eISSN: 2574-9927

Editorial Volume 5 Issue 3

Department of Mechanical Engineering and Materials Science, University of Pittsburgh, USA

Correspondence: Scott X Mao, Department of Mechanical Engineering and Materials Science, University of Pittsburgh, Pittsburgh, Pennsylvania 15261 USA, Tel 412-624- 9602

Received: April 30, 2021 | Published: May 12, 2021

Citation: Zheng S, Mao SX. In situ atomic-scale observation of dislocation-mediated discrete plasticity in nanoscale crystals. Material Sci & Eng. 2021;5(3):93-94 DOI: 10.15406/mseij.2021.05.00161

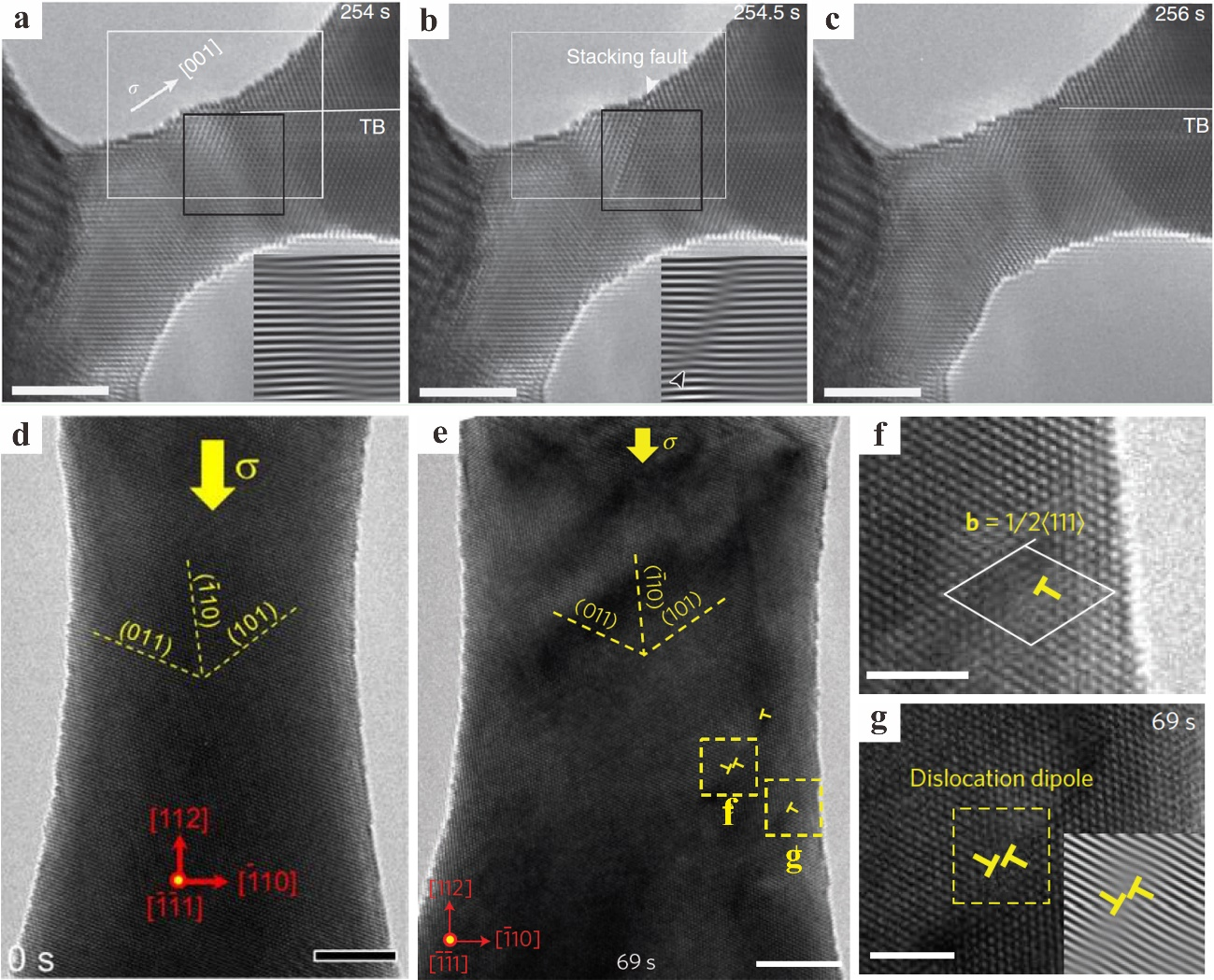

Nanoscale metals with superior mechanical properties are promising building blocks in the next generation flexible electronics.1 Due to the pronounced surface effect caused by the ultrahigh surface-to-volume ratio of nanocrystals, the mechanical behaviors of nanoscale metals are quite different from their bulk counterparts. Dislocation nucleation is demonstrated to be related to the microstructural length scale of materials. With decreasing the feature size, dislocation source changed from Frank-Read source to single-arm dislocation source.2 As sample size decrease to nanoscale, surface dislocation nucleation is the dominant mechanism. In situ transmission electron microscope (TEM) nanomechanical testing opens up an avenue to directly observe the atomic-scale dislocation dynamics in nanoscale metals. Here we report an in situ atomic-scale observation of dislocation-mediated discrete plasticity in gold (Au) and tungsten (W) nanowires NW.3,4 In the tensile test of Au NW loaded along [001] under a strain rate of 10−3 s−1 and viewed along [10], surface steps, consisted of two sets of {111} planes, can act as dislocation nucleation sites. As the stress inside the sub-10-nm Au NW is high enough to induce yielding, a leading partial dislocation nucleated from a surface step, and then glided through the Au NW, leaving behind a stacking fault (SF), as shown in Figure 1A-1B. Subsequently, this SF was eliminated by a trailing partial emitted from the same dislocation nucleation site as the previous leading partial (Figure 1C). Hence, discrete dislocation nucleation and propagation mediated plasticity in Au NW. In addition to Au NW, surface dislocation nucleation was also dominant in W NW under <112> compression viewed along [1].4,5 After yielding, dislocations nucleated from free surface, then glided on the {110} slip planes, and finally annihilated at the opposite free surface (Figure 1D-1G). Dislocation nucleation behavior in W NW was strain-dependent. At a low compressive strain level, 1/2<111>-type mixed dislocations nucleated from (10) surface (Figure 1F); however, at higher strain level, half dislocation loops, that is dislocation dipoles, heterogeneously nucleated from (1) surface (Figure 1G). Such strain-dependent nucleation behaviors can be attributed to the difference in surface morphologies for (10) and (1) planes. The (1) surface planes were zigzag, while the (10) surfaces were atomically flat. At high strain level, there exist local strain concentration at surface facets of (1) planes, favoring surface dislocation nucleation. Similar to face-centered cubic (FCC) and body-centered cubic (BCC) nanoscale metals, surface dislocation nucleation is also dominant in other nanostructured metals, including Au NWs with nanotwins, bi- and penta-twined silver (Ag) NWs, and bicrystalline Ag NWs.6 In summary, our work offers atomic-scale insights into surface dislocation nucleation and the related dislocation dynamics in nanoscale metals, providing guidelines to fabricate nanomaterials with high performance to achieve their potential applications in nanoscale devices. To date, the effect of chemical passivation layer on surface dislocation nucleation remains experimentally unclear, which probably attracts a great deal of interest for future research.

Figure 1 Dislocation-mediated discrete plasticity in nanoscale metals. (A-C) Sequential TEM images showing dislocation dynamics. The insets in a and b are Fourier-filtered images of the black square area. Scale bars in a-c are 3nm. (D-E) TEM images of dislocation dynamics in W NW. (F-G) TEM images of 1/2<111>-typed mixed dislocation loop nucleated from free surface. Scale bars in d-e and f-g are 5nm and 2nm, respectively. Source: (A-C) reprinted with the permission from Ref.3 © 2010, Nature Publishing Group. (D-G) reprinted with the permission from Ref.4 © 2015, Nature Publishing Group.

S.X.M. acknowledges support from the NSF 1760916 through University of Pittsburgh.

The authors declare that there is no conflict of interest.

©2021 Zheng, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.