Journal of

eISSN: 2574-8114

Research Article Volume 10 Issue 1

1Textile Engineering Department, Faculty of Textile Technologies and Design, Istanbul Technical University, Istanbul, Türkiye

2İpekyol Tekstil ve Konfeksiyon A.Ş. Tasarım Merkezi, Şişli, İstanbul/Türkiye

3Marmara University, Faculty of Technology, Textile Engineering Department, Küçükyalı Maltepe, İstanbul/Türkiye

Correspondence: Pelin Altay, Textile Engineering Department, Faculty of Textile Technologies and Design, Istanbul Technical University, Istanbul, Türkiye

Received: January 18, 2024 | Published: January 29, 2024

Citation: Altay P, Çelikkanat OT, Evren A, et al. Influence of different sewing parameters on seam quality. J Textile Eng Fashion Technol. 2024;10(1):11-16. DOI: 10.15406/jteft.2024.10.00359

Seams, which are exposed to strain during the physical movement of end user, play a significant role in textile by joining the pieces of cloth and giving the garment its final shape. Seam performance and quality of a textile are critical factors affecting the final product and the end user. In this study, it was aimed to examine the effects of stitch types, stitchy density and sewing directions on seam quality of cotton sateen fabric in terms of seam strength and seam slippage and to determine the optimum conditions. It was demonstrated that 6 stitches/cm stitch density, lock stitch type and sewing in bias direction can be used for 100% cotton sateen weaved fabric in order to obtain satisfactory seam quality.

Keywords: sewing parameters, seam quality, garment, textile

Seams take a significant role in textile by joining the pieces of cloth and giving form of the garment during garment manufacturing. As a result of this important role, seam performance and quality are critical factors affecting final product and end user. Structural and mechanical properties of fabric and strength, stifness, flexibility, durability, and well-formed shape of a seam specify the seam performance.1,2 Seam type, stitch density of the seam and strength of sewing thread are seam related factors determining seam performence.

Seams are exposed to strain during the physical movement of end user. When the seam is subjected to the force perpendicularly in a fabric, it causes deformation of stitch geometry and movement of the yarn, it produces opening parallel to the seam. The propensity of the warp and weft yarns to slip over another in a woven fabric, is described as seam slippage. It is an important property determining the sewing quality of a finished product. Seam slippage may cause some problems in the garment and decrease the producibility. Amount of seam slippage of a fabric depends on yarn-to-yarn friction, contact angle between threads (cover factor), stitch density and yarn flexural rigidity. Increasing these parameters increase the seam slippage resistance of the fabric. Besides, raw material, fabric construction, type of seam and sewing thread tension, and machine variables such as needle and bobbin thread tension, stitch length, are main factors affecting the seam slippage in a woven fabric.3–5

In a woven fabric, seam slippage resistance of yarns in a seam can be identified by fixed seam opening method (ISO 13936–1:2004) or fixed load method (ISO 13936–2:2004).4,6,7 In fixed seam opening Method, the force (in newtons) required to achieve the predetermined fixed seam opening (to be identified upon between parties) is determined for both warp-wise and weft-wise. The specified seam opening may 2 mm to 6 mm for warp and weft slippage. Stretch fabrics and industrial fabrics are not measured by fixed seam openning method.4,6 On the other hand, in fixed load method the openning amount when the predetermined fixed load (to be identified between parties) is reached, is measured for both warp and weft yarns. This method is applicable for all clothing, upholstery woven fabrics and stretch fabrics. However, industrial fabrics are not measured by fixed load method.4,7 Applied standard loads are depends on the fabric unit weight. For the fabrics with a mass lower than 220 g/m2, 60N load is applied and for the fabrics heavier than 220 g/m2, 120N load is applied. 180N load is suitable for the fabrics used for furnishing.4

There are several factors effecting sewing paramters such as yarn density and structure, sewing direction, fabric construction, stitch density and mechanical properties of the fabric. Higher yarn density causes higher tension in yarns. As a result, the movement of the yarns decreases, leading to reduced seam slippage.2,5 Malciauskiene et al. prooved that weft density affects the seam slippage of a fabric more than warp density.8,9 Seam openning in the weft direction is higher than warp direction since the warp density is higher than weft density. An increase of the angle between weft yarn and sewing direction reduces the seam slippage. Seif demonstrated that sewing in bias direction (45°) gives the best slippage results.10 Fabrics with smoother structured yarns have higher seam slippage due to the low contact points, low interlacing of sewing thread and easliy movement of yarns.5,11 Fabrics with higher cover factor shows high resistance to seam slippage as there is high number of contact points between the yarns, high crimp of yarns and as a result increase of friction between the yarns.12,13

Plain weave is the most resistant weave type to seam slippage. Twill weave, satin weave and panama weave are prone to seam slippage bacause they have less interlacements of yarns and longer floats, and therefore more flexible structures. Dense fabric structures make the movement of yarns difficult, increase the friction of yarns, thus decrease the seam slippage.2,14 As the stitch density (stitch per inch-SPI), which indicates the number of stitches per unit length of seam, incerases, number of contact points between the yarns and sewing thread increases. A higher SPI holds the fabric more firmly and makes the seam stronger.1,15,16 Consequently, friction of the yarns during the tensile loading of the seam increases, and therefore resistance to seam slippage increases.3,17,18 Increased mechanical properties of the fabric such as tensile strength, durability, abrasion resistance, bending strength, stiffness decrease the seam slippage. The contact area between the sewing thread and fabric threads of stiff fabrics is higher. Higher contact area increases frictional resistance during tensile loading, and thus the resistance to seam slippage increases. Increase in fabric thickness and weight decreases the seam openning due to the higher contact area and better interloping of sewing thread into the fabric.8,19–21

In this study, it was aimed to observe the effects of stitch types, stitchy density and sewing directions on seam quality of cotton sateen fabric in terms of seam strength and seam slippage/openning, and to determine the optimum conditions in order to obtain satisfied seam quality.

100% cotton, sateen weaved fabric, with a fabric weight of 170 g/m2 was used in this study. Fabric sample was supplied from Ipekyol Ayaydın-Miroglio Group (Türkiye). The effects of two different stitch types (two-thread lock stitch and four-thread overlock stitch as shown in Figure 1), two different stitch densities (4 mm and 6 mm) and three different sewing directions according to weft yarns (0°, 45° (bias direction) and 90°) on the seam quality were investigated. The zero degree indicates that sewing was carried out in the weft direction, while 90 degrees means that sewing was performed in the warp direction. Test samples were conditioned for 24 hours at relative humidity of 65 ± 2 % and temperature of 20 ± 2 ⁰C before testing. Seam strength and seam slippage were measured according to standards of TS EN ISO 13936-1 and TS EN ISO 13936-2, respectively. Zwick/Roell Z005 seam strength tester was used for the tests. Table 1 shows the sewing paramaters investigated in this study.

|

Factors |

|

|

|

|

Stitch type |

Lock |

Overlock |

|

|

Stitch step in sewing (mm) |

4 |

6 |

|

|

Sewing direction according to the weft |

0° |

450° |

90° |

Table 1 Parameters investigated in experimental work

Determination of the Seam Slippage

Different stitch types; lock and overlock

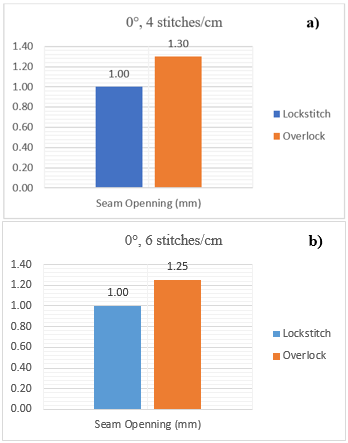

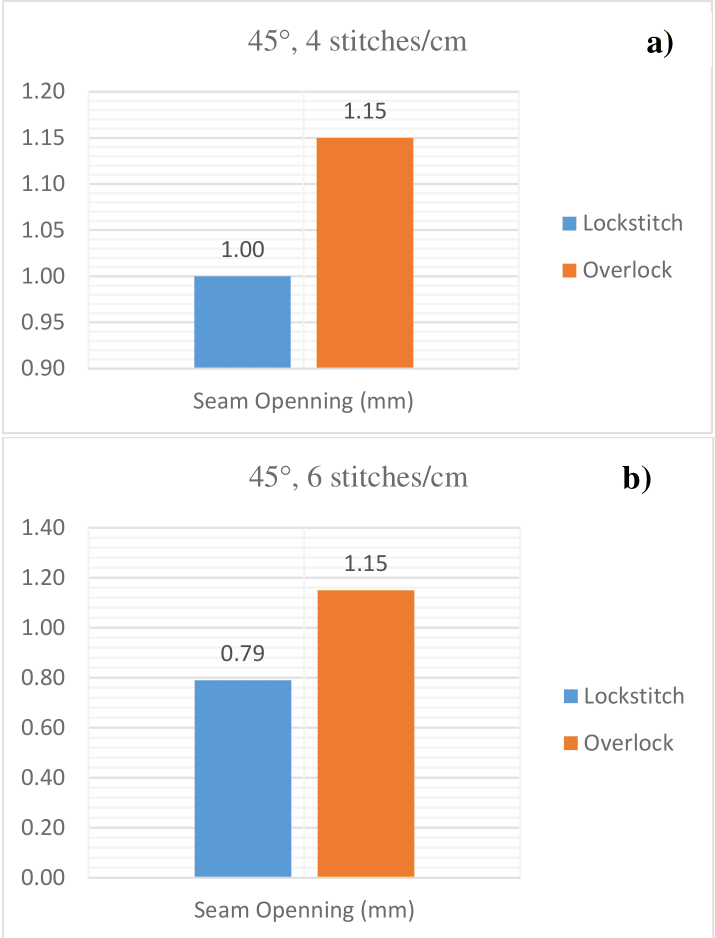

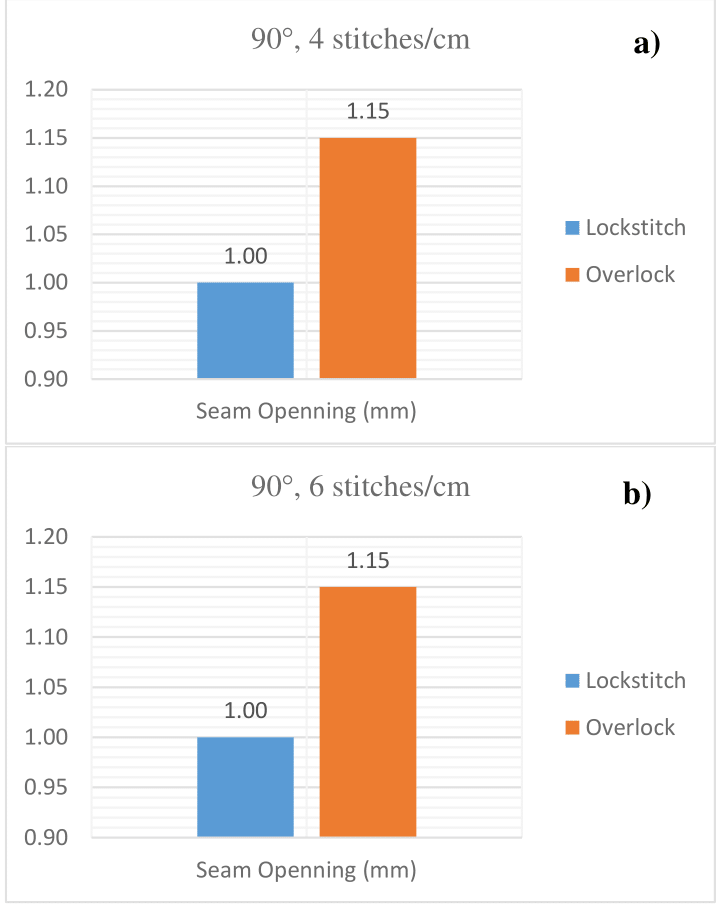

As it can be seen from the Figures 2–4, seam slippage of overlock stitch was higher than that of the lock stitch for all sewing directions and stitch densities. It can be explained with the 'two-thread' loop structure of lock stitch with the needle thread passing through the one side of the fabric, and forming a loop with a small curvature radius by interlacing with an under-thread supplied by bobbin on the other side. Needle thread is pulled back, allowing the stitch to form between the surfaces of the fabrics being sewn. These two threads interlacing below the fabric creates the lock stitch, which is a most commonly used, well balanced and secure stitch type.1,22–25 However, during the formation of overlock stitch, the yarn surrounds the edge of the fabric being sewn. Loops from one group of threads are passed through the material and secured by interlooping with loops from other groups of threads.23,26 Overlock stitch can only be used at the edge of a piece as an edge-finish for a single layer or as a seam that joins two layers together. Overlock stitches can be created using one or more needle and looper threads. Based on the number of threads used, they are considered as one of the most extensible stitch type.27,28

Figure 2 Seam slippage results of different stitch types at 0⁰ sewing direction, a) 4 stitches/cm b) 6 stitches/cm.

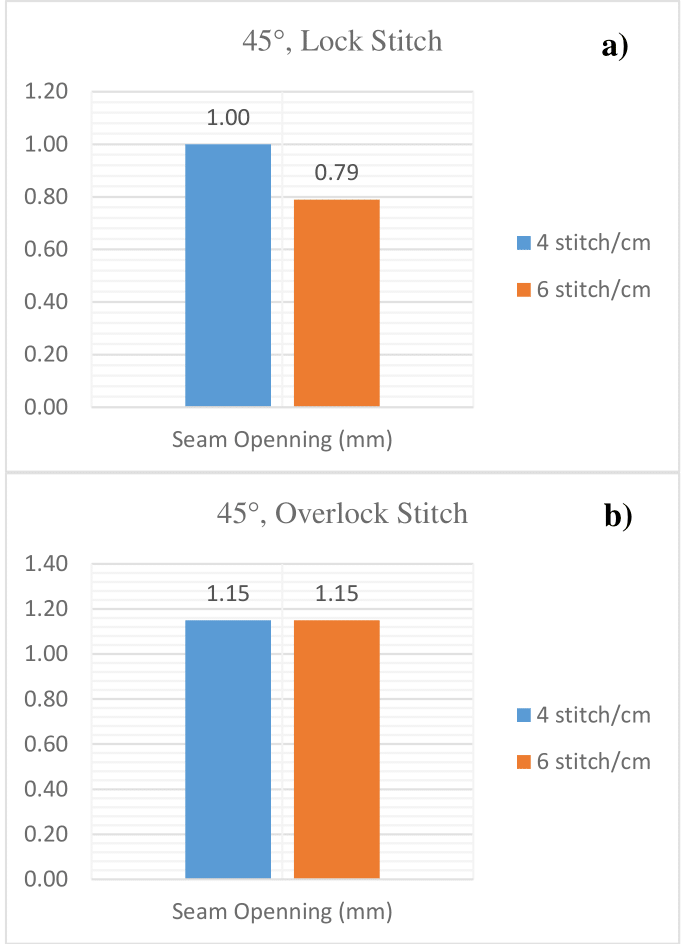

Figure 3 Seam slippage results of different stitch types at 45⁰ sewing direction, a) 4 stitches/cm b) 6 stitches/cm.

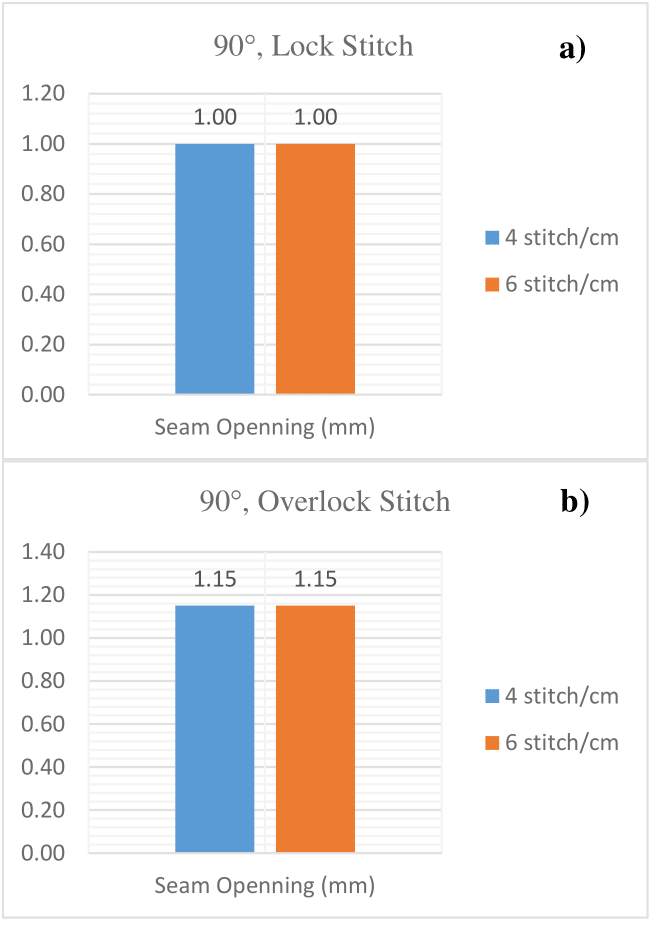

Figure 4 Seam slippage results of different stitch types at 90⁰ sewing direction, a) 4 stitches/cm b) 6 stitches/cm.

The highest seam openning of overlock stitch was observed at 0⁰ sewing direction, which is weft direction and 4 mm stitch density. On the contrary, lowest seam opening of lock stitch was measured at 45⁰ sewing direction and 6 mm stitch density. These results confirmed Seif’s findings that bias direction gives the best seam slippage result.10

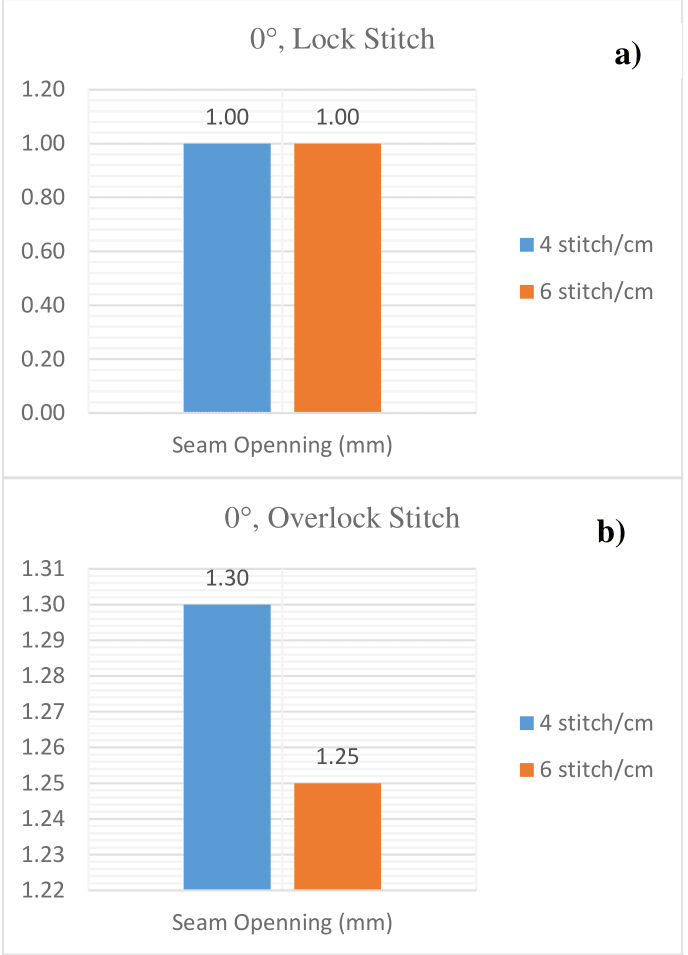

Different stitch densities; 4 stitch/ cm and 6 stitch/ cm

According to results from Figures 5–7, both stitch densities of 4 stitch/cm and 6 stitch/cm caused similar seam slippage values. However, considering the lock stitch, the samples sewn with 6 stitches/cm at 45⁰ provided 21% less seam opening with a seam slippage value of 0.79 mm compared to those sewn with 4 stitches/cm (Figure 6a).

Figure 5 Seam slippage results of different stitch densities at 0⁰ sewing direction, a) lock stitch b) overlock stitch.

Figure 6 Seam slippage results of different stitch densities at 45⁰ sewing direction, a) lock stitch b) overlock stitch.

Figure 7 Seam slippage results of different stitch densities at 90⁰ sewing direction, a) lock stitch b) overlock stitch.

Density of 4 stitches/cm density caused the highest seam slippage with overlock stitch and weft way (00) seam direction. Higher stitch density joins the fabrics more strongly as it causes a higher number of needles inserted per unit area, resulting in a higher number of contact points between the yarn and sewing thread. Due to the higher contact points, friction of the yarns increases during the tensile loading, and therefore the seam shows a higher resistance to slippage/openning.

Different sewing directions; 0° (weft way), 45° (bias direction), 90° (warp way)

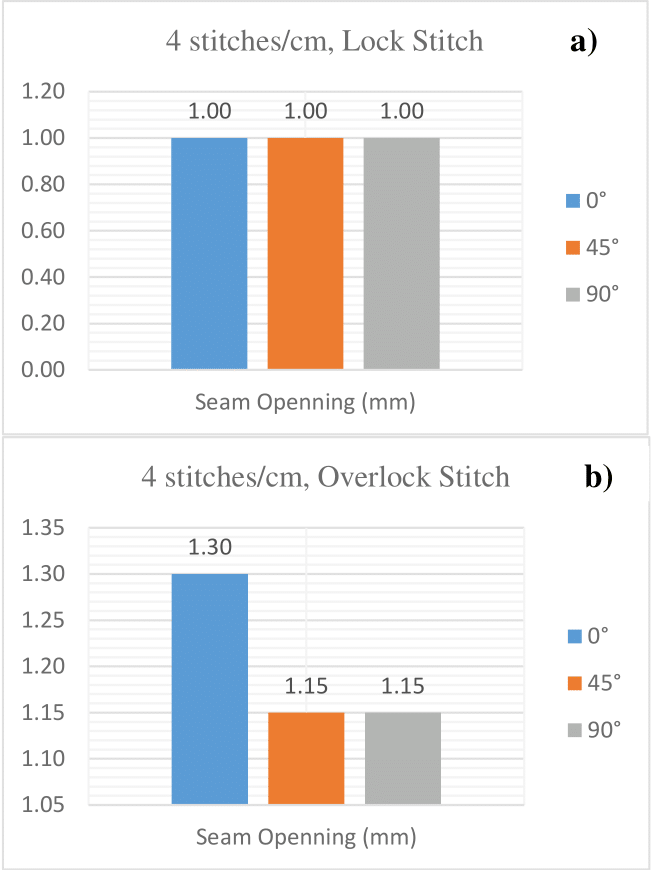

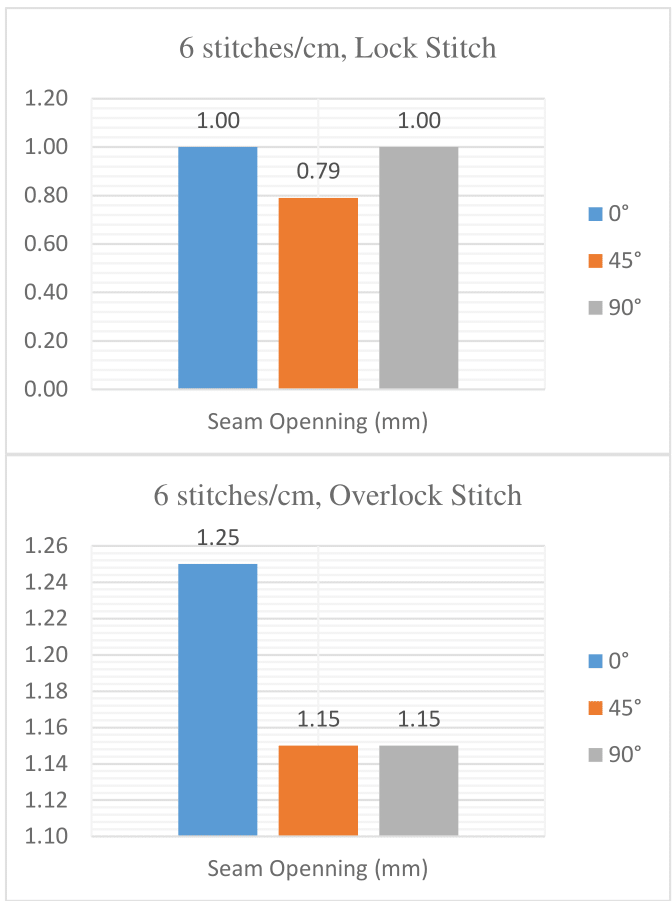

6 stitches/cm, lock stitch, and 45⁰ sewing direction gave the lowest seam slippage value of 0.79 mm. It was observed that weft way seam direction (0⁰) caused higher seam openning with overlock stitch for all stitch densities, as the weft density is lower than the warp density and, therefore the yarn movement is higher (Figure 8) (Figure 9).

Figure 8 Seam slippage results at different sewing directions, 4 stitches/cm, a) lock stitch b) overlock stitch.

Figure 9 Seam slippage results at different sewing directions, 6 stitches/cm, a) lock stitch b) overlock stitch.

Determination of the Seam Strength

Different stitch types; lock and overlock

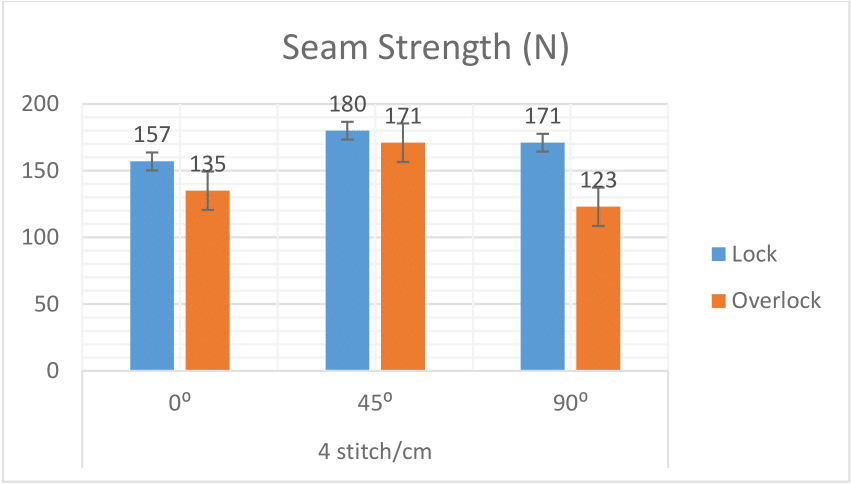

From the Figure 10 and Figure 11, it is concluded that lock stitch had higher seam strength compared to overlock stitch for a stitch density of 4 stitches/cm. The highest seam strength of the lock stitch at 4 stitches/cm was 180N in the 45⁰ sewing direction, while the lowest value was obtained as 157 N in the weft direction (00), resulting in seam breakage. Overlock stitch with 4 stitch/cm stitch density had its highest seam strength at 45⁰ sewing direction while the seam in the warp direction (90º) was ruptured with the lowest seam strength value of 123 N.

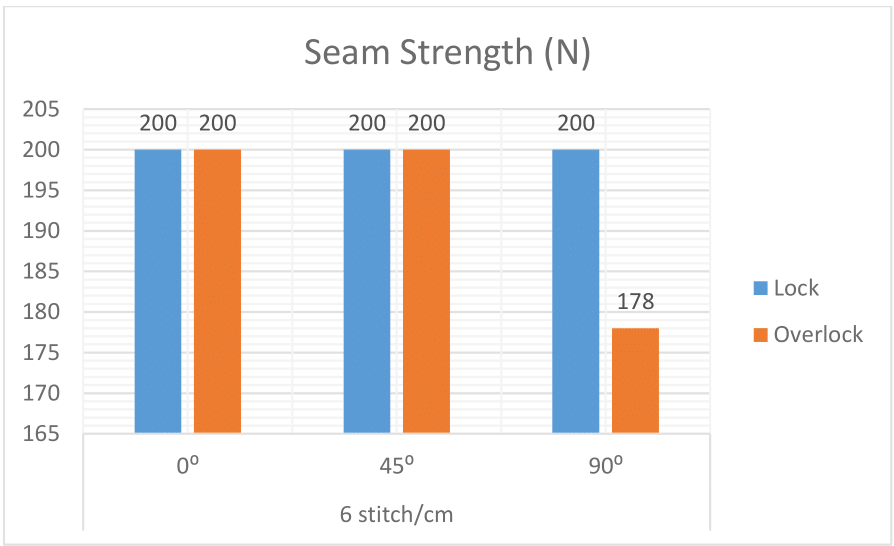

Considering 6 stitches/cm, the same seam strength values (200 N) were obtained in lock and overlock stitches at 0⁰ and 45⁰ sewing directions, and no rupture or opening was observed. When the sewing direction was 900, the seam strength of lock stitch was 11% higher than overlock stitch, which had its lowest value of 178 N and seam was ruptured.

Different stitch densities; 4 stitch/ cm and 6 stitch/ cm

For both lock stitch and overlock stitch, a stitch density of 6 stitches/cm provided higher seam strength compared to a stitch density of 4 stitches/cm (Figure 10) (Figure 11). The seam strength in all seam directions of the lock stitch at a density of 6 stitches/cm was higher than 200 N, without seam rupture and openning. The seam strength values confirmed the seam slippage results, as the stitch density increases, the seam quality increases. Seam ruptures were observed at a stitch density of 4 stitches/cm for both lock and overlock stitch, and 45⁰ sewing direction gave the highest seam strength results.

Different sewing directions; 0° (weft way), 45° (bias direction), 90° (warp way)

Bias sewing direction gave highest seam strength values of 180 N and 171 N for 4 stitch/cm stitch density for both lock and overlock stitched fabrics, respectively. Weft direction caused lowest seam strength of 157 N with seam ruptures for lock stitched fabric. On the other hand, for overlock stitched fabric, warp direction caused seam ruptures with the lowest seam strength value of 123 N (Figure 10) (Figure 11).

Figure 10 Seam strength results of different stitch types at 0⁰, 45⁰ and 90⁰ sewing direction, 4 stitches/cm.

Figure 11 Seam strength results of different stitch types at 0⁰, 45⁰ and 90⁰ sewing directions, 6 stitches/cm.

With the stitch density of 6 stitch/cm, seam strength of the lock stitched fabric in all sewing directions was greater than 200N. Overlock stitched fabric with 6 stitch/cm stitch density had greater seam strength value than 200 N with sewing at weft wise and bias direction whereas warp wise sewing direction caused seam rupture with 178 N seam strength.

In this study, the effects of stitch type, stitch denstiy and sewing direction on the seam performance of saten weaved, 170 g/m2, 100% Cotton fabric were examined. Lock and overlock stitch as stitch types, 4 and 6 stitch/cm as stitch densities and warp-wise, weft-wise and bias direction as sewing direction were investigated.

Considering the decrease in seam slippage and increased seam strength values, it was clearly revealed that higher stitch density, which is 6 stitch/cm in our study showed better seam performance. While the seam slippage values of the lock stitched fabric with a stitch density of 6 stitches/cm were lower than those of the overlock stitched fabric, their seam strength values were similar. Seam strength at different sewing directions was greater than 200 N for the fabric sewn with lock stitch and at a stitch density of 6 stitches/cm, however the bias direction caused 27% lower seam openning compared to the warp and weft seam directions.

It was concluded that seam condition with 6 stitch/cm stitch density, lock stitch type and sewing at bias direction can be used for 100% cotton sateen weaved fabric in order to obtain satisfactory seam performance.

None.

None.

Authors declare that there is no conflict of interest.

©2024 Altay, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.