Journal of

eISSN: 2574-8114

Research Article Volume 9 Issue 4

Mudo Satış Mağazaları A.Ş, Marmara University, Turkey

Correspondence: Meltem Gülmez, Mudo Satış Mağazaları A.Ş, Marmara University, Turkey, Tel 05385266456

Received: August 07, 2023 | Published: August 18, 2023

Citation: Gulmez M, Erdem D, Kocak ED. Influence of cellulose based on knitted fabric on thermal comfort properties performance. J Textile Eng Fashion Technol. 2023;9(4):106-110. DOI: 10.15406/jteft.2023.09.00342

Thermal comfort properties are very important factors for knitted fabrics. Optimized comfort properties are demanding during the design of garments, especially for sportswear, outerwear and underwear. Knitted fabrics produced from regenerated fibers other than cotton are highly preferred due to their eco-friendly, environmentally friendly and superior performance properties.

In this study, the comfort properties of woven fabrics were investigated.

In this study, single jersey knitted fabrics with cotton 100%, bamboo 100%, Modal 100%, Tencel 100% and Cotton/Bamboo (50:50%), Cotton/Modal (50:50%), Cotton/Tencel (50:50%) blend ratios were used. Bursting strength, strength, pilling, air permability, thermal conductivity, thermal resistance and water-vapor permeability properties of single jersey knitted fabrics were investigated. The results of the study showed that the thermal comfort (busting strength, piiling, air permability, thermal conductivity, thermal resistance and water-vapor permeability) of Tencel 100% and Cotton/Tencel (50:50%) single jarsey knitted fabrics were the best. T-shirts were produced by evaluating the obtained data.

Keywords: thermal comfort, thermal conductivity, bamboo, tencel, modal

Nowadays, there is a requirement for new, different and improved product types in the fashion and apparel industry. The production and diversification of different products has become the key to global opportunities. However, in addition to the main factors influencing the consumer's choice of clothing such as aesthetics, appearance and fashion, comfort features are also important. Today, consumers have become much more demanding in terms of clothing properties.

There is a rapid change in fashion and clothing worldwide. In daily life, especially knitted clothing is in high demand among consumers in terms of its features in leisure and sports life. The pleasant appearance of knitted fabrics, their stretching, absorbency, air permeability and breathability, etc. are preferred more than woven fabrics because they offer comfort speacilities. It offers ideal conditions for underwear, fashion and outdoor clothing.1,2

When purchasing textile and apparel products, consumers desire that they allow the transfer of sweat, that sweat on the skin is absorbed quickly and that sweat adhering to the skin diffuses quickly without emitting smells.3,4 This preference may be one of the reasons why slow fashion is increasingly using cellulose fibers in sustainable textiles. Tencel, bamboo and modal fibers, which are obtained from cellulose-based sources with improved environmental processes, are highly preferred because they offer garment comfort properties due to their superior performance properties. Breathable, biodegradable, cool to the touch and antimicrobial properties are at the forefront. It is also preferred in knitted fabric production due to its moisture management, pleasant to the touch and stretch properties.5

Today, bamboo fibers are used in different garments, including sports textiles, socks, as they are comfortable and have excellent moisture and temperature management properties, is preferred for t-shirts and underwear products.6 Tencel's moisture wicking properties can be used to improve the quality of sportswear fabrics while at the same time enhancing the aesthetics of moisture retention and other properties available.7 Similarly, much research has been done for modal and promodal containing soft for good moisture management reasons.8

In this study, Cotton %100, Bamboo%100, Modal%100 Tencel%100 and Cotton/Bamboo (50:50%), Cotton/Modal(50:50%), Cotton/Tencel (50:50%) has been used single jersey knitting fabrics. Busting strength, pilling, air permability, thermal conductivity, thermal resistance and water-vapor permebility specialities are investigated for single jersey knitted fabrics. The results were evaluated and t-shirts with good thermal comfort properties were produced.

Materials

In this study, single jersey knitted fabrics with cotton 100%, bamboo 100%, Modal 100%, Tencel 100% and Cotton/Bamboo (50:50%), Cotton/Modal (50:50%), Cotton/Tencel (50:50%) blend ratios were used. The properties of Egyptian cotton Giza fiber used in the construction of the fabrics are given in Table 1., Also the properties of Bamboo, modal and Tencel fibers are given in Table 2. Moreover, Table 3. shows the properties of the yarns applied in this work.

|

Fiber type |

Length |

MIC |

Rd |

+b |

Trash count |

Tensile Strength |

Elongation % |

Maturity % |

Uniformity |

|

Giza Cotton |

35mm |

3.82 |

66.7 |

10.9 |

40 |

44 |

4.2 |

84 |

86.9 |

Table 1 Cotton fiber properties

|

Fiber types |

Fiber length |

Fiber fineness |

|

Bamboo |

35mm |

1.2dtex |

|

Tencel |

35mm |

1.2dtex |

|

Modal |

35mm |

1.2dtex |

Table 2 Cellulose based fibers properties

|

Properties |

Cotton 100% |

Bamboo 100% |

Tencel 100% |

Modal 100% |

Cotton/Bamboo (50:50%) |

Cotton/Modal (50:50%) |

Cotton/Tencel (50:50%) |

|

Ne |

30/1 |

30/1 |

30/1 |

30/1 |

30/1 |

30/1 |

30/1 |

|

TPI |

19.2 |

20.7 |

18.2 |

19.5 |

18.8 |

20.1 |

19.8 |

|

Irregularity (CV %) |

9.2 |

8.4 |

9.1 |

8.7 |

11.65 |

10.92 |

11.3 |

|

Tensile strength CN/Tex |

17.2 |

14.5 |

26.7 |

25.1 |

15.1 |

17.3 |

24.2 |

|

Elongation (%) |

4.9 |

13.1 |

12.6 |

11.5 |

8.4 |

7.6 |

9.8 |

|

Hairiness (H) |

5.9 |

4.5 |

4.1 |

6.4 |

4.9 |

4.7 |

4.7 |

|

Thin places (-50%) |

2 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Thick places (+50) |

18 |

14 |

6 |

9 |

14.7 |

16.7 |

8.7 |

Table 3 Cellulose based knittted fabric yarns properties

Fabric manufacture

All cellulose based fabrics were knitted with single jersey knitting type. The Cellulose based knitted samples (the single jersey) were produced on the same knitting machine with four different fiber types and blends were produced on Shima Seiki SSG 234SV flat knitting machine (24 gauge, and needle bed of 90 inch at constant). Knitted fabrics were only treated by softening and washing processes. The specifications and the properties of all the cellulose based knitted fabric samples are shown in Table 4 and Table 5.

|

Blend (%) |

Fabric fiber type structure |

Fabric weight (g/m2) |

Thickness (mm) |

Width (cm) |

Courses/inch (CPI) |

Wales/inch (WPI) |

Loop length (mm) tight |

|

Cotton 100% |

Single jersey |

141 |

0.4467 |

45 |

32 |

56 |

2.1 |

|

Bamboo 100% |

Single jersey |

134 |

0.5567 |

46 |

31 |

54 |

2.2 |

|

Modal 100% |

Single jersey |

155 |

0.389 |

43 |

32 |

53 |

2.1 |

|

Tencel 100% |

Single jersey |

141 |

0.4356 |

45 |

33 |

53 |

2.1 |

|

Cotton/Bamboo (50:50%) |

Single jersey |

141 |

0.4255 |

45 |

34 |

55 |

2.1 |

|

Cotton/Modal (50:50%) |

Single jersey |

147 |

0.4876 |

44 |

32 |

53 |

2.2 |

|

Cotton/Tencel (50:50%) |

Single jersey |

147 |

4781 |

46 |

31 |

53 |

2.2 |

Table 4 Structural and physical properties of cellulose based the knitted fabric samples

Fabric testing

Knitted fabric samples are taken. After leaving the finished samples 72 hours in standard conditions:

(Relative humidity = 65 + 2% - Temperature = 20+ 2 c’), the fabric properties were measured.. . The fabric structural and physical fabric properties like aerial density (ASTM D 3776), thickness (ASTM D 1777), wales and courses per unit length (ASTM D 3887: 1996 (RA 2008)) were evaluated. Abrasion resistance of the fabrics were also tested according to ISO 12947-2 and ISO 12947-3 standard on Martindale abrasion tester. Three specimens were tested for each fabric sample The fabric burst strength Bursting strengths of the fabrics were tested according to ISO 13938-2 with 5 repetitions using JH Truburst. Fabrics thermal comfort specialites (thermal conductivity,thermal resistance, water-vapor permeability) TheAlambeta testing device according to ISO 11092 ve air permeability was measured according to TS 391 EN ISO 9237 using Tester FX3300.9

All measurements were performed under standard atmospheric conditions, and they were repeated five times for each of the knitted fabrics. From five readings the averages were calculated.

In this study, blast strength, pilling, air permability, thermal conductivity, thermal resistance and water-vapor permability properties of cellulose based single jersey knitted fabrics and blends were investigated. The characteristics of the measured test samples were analyzed.

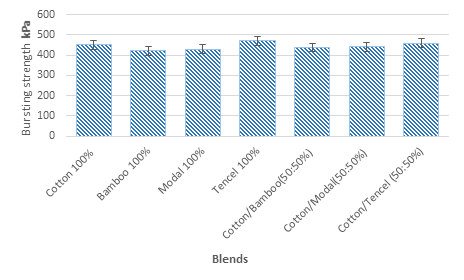

Bursting strength

Blasting is important in knitted fabrics. It determines the resistance property of fabrics. The bursting strength of knitted fabrics is related to the fiber structure that forms them. Accordingly, the results of the blasting strength properties of cellulose-based fibers are shown in Figure 1 Shown.

Figure 1 Blast strength results of single jersey knitted fabrics produced from different cellulose based fibers.

In the blast strength results of single jersey knitted fabrics produced from different cellulose based fibers, the highest value is tencel fabric while the lowest value is bamboo based fabrics.The high blast strength values of tencel knitted fabrics are the special properties of tencel fibers. Compared to other cellulose-based fibers, the strength, high degree of crystal and molecular orientation ratio may have caused these fabrics to give high strength values. The high values of modal-based fabrics after tencel-based fabrics are consistent with the result.10,11

Pilling properties

In the Martindale method measurement, pilling values are graded with a gray scale at the end of the Martindale method at the end of the Martindale method. The average pilling degrees of cellulose-based knitted fabric samples are given in Table 6. All fabrics have the same production parameters. The differences in pilling tendency are due to yarn and fiber properties. Tightly packed fibril structures in the fiber structure increase abrasion resistance. Orientation positively affects the pilling property.12

|

Blend (%) |

Fabric fiber type structure |

Pilling degrees Martindale method |

|

Cotton100% |

Single jersey |

2-3 |

|

Bamboo 100% |

Single jersey |

3-4 |

|

Modal 100% |

Single jersey |

2-3 |

|

Tencel 100% |

Single jersey |

1-2 |

|

Cotton/Bamboo (50:50%) |

Single jersey |

2-3 |

|

Cotton/Modal (50:50%) |

Single jersey |

2-3 |

|

Cotton/Tencel (50:50%) |

Single jersey |

1-2 |

Table 6 Pilling values of the fabrics

Air permeability

Air permeability is measured as the flow rate of air passing through a given area of the fabric in a vertical direction, over a period of time, under a certain pressure. Air permeability is defined as the volume of air in liters.

It basically depends on the weight, thickness and porosity of the fabric. Fabric porosity is the percentage of air space in the fabric. Considering the thermal properties of surfaces made of different fiber types and their interaction with the body, air permeability has an effect. Figure 2 shows the air permeability properties of cellulose-based fabrics. When the air permeability properties of single jersey fabrics are compared in terms of raw material, the highest value is tencel-based single jersey fabric while the lowest value is cotton-based knitted fabrics. By adding regenerated fibers to cotton-based knitted fabrics, the air permeability property is increased. These factors contribute to higher air permeability.13–15

Thermal conductivity and resistance

Heat transfer refers to the rate of energy transferred from a high temperature medium to a low temperature medium. Heat transfer continues until the two media reach the same temperature and equilibrium. The rate of energy transferred depends on the temperature difference between the media and the degree of resistance.16

Thermal properties, thermal conductivity, thermal conductivity, thermal diffusivity, thermal diffusivity, thermal absorption and thermal resistance are mainly affected by fiber properties, fabric structure, garment design made and absorb and transmit ambient temperature and humidity.17

The thermal conductivity and thermal resistance properties of single jersey knitted fabrics composed of different cellulose based fibers and blends are given in Figure 3. The thermal conductivity property is directly related to the fiber morphology cross-sectional shape and hairiness in the yarn structure. Since the yarn and fabric parameters are the same in this study, the thermal resistance depends mainly on the nature of the material. The thermal conductivity and thermal resistance values of knitted fabrics produced from regenerated fibers are higher.The thermal properties of knitted fabrics produced from Tencel and blended are quite good. Cotton has the lowest value. Tencel provides more heat resistance than bamboo and modal.

The good thermal comfort properties of Tencel fabrics are the difference of its fiber morphology from other cellulosic fibers. The nano fibril structures on the surface of Tencel manage the body's moisture. The nano channels on the surface of the fibers absorb body moisture and provide good moisture management. The cross-section of the cotton fiber and its internal corrugation folds cause it to provide thermal resistance. This curved structure, which also traps air providing thermal resistance, is insufficient compared to tencel, modal and bamboo based surfaces.18

Water-vapor permeability

Water-Vapor Permeability properties of single jarsey cellulose based knitted fabrics are given in Figure 4. The moisture absorption ability of regenerated fibers modal, tencel and bamboo fibers is better than cotton. The moisture absorption ability of cotton fiber depends on the lumen development. Single jersey knitted fabrics have the best moisture management. Tencel fibers can diffuse water better due to their higher porosity properties.

In this study, single jarsey knitted fabrics with cotton 100%, bamboo 100%, Modal 100%, Tencel 100% and Cotton/Bamboo (50:50%), Cotton/Modal (50:50%), Cotton/Tencel (50:50%) blend ratios were used. Busting strength, piiling, air permability, thermal conductivity, thermal resistance and water-vapor permeability properties of single jarsey knitted fabrics were evaluated. In this study, cellulose based knitted fabric comfort properties of the fabrics depend on their fiber content. When the results of the study are evaluated;

None.

None.

Author declares that there is no conflict of interest.

©2023 Gulmez, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.