Journal of

eISSN: 2574-8114

Review Article Volume 4 Issue 1

1Department of Fashion Management Studies, National Institute of Fashion Technology, India

2Knitwear Design Department, National Institute of Fashion Technology, India

Correspondence: Dibyendu Bikash Datta, Department of Fashion Management Studies, National Institute of Fashion Technology, Plot-3B, Block-LA, Sector III, Salt Lake City, Kolkata, West Bengal 700098, India, Tel 919433327019

Received: October 02, 2017 | Published: January 16, 2018

Citation: Datta DB, Seal P. Various approaches in pattern making for garment sector. J Textile Eng Fashion Technol. 2018;4(1):29-34. DOI: 10.15406/jteft.2018.04.00118

Today’s garment-making technology has exceeded expectations, has become easier to learn and quickly adapt completely to the specific necessities of apparel designing. The fit is the most significant deciding factor related to the final acceptance or rejection of a garment. Getting to right design is as important as getting a right product with a perfect fit. The well-tailored fit is dependent on the pattern drafting integrating dimensions of the fit model having various shapes, contour and proportions. With the beginning of the industrial revolution and advances in textiles and clothing manufacturing, standardized patterns were vital to the success of ready-to-wear clothing. New technology platforms are facilitating greater flexibility in the areas of pattern designing, grading, marker making, waste reduction, increase in efficiency and accuracy of the cutting room and create accurate samples in time to help reduce costs are some advantage of using of computer-aided design (CAD) system in composite garment manufacturing. Increase in product development costs, the rise in shipping charges, and awful decision making are an entity that many businesses cannot afford. Efforts are required to drive a product to get to the market faster and are saleable. With that in mind, use of advanced technology in apparel manufacturing is an essential competitive advantage for retailers, brands, and manufacturers alike. This paper was designed to understand the various methods of pattern making systems.

Keywords: patternmaking, grading, clothing; toile, fit, cad

Pattern making is the art of designing patterns by making templates from which clothing and craft items can be sewn. A pattern making process actually help to come out with the imagination of designer from the sketching till real product. Pattern makers are also called 'Technical Designers'. When Fashion Designers complete their garment designing, Technical Designers starts their work to prepare the pattern of the garment. The garment making process consists of disparate yet interdependent stages. The aesthetic appearance, correct fit and the drape attributes of a garment depends significantly on every garment making process. Pattern making is considered as the first step in garment production. While making a garment as per design, templates are used to trace the various garment parts of similar style onto fabric prior to cutting and assembling. Generally, patterns are made of paper or cardboard templates that have become a skilled technical process over the centuries.

During the late medieval period, fabric weaving was done manually on primitive looms which were a slow and laborious process and therefore fabric was considered as a coveted commodity. Rectangular shaped fabric pieces were used for garment construction to minimize waste. The seminal art of pattern making began in the fifteenth century. In place of rectangular uncut fabric, pieces were carefully cut as per size and body's contour.1 the art of pattern making prior to the industrial revolution was extremely revered. Tailors worked meticulously to customize patterns based on their client's personal measurements and clothing was elaborate and solely relegated for the rich. The onset of the industrial revolution marked the importance of standardized patterns for the success of ready-to-wear clothing. However, initial attempts for standardized clothing patterns resulted in the positive approach towards systematic size chart of different regions like US or UK size chart.

In traditionally cut bespoke clothing by directly marking measurements on fabric by tailor's chalk were developed for each customer. Which is also known as tailoring method in pattern cutting and home sewing? While in commercial production, industrial patterns were introduced to cater the mass production to fit several standard sizes. Pattern 'blocks' or 'slopers' have been tested to have an impeccable fit and are altered to create a variety of new styles. The process of developing different sizes of a finished pattern is called 'grading'. It helps in creating a line of differently sized or contoured garments that are yet similarly patterned. Various firms sell pre-graded patterns to consumers who further sew them at home. Commercial clothing manufacturers usually employ specialized pattern maker to make their own in-house patterns as part of their design and production process. Pattern makers are responsible for ensuring assembling of accessories and garments by sewer and manufacturers. Each design is examined by pattern makers to find out the best way to break a pattern down into a series of pieces as per design that can be reassembled; build paper outlines of each part of the design and confirm that the design can be properly reassembled; prepare a set of instructions that may be utilized by manufacturer to reassemble the design from the pattern; make notes on the pattern to point out where each piece be attached and where each feature (button, pocket, zipper, etc.) should be located.

A pattern is a guide for cutting the fabric which can be sewn together to form a garment.2 The different types of pattern making within the apparel industry are:

Sloper/block pattern making

It is a basic garment pattern with no seam allowance from which other similar patterns are designed. It is also referred as basic pattern or foundation pattern to develop and design new patterns for garments. All basic sloper/block is based either by standard measurements or by custom measurements. There are two methods for basic block pattern making which are mostly applicable in women's wear.

Flat pattern technique: Involves a variety of straight edges, curves, measurements, and calculations to draw a draft on paper. It is a two-dimensional method that manipulates an existing foundation pattern 'sloper' or a 'block'. The draft is cut out of muslin fabric having comfort ease to fit a dummy body or an individual. The desired changes are marked on the paper draft. Making patterns following flat pattern making method is easy since patterns are based on templates. The hard part is in making the templates either manually or by using pattern making softwares. They look simple but are hard to make as they require many human body measurements and lots of test fitting. They should be perfect since other patterns are developed based on them. Use of certain geometric rules will derive different patterns from the basic block, and they would fit perfectly like the blocks. Once the blocks are made, the rest is significantly easier given that there is no need to measure the figure anymore, or even test fit new patterns on it.3

In flat method, the pattern maker traces the basic blocks and carry out the necessary manipulation along with essential sewing and other allowances to each component. A small mark on the outside edge of the seam allowance on the pattern is marked to ensure alignment and matching during sewing known as 'notches'. All these exercises produces 'working pattern'. Once test fit is done, the working pattern becomes 'production pattern'

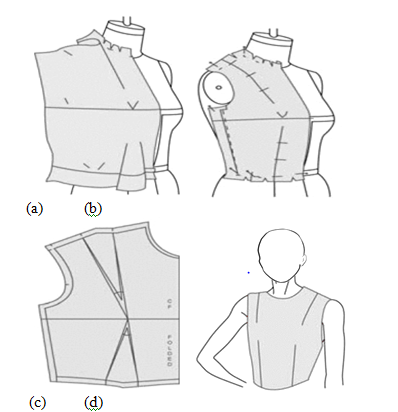

Modelling: Often called 'draping on the stand' is a pattern cutting method which involves muslin fabric for fitting of block garment generally on a designated dummy body of appropriate size. The designers/pattern makers manipulate, mark and adjust the three-dimensional mock-up (creating many variations in style) until they satisfy on the shape and fitness. Mock-up or muslin is also referred as 'toile'. Toile is usually not neatly finished or hemmed like the actual garment would be, and they are made from a translucent cotton or linen fabric so that the design can be tested and perfected. Each component is transferred onto pattern paper and the required allowances added (Figure 1).

Draping is referred to as 'creative pattern making' and is widely used in high-class fashion because this method can provide a clear view of the product to designers in the pattern construction process. In this process, designers may need to use lots of fabric. The styled patterns that are utilized in cutting the original garment sample may be produced in various ways, including flat method, modelling or both together. Modelling method is more time consuming than other two-dimensional methods.4

Figure 1 The draping process from 2 D muslin to finished garment. (a) and (b) Use of muslin to drape front bodice; (c) Finished pattern with seam allowance; (d) Finished garment.

Computerised pattern making

Computer technology has integrated into every aspect of our work-lives. Applications of CAD/CAM made their first appearance in the cutting room in the 1970s. In recent years, however, computers became economical; pattern making and grading software still remain an expensive investment. Creating a flat pattern using CAD is the easiest and most advanced of all design techniques once one become familiar with the system one is working with. Many new design entrepreneurs use a computer to relieve some of the work required to develop a new style. Digitisation of manual pattern and using for production is also done in the industry.

The pattern maker work by using a life-sized, sensitized table and a stylus attached to a computer. Designers use many geometric designs that are based on various shapes and lines to create patterns. Changes can be made easily on the screen if necessary and correct patterns get ready for further operation like grading and marker making. Computers are useful for making patterns that are repetitive. Some pattern makers draft on hard paper and then use the scanner to convert the pattern into a computerized format. Then they make the changes on the pattern on-screen. The major technological features are 'pattern design systems' and 'pattern generation systems'. Pattern design systems speed up the process of pattern making and they improve accuracy. An experienced production pattern maker that is efficient in the use of the pattern design systems drafts the block on the computer efficiently and construct garment patterns by putting in place all the block patterns in current use. Pattern generation system creates the pattern from the pattern components automatically via pattern design system (Figure 2).

Many companies use CAD systems to make patterns. CAD can be used for many fashion design processes such as creating design sketches, apparel designing, pattern making and grading, draping, virtual imaging, garment specification sheets, storyboards, prints for fabrics and technical drawings. Overall CAD saves time during the design process, helps to create new design ideas, shows every design components, develops a prototype and helps to amend the new design before producing. There are different CAD software systems; however, the best come from Lectra Systems, Gerber Technologies, Tukatech, and Optitex.5

A pattern maker interprets a design by drafting it through pattern pieces as per the body measurement following a set of instructions in order to create a style. The process is known as pattern drafting. Individual body measurements are converted into a series of straight lines and curves on template paper. At a later stage, the lines and curves determine the overall sections of the patterns pieces to cut and eventually develop a reusable pattern and tested for fit. Pattern pieces represent the garment in sections and have information on size, grain line, balance marks, pockets, and placement for buttons, buttonholes, notch mark, seam, and hem allowances. They are termed as 'pattern information'. Specific methods and stages of pattern drafting vary from pattern maker to pattern maker.

The 'first pattern' is the first set of a pattern that has been obtained from pattern drafting as per continent's size chart either in women's or men's wear area. Wherein tracing of the main line or necessary lines are done from drafting pattern excluding any seam allowances. Seam allowances are given in production pattern. It usually prepares to check the pattern shape concerning to the steps of cutting, copying, folding, modifying and experimenting to get the first pattern developed for each design from the basic block. Half a pattern for front, back and sleeve are developed unless the design is asymmetrical (Figure 3).

After testing or checking shapes from the first pattern, seam allowance, trimming allowance (optional), buttonhole, button attaching, dart, pleat, notch, ease, etc are included in the copied pattern known as a 'working pattern'. Working pattern is used as a base for manipulation to generate design patterns and is required for every part of garments. Working pattern pieces are cut and labelled for parts name and garment size to which it belongs. This pattern is generally made by tracing the basic blocks on paper and requires fitting and adjustments. It is then transferred onto a fabric for a test fit purpose. The pattern pieces are stitched to get a sample garment (a prototype of the design sketch) and checked for the fit as per the particular body measurement. After checking of the sample in case of any fitting related problem the working pattern is modified to make it eligible for a second test fit and is called 'revised pattern'. Based on the revised pattern stitching is done and checked for the fit. On necessary approval of the buyer, the revised pattern is considered to be the 'production pattern'. 3D vision of a pattern can be seen on a simulated dummy in CAD software systems / body scanner. Thus the approved production pattern goes to the fabric cutting section for marker making and cutting.

The interpretation of the design is done by following pattern making rules which are primarily acquired through experience.6 The pattern pieces as per the design sketch are derived from their individual basic block or sloper which are usually without seams as it hinders proportioning and developing design variations. These basic pattern shapes are used by pattern cutters for every season to draft pattern as a clothing reference with different fitting ease for close-fitting, semi-fitted, fitted, loose-fitting or very loose-fitting. Ease is the amount of space in a garment beyond the body measurement. The specific amount of ease will vary from style to style.

Different garment types have different fashion features.7 A fashion feature relates to the various physical components of the garment and its generic shape. Some of the fashion features are darts, design lines (lines of illusion), pleats, long/short/less sleeve, sleeve in regular/raglan style, flare skirt, collarless bodice, tapered trousers, zipper fly opening, etc. Anything that influences the garment geometry is regarded as fashion feature (Figure 4).

An arrangement of fashion features that are laid to a piece of garment is defined as a fashion style. The existence of a fashion feature may affect the relevant basic blocks by affecting their shapes and dimensions, involve markings to locate positions and creates added pattern pieces as per design. Accordingly, each fashion feature exclusively follow its pattern making rule stating the drafting of such pattern pieces belonging to a particular garment type. Every pattern maker, therefore, set their rules of understanding based on the garment types. Due to the variety and preconception of such rules, every pattern maker usually specializes only for making few types of garment. Hence, they categorize a new design to its applicable garment type related to their recognized set of rules to get similar intermediate style. The final design is achieved through addition, modification or deletion of the fashion features from the intermediate style (Figure 5).8

Pattern making, therefore, consists of three step namely fashion analysis, spec sheet design, and pattern drafting. New fashion designs are analysed by disintegrating them into a look like intermediate style. The intermediate style consists of various garment segments which are further disintegrated and termed as secondary pattern pieces. The secondary pattern pieces usually have features like pleats, flares, darts, and cuts to give required shapes of the garment part. Hence, to expedite the pattern making method, often designs are adapted from existing secondary pattern pieces, in lieu of basic block because of its accuracy of sizing and pace with which ranges can be developed. These designs have minor variation in fashion styles in compare to the related secondary forms.

Pattern grading is step-wise increase and/or decrease of base size or sample size proportionate to specific instructions using a size specification sheet according to measurements. It can be done manually or by using computerized pattern cutting software and does not create a shape or change shape. Grading is an essential step that must be taken before approaching sample manufacturers or factories because they require sets of specific patterns and an order of clothing to be produced. Grading determines how the garments will fit in all sizes. Having a range of sizes for each of clothing category fills out minimum garment order cost effectively.

Although fashion trends come and go, the pattern making principles do not change. The rules and methods are always followed for designing and drafting pattern pieces. Finally, the production pattern is achieved that is correct and perfect, containing every pattern piece required completing the garment. In the production, a pattern has the seam allowance and all requisite information like grain line, style name, size, and sometimes the number of cuts.9 Different signs which a pattern maker uses in patterns to communicate with the buyer and the end users are (Figure 6):

Importance of pattern making

Pattern making converts a sketch into a garment hence it is a link between the design and production. There are three major elements-interpretations, technique, and technology that completes the development of garment pattern making.

Interpretation: This is the ability to read and understand the design/sketch and its objective, technical challenges can be resolved by a technician but none of it completes until design goal is achieved/accomplished.

Technique: The pattern maker should have a large set of tools which can be implied/selected or used while making different specifications/designs and to achieve its results.

Technology: To a huge extent, the efficient and fruitful customised production of a garment is dependent upon the technological facts interpreted into the pattern making. One (pattern maker) should have technological mindset and should understand the production implementations of each detail in the relevant pattern.

Pre-requisite: For pattern making, knowledge of basic geometry is a must, because pattern making is totally based on logic and mathematical calculation whether it is done manually or by using software.

In the fashion universe, design and pattern cutting go hand-in-hand. A truly great pattern cutter is behind every great designer. The distinctive visual style is based on the cutting techniques that have been followed by their pattern cutters.

The pattern provides the clear idea of right style & accurate measurements of garments. A correct pattern helps to make an appropriate sample and contains clear information on construction, sewing allowance, grain line & fabric cutting direction and eliminates fabric wastage. In case of the bulk production process, the factory can estimate the resources required for construction of a particular style based on the pattern and can get more orders from buyers. More accurate interpretation with proper techniques and technology used reduces the pre-production process, helping the buyer to receive trouble free shipment

Design practice and pattern inspiration

During research work, and mostly while developing the design briefs for design experiments, different approaches are practiced by the fashion designers and pattern makers to arrive at the final design based sample garment.8 The different practices that have so far been conducted are:

Ready-made garments industry is one of the most dynamic sectors in the global trade. The industry is expected, estimated and generate a considerable amount of revenue and employment in a global perspective. Manufacturing garments are one of the demanded businesses in the global arena. Pattern making methods and its way of processing are crucial steps for the industry. With the technological development and innovation, pattern making software packages have become more sophisticated and finely tuned to effectively address the requirements of the apparel manufacturer. These days, pattern making tools are carefully tailored to easily automate repetitive time-consuming tasks that can quickly ramp up manufacturing to deliver to the fast-moving world of fashion. The pattern is most important to make an accurate sample to buyers for collecting order. Except for pattern it difficult to make a sample. It always provides clear idea to require resources for the industry. It helps to reduce fabric wastage.

No matter how technology is used, manual pattern making is the mother of pattern making software without which none can produce a pattern that will fit into a particular size without any alteration. The industry's first choice is to digitize accurate manual pattern otherwise even software will fail to produce satisfactory results on repeated iterations.

None

Author declares there is no conflict of interest in publishing the article.

©2018 Datta, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.