Journal of

eISSN: 2574-8114

Mini Review Volume 2 Issue 4

1Department of Nonwoven Material and Engineering, Nantong University, China

2Department of Textile Engineering, Nantong University, China

3Department of Nonwoven Material and Engineering, Nantong University, China

Correspondence: Wenyan Gu, College of Textile and Clothing, Nantong University, Nantong City 226019, Jiangsu Province, China, Tel 8651385012871, Fax 8651385012871

Received: July 21, 2017 | Published: August 11, 2017

Citation: Gu W, Wu S, Li. Elucidation of the thermal insulation in textile materials. J Textile Eng Fashion Technol. 2017;2(4):453-455. DOI: 10.15406/jteft.2017.02.00068

It is discussed in this paper the latest research and development on thermal insulation of textiles. The property of clothing thermal insulation provides average consumers with thermal balance between the body and the environment to some extent, when they are dressed, or in vehicular cabins, buildings and so on. Meanwhile, it also provides emergency service personnel with an additional workable environment in fully encapsulated impermeable personal protective equipment. There is a dilemma between thermal comfort and ergonomic comfort when we are seeking for suitable thermal insulation materials of clothing. Recent years have seen many efforts made on thermoregulation property of clothing with varied textile material or clothing structure, while thermal manikin test, clothing microclimate test, psychology evaluation, or simulation experiment is often employed in analysis to be closer to reality besides thermal insulation index. Consumers show great demand for sophisticated thermal insulation of textile materials, which has a direct effect on individuals’ physiological and physical activities. Thus, thermal insulation textiles will surely embrace great innovations along with global changes in climate and environment in the near future.

Keywords: thermal, insulation, textile, microclimate, manikin, psychology, simulation

CBRN, chemical biological radiological and nuclear; PET, polyethylene terephthalate; PP, pre-production; PVA, poly vinyl alcohol; PTFE, poly tetra fluoro ethylene

In pace with the increase in purchasing power, consumers show great demand for sophisticated textile production, processing, and preparation in the apparel and fashion market, which accordingly has stimulated research and development in apparel, textile and clothing industry. However, it is undoubtedly that thermal insulation of clothing, which is concerned with the fundamental properties of clothing, is always one of the most important aspects in both consumers’ purchasing consideration and companies’ ad awareness 1,2. The property of clothing thermal insulation provides average consumers with thermal balance to some extent between the body and the environment, such as clothing, vehicular cabins, buildings and so on. Meanwhile, it also provides emergency service personnel, who are “required to respond to chemical, biological, radiological and nuclear (CBRN) threats, with an additional level of protection in the form of fully encapsulated impermeable personal protective equipment” 3. Thus, thermal insulation of textiles has a direct effect on individuals’ physiological and physical activities on this planet.

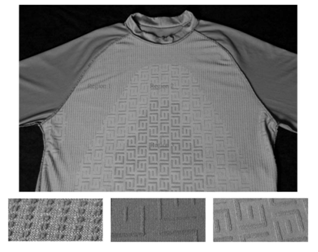

Researches on thermal comfort of clothing are conductive to its new process and good performance. Research in the late 1930s “showed a constant skin temperature of 33.8˚C in environments from 25˚C to 32˚C”.4 In the zone from 28˚C down to 23˚C, “the body cools without physiological restraint until onset of chill”.4 And there is no visible sweating “in conditions of rest or light activity”4 in the zone between 28˚C and 30˚C, which thus was termed as “the zone of pure vasomotor regulation”.4 It was concluded that “indoor clothing stretches the neutral zone from 2 to 7 degrees, and with the addition of heavier clothing the lower temperature limit may be extended almost indefinitely”.4 Heavier clothing seems helpful to maintain constant skin temperature, but would worsen cloth furnish comfort. Thus, this displays the dilemma between thermal comfort and ergonomic comfort when we are seeking for suitable thermal insulation materials of clothing. Recent years have seen many efforts made on thermoregulation property of clothing with varied textile material or clothing structure. For example, Iwona Frydrych5 and Wioletta Sybilska6 reported that the employment of thicker laminate contributed to the higher value of thermal resistance, hence better protection against the cold. Wenyan Gu7 evaluated thermal resistance of melt spun thermal material with different thickness, and got the same result as that of the former. Patrick Kinnicutt8 compared a 3D textured knitting shirt with a non-3D textured knitting shirt. Those knitting shirts were worn next to the wearers’ skin in hot and cold conditions respectively, and thermal images of wearers were taken. It was indicated that a 3D textured knitting shirt would be superior to non-3D textured knitting shirt in thermal insulation performance. As shown in Figure 1,8 with regard to the property of thermal insulation, the difference between a 3D textured knitting shirt and a non-3D one is similar to the difference between a thicker shirt and a thick one. In this way, the conclusion is in agreement with the previous.

However, thermal insulation property of textile materials cannot be only optimized by arranging internal structures of such materials. Many environmental and personal factors also play an important part. So mathematical models9-12 were set up, considering not only personal factors, which include activity level and clothing insulation, but also environmental factors, such as air temperature, air velocity, radiant temperature and relative humidity. Therefore, the heat and transfer in textiles was displayed, the textile structure was optimized, and clothing insulation inside a vehicular cabin was estimated as shown in Table 1,11 as well as in a building.

Description |

Thermal Insulation Range(Clo) |

Winter outdoor clothing |

2-3 |

Normal indoor clothing |

1.2-1.5 |

Summer indoor clothing |

0.8-1.2 |

Indoor “Lightweight” clothing |

0.3-0.5 |

Table 1 Clothing Levels and Insulation10

Temperature was found to have an effect on the frequency of accidents as early as the beginning of 19th century.13 Activity at extreme temperatures is more dangerous than the same activity at moderate temperature. So the research on thermal protective performances of textiles used under extreme temperature conditions is reasonable and meaningful. Chao Sun14 carried out a sweating fabric manikin experiment on multilayer textiles against low temperatures to varify the textiles with good thermo insulation performance. The multilayer textiles used PET batting as basic layers, and PA net, PP web, PP/PVA and nano-fibrous PP/PVA/AL were used for interlayer respectively. It was found that PP/PVA/AL inter layers were helpful to improve the cold protective performance of multilayer textiles. Shinjung Yoo15 conducted a human physiological study on a multilayer textile in low temperature, and verified that condensation in textile could be reduced by the structure of a layer. Thus, the appropriate layer structure should be adopted in the clothing design for low temperatures. VL Richmond3 recruited persons from firefighters, policeman, and military personnel. They wore as many their personal protective devices as the ones they should wear when they fulfilled their duties. He monitored their insulated skin temperature in personal protective devices at the temperature of 18˚C and 30˚C respectively. With experimental data and statistics analysis, it was declared that a rectal temperature in extreme conditions could be predicted in a curvilinear model. Hualing He16 selected 2 kinds of high performance thermal protective multilayer textiles from the extensive commercial applied thermal protective textiles in Industry, Fire and Rescue, etc. Such materials are often facing thermal hazards, so the moisture and the air in layers affect their thermal protective performance. The structure of the 2 multilayer textiles consisted of out shell (m-aramid twill), moisture barrier (para-aramid water thorn + PTFE), and thermal liner (para-aramid needling + cotton woven), and they were similar in both thickness and weight. He “simulated second-degree burn time for the two fabric assemblies under discrete specific moisture levels”.16 It was shown that the air entrapped in multilayer textiles was positively effective on thermal protective textiles, but the air transport would cause changes.

In the research of thermal insulation of textiles, the influence of the microclimate between clothing and the body or the climate around the body, on insulation performance tends not to be ignored. As a result, the thermal manikin test, clothing microclimate test, psychology evaluation, or simulation experiment is often employed in analysis to be closer to reality besides thermal insulation index.

It is obvious that thermal insulation textiles have immense potential because they can be applied in individual functional thermal protection clothing and household stuffs as well as protective clothing under extreme temperature climate conditions. Thermal insulation textiles will surely embrace great innovations along with global changes in climate and environment in the near future.

This research was supported by Production, Practical, Experience and Research of Prospective Joint Research Projects of Jiangsu Province (BY2016203).

None.

©2017 Gu, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.