MOJ

eISSN: 2573-2919

Research Article Volume 5 Issue 3

1Department of Forestry and Wildlife, Faculty of Agriculture, University of Uyo, Nigeria

2Department of Geography and Natural Resources, University of Uyo, Nigeria

Correspondence: Kufre Edet Okon, Department of Forestry and Wildlife, University of Uyo, Akwa Ibom State, Nigeria, Tel +2349031598680

Received: December 28, 2019 | Published: June 22, 2020

Citation: Okon KE, Akpan M, Okon IAK, et al. Effect of tin-bath treatment on anatomical properties of Firmiana simplex wood. MOJ Eco Environ Sci. 2020;5(3):137-139. DOI: 10.15406/mojes.2020.05.00186

Wood modification in general, is an environmental non-biocide method to modify and improve certain wood properties to enable its utilization for diverse purpose. In this study, Firmiana simplex wood was modify using low melting point tin-alloy as the heat-treatment medium. The anatomical properties of the tin-bath treated wood were studied using a light microscope and scanning electron microscope analysis. Microscopic analyses with a light microscope showed that the morphologies of the wood were less smashed by the impact of the treatment with no deformation of the vessels after tin-alloy treatment while scanning electron microscope revealed collapse in the wood structures with damages to the cell walls and vessels. It was also evident from scanning electron microscope analyses that tin-alloy penetrated the wood structure, therefore forming a film covering the cell walls and partly occupying the wood cell lumens.

Keywords: Wood modification, Scanning electron microscopy, light microscope, thermal treatment, anatomical properties of wood

Wood modification at high temperature (150 to 260˚C) in general is an environmental non-biocide and non-toxic method to modify and improve certain wood properties to enable the use of wood for some outdoor applications.1,2 Degradation of cellulose and hemicellulose structures, changes in lignin and wood extractives loss are some permanent changes observed during thermal treatment. Furthermore, biological durability is improved3 while on the other hand, mechanical properties are decreasing4 and the brittleness of the thermally-treated wood is increase as well as changes in the anatomical structures.5 In addition, thermal modification increases the crystallinity properties of the wood.

Previous researches have reported changes in wood anatomical structures when subjected to thermal modification.5–7 Changes in chemical composition, not anatomical structures have been reported to be the reason for some changes in wood properties after thermal modification.8 Though, there are some publications related to the anatomical properties of thermally modified wood, published information related to changes in anatomical characteristics of modified wood are comparatively insufficient with regards to other wood properties. Defects such as cracks, cell wall collapse and deformation, pit deaspiration, damages to the tracheid walls, parenchyma cells, resin canals as well as vessels can occur in microscopic wood structure.5,8,9 This depends on the specific treatment method parameter which includes temperature and time, heating rate and wood species.10

The objective of this work was to investigate the effect of tin-bath modification on the anatomical properties of Firmiana simplex wood. This was examined by using transmission light microscopy (TLM) and scanning electron microscopy (SEM) to observe the likely changes in wood morphological properties.

Materials

Chinses parasol (Firmiana simplex L.) wood was used to investigate the changes in the anatomical properties of the wood after tin-bath treatment. Oven-dried wood samples with average moisture content (MC) of 12% were used for this study. Tin-alloy was procured from Chemicals Regent Beijing Company Limited, Beijing, China.

Tin-bath modification

Tin-bath treatment was performed in this research based on a pilot experiment and previous scientific work 11 in a laboratory scale using metal bath. Low melting point tin-alloy served as a medium of heat transfer and the samples were immersed in a pre-heated metal bath at 150 and 210˚C. The samples were then treated for 4h when the temperature of the melted tin-alloy had reached the target temperature as stated above. After the treatment process, all the samples were wiped, cooled in a silica gel desiccator and kept in a conditioning chamber at a temperature of 20˚C and relative humidity of 65% for anatomical analysis.

Transmission light microscopy (TLM)

Small block of wood with dimension 20x20x20mm obtain from untreated and tin-alloy treated samples were soften by soaking in water for several days until it became saturated and sink on its own. Thin smooth sections were obtain using a Reichert-Shandon microtome sliding machine for microscopy. The thickness of the thin slices cut from traverse section, tangential and radial surfaces of wood was 18µm. Staining was carried out by adding drops of safranin solution to the thin section in a petri dish. Samples where then placed on slides, covered with microscopic coverslip and oven-dried to remove air bubbles. A binocular microscope (Nikon, ECLIPSE 80i) was used to analyze the anatomical properties with magnification of 40x.

Scanning electron microscopy (SEM)

25µm sections of the samples were cut from untreated and tin-alloy treated F. simplex wood. The samples were sliced using a Reichert-Shandon microtome and were mounted on holders with double-sided adhesive tape after coating with a gold sputter. Morphological properties of the samples were examined using a SU8010 Scanning Electron Microscope (Japan) at different magnifications and a voltage of 5kV (Figure 1).

Transmission light microscope observation

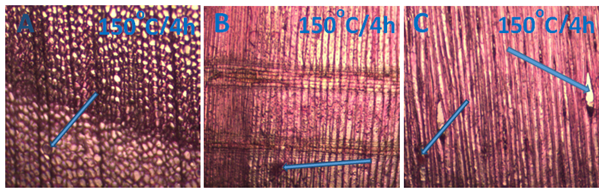

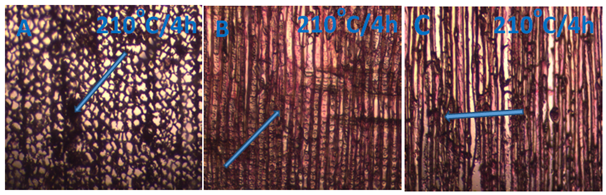

The anatomical properties of the untreated and tin-alloy treated F. simplex are shown in Figures 2–4. Microscopic examinations were performed on the three sections that are, the transverse, radial and tangential sections to observe the changes on the wood anatomy as a result of the influence of tin-alloy modification on the anatomical properties of the wood. The close observation indicated that the wood pores were visible on the images (Figures 2–4) and the colour of the wood became darken after tin-alloy treatment particularly at 210˚C (Figure 4).

Figure 2 Anatomic image of untreated Firmiana simplex: (A) traverse section, (B) radial section, (C) tangential section. Cell walls, vessels and other wood structure intact.

Figure 3 Anatomic image of tin-alloy treated Firmiana simplex at 150˚C /4h: (A) traverse section, (B) radial section, (C) tangential section. Vessels not deformed after tin-alloy treatment of the wood at low treatment temperature.

Figure 4 Anatomic image of tin-alloy treated Firmiana simplex at 210˚C /4h: (A) traverse section, (B) radial section, (C) tangential section. Vessels, fibers and ray parenchyma cells partially damage after tin-bath treatment of the wood at high temperature.

The anatomical structure of the wood appears to be less smashed by the impact of the treatment and there are signs of slight cracks and distortion of the vessels after tin-alloy treatment of F. simplex at 150 and 210oC for 4h compared with the untreated (Figure 3) (Figure 4). Radial and tangential cracks were observed in transverse section, but the shape of the vessels of the tin-bath treated F. simplex wood were not deformed, demonstrating that the anatomical structures of the wood was less affected during tin-bath treatment. Previous research established that the effects of the thermal modification on wood anatomy are strongly linked to the wood species, thus it is difficult to ascertain how cracks develops.5

The shape of the vessels, fibers and ray parenchyma cells in the tin-bath treated samples at 210˚C for 4h were observed to be partially damaged (Figure 4). This maybe as a result of the stresses which occurred between earlywood and latewood6 when subjected to tin-bath treatment. In addition, the extractives deposition in the resin canal vanishes and no damage to the bordered pits were detected after tin-bath treatment of F. simplex.

In summary, the effect of tin-bath treatment on the anatomical structures of F. simplex wood was not significant. Our findings agree with the report of recently published work.12 Previous studies asserted that the influence of treatment method on anatomical structures of wood varied principally according to the different modifications system.1,5 Contrarily, another study asserted that different modification system (open and closed system) does not have a significant bearing on anatomical changes.13

Scanning electron microscopy observation

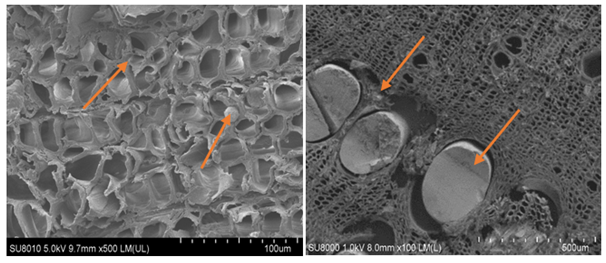

SEM analyses of untreated and tin-bath treated F. simplex wood are shown in Figures 5–7. The microstructure observation of the untreated samples revealed that the vessels and the cell walls of the wood were intact as well as the visibility of other wood structures (Figure 5). On the contrary, tin-bath treatment of the wood at 150˚C and 210˚C leads to the collapse of some of the wood structures (Figure 6) (Figure 7), especially partial damages to the cell walls and vessels were observed.6 This is in line with an earlier report which observed damage of tracheid walls, pit deaspiration and ray tissues after heat-treatment.8 This could be due to macromolecular chain scission of the primary wood components, particularly cellulose and hemicelluloses during tin-bath treatment. Previous work reported wood chemical components (mainly hemicelluloses) degradation which subsequently formed acetic, formic as well as phenolic acids.8

Figure 5 Micrograph of the untreated Firmiana simplex wood. No collaps of the vessels and cell walls.

Figure 6 Micrograph of the tin-bath treated Firmiana simplex wood at 150˚C for 4h. Evident of modification of vessels and cell walls as well as penetration of tin-alloy into the wood.

Figure 7 Micrograph of the tin-bath treated Firmiana simplex wood at 210˚C for 4h. Evident of cracks, broken vessels and cell walls and penetration of tin-alloy into the wood.

As indicated using arrows in Figure 6 and Figure 7, vessels were filled with tin-alloy used as a heating medium. It is evident that the tin-alloy partially entered the wood structure, formed a film covering the cell walls and corners and partly occupies the wood cell lumens. The blocking effect of tin-bath treatment in this study has the potential to improve the physical properties of the wood by eliminating water from the wood structure, therefore improving the physical properties of tin-bath treated wood by reducing the numbers of the hydroxylgroup. Generally, low water absorption in thermal-treated wood is as a result of the modification of the chemical components of the wood compared to anatomical structure.8

Tin-bath treatment of Firmiana simplex hath less impact on the anatomical structures of the wood, though there were signs of slight cracks on the cell walls, vessels, fibers and ray parenchyma cells were partially damaged. The results of this study showed that the effect of tin-bath treatment on the anatomical structures of F. simplex wood was not significant.

On the other hand, SEM micrograph of tin-bath treated F. simplex revealed the collapse of cell walls, vessel as well as the partial penetration of tin-alloy into the wood structure, therefore blocking the cell lumens and vessels of the treated wood.

The authors are grateful for the support of Professor Huang Biao of the College of Material Engineering, Fujian Agriculture and Forestry University, P. R. China, during this study.

None.

The authors declared that there are no conflicts of interest.

©2020 Okon, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.