Journal of

eISSN: 2574-8114

Research Article Volume 5 Issue 1

1Department of Fiber and Composite Materials, Feng Chia University, Taiwan

2Textile and Material Industry Research Center, Feng Chia University, Taiwan

Correspondence: Kuo-Bin Cheng, Department of Fiber and Composite Materials, Feng Chia University, 100, Wen Hua Rd, Sea Tween District, Taichung 407, Taiwan, Tel 886-912583211, Fax 886-4-24514625

Received: February 18, 2019 | Published: February 26, 2019

Citation: Huang FL, Huang JY, Cheng KB. The fabrication and functional properties of cooling, thermal insulation, and anti-UV polyester knitted fabrics. J Textile Eng Fashion Technol. 2019;5(1):64-67. DOI: 10.15406/jteft.2019.05.00182

The functional cooling and thermal insulation (TI) powders were ground by a wet ball grinding machine with 360 nm mean (D50) and 736 nm maximum (D99) particle size. A 1.0 wt% sodium dodecyl sulfate (SDS) dispersant was added to avoid the aggregating phenomenon and to make the dry type of cooling and thermal insulation powders dry by the spray drying method. Then, the functional polyester/cooling and TI master batch with 12% powder content were fabricated by a twin screw machine. The 120d/72f cooling polyester partial oriented yarn (POY) with cooling powder was made by the melting spinning machine and 75d/72f cooling polyester draw textured yarn (DTY) was spun by a Barmag type false twist machine. The 100d/144f polyester DTY yarn with thermal insulation function was made from the above same methods. Furthermore, the circular interknitted fabrics was fabricated by circular knitting machine with 28 gauges and the finished knitted fabric was produced by scouring, bleaching, dyeing and tentering processes. The 100d/144f DTY TI yarn with 58 wt% and 62 wt% were used as technical face and 75d/72f DTY (WINDRY) with 42 wt% and 38 wt% as technical back of knitted fabric to form an interlock knitted structure. Finally, the cooling and thermal insulation functions of the finished knitted fabrics and their end applications were investigated.

Keywords: circular knitted fabric, composite mineral stone cooling particles (CMSCP), polyester, UPF, cooling and thermal insulation functions, melt spinning method, draw textured yarns (DTY)

Due to rapid changes in the climate and environmental pollution as well as the terrible sunlight is becoming increasingly serious; the wearer will gradually feel the discomfort caused by the higher temperature and humidity weather. Therefore, fiber products with cooling and anti-UV, thermal insulation, moisture transfer and water absorption etc. functions become an urgent need for the product in summer and spring seasons. Recently, the composites slurry formulation, polymer and inorganic particles have attracted much more attention and made a great advance in the fiber, polymer, film, fabric, and composite materials fields. One of the most prevalent or popular classes of fiber is composed of materials containing an organic bonding matrix with inorganic material such as the functional fillers. Polyester fiber is the world largest amount, is cheaper, has superior mechanical properties and is the most widely used in man-made fibers. To overcome the disadvantage of regular polyester fiber products, thus incorporated the organic polymer or fiber with inorganic filler (powders) can produce materials of improved functional properties with less inorganic powder content than in conventional polymer material. Recent functional polyester fiber products were spun by the melt spinning system in Taiwan which have included cooling, warming, antibacterial, deodorant, anti-UV, anti-electrostatic, and full dull etc. polyester yarns which could be used in Summer and Spring seasons’ garments, such as sport wear, underwear, jeans, socks, sleeves, shoes, pants and curtains etc. In this paper, the functional polyester circular interknitted fabrics emphasized on comfort, health, safety, and skin care application fields. The current report demonstrates that fabric performance or functions can be tailored to added amount and size of cooling and thermal insulation powder, fiber fineness, yarn denier, fabric density, and functional yarn content variations. The findings of this report suggest that a complete fabric forming system is possible through the integration of the different types of fiber based functional elements. This work intends to be a starting point for standardization and functionalization of functional fabric fabrication techniques and intelligent textile fabrication methods. Finally, static temperature difference, instant cooling value (Qmax), UPF value, thermal insulation, and water absorption height of functional polyester circular knitted fabric which are based on FTTS- FA-005-2010, CNS 15687, AATCC 183-2010, Reflector Lamp method, and FA-004-2011 4,4 respectively would be investigated.1–7

The production of compound mineral stone cooling (CMSCP) and thermal insulation particles, produced by wet the grinding method with sodium dodecyl sulfate (SDS) dispersant, were studied in this paper. In order to obtain the uniform distribution and smaller particle size of CMSCP water borne slurry and make CMSCP and thermal insulation distribute into the polyester fiber evenly, the zeta potential tester would be tested in the first step and controlled over 40 mV around 7.0-8.0 pH value. Added 1.0 wt% SDS dispersant to avoid the aggregating phenomenon and make the dry type of cooling and thermal insulation powders by spray drying method, passed through the twin screw machine to fabricate the master batch. The 120d/72f cooling polyester partial oriented yarn (POY) was made by melting spinning machine and 75d/72f cooling polyester draw textured yarn (DTY) was spun by the Barmag false twist machine. The 75d/72f draw textured yarn (DTY) with cooling function, 100d/144f polyester DTY yarn with thermal insulation (TI) function and other yarn specifications have been produced commercially. The specifications and constitutions of Circular interknitted fabrics with cooling and thermal insulation functions are shown in Table 1. It was expected that the cooling yarns could be used for the unique Windry, and Ecowindry fiber products with better cooling, UV shielding, thermal diffusivity, hand feeling, thermal insulation and water absorption functions. Finally, the yarns were used as the raw materials to fabricate knitted fabrics by circular knitting machine having cooling, thermal image temperature, UV shielding, hand feeling, thermal insulation, and water absorption functions which achieved the demands of FTTS- FTTS- FA-005-2010, CNS 15687, AATCC 183-2010, Reflector Lamp method, and FA-004-2011 4,4 testing standards respectively. The submicron CMSCP powders, and PET/ CMSCP draw textured yarns (DTY) as well as submicron thermal insulation powders (TIP), and PET/TIP DTY which can be interknitted to a knitted structure have been fabricated successfully. Finally, the finished knitted fabric passed through scouring, bleaching, dyeing and tentering processes for summer and spring garment applications.8–12

|

|

Technical face |

Technical back |

Fabric weight (g/m2) |

|

A |

100D/144F polyester DTY with thermal Insulation function occupied 58 wt% |

75D/72F polyester DTY -(WINDRY) with cooling function occupied 42wt% |

240.6 |

|

B |

100D/144F polyester DTY with thermal Insulation function occupied 62wt% |

75D/72F polyester DTY -(WINDRY) with cooling function occupied 38wt% |

339 |

|

C |

75D/72F regular polyester DTY occupied 50wt% |

75D/72F regular polyester DTY occupied 50wt% |

207.4 |

Table 1 Circular knitted fabric specifications with different constitutions

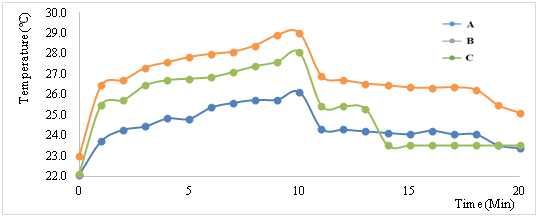

The effect of different constitutions on thermal image temperature difference of circular interknitted fabrics

The data of various temperature differences of circular interknitted fabrics with the different constitutions is shown in Figure 1. The knitted fabrics were irradiated with 500 watts of halogen lamp for 10 minutes after the initial temperature (T0) of the temperature difference which is called (T10-T0) temperature by FLIR thermal image camera. (T10-T0) temperature shows the situation in 10 minutes of the temperature raising. The (T10-T0) temperature rising rate increases with increasing the fabric weight or thickness, presumably due to much lower thermal conductivity of the lighter fabric A, which was better than regular polyester knitted fabric and heavier fabric B. Furthermore, (T10-T20) temperature drop rate increases with decreasing the fabric weight, presumably due to much higher thermal diffusivity of lighter fabric A, which was better than regular polyester knitted fabric and heavier fabric B. It shows that the heat absorption is slower and the heat dissipation is faster. The testing results of temperature difference achieved the expected goal and industrial demand.

Figure 1 The Effect of Different Constitutions on Thermal Image Temperature Difference of Circular Interknitted Fabrics.

The effects of different constitutions on instant cooling value (Q-max) of circular interknitted fabrics before and after laundry

Table 2 shows Q-max value of circular interknitted fabrics with different constitutions before and after laundry. The Q-max value was tested according to CNS15687 testing standard. Fabric A and B have almost the same Q-max value and better than regular polyester knitted fabric. It is probably because the added amount of cooling and thermal insulation powders are almost the same in fabrics A and B.

|

Nomenclature |

Laundry |

Q-max value (W/cm2) |

|

A |

Before Laundry |

0.173 |

|

20 times Laundry based on AATCC 135 |

0.17 |

|

|

B |

Before Laundry |

0.179 |

|

20 times Laundry based on AATCC 135 |

0.167 |

|

|

C |

Before Laundry |

0.102 |

Table 2 Q-max Value of Circular Interknitted Fabrics with Different Constitutions before and after Laundry

Table 3 shows thermal insulation rate of circular interknitted fabrics with different constitutions before and after laundry. The thermal insulation rate was tested based on the reflection lamp method (Refer JIS testing standard). Fabrics A and B have almost same thermal insulation rate but better than regular polyester knitted fabric. That is probably because the added amount of cooling and thermal insulation powders are almost the same in fabrics A and B. Furthermore, the oil on the interknitted fabric is a temperature-concentrating substance, therefore the oil would be removed after the dyeing and finishing processes, so the thermal insulation rate of knitted fabric would be improved after laundry.

|

Nomenclature |

Laundry |

Thermal insulation rate |

|

A |

Before Laundry |

41.20% |

|

20 times Laundry based on AATCC 135 |

46.00% |

|

|

B |

Before Laundry |

41.40% |

|

20 times Laundry based on AATCC 135 |

44.00% |

|

|

C |

Before Laundry |

25.10% |

Table 3 Thermal Insulation Rate of Circular Interknitted Fabrics with Different Constitutions before and after Laundry

Table 4 shows water absorption rate of circular interknitted fabrics with different constitutions before and after laundry. The water absorption rate was tested according to FTTS-FA-004 testing certification. Fabric A and fabric B showed a poor water absorption rate before laundry. It is because of the oil on interknitted fabrics. After laundry, since the oil was removed through dyeing and finishing processes, therefore the water absorption rate would be improved. Otherwise, fabric B has a better water absorption rate than fabric A, because the former fabric B has a heavier weight than later one.

|

Nomenclature |

Laundry |

Water absorption rate |

|

A |

Before Laundry |

0.40% |

|

20 times Laundry based on AATCC 135 |

2.30% |

|

|

B |

Before Laundry |

0.40% |

|

20 times Laundry based on AATCC 135 |

4.90% |

Table 4 The Water Absorption Rate of Circular Interknitted Fabrics with Different Constitutions before and after Laundry

Ultraviolet protection factor (UPF) is used to measure its ability to protect against UV rays. UPF description indicates the ability of clothing to protect against UVA and UVB. Table 5 shows UPF of circular interknitted fabrics with different constitutions before and after laundry. The UPF was tested according to the AATCC 183 testing standard. Fabrics A and B have excellent UPF before and after laundry. This is because the cooling and thermal insulation powders were added in the DTY. Otherwise, fabrics B and A have excellent UPF after laundry, because of the permanent functional DTY used in this paper.

|

Nomenclature |

Laundry |

UPF |

|

A |

Before Laundry |

50+ |

|

20 times Laundry based on AATCC 135 |

50+ |

|

|

B |

Before Laundry |

50+ |

|

20 times Laundry based on AATCC 135 |

50+ |

Table 5 The UPF of Circular Interknitted Fabrics with Different Constitutions before and after Laundry

Throughout the above experimental results it was found that the key performance index was as follows: the testing results of temperature difference should be over 1.0℃. The Qmax value should be over 0.13 W/cm2, UPF value over 50, thermal insulation rate over 30%, and water absorption height could be over 12cm/10 min.8 Furthermore, the PET/ CMSCP and PET/TIP interknitted fabric has better bursting strength, dimensional stability, water absorption, dyeing ability, drape ability, air permeability, moisture transfer, soft and comfort hand, silk like appearance, and less electrostatic problem. The cooling PET/ CMSCP yarn is a kind of excellent and unique yarn material to produce high grade cloth, and can be blended with natural cotton or other synthetic fibers to knitted fabrics for improving the functions, hand touch and appearance, so that the application fields could be wider extended, the raw material cost would be saved and also the efficiency would be modified. The end applications of these cooling knitted fabrics could be such as scarfs, under wear, short pants, socks, hats, bed clothes, pillow covers, sleeve, masks, T shirts, jackets and jeans etc. worn in spring and summer seasons. The commercialized Windry and Ecowindry knitted fabrics have been provided to international brands such as Triumph, Wacoal, Victoria Secret (VS), Vanity Fair (VF), UA, Easy Shop etc., to sell in the USA and Asian countries. It also expected to satisfy customer’s and market needs regarding comfort, function, health care, safety, and sanitation etc. After dyeing and finishing, fabrics made of PET cooling and thermal insulation yarns still have excellent functions, and can be dyed various colors and color fastness. The AATCC135 test shows that washed 20 times in a home washing machine it can retain over 90% of its functions. The PET/ CMSCP and PET/ TIP interknitted fabric also passed the "OECD Guideline 401" oral toxicity test, ISO 10993-5 for cell toxicity, ISO10993-10 for skin irritation and ISO 10993-10 for skin sensitivity.

Through the above results and discussion, the following conclusions can be obtained after the consolidation.

The authors are very grateful and wish to thank the Inorganic/Organic Composites laboratories of the Department of Fiber and Composite Materials, Textile and Material Industrial Research Center, Feng Chia University, the Zhanyi Science & Technology Co. Ltd. for their technical support in completing this work and Professor Gordon Dixon from Manchester Metropolitan University, UK for his assistance in English writing correction. There is much appreciation also for the financial support of the Ministry of Science and Technology, Taiwan (106-2622-E-035-020-CC2).

Author declares there is no conflict of interest in publishing the article.

©2019 Huang, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.