Journal of

eISSN: 2574-8114

Research Article Volume 4 Issue 4

1College of Textiles, Donghua University, China

2Faculty of Clothing and Design, Minjiang University, China

3Fujian Key Laboratory of Novel Functional Fibers and Materials, Minjiang University, China

Correspondence: Nanliang Chen, College of Textiles, Donghua University, Shanghai 201620, P.R. China, Tel 021-67792264

Received: June 14, 2018 | Published: July 10, 2018

Citation: Yan T, Shi Y, Chen D. Electromagnetic shielding performance of CSA-PANI/PAN electrospun fiber membrane added with CB and CNT. J Textile Eng Fashion Technol. 2018;4(4):269-273. DOI: 10.15406/jteft.2018.04.00155

Electromagnetic radiation protective clothing is the main means of individual protection of electromagnetic radiation, and the ESPESF plays a key role. In this paper, 8%, 10%, and 12% pure PAN electrospinning fiber membranes were prepared, and 0.5% and 1% CSA were added to a pure PAN solution in DMF. The fibrous membrane was used to determine the most stable electrospinning process. Subsequently, 1%, 2%, 3%, 4%, and 5% carbon black (CB) was added to the 10% PAN and 1% CSA-PANI solution to prepare electrospinning. Fibrous film, and later added 0.5%, 1%, 1.5%, 2%, 2.5% of carboxy Carbon nanotube and hydroxyl Carbon nanotube in a 10% PAN and 1% CSA-PANI solution to prepare composite nanofiber membranes, Finally, the effect of the addition of various carbon materials on the electromagnetic shielding performance of electrospun fiber membranes was comparatively studied. The shielding properties of polyaniline fiber membranes added with Carbon nanotube were improved. At the same concentration, the electromagnetic shielding performance of the CNT (COOH-)/CSA-PANI/PAN fiber membrane was similar to that of the C/CSA-PANI/PAN fiber membrane. The electromagnetic shielding performance of the CNT (OH-)/CSA-PANI/PAN fiber membrane is much better than that of the C/CSA-PANI/PAN fiber membrane.

Keywords: electromagnetic shielding performance, CSA doped PANI, CSA doped PANI, carbon nano tube

In 1862, polyaniline was first used as a dyestuff in H.Letheby’s research. The research of poliyaniline in the following century had gone through 3 phases: The discuss on “Aniline Black” as a dyestuff, the research of organic semiconductor and the extensive studies of conducting polymer. Due to the lack of profound theoretical knowledge of macromolecular at that time, the further study of polyaniline had been dragged on for nealy a century. Until 1976, MacDiarmid and his stuff from University of Pennsylvania restudied polyaniline and found some unique properties as electric conduction, therefore polyaniline was considered as a conductive polymer which would be most likely widespread in real life. Polyaniline has many excellent characters including easy obtainment of the raw material, easily manipulated synthetic process, and high conductivity, and unique doping performance, excellent electromagnetic microwave absorbing performance, environmental stability, chemical stability and optical properties. Nowadays the synthetic material on the basis of the polyaniline was widely used in such high-tech sectors like marine antifouling, all plastic metal anticorrosion technology, electromagnetic shielding, stealth technology, antistatic technology and sensor components, electroluminescent, solar battery, secondary battery materials, catalytic materials and anti-corrosion materials.

As a polymer that is inherently conductive, it has a high degree of stringent skeletal characteristics of aromatic molecules and is present in a relatively short molecular weight form, so that the viscosity of the solution is generally difficult to directly use electrospinning to prepare polyaniline fibers.1 However, polyaniline is the most studied conductive polymer because of its relatively easy synthesis, high conductivity, protonization, and relative environmental stability.2 Factors that affect the conductivity of PANI are temperature,3 solvents, dopants, humidity,4,5 structural defects,6 polymer morphology,7 But the biggest influence factor is the proton doping level.8 The maximum conductivity of PANI is that when it is 50% doped with protons, the partial amines are protonated above 50%, and when less than 50%, some imines have not been protonated. In both cases, the delocalized charge carriers on the polymer backbone are destroyed, resulting in a decrease in the overall conductivity of the polymer.9 In order to avoid the characteristics of difficult spinning of polyaniline electrospinning, in order to improve its conductivity, and expand its application fields, researchers have made a lot of efforts.

Carbon nanotube (CNT) was electrospinned directly without surface functionalization, and they are easily dispersed unevenly. Spinning effects may be poor, and beaded fibers are easily formed. The MWNT and the polyurethane were added to N,N-dimethylformamide (DMF), and the fiber membrane was prepared by electrospinning. The irregularity of the fiber thickness of the fiber membrane was very high.10 Many literatures confirm that the surface functionalization of CNT facilitates electrospinning, it was confirmed that MWNT-COOH was formed after oxidative acidification of MWNTs, the entanglements between the tubes weakened, and the dispersion was enhanced,11 After the multi-walled Carbon nanotube were first treated with nitric acid and then treated with hydrochloric acid, the surface of the multi-walled Carbon nanotube was carboxylated, and the prepared carbon nanotube-adsorbed nylon nanofiber membrane had a conductivity of 0.15 S/cm,12 The surface of MWNTs can be treated with sulfuric acid and nitric acid first, then treated with thionyl chloride (SOCl2) solution, and finally treated with ethylenediamine solution to achieve amino functionalization of MWNTs.13

Researchers pay more attention to the effects of carbon-based materials on the electrical conductivity of fibers, conduct qualitative and quantitative studies on them, explore their impact mechanisms, and seek basic theoretical support. The researchers found that adding only a small amount of Carbon nanotube significantly improves the conductivity; Kim YT used electrospinning technology to prepare SWCN/PVDF nanofiber membranes.14 It was found that the critical point of insulator-to-conductor transition was 0.04wt% SWCNT content.15 Study confirms that the electrical conductivity of ordered electrospun PMMA nanofibers with 2% added MWCNTs is 10 orders of magnitude higher than pure PMMA fiber.16 The effect of the content of SWCNT, DWCNT and MWCNTs on the performance of electrospun nanofibers was studied. The trifluoroacetic acid (TFA) and dichloromethane (DCM) solutions were dissolved in PET, and the Carbon nanotube was uniformly dispersed in the solution. Electrospinning was used to prepare PET-CNT nanofibers. It was found that the mechanical properties of SWCNT with the same mass fraction were better than MWCNTs, but the conductivity of SWCNT with the same mass fraction was worse than that of MWCNTs.17,18

Electrospinning is a process that uses electrostatic forces to form fibers.19 This process uses a high voltage supply, which induces the charge of a certain polarity into a polymer solution or a polymer melt that is accelerated to a collector that has the opposite polarity. The obtained electrospun fibers have a small diameter; in the micrometer to nanometer range.20 The high surface area per unit mass and high porosity of electrospun fibers are advantageous for applications in many fields. In fact, the electrospun fibers have potential uses in various applications such as filtration and protective clothing, as well as biomedical and tissue engineering scaffolds that includes drug delivery systems.21,22

In this paper, 8%, 10%, 12% concentration of pure PAN electrospinning fiber membranes were prepared, and 0.5% and 1% CSA doped polyaniline was added in 10% PAN solution for electrospinning fiber membranes, and then added 1%, 2%, 3%, 4%, 5% CB in 10% PAN and 1% CSA-PANI solution, and later added 0.5%, 1%, 1.5%, 2% and 2.5% of carboxyl Carbon nanotube and hydroxyl Carbon nanotube were added in 10% PAN and 1% CSA-PANI solution for electrospinning, and studied the electromagnetic shielding performance of all of the electrospun fiber membranes.

Materials and equipment

Camphorsulfonic acid (CSA) and polyacrylonitrile (PAN) (MW 150,000) was purchased from TCI (Shanghai, China). CNT was purchased from Beijing Boyu High-tech Materials Technology Co., Ltd. (Beijing, China). Carbon black (CB) was purchased from Damao Chemical Reagent Factory (Tianjin, China). N,N-Dimethylformamide (DMF) was purchased from Tianjin Zhiyuan Chemical Reagent Co., Ltd (Tianjin, China). All chemicals were analytical reagent and were used without alteration. Ultrasonic cleaner CD-4800 was purchased from Changzhou Ruipin Precision Instrument Co., Ltd.. (Changzhou, China). The high pure water system EXPLORER was purchased from Chenhuang Scientific Instrument co., LTD (Shanghai, China). The high voltage DC power supply DW-P503-1ACDF was purchased from Dongwen High Voltage Power Supply co., LTD (Tianjin, China). The two-channel trace injection pump WZS-50F6 was purchased from Smith Medical Instrument co., LTD (Zhejiang, China).

Methods

Separately weigh 8%, 10%, and 12% of the PAN powder in a reagent bottle containing an appropriate amount of DMF. After the PAN powder was dissolved in a magnetic stirrer at a constant temperature of 50 degrees, it was ultrasonically dispersed for 30 minutes, magnetic stirring was continued for 12 hours, and the fully dissolved PAN solution was deeper than the previous yellowish one, and the electrospun membrane was prepared using a self-made electrospinning apparatus. Take appropriate mass fractions of PAN, 8%, 10%, and 12%, and weigh equimolar polyaniline and camphor sulfonic acid (CSA) into PAN solution. The content of doped polyaniline is 0.5% and 1%. The mixed solution was stirred on a magnetic stirrer for 12 hours, and an electrospun membrane was prepared using a self-made electrospinning apparatus. Taked appropriate amount of 10% PAN and 1% doped polyaniline solution, added CB 1%, 2%, 3%, 4%, 5%, 6% and 7% respectively, added CNT (COOH-) and CNT (OH-)0.5%, 1 %, 1.5%, 2% and 2.5% respectively. The mixed solution was stirred for 12 hours and an electrospun membrane was prepared using a self-made electrospinning apparatus.

Electromagnetic shielding test

Electromagnetic shielding performance testing instrument uses DR-913G fabric anti-electromagnetic radiation performance tester, each sample size is 18cm×18cm square sample, electromagnetic shielding data was got from the DR-913G fabric anti-electromagnetic radiation performance tester.

The value of fabric electromagnetic shielding shows that the smaller the negative amplitude of fiber radiation, the greater the absolute value and the smaller the amount of transmission, ie, the better the electromagnetic shielding performance. According to the formula.

In the formula: Electromagnetic shielding amplitude (dB)

Transmission

Reflection amount

It is relatively straightforward to represent the trend of shielding performance with the line graph of absolute value of the absolute value. The line chart intuitively shows the tendency of electromagnetic shielding performance with different concentration of fiber membrane radiation amplitude at three different frequencies of 1MHz, 30MHz and 300MHz. Figure 1 represents an electrospun fibrous membrane prepared by the electromagnetic shielding curve of the control group at a PAN concentration of 10% and a CSA doped polyaniline concentration of 1%. When the frequency is 1MHz, the radiation amplitude is -30dB, and when the frequency is 30MHz, the radiation amplitude is -20.4dB, and when the frequency is 300MHz, the radiation amplitude is -3.4dB. The change in the CB concentration at 30MHz and 300MHz in Figure 2 shows a relatively gradual change in the electromagnetic shielding performance. At 1MHz, the difference in the variation can be seen and the radiation amplitudes are -31, -39, -57, -158, -26, -1dB, respectively. The electromagnetic shielding performance of the polyaniline composite fiber with CB was improved. Among them, when the CB concentration was 3% and 4%, the transmission amount was very small, and the electromagnetic shielding performance was relatively best. It can be seen from the Figure 2 that the electromagnetic shielding performance of the fiber membrane with different radiation frequencies is approximately the same with the concentration change trend, and the trend changes significantly at a frequency of 1MHz.

Figure 3 shows the electromagnetic shielding performance at a frequency of 30MHz and 300MHz when the carboxyl carbon nanotube concentration is changed, and the change in the curve tendency is gentle. At 1MHz, the trend of electromagnetic shielding performance changes significantly, with radiation amplitudes of -56, -59, -53, -37, and -31dB respectively. The shielding performance of polyaniline composite fiber membranes with carboxyl Carbon nanotube was improved compared with the 10% PAN and 1% CSA-PANI. The concentration of carboxyl Carbon nanotube increased, and the electromagnetic shielding performance of fibers showed a decreasing trend.

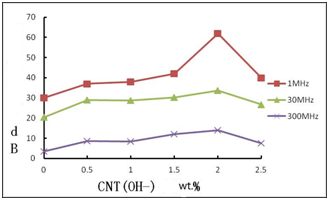

Figure 4 shows the EMI shielding effectiveness of CNT (OH-) at three different frequencies. The performance trends are approximately the same. At 1MHz, the radiating amplitudes are -37, -38, -42, -62, and -40dB, respectively. The shielding performance of the polyaniline composite fiber membrane added with hydroxyl Carbon nanotube was improved compared with the control group. With the increase of the concentration of hydroxyl Carbon nanotube, the electromagnetic shielding performance of fibers is generally on the rise. The electromagnetic shielding performance is best when the concentration of Carbon nanotube is 2%.

Figures 5–7 represents the electromagnetic shielding performance of C/CSA-PANI/PAN and CNT/PANi/PAN fiber membranes at different frequencies. At the same concentration, the electromagnetic shielding performance of C/CSA-PANI/PAN fiber membrane is better than that of CNT/CSA-PANI/PAN fiber membrane. The electromagnetic shielding performance of the CNT (COOH-)/CSA-PANI/PAN fiber membrane and the electromagnetic shielding performance of the C/CSA-PANI/PAN fiber membrane are comparable, but the electromagnetic shielding ratio of the CNT(OH-)/CSA-PANI/PAN fiber membrane is C/CSA-PANI/PAN fiber membrane has much better electromagnetic shielding performance in.

Under the same external conditions, when the concentration of PAN and doped polyaniline is the same, the spinning solution containing CB is more viscous than the spinning solution containing Carbon nanotube, and the CB concentration increases, and the spinning solution will follow. Become viscous. The viscosity of the solution can affect the electrospinning efficiency. C/CSA-PANI/PAN spinning films are brittle compared to CNT/CSA-PANI/PAN and are brittle. Compared with the electromagnetic shielding performance of the 10% PAN and 1% CSA-PANI fiber membrane in the control group, the shielding performance of the polyaniline composite fiber with CB was improved, and the transmission was very low when the CB concentration was 3% and 4%. Electromagnetic radiation performance is relatively best. The shielding properties of polyaniline fiber membranes added with Carbon nanotube were improved. At the same concentration, the electromagnetic shielding performance of the CNT (COOH-)/CSA-PANI/PAN fiber membrane was similar to that of the C/CSA-PANI/PAN fiber membrane. The electromagnetic shielding performance of the CNT (OH-)/CSA-PANI/PAN fiber membrane is much better than that of the C/CSA-PANI/PAN fiber membrane.

None.

Author declares there is no conflict of interest in publishing the article.

©2018 Yan, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.