Journal of

eISSN: 2574-8114

Research Article Volume 6 Issue 1

Department of Textile Engineering, Faculty of Engineering, Daffodil International University, Bangladesh

Correspondence: Asit Ghosh, Assistant Professor, Department of Textile Engineering, Faculty of Engineering, Daffodil International University, Bangladesh, Tel 01741886680

Received: February 04, 2020 | Published: February 19, 2020

Citation: Ghosh A, Tonmoy AA, Saha S. Effect of Lycra percentage on the physical properties of single jersey weft knitted fabric. J Textile Eng Fashion Technol. 2020;6(1):29-35. DOI: 10.15406/jteft.2020.06.00223

This research studies the effect of increase percentage of Lycra yarns during loop formation on the geometrical, physical mechanical properties of plain jersey fabrics. Samples with 100% cotton yarns, Lycra yarns in alternating courses (half feeder) and Lycra yarn in every courses (full feeder) were produced on a circular knitting machine, the two later cases were produced at five different levels of Lycra extension. Thermal setting was carried out without any traverse tension during finishing thus evaluates the full effect of Lycra extension. Results show a sharp increase in the course density rather than the wales density. Fabric thickness and weight per unit area also increased and air permeability in the case of the half and full plating fabrics decreased considerably. The breaking load and extension also increased while the initial electricity modulus decreased with an increase in abrasion resistance in the case of full plating. A comparison between half and full feeder methods contribute improving fabric quality by determining optimal Lycra percentage.

Keywords: Lycra, half feeder, full feeder and knitting

Purpose and significant of study

A physical property describes a state of a physical system are often referred to as observables. The effect of Lycra fiber on the physical properties of single jersey knitted fabric such as strength, elasticity, shrinkage, spirality etc.1

Aim of project

This project intends to identify physical property (diameter, GSM, shrinkage, spirality etc.) of the full feeder and half feeder Lycra weft knitted single jersey fabric.

Objectives:

Research question

How does Lycra% effect on the physical properties of single jersey fabric?

Review

A physical property is measureable whose value describes a state of a physical form. Physical properties are often referred to as observables. The effect of Lycra fiber on the physical properties of single jersey knitted fabric such as strength, elasticity, shrinkage, spirality etc.

Lycra

Lycra is a synthetic elastene fiber that can stretch up to six times its length and returns to its original state again. It was invented in 1958 by Chemist Joseph Shivers at Duponts Benger Laboratory in Waynesboro Virginia.

Generally (150+40), (150+70), (200 +40), (10 +70), (16+70) Denier yarn is used.

INISTA makes Lycra fiber. It’s the supportive company of KOCH INDUSTRIES INC. There are also COOLEX, CORDURA and ANTRON Lycra product used.

Spandex or Lycra is used our textile industry to make up elastene types garments especially in weaving & knitting garments. Lycra is a Synthetic fiber (man-made fiber) that is used a wide range of skin tight garments, zentia suits, competitive wear, detective sector, shorts, ski pants, yoga pants etc.

Single jersey

Weft knitting is a knitted piece of fabric where the stitches run from left to right horizontally across the fabric. Types of weft knitting include Jersey (Single, Double), Doubir knit, Circular Knit, Cable knit.

Weft knitted fabrics shrinks easily, good insulator, very elastene, comfortable. Generally used to make up underwear, T-shirts, baby clothes, pyjamas knitwear such as jumpers, scarves, hats and gloves etc.

Single Jersey fabric is weft knitted fabric which formed by one set of needles. In single jersey the appreance of face side and back side is different. This fabric is much warns flexible, stretchy and wears to comfort.

Full feeder: Elastene or Lycra used in the every feeder with yarn is called full feeder.

Half feeder: Elastene or Lycra used in the alternative feeder with yarn is called half feeder.

Why single jersey is used?

Mainly elastene yarn is used in single jersey to increase the elastic property. And shrinkage, spirality, gsm(gram per square meter) etc variation are noticed on single jersey.

Byezit2 investigated the dimensional and physical properties of full feeder cotton spandex single jersey fabrics and compared the results with half feeder cotton spandex single jersey knitted fabrics. It was apparent that as the amount of spandex increased the loop length value remained nearly the same and the course and wale spacing decreased. Furthermore, because spandex containing fabrics tend to be tighten. The weight per unit area and thickness of the fabrics are higher but the permeability, the pilling grade, and the spirality are on lower side.

Herath3 studied the dimensional characteristics of a core spun cotton/spandex interlock structure. The results were compared with those for similar fabrics knitted from 100% cotton. Diamentional characteristics for both types of samples were measured by considering the change of the courses and the wale and the stitch densities under dry, wet and full relaxtion conditions. It was found that, the wale and the course densities were lower for 100% cotton structure during relaxtion. Also, the stitch density variations of cotton/spandex interlock structures were significantly higher than the ones of 100% cotton during relaxation.

Chathura4 studied the dimensional stability of core spun cotton/spandex single jersey structure with high, medium and low tightness factors under dry, wet and full relaxtion conditions. Results were compared with those for similar fabrics knitted from 100% cotton fabrics. The courses, the wales and the stitch density were increased with of the relaxation and higher values were reported with cotton/spandex 1x1 rib knitted structures.

Serkan Tezel5 investigated the effect of spandex brand, the tightness factor of the base and spandex yarn on the dimensional and physical properties of cotton/spandex single jersey fabrics. This was done in order to produce tight, medium and loose. Four different spandex yarns were used. Shown that the largest tension values under a constant draw ratio give the highest the weight per unit area, the number of courses/cm, the number of stitches/cm²,the thickness but lowest the air permeability values.

Most of the researches2–8 studied the diamentional and physical properties of the knitted fabric produced from core spun yarn and few of these researches investigated the properties of the knitted fabric produce from cotton and Lycra yarns. As Lycra yarns are often used in alternating courses (half plating) instead of every the course (full plating) either for economical reasons or for better fabric quality, there is a necessity to compare these two cases under different levels of the lycra extension percent. Such comparison is the aim of this research.

In this experiment we used manual method, ISO, & AATCC methods on four properties of fabric (Dia, Fabric weight, Shrinkage & Spirality).

Diameter is considered as the width of fabric. In this experiment we measure the fabric diameter by manual process with the help of measuring tape.

The outcome of how a fabric has been woven or knitted is known as Fabric weight. Fabric weight is measured by electric balance, after cutting with GSM cutter (ISO 33071 method is used).

The process in which a dimension of fabric reduces or increases and fabric becomes smaller or longer than its original size (either widthwise, lengthwise or both) is called as shrinkage of fabric. Shrinkage is determined with m/c washcator (ISO 6330 method is used).

Spirality is the de-twisting tendency of yarn in the fabric. Spirality is measured with method AATCC 179 (Table 1).

Tests |

Methods |

Equipments |

Dia |

Manually |

Measuring Tape |

Fabric Weight |

ISO 33071 |

GSM Cutter, |

Electric Balance |

||

Shrinkage |

ISO 6330 |

Washcator |

Spirality |

AATCC 179 |

N/A |

Table 1 Testing methods and equipments

Material used:

Machine details: Single Jersey (Table 2)

m/c details |

Origin |

m/c model |

m/c dia |

m/c guage |

No of feeder |

Keum-Young |

KOREA |

KM-3WVX |

30 |

24/32 |

90 |

Table 2 Machine details of Single Jersey

Knitting parameters:

Washing stage: Washing m/c details (Table 3)

M/c Brand |

Origin |

Model |

Efficiency |

Maximum capacity |

Compressed air (Nm³/kg) |

Tonello |

Italy |

70LD |

88% |

200L |

0.005 |

Table 3 Washing machine details

Condition: Water-40L (cold)->5minutes run

Heatset stage: M/c Brand: Stenter m/c

M/c Brand: Bruckner (Table 4)

M/c rpm |

Temperature(˚C) |

Over fit |

Allow dia |

Time |

19 |

200 |

40% |

61 |

30 minutes |

Table 4 Heatset stage

Condition

Bleaching stage:

Condition

Temperature 95˚C + 25 g/L H2O2 + 22g/L costic soda + 4g/L stabilizer + 1g/L Sequestering agent + pH 5 +average 400L water + then drying at 140-170˚C

Dyeing stage:

Exhaust dyeing

M/c Brand: DILMENLER

Origin: Turkey

Condition:

Dyeing Bath: enzyme 0.3%

Fabric: Water = 3:7

Dimensional Stability: Sample cutting (50cm×50cm) & sewing 4 side

Determination of dimensional change and calculation before wash-after wash.

Measuring

Shrinkage: After conditioning shrinkage of resin treated sample were measured by using Shrinkage test board and ruler. The raw fabric sample was measured (35cm×35cm)

Spirality: The length of two diagonals of each sample fabric was measured and spirality was measured from the following formula

GSM: GSM of each samples were measured by GSM cutter.

The chapter provides the details discussion on the factor about effect of Lycra% on the physical properties of the single jersey fabrics. Different chart and tables are shown to describe the results of various tests.

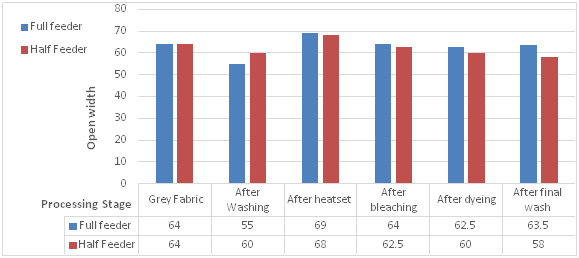

Open width of full feeder& half feederlycra single jersey fabric at different processing stage

Discussions: For full feeder the final width (after final wash) is quite same to initial width but in case of half feeder the width decreases more than full feeder (Table 5) (Figure 1).

Processing stage |

Open width (Inch) |

|

Full feeder |

Half feeder |

|

Grey Fabric |

64 |

64 |

After Washing |

55 |

60 |

After Heatset |

69 |

68 |

After Bleaching |

64 |

62.5 |

After Dyeing |

62.5 |

60 |

After final Wash |

63.5 |

58 |

Table 5 Different width of single jersey fabric at different process stage

Figure 1 Open width of full feeder& half feederlycra single jersey fabric at different processing stage.

GSM of full feeder& half feederlycra single jersey fabric at different processing stage

Discussions: For full feeder the fabric weight (after final wash) decreases from initial GSM but in case of half feeder GSM increases (Table 6) (Figure 2).

Processing stage |

GSM(gm/m²) |

|

Full feeder |

Half feeder |

|

Grey Fabric |

170 |

120 |

After Washing |

288 |

191 |

After Heatset |

155 |

122 |

After bleaching |

146 |

120 |

After dyeing |

185 |

138 |

After Final Wash |

158 |

140 |

Table 6 GSM effect on full feeder& half feederlycra SJ fabric at different stage

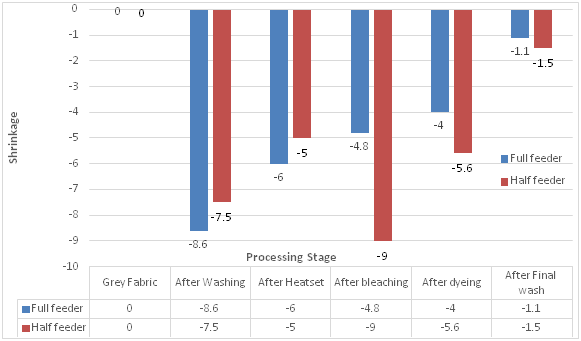

Length wise shrinkage of full feeder& half feederlycra single jersey fabric at different processing stage

Discussions: For full feeder the final shrinkage % (after final wash) decreases less than half feeder from initial shrinkage % in length (Table 7) (Figure 3).

Processing stage |

Shrinkage (%) |

|

Full feeder |

Half feeder |

|

Grey Fabric |

0 |

0 |

After washing |

-8.6 |

-7.5 |

After Heatset |

-6 |

-5 |

After bleaching |

-4.8 |

-9 |

After dyeing |

-4 |

-5.6 |

After final wash |

-1.1 |

-1.5 |

Table 7 Length wise shrinkage of full feeder and half feeder Lycra single jersey fabric at different processing stage

Figure 3 Length wise shrinkage of full feeder& half feederlycra single jersey fabric at different processing stage.

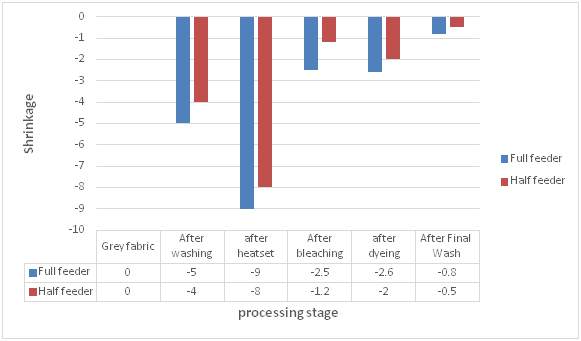

Width wise shrinkage of full feeder& half feederlycra single jersey fabric at different processing stage

Discussions: Width wise and for half feeder the final shrinkage % (after final wash) decreases more than full feeder from initial shrinkage % in length and width wise (Table 8) (Figure 4).

Processing stage |

Shrinkage ( % ) |

|

Full feeder |

Half feeder |

|

Grey fabric |

0 |

0 |

After washing |

-5 |

-4 |

After Heatset |

-9 |

-8 |

After bleaching |

-2.5 |

-1.2 |

After dyeing |

-2.6 |

-2 |

After final wash |

-0.8 |

-0.5 |

Table 8 Width wise shrinkage of full feeder and half feeder Lycra single jersey fabric at different processing stage

Figure 4 Width wise shrinkage of full feeder& half feederlycra single jersey fabric at different processing stage.

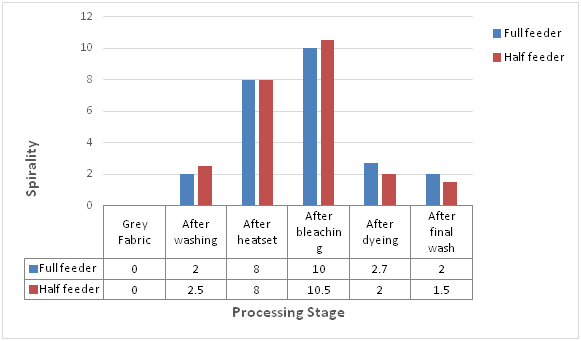

Spirality of full feeder& half feederlycra single jersey fabric at different processing stage

Discussions: For full feeder the final spirality % (after final wash) increases more than half feeder and for half feeder the final spirality % (after final wash) increases less than full feeder (Table 9) (Figure 5).

Processing stage |

Spirality (%) |

|

Full feeder |

Half feeder |

|

Grey fabric |

0 |

0 |

After washing |

2 |

2.5 |

After heatset |

8 |

8 |

After bleaching |

10 |

10.5 |

After dyeing |

2.7 |

2 |

After final wash |

2 |

1.5 |

Table 9 Spirality of full feeder and half feeder Lycra single sersey fabric at different processing stage

Figure 5 Spirality of full feeder& half feederlycra single jersey fabric at different processing stage.

Summary

Lycra has a great effect on single jersey fabric properties which increases the elastic properties on single jersey fabrics.

The aim of this project was to know the different properties variation between half feeder and full feeder Lycra single jersey fabric. The available sample was analyzed. We discuss the dimensional and physical properties of full feeder & half feeder Lycra single jersey fabrics and we conclude that these parameters are affected by the amount of elastane in the fabric. It is also apparent that the widthwise dimensional variations for fabric knitted with half feeder are higher than full feeder while the length wise variations for the same fabrics are less after relaxations at different processing stage.

None.

None.

Authors have declared no conflicts of interest.

©2020 Ghosh, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.