eISSN: 2577-8307

Review Article Volume 5 Issue 1

Olasgarden Forest & Roads, Sweden

Correspondence: Iwan Wästerlund, Olasgarden Forest & Roads, Solvägen 9, 918 32 Sävar, Sweden

Received: December 30, 2021 | Published: July 22, 2022

Citation: Wästerlund I. Alpine routes reinforced with geonet. Forest Res Eng Int J. 2022;5(1):1-4. DOI: 10.15406/freij.2022.05.00100

Peatlands in the alpine area are very soft and when the carex (sedge) vegetation and roots are destroyed, the sinkage could be more than 0.5 m deep because the bearing capacity is very low and only water filled ruts remain.

In this project the aim to design both methods and technics to reinforce used routes for sami people working in this area with their reindeers but also travelling to their alpine cottages. By including a strong geonet to reinforce the ground a multi-passing on the routes could be achieved with ATVs without rutting the ground but only good products should be used that withstand the traffic.

Keywords: alpine peatlands, geonet, anchoring, vegetation root mat

Peatlands have low bearing capacity for both walking and terrain vehicles, but on top also very low capacity to recover especially in alpine environment (Figure 1).

Figure 1 The project leader stuck with his ATV in a mud hole caused by a dug ditch in the alpine landscape and calling for help.

Air borne photos with infrared colours in the alpine landscape1 have shown areas with huge damages on ground and vegetation. To some extent it is depending on the Laplanders (Sami people living in the Sapmi area) work with reindeers e.g. at calf marking, but some is depending on tourism traffic, hunters and fishermen. There is a law forbidding private terrain traffic (excluding the Laplanders and forestry work), but it is difficult to control that traffic. On the other hand just walking can by trampling destroy the vegetation and create rutting in the waterfilled peatlands, like on the Kings route (a walking trail) with maybe 1000 persons walking near the Norwegian border but also on the Swedish side there are partially big damages on the ground in the weak ground.2 County ministers are by law forced to repair and channelize the traffic but do not know how. Similar damages are also seen in Alaska and they try just to fix the worst damages by spade.

The project started with a Norwegian patent (Norvia AS) as a base where a net was just put out on the ground and anchored with big screw types made of plastics. Then ATVs (All Terrain Vehicles) were supposed to be able to travel on that reinforced ground (Figure 2).3

Figure 2 Alpine landscape with sparse birch forest growing on top of a peaty landscape. Just waterfilled underground peat with no strength but looks ok from above view.

Aim

We (Mårten Jonsson and the author of this report) were missioned to:

Laboratory tests

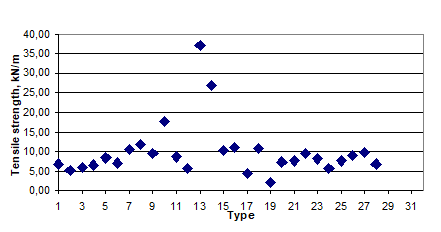

To study the geonets properties the tensile strength were tested with a Hounsfield tensile tester where both the tensile strength and elongation were studied. The pulling rate was 50 mm/min, which is much higher than the standard (1.25 mm min-1 according to ASTM). Most of the tested materials had fact sheets but was missing for Norvia AS, but the data sheets did not tell how they breaks (sudden or tough) and interesting was also how they behaviour at much higher pulling rate. Together more than a. 40 tests were done and three of the nets were of the type plane stiff PP-nets. The increased rate did not affect the tensile strength but the elongation, which decreased.

Field tests

Vegetation measurements was done by putting a wooden frame (0.5x0.5 m) on random places along the travelled passages on geonet (more than 3 per vegetation types) and similarly from untouched ground (at least 6 per place) The biomass was cut with a scissor near the ground and weighted wet. Theory: Show the amount of vegetation, but we are not specialist to tell what species are growing there, just collect the amount of above ground vegetation.

Plate testing/plate penetrometer was used to measure the strength of the ground with and without armouring.4 With the registration penetrometer (Eijkelkamp penetrologger) and a round plate screwed on the penetrometer (10 cm2, radius 17.85 mm) was pressed down by hand with roughly 3 cm s-1 and the depth measured ultrasonic. The force to press down the plate was max 500 N (70 % of the mass of the handling person). The plate had to be of that size to fit over squares in the net.

The new constructed plate was 13x7 cm (=91 cm2). The loading was applied with a hydraulic cylinder powered by a small hydraulic pump powered by a small petrol engine, pressure and sinkage were measured once per second with help of a geared potentiometer.

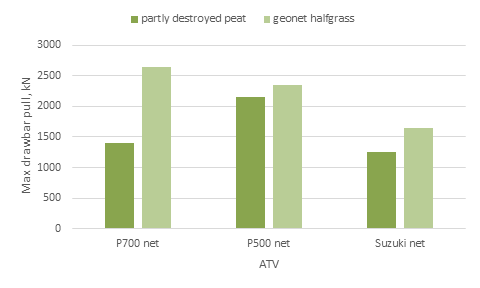

The shear strength between the ground/geonet and the wheels should be done dynamically, but the breaks of the vehicles were to bad so we had to do it static out in the alpine area (Wong 1978). To measure the rolling resistance we pulled one ATV using the electric winsch on the 6WD and pulled with a rate 0.17m s-1. The tensile tester was a Bofors KRG-4 load cell, which was rated to 5 ton as maximum pulling strength.

Anchoring was tested on 5 different types of anchoring. They were put in for 2-3 hours before testing and was pulled up at 20° angle simulating a person pulling up the geonet (a trailer with a big tube to roll up/off the geonet) A string was put around the top of the anchoring plug and pulled up with a rate of 0.17 m s-1 with the winsch on the ATV.

The 6WD had a rubber track around the rear bogie wheels, which also was the vehicle used for putting out (rolling) the geonets. It was often raining during our measurement and figure 3 can show the water puddles during the tensile testing on the geonet put out the year before side by side to the old rutted trail ( on the right side) and water running across the route (Figure 3).

The tests with the plate showed and the tensile tester showed that many PE geonets had quite low strength and could stretch 40-50 % while the PP net had only 10 % elongation and some PP-nets could not even get to break but started to slide in the clamps (Type 13). Thus, we coosed a PPnet to be our main geonet to protect the ground, which proved to be good choice at the tests (Figure 4).

Figure 4 Test results from the tensile testing of varying types of geonets. Type nr 13 and 14 was a PP plane stiff geonet, that we used during further tests.

Vehicle

Wheel inflation pressure was 40-50 kPa and the mass with 75 kg operator was between 420 (4WD) and 670 kg (6WD). The 4WD vehicle could produce traction of 3.5kN. On the rutted swampy peat land the maximum traction sank to 3 kN and on the destroyed trail the traction sank to 2 kN. The friction coefficient could be calculated to 0.65. On the geonets the friction was 0.6, mostly because the lugs in the tyre did not fit into the mesh to get proper grip.

Calculated as net traction (rolling resistance – max traction) it becomes rather small loads that can be pulled on a horizontal but destroyed alpine road (Figure 1). Practically that means a vehicle pulling a trailer, starts to slip and then break the ground, thus, the rolling resistance becomes heavier than the net traction and the ATV is stuck!

When similar pulling tests were made on a geonet the net pulling force became almost double stronger (Figure 5).

Figure 5 Measured maximal ATV net traction on different grounds with and without geonets and on ground with only Carex and peaty ground.

In summary for the vehicles

The properties of the ground

The plate tests showed that the Carex meadow with some water running on top of the ground had a rather thick grass overlay the peatland and with a root layer 3-8 cm thick with 350 kPa strength. Below that mass of roots the strength sank to 200 -250 kPa . When the grass/ root layer is destroyed the strength is very weak and an ATV sinks down 5-8 cm in the ground which means the rolling resistance increases considerably. With a geonet on top of the ground, we increase the ground strength considerably. The shoe in Figure 6, sinks down 2-3 cm, thus you will need a rather thick sole on the shoe to not getting wet.

Figure 6 Measured plate strength with 10 cm2 round plate on undisturbed halfgrass meadow (n=3) and straight (X) on a halfgrass (sedge) meadow with geonet. Max. applied force was 450 kPa. The shoe indicates a human foot pressure sinkage on the muddy ground.

The strength of the geonets had to be measured with a hydraulic cylinder to be able to produce enough of force 500 kPa (trailer loaded with an ATV plus two persons to load the trailer). It showed that a PE net sank down into the peaty ground at only 450 kPa load. With anchored PP net it could withstand 650 kPa until the peaty ground started to give away. Thus, with a pp net much higher forces could be with stand, but still there is a great variability on the alpine peaty meadows. A PE net would increase the strength considerably, but after 280 kPa it could be pressed down into the peaty ground. With a PP net the load could be increased up 500 kPa, thus, double the strength of the peat bog.

Anchoring of the nets and vegetation

We learned two important things during our work on the alpine meadows. First thing was that the vegetation had to be cut before putting out the net on the ground, because when the grass is bent down it will choke the vegetation below it and their roots, which will weakening the mat. After cutting the new growth through the geonet could amount to 180 g fresh weight/m2 after two months of growth compared to 270 g m-2 without any net, thus although cutting of the vegetation and the net only somewhat reduced growth of the vegetation 2.5 months afterwards. We had some proofs (only with a picture) showing that the geonet completely disappeared after 2 years but the net was still protecting the ground, not shown here).

The other thing was that the anchoring of the net must survive both the winter and hold the net on place. The first material we tested was the Norvia types of screws. It was a plastic type with fibre filling. But as Kiguchi noted in his report something is happening between the plastic material and the wood fibres and the whole thing becomes white and brittle. On top of that we discovered that the thawing during the winter lifted up the screws and the year afterwards many were all lifted up 1-3 cm above the geonet.

The strength of the geonets had to be measured with a hydraulic cylinder to be able to produce enough of force 500 kPa (trailer loaded with an ATV plus two persons to load the trailer). It showed that a PE net sank down into the peaty ground at only 450 kPa load. With anchored PP net it could withstand 650 kPa until the peaty ground started to give away. Thus, with a pp net much higher forces could be with stand, but still there is a great variability on the alpine peaty meadows. A PE net would increase the strength considerably, but after 280 kPa it could be pressed down into the peaty ground. With a PP net the load could be increased up 500 kPa, thus, double the strength of the peat bog.

Anchoring of the nets and vegetation

We learned two important things during our work on the alpine meadows. First thing was that the vegetation had to be cut before putting out the net on the ground, because when the grass is bent down it will choke the vegetation below it and their roots, which will weakening the mat. After cutting the new growth through the geonet could amount to 180 g fresh weight/m2 after two months of growth compared to 270 g m-2 without any net, thus although cutting of the vegetation and the net only somewhat reduced growth of the vegetation 2.5 months afterwards. We had some proofs (only with a picture) showing that the geonet completely disappeared after 2 years but the net was still protecting the ground, not shown here)

The other thing was that the anchoring of the net must survive both the winter and hold the net on place. Thus, we had to make our own type. In our tests we also realised that below 12-15 length there were of no use to have the anchor attached to peat mud. Mårten took his band saw and played around and made a prototype, which we called prototype 1. This one was with two legs and supplied with a bow to be able just to tramp it down and a shank for the two legs (Figure 7).

Figure 7 The factorial design of prototype 1 used to anchor the geonets and one per meter net was enough.

In our tests it became almost completely outstanding compared to all other types including Tenax and Tensar types for anchoring of tents. The benefit of having two legs was that we could get a hold on two or more meshes. Thus, we had now a whole system with both how to cut the vegetation, how to put out the geonet by rolling it out from a trailer after the 6WD ATV and anchoring + wooden bridges to overcome small streams not shown here).

This project was closed down without any further action from the county ministers involved in the project and the Sami people had to work further with any support.

Environment

The first criteria was the reindeers. Most of them had no problems to walk on the geonet. We learned also from the Sami people that a reindeer calf had hoofs that demands a mesh size 30x30 mm to be able to walk on the geonet without getting stuck.

The other aspect is if something can leach out from the plastics. But, it is a completely inert material. Testing done at Luleå Technical University5 showed that the material was totally inert and had no leaching substances.

Third aspect, if you regret the net, it is very possible to just pull up the net. If carefully pulled up their will be no residues at all left on the ground compared to wooden bridges often used to reinforce walking path!

Practical recommendations

Final test

We let our project leader take his car and ran 10 times back and forth on our newly reinforced peatbog. He just stepped out from his car and looked surprised. It was a 2 tonnes car with 4WD and there were no marks after the driving (Figure 8)!

Figure 8 Our project leader surprised after been driving back and forth 10 times on a peatbog with PPnet anchored with what we called prototype 1 and he could just return back to road without any marks after a 2 tonnes car. He stands beside his car just surprised.

Explanations: PE, polyethylene; PP= propen strong net.

None.

Authors declare that there is no conflict of interest.

©2022 Wästerlund. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.