 |

246.3 |

250.8 |

S/J |

292.8 |

253.6 |

272.8 |

258.4 |

|

Rib |

265.1 |

214.8 |

246.2 |

220.9 |

|

Interlock |

309.7 |

260.5 |

264.6 |

261 |

|

Polo pique |

285.1 |

100 |

228 |

243.2 |

241.7 |

S/J |

292.8 |

246 |

238.5 |

249 |

|

Rib |

265.1 |

201.7 |

242.8 |

211.6 |

|

Interlock |

309.7 |

240.3 |

255.6 |

246 |

Table 7 Bursting strength of different fabrics treated with water repellent chemicals at 70g/L, 90g/L and 100g/L conc

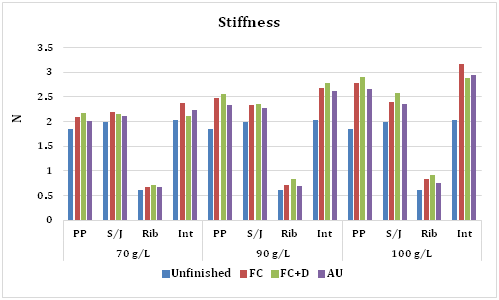

Stiffness test

Stiffness test has enormous effect after water repellent finish as resin cross links in amorphous region of cellulose leading lower flexibility and harsh hand feel. For that reason fabric stiffness is increased after finishing. It was done according to ASTM D 4032 method. In here, in the chart the stiffness of the cotton knit fabric shows stiffness increased for all types of water repellent finishes. The fabric stiffness is increased by increasing of water repellent chemical conc. Among three water repellent chemicals, AU (alkyl urethane) treated fabrics shows less stiffness after finishing (Table 8) (Figure 10).

Fabric Name |

Unfinished fabric’s stiffness (N) |

Conc. (g/L) |

FC |

FC+D |

AU |

Polo pique |

1.84 |

70 |

2.08 |

2.18 |

2.01 |

S/J |

1.98 |

2.19 |

2.16 |

2.11 |

|

Rib |

0.6 |

0.68 |

0.72 |

0.67 |

|

Interlock |

2.02 |

2.38 |

2.1 |

2.24 |

|

Polo pique |

1.84 |

90 |

2.48 |

2.56 |

2.33 |

S/J |

1.98 |

2.34 |

2.36 |

2.28 |

|

Rib |

0.6 |

0.71 |

0.83 |

0.69 |

|

Interlock |

2.02 |

2.68 |

2.78 |

2.62 |

|

Polo pique |

1.84 |

100 |

2.78 |

2.9 |

2.66 |

S/J |

1.98 |

2.4 |

2.57 |

2.36 |

|

Rib |

0.6 |

0.84 |

0.92 |

0.75 |

|

Interlock |

2.02 |

3.16 |

2.89 |

2.95 |

Table 8 Stiffness of different fabrics treated with water repellent chemicals at 70g/L, 90g/L and 100g/L conc

Color fastness

All dyed knit fabrics are treated with water repellent chemicals at 100g/L conc. to measure the effect of different color fastness. As 100g/L conc. treated fabrics shows the best water repellency and physical properties compared with other concentrations. To evaluate the effect of color fastness of all treated fabrics are rated under grey scale for both color change and color staining.

Color fastness to wash: Color fastness to wash is measured with ISO 105-C06-C2S method. The rated chart is given below in Table 9. At first the sample is washed with standard recipe and then color change and staining are measured to the washed sample with the unwashed sample and compared.

Color fastness to wash |

||||||||||||

Sample |

Unfinished |

FC |

FC+D |

AU |

||||||||

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

|||||

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

|||||

Polo pique |

4 |

3 |

4 |

4 |

3 |

4 |

4 |

3 |

4 |

4 |

3 |

4 |

S/J |

4-5 |

4 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

Rib |

4-5 |

4 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4 |

4-5 |

Interlock |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

Table 9 Color Fastness to wash of different knit fabrics treated with water repellent chemicals at 100g/L conc

The wash fastness of FC, FC+D and AU water repellent treated fabrics shows better result than unfinished one for S/J, rib and interlock fabrics. But wash fastness of water repellent treated polo pique fabric remain same as unfinished one. The improvement of wash fastness of water repellent finished fabric is because of the dye molecules trapped inside the crosslinking film.

Color fastness to sea water: It is done by ISO 105-E02 method. The rated chart is given below in Table 10. The sea water fastness of FC+D water repellent chemicals shows better result than FC and AU chemicals for polo pique, S/J and rib fabrics. The improvement of sea water fastness of water repellent finish is because of the dye molecules trapped inside the crosslinking film.

Color fastness to sea water |

||||||||||||

Sample |

Unfinished |

FC |

FC+D |

AU |

||||||||

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

|||||

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

|||||

Polo pique |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

S/J |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

Rib |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

Interlock |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

Table 10 Color fastness to water of different fabrics treated with water repellent chemicals at 100g/L conc

Color fastness to saliva: It is done by DIN 53160-1:2010-10 method. The color fastness to saliva of water repellent treated fabrics at 100g/L concentration are rated under grey scale for color change and color staining. The rated chart is given below in Table 11. The color fastness to saliva remains unchanged for all FC, FC+D and AU treated S/J and interlock fabrics compared with untreated one. Whereas, it slightly decreased for all treated fabrics of polo pique and rib structure.

Color fastness to saliva |

||||||||||||

Sample |

Unfinished |

FC |

FC+D |

AU |

||||||||

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

Color change |

Color staining |

|||||

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

Cotton |

Wool |

|||||

Polo pique |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

S/J |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

Rib |

4-5 |

4-5 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4 |

4-5 |

4-5 |

4 |

4-5 |

Interlock |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

Table 11 Color fastness to saliva of different fabrics treated with water repellent chemicals at 100g/L conc

Rubbing fastness: The rubbing fastness of water repellent treated dyed fabrics are rated under grey scale for the measurement of color staining against dry and wet white fabric. The rated chart of rubbing fastness for wet and dry rub are given below in Table 12. It shows that both dry and wet rub are remain same or slightly decreased after water repellent finish on conc. 100g/L than untreated one as water repellent chemical make a thin coating on fabric surface.

Rubbing fastness |

||||||||

Sample |

Unfinished |

FC |

FC+D |

AU |

||||

Dry |

Wet |

Dry |

Wet |

Dry |

Wet |

Dry |

Wet |

|

Polo pique |

4-5 |

3-4 |

4 |

3-4 |

4 |

3-4 |

4 |

3-4 |

S/J |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

4-5 |

Rib |

4-5 |

3 |

4 |

3-4 |

4 |

3 |

4 |

3 |

Interlock |

4-5 |

4 |

4-5 |

4 |

4-5 |

4 |

4-5 |

4 |

Table 12 Rubbing fastness of different fabrics treated with water repellent chemicals at 100g/L conc

It is found that all three FC, FC+D and AU chemicals shows average rubbing (dry and wet) fastness. Dry rub staining of polo pique and rib fabrics shows slightly decreased for FC, FC+D and alkyl urethane water repellent finish than untreated one. It may be because of after finishing, fabrics become harsh. For that reason, Dry rubbing fastness is decreased as more friction is occurred between fabric and white cloth. Moreover, another possibility is both polo pique and rib fabrics has uneven surface than S/J and interlock which caused more friction between fabric and white cloth.

Color fastness to light: To measure the effect of light fastness of water repellent treated fabrics are rated under grey scale for color change. It is done by ISO 105-B02 method. The rated chart is given below in Table 13. At first the sample is exposed against light for certain time and then compare the color change with the unexposed sample.

Color fastness to light |

||||

Sample |

Unfinished |

FC |

FC+D |

AU |

Color change |

Color change |

Color change |

Color change |

|

Polo pique |

4-5 |

4-5 |

4-5 |

4 |

S/J |

4 |

4 |

4 |

3-4 |

Rib |

4-5 |

4-5 |

4-5 |

4-5 |

Interlock |

4 |

4 |

4 |

3-4 |

Table 13 Color fastness to light of different fabrics treated with water repellent chemicals at 100g/L conc

Moreover, from the data sheet (color change), it is found that light fastness characteristics are not affected by FC, FC+D treated all knit fabrics except alkyl urethane. Furthermore, FC, FC+D treated fabrics shows same light fastness as untreated one though for alkyl urethane treated fabrics, it slightly decreased for all knit structure.

In this experiment, both single jersey (polo pique, S/J) and double jersey (rib, interlock) derivatives of knit fabrics were finished with three types of water repellent chemicals. Two of them are fluorocarbon based and another one is fluorocarbon-free resins which are applied on different structured knit fabrics by pad dry cure process. Water repellent chemicals conc. on the repellence of the fabrics was investigated. To do so, 72 water repellent treated different structured knit samples were tested and evaluated. Variety mechanical and different color fastness properties of finished knit fabrics were evaluated and showed that different water repellent chemicals and their varying conc. significantly influenced water repellency of knit fabrics. Changing conc. from lower to higher conc., gives gradually upgraded water repellency, regardless of repellent chemical type. When fluorocarbon with dendrimers (FC+D) was used, then the best water repellency is obtained by evaluating both the sprat rating test and hydrostatic head test. But fluorocarbon-free alkyl urethane (AU) gave less stiffness and improved hand feel than other water repellents. The results showed that the fluorocarbon-free alkyl urethane based resin treated fabrics exhibited competitive result on water repellency, other physical and chemicals properties. Furthermore, unlike the findings of previous research works which discussed that with implementing higher conc. of the water repellent, strength is reduced. The repellent chemicals and their changing conc. did not cause significant loss of bursting strength of knit fabrics. The water repellent finish type and conc. were very important criteria to obtain good water repellency. There was no significant variation is observed in GSM on the basis of different types of water repellent chemicals and their varying conc. A higher in repellent conc. caused a good wash fastness, sea water fastness, color fastness to saliva, rubbing fastness and light fastness. The finishes after dyeing had no effect on water repellency is another important conclusion of this work. Moreover, environmental friendly fluorocarbon-free water repellent chemicals could be a good alternative than fluorocarbon based water repellent chemicals.

I should like to express my deep gratitude to MICRO FIBRE for providing me the lab facilities. I should also like to thank Essential Clothing Ltd for providing me sample fabrics. Again special gratitude also goes to the Wet Processing Lab and the TTQC Lab of Bangladesh University of Textiles (Butex).

Author declares there is no conflict of interest in publishing the article.

©2018 Chowdhury. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.