eISSN: 2574-9927

Research Article Volume 5 Issue 5

Plastic Liquid Crystal Technology, Italy

Correspondence: Hakemi H, Plastic Liquid Crystal Technology, Via Lambro 80, 20846 Macherio (MB), Italy, Tel +39 349 5679838

Received: October 08, 2021 | Published: October 25, 2021

Citation: Hakemi H. The effect of liquid crystal concentration on the morphology of few flexible polymer dispersed liquid crystals. Material Sci & Eng. 2021;5(5):153-157 DOI: 10.15406/mseij.2021.05.00171

In this study, we investigated the effect of concentration of TNO623, TNO403 and E43 liquid crystals on the morphology of flexible PDLC films. The PDLC films were prepared on ITO-PET support rolls by Polymerization Induced Phase Separation (PIPS) through UV radiation curing technique. We found that, regardless of the type of liquid crystal and process conditions, the liquid crystal micro-droplet morphology, including the dimensions, number densities and weight fractions, were mostly exhibited the same dependency trends on liquid crystal concentration in PDLC formulation.

Keywords: liquid crystal, concentration, flexible PDLC, morphology, phase separation, micro-droplet

The field of Polymer Dispersed Liquid Crystal (PDLC) has been the subject of many academic and industrial research and development in the past four decades. The correlation between PDLC materials and process conditions with morphology and electro-optical properties is essential in the industrial development and manufacturing technology. The chemical structure and physical properties and concentration of raw materials, thickness, phase separation and curing processes are essential parameters to influence the performance of PDLC film products. Almost all PDLC literature is based on academic research dealing with the effect of material and process conditions, such as type, composition, radiation, temperature, time and thickness on the electro-optical properties in various types of glass-based PDLC films.

According to some recent academic studies on thermoset and UV-cured PDLC films, it has been shown that the morphology and electro-optical properties of PDLC devices were affected by many material and process parameters, including the concentration, cure temperature, cure time and thickness.1–9 In this respect, the control of inter-dependent material and process parameters have to be identified and their correlations requires experimental verification. The morphology of PDLC film depends on a numbers of factors, such as the type of liquid crystal, the nature of pre-polymers and polymeric conditions. These factors are shown to affect the microstructure of the polymer matrix, the size and the shapes of the LC domains and anchoring of LC molecules within droplets.10–14 The present study has been part of industrial R&D program to establish empirical relations, first between curing parameters and morphology and second between morphology and electro-optics for eventual scale-up and manufacturing of PDLC film products. These relations at industrial scale will serve to develop quantitative correlations between process parameters and morphology, as well as the electro-optical properties of PDLC films, which are essential for product’s quality control and manufacturing. In order to have a better understanding of structure-property relations in PDLC products, in this work we studied the effect of the concentration of liquid crystal (CLC) on the morphology of flexible UV-cured PDLC formulations by Polymer Induced Phase Separation (PIPS) method. In the subsequent work, we will provide the effect of concentration of liquid crystal on electro-optical properties of flexible PDLC films.

Materials

The utilized materials were consisted of UV-curable NOA65 pre-polymer resin (Norland Optical Adhesives), five nematic liquid crystal mixtures including TNO623 and TNO403 (Hoffmann-La Roche) and E43 (Merck Ind. Chem.), 10-15mm thick plastic Micro-Pearl (Sekisui) micro-spacers, Irgacure819 photo-initiator (Sigma-Aldrich) and 100W. ITO-PET film supports (Sheldahl). All materials were used without further purification. The optical and physical parameters of utilized liquid crystal mixtures, including the ordinary refractive index (no), birefringence (n), Dielectric anisotropy (De), parallel dielectric constant (e//), nematic-isotropic transition temperature (Tni) and viscosity (h) are tabulated in Table 1.

|

Liquid crystal |

No |

n |

De |

e// |

Tni(°C) |

h(cst) |

|

TN0623 |

1.507 |

0.198 |

17.2 |

19.6 |

105 |

66

|

|

TN0403 |

1.524 |

0.258 |

19.2 |

24.8 |

82 |

66

|

|

E43 |

1.525 |

0.238 |

17.1 |

23.1 |

87 |

60

|

Table 1 Optical & physical parameters and transitional temperatures of liquid crystals

Preparation and methods

The PDLC film preparation with each formulation was carried out with Polymerization Induced Phase Separation (PIPS) method by UV radiation (UV-PIPS). The flexible PDLC films were prepared by a custom-made in-situ coating and lamination system of homogeneous mixture for each formulation consisting of NOA65 pre-polymer, liquid crystals at corresponding concentrations, 1% Irgacure819 and 0.2% plastic spacers versus total formulation where pre-heated at 30-80 °C temperatures for 10-30 minutes.7,8 The uncured homogenous PDLC formulations were mixed for three hours at above nematic-isotropic transition temperature and then were poured between the vertical gap of two heated vertical rolls of ITO-PET supports films on a custom-made plastic coater/laminator system shown in Figure 1. Immediately under the coating/laminating rolls, the uncured PDLC films were passed through a pressure roll to insure the uniformity of the film separated by plastic micro-spacers. The uncured PDLC films were then cut and transferred to a custom-built conveyor system (see Figure-1) and cured by a high-intensity UV lamp with corresponding radiation intensities at line speeds of 0.5 meter/minutes at relevant cure temperatures. The cure temperature was measured by a thermocouple during the curing process. The experiments were carried out on three PDLC samples for each formulation and the reported experimental results are the average values of three samples. The morphology of PDLC films, including the average micro-droplet dimension (<D>), number density per unit area (<N>) and droplet volume fraction (<a>), were measured from the areas of micrographs of both horizontal and fractured micrographs with a JOEL model JSM-6300 scanning electron microscope (SEM). Determination of <D> and <N> were carried out through direct two-dimensional image analysis of SEM micrographs of the samples. The PDLC layer thicknesses were also measured by both cross-sectional SEM micrographs and Mitutoyo-7007 specimeter. The resistivity r of TNO623 liquid crystal was measured at 1 Volt and 100 Hz frequency and their nematic-isotropic transition temperatures were measured under Leitz model Laborlux-12polarizing optical microscope equipped with Mettler model FP5microscopic hot-stage.

We studied the effect of liquid crystal concentrations on the morphologies of PDLC film formulations with TNO403, TNO623 and E43 eutectic mixtures. The studied morphologies in these formulations included the micro-droplet size (<D>), number density per unit area (<N>) and volume fraction of phase separated liquid crystal micro-droplets (<α>). The phase-separated liquid crystals micro-droplets <α> is inversely proportional to the amount of liquid crystal plasticized in the matrix. From the morphological data, we calculated <α> values in the three PDLC systems according to the following equation:

<α> = p.<N> . (<D>/2)2. X/(100-X) . (rre / rlc) (1)

where <N> is the droplet number density per unit area, <D> is the droplet sizes from micrographs, X is the amount of liquid crystal weight per cent, rlc=1.03 and rre=1.15 are the average specific densities of liquid crystals and cured NOA65 matrix, respectively. The experimental results of the effect of liquid crystal concentration (CLC) on morphologies in three flexible PDLC formulations with TNO403, TNO623 and E43 liquid crystal mixtures are presented as follows:

Morphology vs concentration in PDLC-TNO403 films

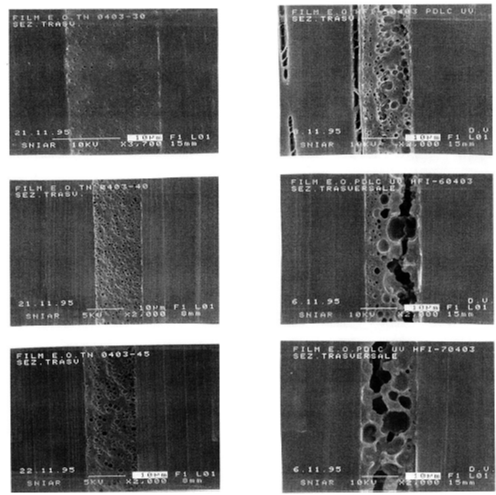

The PDLC samples with TNO403 were carried out at film thickness of 15mm, curing temperature of 50°C, UV curing intensity of 20mW/cm2 (EUV=2000mJ/cm2) at concentrations range of CLC=30-70%. In Table 2 & Figure 2, we present the CLC dependency of <D>, <N> and <α> in PDLC-TNO403 formulation. Also in Figure 3, we present the typical SEM micrographs of liquid crystal droplet sizes of <D>) in PDLC-TNO403 film formulations as a function of TNO403 concentration.

|

TNO403(%) |

<D>(mm) |

<N>106cm-2 |

<α> |

|

30 |

0.31 |

37.0 |

0.03 |

|

40 |

0.69 |

34.4 |

0.19 |

|

45 |

1.01 |

27.9 |

0.22 |

|

50 |

1.34 |

22.7 |

0.32 |

|

60 |

1.8 |

16.1 |

0.38 |

|

70 |

2.95 |

7.1 |

0.48 |

Table 2 Effect of CLC on the morphologies of PDLC-TNO403 film formulations

Figure 3 The SEM micrographs of <D> as a function of CLC in PDLC-TNO403 film formulations at 30% (left top), 40% (left middle), 45% (left bottom), 50% (right top), 60% (right middle) & 70% (right bottom) of TNO403.

Morphology vs concentration in PDLC-E43 films

The PDLC formulation with E43 was carried out at a film thickness of 15μm, curing temperature of 30-80°C, UV curing intensity of 8-40mW/cm2 at concentration range of CLC=40-60%. In Table 3 & Figure 4, we present the effect of CLC on <D> and <N> in PDLC-E43 film formulations.

|

E43(%) |

<D>(mm) |

<N> 106 cm-2 |

<α> |

|

40 |

0.5 |

111 |

0.016 |

|

45 |

0.8 |

82 |

0.038 |

|

50 |

1.0 |

75 |

0.066 |

|

60 |

1.7 |

34 |

0.129 |

Table 3 Effect of CLC on the morphologies of PDLC-E43 film formulations

Morphology vs concentration in PDLC-TNO623 films

The PDLC samples with TNO623 were carried out at film thickness of 10mm, curing temperature of 80°C, UV curing intensity of 40-80 mW/cm2 at concentrations range of CLC=30-90%. In Table-4 and Figure-5, we present the effect of CLC on <D> and <α> in PDLC-TNO623 film formulations. We believe that such behaviour.

|

TNO623 (%) |

<D> (mm) |

<N> 106cm-2 |

<α> |

|

32 |

0.50 |

279 |

0.025 |

|

34 |

0.65 |

269 |

0.035 |

|

36 |

0.8 |

206 |

0.065 |

|

38 |

1.1 |

183 |

0.150 |

|

40 |

1.4 |

175 |

0.200 |

|

45 |

1.5 |

185 |

0.300 |

|

50 |

1.45 |

187 |

0.345 |

|

55 |

1.5 |

162 |

0.390 |

|

60 |

2.0 |

84 |

0.440 |

|

65 |

3.3 |

33 |

0.580 |

|

70 |

4.8 |

12 |

0.580 |

|

75 |

5.5 |

7 |

0.575 |

|

80 |

5.5 |

5 |

0.520 |

|

85 |

5.8 |

3 |

0.465 |

|

90 |

6.0 |

2 |

0.480 |

Table 4 Effect of CLC on the morphologies of PDLC-TNO623 film formulations

As expected, the increase in liquid crystal concentration provide the same trends on the morphologies of all three PDLC film formulations. According to Figure 2-Figure 5, the results indicate a systematic increase of <D>, decrease of <N> and increase of <α> as a function of CLC in all PDLC films with TNO403, E43 and TNO623, respectively. A typical example of variation of droplet size with CLC is also presented by SEM micrographs for PDLC-TNO403 films in Figure 3. Similar trends of morphology with concentration of liquid crystal have been observed in glass-based PDLC films in few literature works. Generally, the kinetics of phase separation and polymer curing are inter-related phenomena, where the higher phase separated micro-droplets the more matrix swelling and less plasticization by liquid crystal occurs. Although in PDLC-TNO403 (Figure 2) and PDLC-E43 films (Figure 4) the effect of CLC on the morphologies are predominately linear, such trends in PDLC-TNO623 (Figure 5) film is not and requires some explanation. It is however noteworthy that this difference could be due to limited CLC range (30-70%) and points in TNO403 and E43 cases with respect to (30-90%) and more points in TNO623 case. Also in PDLC-TNO623 films (Table 4 & Figure 5), the average droplet size <D> first exhibits a linear increase at low CLC range (30-40%), in mid concentration range (40-60%) it becomes independent of CLC and at high concentration range (60-80%) <D> again increases linearly with CLC but converges at above 80%. The CLC dependencies of <N> and <α> in PDLC-TNO623 follow trends similar to that of <D>. It should be noted that, deviation of <D> and <α> from linearity at above CLC 80% in PDLC-TNO623 formulation (Figure 5) is attributed to convergence of the sizes and phase separated micro-droplets, which is the result of larger plasticization of PDLC matrix by liquid crystal due to geometrical constraint at thin (10mm) film thickness with respect to those (15mm) in PDLC-TNO403 and PDLC-E43 films. This analogy could correctly predict that, due to relatively longer cure time and larger amount of plasticized liquid crystal at highest range of CLC should produce smaller phase-separated micro-droplets.

In addition, we should also consider the different process conditions as alternative reason for differences in CLC dependencies in the three studied formulations, particularly in PDLC-TNO623 case with more and wider studied concentrations. another reason for nonlinear behaviour of morphologies could be due to its thinner PDLC layer thickness (10mm), as well as the establishment of equilibrium temperature across the film would require longer time, which in turn causes a gradual increase in the viscosity of pre-cured mixture. In short the experimental results of the three studied PDLC formulation systems indicate that in, at higher CLC and lower thickness range, due to larger two-dimensional matrix swelling, shorter curing time, larger surface effect and smaller matrix plasticization, a faster phase separation creates larger micro-dr0plet <D>; smaller <N> and larger <α> values. On the other hand, at lower CLC range, the matrix dominant effect causes longer matrix curing time, larger plasticization, and consequently smaller <D>; larger <N> and smaller <α> values. Aside from quantitative effect of CLC on the morphologies, the experimental results are also due to a subtle qualitative change in the mechanisms of phase separation and polymer curing kinetics. In another words, the phase separation of thermoset PDLC is also governed by a series of inter-dependent factors, such as the solubility temperature of liquid crystal and pre-polymer, intensity and temperature of UV radiation, the degree of cross-linking and plasticization of matrix, which all require further investigation and understanding. Conclusively, the present work is part of our systematic industrial R&D on the effect of chemical, physical and process conditions on morphology, as well as electro-optical properties of flexible PDLC films. The results indicate that, regardless of the types of materials and process techniques for preparation of PDLC film, the studied liquid crystal concentration has a significant effect on micro-droplet morphology (dimension, number density and weight fraction). We believe that further detail investigation is necessary to provide a deeper understanding of structure-property relations on morphology and electro-optical performances, which is essential for manufacturing of high-quality flexible PDLC products.

None.

The author declare that there is no conflict of interest.

©2021 Hakemi. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.