Journal of

eISSN: 2574-8114

Research Article Volume 8 Issue 2

1IRNASUS – CONICET, Catholic University of Cordoba, Argentina

2University Nacional de La Rioja, Argentina

3Sede Chamical, Argentina

Correspondence: Eduardo Frank, PhD, Designation Professor, Catholic University of Cordoba, and UNLAR, Armada Argentina 3555, Córdoba, Argentina, Tel 54 351 4938030

Received: May 07, 2022 | Published: May 18, 2022

Citation: Castillo MF, Frank EN, Prieto A, et al. Development and validation of a commercial grade technique for Patagonian cashmere fiber. J Textile Eng Fashion Technol. 2022;8(2):54-57. DOI: 10.15406/jteft.2022.08.00301

The double-coated goat fiber that is commercially called cashmere must have an average diameter of fine fibers (ADFF) less than 19 µm. In the flock studies, values below 50% of animals that produced fleeces with that fiber diameter were obtained. The determination of the diameter in the laboratory (fineness) by automatic equipment is not applicable in large-scale flocks due to its costs and care/protection. This makes it necessary to look for a fast and cheap commercial classification system whose precision at least allows for the formation of homogeneous batches that highlight the use of the finest fleeces (below 19 µm). In this work, the objective of developing and validating a method of visual and semi-quantitative classification of the fiber from the Creole goat of the north of the Argentine Patagonia was raised. Two tests were carried out: one following a drawn crimp scheme as a reference and the other assuming a coarse fiber/fine fiber length ratio of about 1 as an indicator of fiber <19.0 µm. The results indicate that the combination of both methods allows classifying types of fleece that are significantly separated by ADFF and allow forming homogeneous batches for the commercialization of the fiber of this type of animal.

Keywords: cashmere, grading, commercial grade, fineness, validation.

In population survey works carried out in the western area of the province of La Pampa,1 and northwest of the province of Neuquén,2,3 a wide range of types of types of fleece and fineness in the caprine populations studied. Since the textile definition of Cashmere establishes that a fiber less than 19µm in diameter is considered as such, the diameter classification is important. With an average diameter of about 20µm,4,5 indicates that less than half of the fiber meets the requirement.

It was determined the production of down fibres and to assess the quality and variability of the fleece characteristics of the Northern Patagonian Creole goats. From late winter to early spring of 2005–2008, 2397 fibre samples were collected from five areas of NW Neuquén in Northern Patagonia. The most common grade of fineness (57.5%) was >19.0µm, indicating that 42.5% of the fibre was below 19µm in fine fiber diameter. The other variables were significantly different within LC, short cashmere (SC) and intermediate cashmere (IC) styles when the grade of fineness was compared. The styles with lustre effect (CG and L) showed very low crimp as compared to the other styles.6 It was concluded that the classification by styles and fineness could determine more than 42% of fleece complies with the cashmere textile industry requirements.

However, in work carried out in other countries (Central Asia and Afghanistan) with a goat population with history similar to the Patagonian, the importance of classification is demonstrated.7

Experiences in Australia with the population of local goats crossed with Angora (Isla Faure), the fiber classification to possible to separate the long cashmere in that case from other types of lower quality fleece.8 Starting from the observation of the curl (undulations or crimp) of the fine fiber, the local association (ACMC) performs a classification in 5 styles or types of fleece (TF). Using the degrees of curvatures (crimps) as a tool for diameter change in the selection or to classify homogeneous fiber lot for sale, effective results are obtained within flocks. This is similar to what is done with Mohair.9

Cashmere fiber requires pre-textile dehairing processing, and the efficiency of this process depends a lot on the previous classification of the fiber. Where, the diameter and the frequency of crimps have affected the efficiency in the sense that the smaller the diameter and the higher the frequency, the greater the efficiency.10

The correlation between the degree of curvature (objective measurement of crimp) and the mean fiber diameter ranges from –0.40 to -0.65,6,11–13 Another important criterion is the ratio between the length of the coarse fibers and the length of the fine fibers, the higher the ratio, the finer the fleece.14 This determines that the coarse fiber is shorter than the fine fibre, and the latter forms a loop at the tip of staple.

In the case of the Patagonian fiber, a situation similar to that of the Australian goat is presented, due to the indeterminate cross with the Angora goats. In addition to the crimp and the ratio of coarse/fine fiber lengths, details of the staple associated or not with Mohair are also added15. For Texas cashmere goats, a fleece style prediction method is tested and validated, using a quantitative scale based on quality of crimp definition (character or style). The scale goes from 1 (excellent style) to 5 (poor style). A strong negative correlation was obtained between style and crimps per centimetre.16

The classification of the fleeces, in any way, does not require a high precision in the location of each fleece, since what is appreciated in the commercialization and subsequent industrialization is the average of the lot. For this, batches of up to 16.5µm (H) and between 16.6 and 19µm (W) are basically required.17 Outside this arbitrary limit there are significant amounts of non-cashmere fiber (S) that may receive different names in different countries such as Middle Micron in Australia for fiber from 19 to 22µm and Cashgora when it also has 3 types of fibers (down, intermediate and guard hair) and the reminiscences of the lustre coming from Mohair.8

Based on these premises and with the significant number of processed samples from different areas of the northwest, centre west and north of Neuquén (argentine Patagonia), the following work was proposed with the aim to develop and to validate a commercial classification method for cashmere fiber.

Origin of the samples: 324 entire fleece samples were used from the base of 5400 fleece samples obtained in the northwest area of the province of Neuquén, selected in such a way to ensure the greatest possible variety of types of fleece and fineness and the most balanced form possible. They adjusted to an average diameter average of around 20 µm as in reality if the lots by diameter are not classified.4,5

Classification bases: Crimps diagram: A scale of 13 degrees of crimp drawn was made on computer from a frequency of 7.5crimp/cm to 1crimp/cm (Figure 1). From each sample, a staple was extracted as the best individualized as possible and dissected previously extracting the coarse and intermediate fibers and separating the fine fibers (´Down´), in such a way to visualize as well as possible the crimps in form and frequency. This dissected portion of the staple was contrasted with the scale of crimp degrees and awarded each sample a value that the classifier considered coincident.

Styles or types of fleece: the classification by types of fleece or styles made in the first works on the Patagonian cashmere fiber was used in principle.1,3 The ratio of the length between the fine fiber (´down´) (FFL) and the length of the coarse fiber (´guard´) (CFL) was added, adjusting for long Cashmere (CA) the relationship to 1:1, considering fine (FC) the one that shows a lower relationship and strong (SC) the one that equals or exceeds that relationship. After performing the statistical analysis and obtaining the comparison of means, aligned on a velvet plate, after rapid dissection of the staple, the same relationship was determined assuming that FC is equal to or less than 50% of the LFF/LFG ratio and above this ratio it is equivalent to SC (Figure 2).

The separation between fine cashmere and coarse cashmere is made by the ratio coarse fiber length/fine fiber length (FLL) without considering the intermediate fiber (Figure 3).

Laboratory measurements: the samples classified by both methods were measured with a microprojector, determining the mean diameter of the fine fiber (ADFF) and the coefficient of variation (ADFFCV), as a reference for the other measurements made with MiniFiber EC, Fiber Lux, Wool View.18

Statistical analysis: with the degrees of curls, an ANOVA was initially performed using the linear model method and a post hoc analysis by Duncan. The categories that were not significant were grouped in relation to the significant ones. The results were then grouped according to the 3 significant categories obtained and a new ANOVA was performed, but using the Dunett method for comparison, to compare means and obtain the confidence intervals of ADFF. With the TVs, a box diagram was plotted and an exploratory analysis was carried out, which indicated the absence of normality when considering the variance within each style. With the box plot, the styles were placed in order of the ADFF pairwise comparisons between the means of the ranges by the non-parametric Kruskall-Wallis method. The statistical package INFOSTAT (2002) was used.19

Classification by crimp diagram: degree 10 of the diagram did not have any assignment and crimp degrees 11, 12 and 13 had only one each, therefore the 3 were grouped as crimp degree 11. The ANOVA linear model explained 35% of the diameter variation above that obtained by correlating fiber diameter with the style scale in American cashmere,16 but slightly lower than data from other countries.11–13

Table 1 shows that crimp grades 1 to 3 can be grouped as Grade 1, grades 4, 5, 6 are regrouped (Grade 2), and grades 7, 8, 9 and 11 are grouped as Grade 3. It is considered that each summary Grade of crimp represents a characteristic fineness, for which an ANOVA and a comparison of means were performed again using Dunnett's to obtain the confidence intervals of each comparison considering Grade 1 and Grade 3 as fixed or control, respectively (see Table 2).

Crimp Grade |

ADFF |

|

S. E. |

Confidence Interval 95% |

||

|

|

|

|

|

Low Límit |

Upper Límit |

1 |

1 |

17.92 |

a |

0.99 |

15.97 |

19.88 |

2 |

1 |

16.52 |

a |

0.28 |

15.97 |

17.07 |

3 |

1 |

17.24 |

a |

0.25 |

16.75 |

17.73 |

4 |

2 |

18.49 |

b |

0.25 |

17.99 |

18.99 |

5 |

2 |

18.98 |

b |

0.32 |

18.35 |

19.61 |

6 |

2 |

18.58 |

b |

0.42 |

17.75 |

19.42 |

7 |

3 |

20.94 |

c |

0.43 |

20.08 |

21.79 |

8 |

3 |

22.43 |

c |

0.81 |

20.84 |

24.03 |

9 |

3 |

22.22 |

c |

0.99 |

20.27 |

24.18 |

11 |

3 |

25.95 |

d |

1.15 |

23.69 |

28,21 |

Table 1 Comparison of means between crimp grades of the mean diameter of the fine fiber (ADFF)

Means with a common letter are not significantly different (p > 0.05)

(I) Crimp Grades |

(J) Crimp Grades |

(I-J) |

E. E. |

Confidence Interval 95% |

|

|

|

|

|

Low Límit |

Upper Límit |

2 |

1 |

1,70 |

0,27 |

1,11 |

2,30 |

2 |

3 |

3,13 |

0,40 |

2,27 |

4,00 |

3 |

1 |

4,84 |

0,40 |

3,94 |

5,73 |

Table 2 Comparisons of means with confidence intervals for the differences between Crimp Degrees summarized by Dunnett's method (two-tailed, p<0.05)

Based on observed means. *The difference between means is significant at the p<0.05 level.

The variance explained by the fixed variable Crimp Degree (summarized as 1, 2, 3) was similar to the case in which all the degrees of the crimp scheme (Crimp Type) were considered. This gives validity to the analysis carried out after grouping. In the sense that the grouping did not reduce the variance, despite what was expected (Table 2).19

Classification by Styles or types of fleece: the exploratory analysis that was carried out with the data grouped according to the length coarse/fine ratio of 1, obtained many extreme data. However, this was corrected by isolating the intermediate fibers as well and carefully looking only at the coarse/long fibers relative to the fine/short fibers. If the truncation of the fine fiber cone is considered to be the upper limit (when it occurs), it considerably improves the H (Kruskall-Wallis)19 and results in a behaviour very similar to that obtained with Iranian goats when correlating degrees of objective curvature with ADFF13. The result was further improved by using the summary crimp scheme to separate the borderline situations between FC and SC.

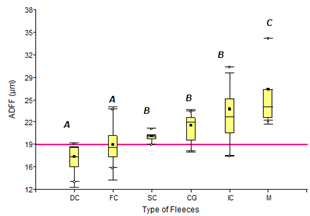

Figure 4 presents the different types of fleece in which extreme values (´whiskers´) are the cases with values more than 3 times the IQ range. Extreme values represent poorly cut samples to extract them from the animal and/or silent fine fibers, which prevents the crimp correctly. The red line represents 19µm of the ADFF. This type of classification that combines the relationships between the lengths of coarse fibers and fine fibers and is helped by the crimp scheme to establish the FT is faster than that only uses the crimp scheme, although it has difficulties in separating the fineness H (<16.5µm).

Figure 4 Box-Plot of ADFF Comparison by Kruskal-Wallis.

Means with a common letter are not significantly different (p > 0.05)

The short cashmere type (DC) presents an average of DMFF: 17.5 not significant with classic long cashmere (FC): 18.0. Both in this test grouped 48% of the frequency of the types of fleeces, which coincides with population data3. The interesting thing is that Long Fiber Count 7 and Mohair: 28.1µm. This last group represented 52% of the samples (also coinciding with the field data)3 and of which 19% was the SC separate from FC.

If samples are grouped by crimp frequency and long fiber ratio of coarse fiber as degrees of fineness (H, W and S) and compared on the basis of the diameter measured with lanameter (reference method), and Minifiber EC, Fiber Lux, Wool View as commercial device, are obtained significant consistent results between the three degrees and FFL (p <0.05) (Table 3).

Fitness |

MiniFiber EC |

Sig |

Wool view |

Sig |

Fitnessx legnth |

Sig |

H |

17,33 |

a |

17,47 |

a |

16,89 |

a |

W |

18,19 |

b |

18,06 |

a |

18,40 |

b |

S |

19,72 |

c |

19,98 |

c |

19,57 |

c |

Table 3 Fineness grade determined by measure by different methods and mean comparison

A comment to improve the understanding of Table 4: there is a 95% probability that the average ADFF of grade H is between 16.13-17.65 µm; so on for the other 2 Fineness Degrees. The narrow interval indicates that the classification within each grade is obtained with low variability (between samples variance lower than within sample variance), which gives a wide possibility of using the technique. What is also interesting is that the CI of W does not include the mean of H and the CI of S does not include the mean of W, therefore there is a statistically significant difference (p<0.05) between the Degrees of Fineness in ADFF when determined by FLL.

|

Fineness x length CI (95%) |

|

H |

16.13 |

17.65 |

W |

17.85 |

18.95 |

S |

19.18 |

19.96 |

Table 4 Average diameter of fine fibre classified by length (FLL)

None.

None.

©2022 Castillo, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.