Journal of

eISSN: 2574-8114

Opinion Volume 11 Issue 4

1Tashkent Institute of Textile and Light Industry, Tashkent, Uzbekistan

2Karakalpak State University, Nukus, Uzbekistan

3Jizzax Politecnic Institute, Jizzax, Uzbekistan

Correspondence: Zakirova Dilfuza Khabibullaevna, Tashkent Institute of Textile and Light Industry, Tashkent, Uzbekistan

Received: April 16, 2025 | Published: September 9, 2025

Citation: Khabibullaevna ZD, Adkhamovich AJ, Qizi TSI, et al. Selection of raw materials for fashioned threads from chemical threads by the method of heat treatment. J Textile Eng Fashion Technol. 2025;11(4):211-213. DOI: 10.15406/jteft.2025.11.00424

The article presents the research on the selection of raw materials for fancy threads made of chemical fibers. The research was conducted using the method of heat treatment in a dry and humid hot environment. Polyester and viscose threads of different linear density were used as raw materials. The heat treatment process was carried out for 2, 5, 10, 15, 20 minutes and at temperatures of 40, 50, 60, 70, 80, 90°C. The recommended heat treatment parameters are based on the shrinkage of threads along the length as a result of heat treatment.

Keywords: polyester, viscose, bulk, dry hot environment, wet hot environment, heat treatment, twist, temperature, fancy thread, linear density, diameter, volume

Research and development work is being carried out in the world aimed at expanding the range of threads from chemical threads, which are raw materials for the weaving and knitting industry and finished textile products, as well as creating energy- and resource-saving technologies through the use of modern technologies. In this area, priority is given to research on obtaining types of textile products by producing assortments of fancy threads. In this regard, the creation of technology for the production of new assortments of fancy threads on existing equipment of textile enterprises by improving the technology for the production of fancy threads from local chemical and natural threads is of particular importance.1–6

The research work is aimed at creating new ranges of fancy threads by improving the production technology. There are several methods of producing fancy threads in the textile industry, and this research focuses on the method of obtaining fancy threads by heat treatment. Before starting research, it is important to select raw materials for obtaining fancy threads. It is advisable to produce a new range of fancy threads using the raw materials available in our country and the operating equipment at textile enterprises. In the world, due to population growth and the reduction of areas suitable for growing natural fibers, the demand for natural fibers and yarn is increasing. Accordingly, the prices of raw materials for natural fibers and the cost of products from them are growing. At present, in a number of regions of our country, along with natural fibers, chemical fibers are produced by local manufacturers. This will lead to an expansion of the range of textile products manufactured, a reduction in the cost of production, and the elimination of a number of problems in the supply of raw materials. In enterprises, you can find processed and unprocessed chemical threads of various linear densities. Due to these threads, it is possible to provide textile enterprises with local raw materials and allow them to produce textile products at much lower costs and supply products to the domestic and foreign markets.

Fancy yarns obtained by improving the technology of fancy yarn production are mainly used for consumer goods, decorative items, outerwear, curtains and hosiery. Therefore, fancy yarn is planned to be produced from chemical yarns, and if possible from local raw materials.7–10

The proposed method for producing fancy threads is carried out by heat treatment in a dry and humid hot environment. Samples for fancy threads, which will be produced by the new method, were taken from the selected raw materials. The studies were conducted by exposing them to dry and humid hot air. The obtained samples had a certain length, and the effect of different temperatures and processing times was studied. In this case, the shrinkage of the selected threads was observed both in a dry and in a humid hot environment. The shrinkage of the thread selected as a raw material was studied depending on time and temperature. Experiments were conducted in environments with a temperature of 40, 50, 60, 70, 80 and 90oC.

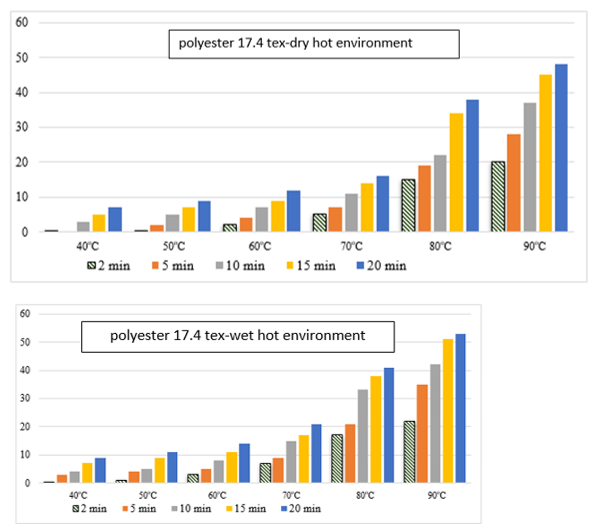

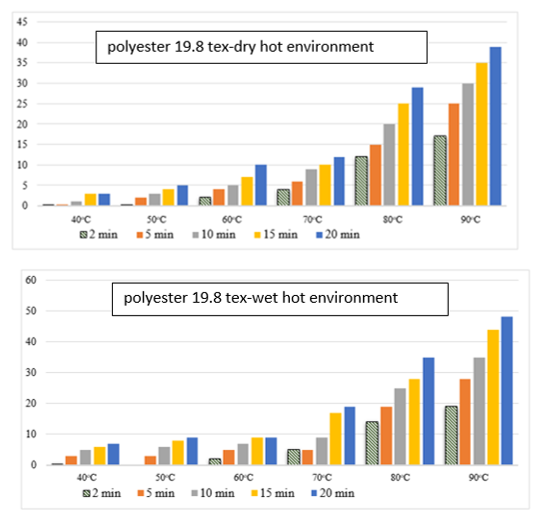

It was found that all the selected types of raw materials have shrinkage along the length. However, the greatest shrinkage was observed in polyester threads, and viscose threads showed different shrinkage depending on their linear density. At temperatures below 60 °C, shrinkage of the threads was practically not observed, and if it did occur, it was unnoticeable for a long time. The results of the studies are presented in Figures 1–4.

Figure 1 and Figure 2 show the results of thread shrinkage along the length during processing in a dry and humid hot environment at temperatures of 40oC, 50oC, 60oC, 700C, 80oC and 90oC of polyester threads with a linear density of 17.4 tex and 19.8 tex, selected as raw materials for the production of new ranges of fancy threads obtained by improving the technology for the production of fancy threads. When processed in a dry hot environment at a temperature of 40oC at different intervals of time, the threads showed shrinkage of 3-7%, at a temperature of 50°C 3-9%, at a temperature of 60°C 3-12%, at a temperature of 70°C 4-16%, at a temperature of 80°C 12-38% and at a temperature of 90°C 17-48%. When processed in a humid hot environment at a temperature of 40oC, the threads showed shrinkage of 3-9%, at a temperature of 50°C 3-12%, at a temperature of 60°C 3-14%, at a temperature of 70°C 5-21%, at a temperature of 80°C 14-41% and at a temperature of 90°C 19-53%.

Figure 1 Diagrams of the dependence of shrinkage of polyester threads with a linear density of 17.4 tex on the time of processing in a dry and humid hot environment at temperatures of 40oC, 50oC, 60oC, 70oC, 80oC, 90oC.

Figure 2 Diagrams of the dependence of shrinkage of polyester threads with a linear density of 19.8 tex on the time of processing in a dry and humid hot environment at temperatures of 40oC, 50oC, 60oC, 70oC, 80oC, 90oC.

Figure 3 and Figure 4 show the results of shrinkage of threads along the length during processing in a dry and humid hot environment at temperatures of 40oC, 50oC, 60oC, 70oC, 80oC and 90oC of viscose threads with a linear density of 16.3 tex and 23.4 tex, selected as raw materials for the production of new ranges of fancy threads obtained by improving the technology for the production of fancy threads. During processing in a dry hot environment at a temperature of 400C, the threads did not show shrinkage, at a temperature of 50°C and 60°C they showed shrinkage of 2%, at a temperature of 700C 2-4%, at a temperature of 80°C 3-5% and at a temperature of 90°C 5-7%. When processed in a humid hot environment at a temperature of 40oC, the threads did not show shrinkage, at a temperature of 50°C and 60°C they showed shrinkage of 2-3%, at a temperature of 70oC 2-5%, at a temperature of 80°C 5-6% and at a temperature of 90°C 5-7%.11–14

Based on the results of the studies on the selection and justification of raw materials for fancy threads, it can be concluded that the maximum shrinkage of chemical threads was observed during processing in a dry and humid hot environment at a temperature of 80-90oC and by means of heat treatment it was proven that fancy threads can be produced from these chemical threads. Accordingly, for the production of fancy threads by the method of heat treatment by improving the technology for producing fancy threads from chemical threads, a processing temperature of 80-90oC and a duration of 15-20 min were recommended. Based on the results of shrinkage of heat-treated threads, it is recommended to mix chemical threads in various ratios: polyester (17.4 tex) + polyester (19.8 tex), polyester (17.4 tex) + polyester (19.8 tex x 2), polyester (17.4 tex) + viscose (16.3 tex) and polyester (19.8 tex) + viscose (23.4 tex).

When studying the effect of heat treatment, the highest values were shown by polyester thread with a linear density of 17.4 tex. Therefore, the shrinkage process of polyester thread with a linear density of 17.4 tex at different temperatures over time was theoretically investigated

None.

None.

The authors declare that there is no conflict of interest.

©2025 Khabibullaevna, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.