Journal of

eISSN: 2574-8114

Short Communication Volume 9 Issue 1

1Department of Textile Engineering, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

2BGMEA University of Fashion and Technology (BUFT), Dhaka, Bangladesh

Correspondence: Dr. Engr. Mohammed Rubaiyat Chowdhury, Department of Textile Engineering, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

Received: January 26, 2023 | Published: March 6, 2023

Citation: Chowdhury MR, Khan AN. Study on the properties of yarn produced by 100% pima cotton fibre. J Textile Eng Fashion Technol. 2023;9(1):21-24. DOI: 10.15406/jteft.2023.09.00328

To produce higher count of yarn long staple length cotton fibres are used. Specially, long staple length Pima and Giza cotton fibres are used for this purpose. In this study to produce 80Ne carded yarn Pima cotton fibre was used. Pima Cotton is a long stable fiber. Which is normally produced in Australia and America. In this study different properties of yarn like thick, thin and neps, CSP, fineness of pima cotton fibre were tested. It was evident that the quality of the yarn produced was good in quality to produce different fine quality fabrics.

Keywords: HVI (high volume instrument), uster tester 4, IPI (imperfection index)

Cotton fiber is the purest source of cellulose and the most significant natural fiber. The economic significance of cotton in the global market is evident by its majority share (over 50%) among fibers for apparel and textile goods. Both the market value and the quality of cotton products are directly related to fiber quality. Competition with other fibers is affected by innovations and commercialization of other fibers including microdenier (polyesters and nylons), elastomeric (spandex), and lyocell fibers, among others. Fundamental understanding of the fibers (structural formation during development, chemistry, physics), significant improvement in fiber quality as well as in process innovation and product differentiation are critical to uphold the inter-fiber competitiveness of cotton fibers and the share of cotton fibers in the global apparel and other textile markets. Cotton fibers are the purest form of cellulose, nature’s most abundant polymer. Nearly 90% of the cotton fibers are cellulose. All plants consist of cellulose, but to varying extents. Bast fibers, such as flax, jute, ramie and kenaf, from the stalks of the plants are about three-quarters cellulose. Wood, both coniferous and deciduous, contains 40–50% cellulose, whereas other plant species or parts contain much less cellulose. The cellulose in cotton fibers is also of the highest molecular weight among all plant fibers and highest structural order, i.e., highly crystalline,oriented and fibrillar. Cotton, with this high quantity and structural order of the most abundant natural polymer, is, not surprisingly, viewed as a premier fiber and biomass.1

Cotton fibers are composed of mostly a-cellulose (88.0–96.5%) (Goldwaith and Guthrie, 1954). The noncellulosics are located either on the outer layers (cuticle and primary cell wall) or inside the lumens of the fibers whereas the secondary cell wall is purely cellulose. Vary by their varieties, growing environments (soil, water, temperature, pest, etc.) and maturity. The noncellulosics include proteins (1.0–1.9%), waxes (0.4–1.2%), pectins (0.4–1.2%), inorganics (0.7–1.6%), and other (0.5–8.0%) substances. In less developed or immature fibers, the non-cellulosic contents are much higher.2

Pima cotton is the actual high-end luxury cotton. Pima cotton is a superior kind of cotton also known as extra-long-staple (ELS) cotton. Due to its long-staple Pima cotton is durable and highly absorbent. Pima cotton is named after the Pima people of Arizona, America but it was originated in South America, not in South America.Basically Pima cotton is a plant that is also called Gossypium barbadense scientifically.3 The main quality of Pima cotton is Extra-Long-Staple (ELS) that makes its fabric durable and superior. Pima cotton fiber measures between 1 ¼ to 2-inch in length that is, 50% longer than regular cotton. There are three main types of Pima cotton; Acala Cotton, Egyptian Cotton, Upland Cotton. Pima cotton is grown mainly in the United States, Australia, and South America. It is known for its richness of texture and softness that's why it is used in luxury bedding sheets and different forms of clothing. When it's come to cotton and Pima cotton, Pima is slightly different from cotton. Cotton is well known as a good fabric whereas Pima cotton is a kind of cotton. And the slight difference between cotton and Pima cotton is “fibers”. The fibers of conventional cotton ranges from 00.50 inches to 01.10 inches and fibers of Pima cotton (Extra long-staple cotton) ranges from 01.40 inches to 02.00 inches. This extra-long-staple makes Pima cotton a better fabric than conventional cotton, which gives extra softness and durability to the fabric.4

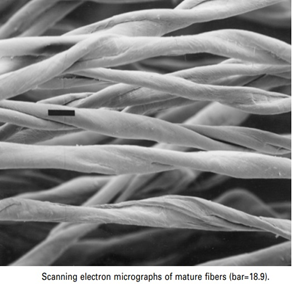

Pima cotton is one of the two distinct species of cotton that end up on store shelves. The most common type is Upland cotton (Gossypium hirsutum), comprising nearly 90% of all cotton produced around the world. The remaining 10% is made up of two higher-quality cottons — Egyptian cotton and Pima cotton. Both of these cottons are actually the same species of “extra-long staple cotton” (Gossypium barbadense), with longer, silkier individual cotton fibers for a premium fabric that is both luxuriously soft and incredibly strong. While Egyptian cotton, when it’s authentic, is a premium fabric that originates in the Nile River Valley, pima cotton has a decidedly American story. Since it’s considered the finest cotton in the world, it’s no wonder that farmers were keen to cultivate extra-long staple cotton on American soil. Pima traces its roots to cotton that was grown on the famed Sea Islands of South Carolina as early as the 1790s. Through selective cross-pollination with Egyptian varieties throughout the 19th century, producers have developed a uniquely American extra-long staple cotton. This cotton, originally called American-Egyptian cotton, offered an incredibly high-quality fiber that resulted in a luxurious fabric as soft as it was strong. It wasn’t until the early 1900s that the U.S. Department of Agricultural got involved, working with the Pima tribe of Arizona to perfect this young crop. It was in honor of these pioneering farmers that the USDA named the American extra-long staple variety “pima cotton.” The 1950s saw great advances in pima seed quality, and innovation on this superior quality crop continues today through the efforts of our pima farmers in the San Joaquin Valley of California (Figure 1) (Table 1).5

Figure 1 Photograph of matured cotton fibre.6

|

Official colour grades of US upland cotton_ Adapted with permission from International Trade Center UNCTAD/IWO: Cotton Exporter's Guide, ITC,. Geneva, 2007 |

|||||

|

|

White |

Light spotted |

Spotted |

Tinged |

Yellow stained |

|

Good middling |

11 |

12 |

12 |

— |

|

|

Strict middling |

21 |

22 |

23 |

24 |

25 |

|

Middling |

31 |

32 |

33 |

34 |

35 |

|

Strict low middling |

41 |

42 |

43 |

44 |

|

|

Low middling |

51 |

52 |

53 |

34 |

— |

|

Strict good ordinary |

61 |

62 |

63 |

|

— |

|

Good ordinary |

71 |

— |

— |

|

— |

|

Below grade |

81 |

82 |

23. |

64 |

85 |

Table 1 Official color grades of US upland cotton7

Physical standards in bald, descriptive manda Ms in italics.

Material Selection: 100% Pima cotton fibre.

Sample selection: Fibre length was 17/16” .20 cotton bales were collected for the test. The fibres were then sent to the process to produce yarn. When the yarn was manufactured its properties were tested.

Machines or instrument used:

The following machines and equipment were used for the test data collection

The USTER® HVI 1000 (High Volume Instrument for fiber testing) was used to determine the following parametrrs of fibre. The HVI 1000 system (either model) measures physical fiber characteristics defined by the United States Department of Agriculture (USDA) in its cotton marketing system.

Length 2. Strength3. Elongation 4. Micronaire value 5. Color 6. Trash 7 Moisture 8. Short Fibre Index (SFI) 9. Maturity 10. Spinning Consistency Index (SCI) 11. Neps 12. Rd and + b

The above fibre properties are very important for determining the fibre quality and to p[roduce yarn of desired quality.

The yarns prepared from the collected fibres were tested. The test results are mentioned below:

From Table 2 and Table 3 it is evident that the fibre properties like moisture content, strength, Micronaire Value, Maturity ,UI, Rd and +b are very good compared to short and medium staple fibre.8 The yarn properties like U%, CVm, IPI ( Thick, Thin and Neps), H. Sh and Rel Cnt are also very good in quality.9 The CSP for carded yarn is 3080 which is very good as per the carded yarn standard (Figure 2) (Figure 3).10

|

Sample # |

SCI |

Moisture content % |

Micronaire Value |

Maturity |

UI |

Strength (gram/text |

Rd |

+b |

|

1 |

203 |

6.2 |

4.09 |

0.87 |

86.9 |

41.8 |

73.2 |

12.2 |

|

2 |

221 |

7.2 |

3.77 |

0.86 |

89 |

43.5 |

70.8 |

11.7 |

|

3 |

244 |

6.4 |

3.65 |

0.86 |

90.6 |

49.4 |

68.7 |

12 |

|

4 |

232 |

6.2 |

3.82 |

0.86 |

89 |

47.5 |

66.2 |

11.2 |

|

5 |

216 |

7.4 |

3.86 |

0.86 |

89 |

42.1 |

71.2 |

11.5 |

|

6 |

222 |

6.8 |

3.68 |

0.85 |

89.9 |

42.2 |

72.2 |

12.6 |

|

7 |

219 |

6.4 |

3.68 |

0.86 |

87.5 |

44.5 |

73.5 |

11.9 |

|

8 |

233 |

7 |

3.76 |

0.86 |

90.5 |

43.9 |

73.2 |

12 |

|

9 |

195 |

7.4 |

3.89 |

0.86 |

85.7 |

40.4 |

73.7 |

11.4 |

|

10 |

245 |

6.6 |

3.75 |

0.86 |

90.4 |

48.7 |

72.7 |

12.4 |

|

11 |

219 |

6.4 |

3.45 |

0.85 |

88.3 |

44.8 |

71.4 |

11.9 |

|

12 |

193 |

7.2 |

3.97 |

0.86 |

86.4 |

40.3 |

72.1 |

12 |

|

13 |

208 |

6.4 |

3.89 |

0.86 |

86.5 |

45.2 |

72.4 |

11.4 |

|

14 |

212 |

6.4 |

3.84 |

0.86 |

89.3 |

40.9 |

73.6 |

12.4 |

|

15 |

227 |

7.5 |

3.87 |

0.86 |

88.4 |

46.9 |

71.5 |

11.9 |

|

16 |

234 |

6.7 |

4.07 |

0.87 |

90.1 |

47.5 |

71.4 |

12 |

|

17 |

206 |

6.9 |

3.73 |

0.85 |

87.7 |

41 |

73.7 |

12.5 |

|

18 |

208 |

7.1 |

4.03 |

0.86 |

89.9 |

39.4 |

69.1 |

12.1 |

|

19 |

225 |

7 |

3.46 |

0.85 |

87.9 |

46 |

66.8 |

12.2 |

|

20 |

199 |

6.7 |

3.86 |

0.86 |

86.5 |

40.5 |

72.5 |

11.8 |

|

Mean |

218.05 |

6.795 |

3.806 |

0.859 |

88.475 |

43.825 |

71.495 |

11.955 |

Table 2 HVI test report for 100% pima cotton

|

Sample |

U% |

CVm |

CVm |

CVm |

CVm |

Thin |

Thick |

Neps |

Neps |

H |

sh |

RelCnt |

|

No.1 |

|

|

1m |

3m |

10m |

-50% |

50% |

200% |

280% |

|

|

± |

|

1 |

13.49 |

17.3 |

5.56 |

4.18 |

3.05 |

87.5 |

367.5 |

645 |

280 |

3.57 |

0.92 |

1.2 |

|

2 |

13.63 |

17.29 |

5.64 |

4.2 |

3.39 |

82.5 |

340 |

615 |

235 |

3.66 |

0.94 |

-0.2 |

|

3 |

13.65 |

17.3 |

5.91 |

4.3 |

2.78 |

127.5 |

292.5 |

685 |

275 |

3.65 |

0.91 |

1.2 |

|

4 |

13.98 |

16.84 |

5.4 |

3.82 |

2.84 |

700 |

290 |

622.5 |

270 |

3.77 |

0.95 |

-1.2 |

|

5 |

12.93 |

16.56 |

5.43 |

3.87 |

2.98 |

67.5 |

255 |

500 |

215 |

3.57 |

0.86 |

-1 |

|

Mean CV |

13.33 |

17.06 |

5.59 |

4.07 |

3.01 |

87 |

309 |

613.5 |

255 |

3.65 |

0.92 |

0 |

Table 3 Yarn properties of uster tester test report for 100% pima cotton

80s/1 KW- IPI = 1009.5

C.S.P.- 3080

To produce high quality fabric long staple fibres are required. PIMA cotton fibre is a extra long staple fibre with better fibre properties which leads to manufacture a high quality yarn with the parameters like IPI, CVm, H, Sh and CSP achieving high value. The study showed higher quality parameters of fibre and yarn. The fibre parameters like moisture content, strength, Micronaire Value, Maturity, UI, Rd and +b are high and the yarn parameters like IPI, CVm, H, Sh and CSP also were among the high value which indicates that with PIMA cotton a very high end cotton yarn can be produced and eventually can be used to produce high end fabric. It would have been better if we could produce a high end fabric and study the parameters of fabric. However, the study gave a clear statistic about the influence of PIMA cotton in respect to produce high quality yarn.

None.

None.

Authors declare that there is no conflict of interest.

©2023 Chowdhury, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.