Journal of

eISSN: 2574-8114

Research Article Volume 11 Issue 4

1Tashkent Institute of Textile and Light Industry, Uzbekistan

2Andijan State Technical Institute, Uzbekistan

3Silk Research Institute, Uzbekistan

Correspondence: Umurzakova Khalima Khabibullayevna, Tashkent Institute of Textile and Light Industry, Uzbekistan

Received: August 30, 2025 | Published: September 12, 2025

Citation: Khabibullayevna UK, Axmadjonovna MZ, оgli AIK. Determination of the performance properties of nonwoven materials for medical purposes from natural silk waste. J Textile Eng Fashion Technol. 2025;11(4):220-226. DOI: 10.15406/jteft.2025.11.00426

This article studies the compliance of nonwoven fabrics made from natural silk fiber waste with the requirements of GOST 6943.18-94 (ISO 4603-78) (ISO 9073-2) standards. The appearance and operating principles of the equipment used to obtain the results during the experiments are presented. 6 different types of nonwoven fabrics made from silk waste, H1, H2, H3, H4, H5, were used for the experiment. When comparing the water and air permeability of the silk nonwoven fabric with existing samples, it was found that the water absorption was 55.5% higher and the air permeability was 25% higher than that of samples H2, H3, H4, H5. When comparing the thickness and strength of nonwoven fabrics with existing samples, the thickness of H2 and H5 increased by 4.5-9% compared to samples, and the tensile strength increased by 5.7-27% compared to H1, H2, H3, and H5.

Keywords: silk, nonwoven fabric, substandard and nonstandard cocoons, thickness, surface density, humidity, climate

One of the pressing problems of world medicine is the development and creation of drugs and medical materials used to treat wounds of various origins, since only multifunctional medical materials are in high demand. Thus, biomaterials with the best regenerative effect should be biocompatible, harmless, non-allergenic, have high absorption capacity, are protected from microorganisms, have properties of permeability to gases, water vapor, etc.

Leading research centers around the world are conducting intensive research on the creation of multifunctional medical materials. However, despite all efforts, currently available composite materials cannot fully meet the requirements. Therefore, additional research is needed in this area.

Currently, in our country, large-scale measures are being taken to create new import-substituting medical products based on local raw materials, to further develop the textile industry. The local pharmaceutical industry has practically no local developments in the field of production of permanent and multifunctional collagen-based connective materials. In the Strategy of Actions for the Further Development of the Republic of Uzbekistan, including “… increasing the competitiveness of the national economy, … reducing energy and resource consumption in the economy, and widely introducing energy-saving technologies into production”, further development of the pharmaceutical industry , medical institutions, and improving the provision of the population with affordable, high-quality medicines and medical products are among the urgent tasks.

Improving the quality of cocoons grown in the Republic of Uzbekistan will lead to a higher efficiency of the sericulture industry.1–4 Our people have long valued products made from natural silk, cotton, wool, linen and other raw materials. Because, compared to chemical textile raw materials, natural raw materials have superior properties.5–9

The prospects for the world production and processing of textile raw materials are presented. Silk, which accounts for the smallest share of raw materials, has the highest indicators among natural fibers in terms of its properties.10–15

The skin is the largest organ in the human body by volume and is composed of three distinct layers: the keratinized epidermis, the stratum corneum, and the underlying four-layer epidermis, which are composed mainly of nucleated keratinocyte cells; and the dermis, where the main cells are fibroblasts, as well as follicles, glands, nerves, and capillaries are located in the extracellular matrix.16

The skin is a barrier between the external environment and our body, protecting us from dehydration, pathogenic microorganisms and harmful effects. The key to good function is the balance of all processes that provide physical protection, biochemical and adaptive immunity. The slightest failure in this balance, due to external (injuries) or internal damage (for example, diabetes), leads to impaired function and the development of inflammatory processes, ulcers, boils, etc.17

In this case, rapid and effective treatment and recovery are necessary to avoid bacterial colonization, chronicity, and serious injury. In cases of severe injury and disruption of the integrity of the body, pharmacotherapy is necessary.

However, treatment options vary depending on the origin and pathology of the wounds and represent a significant challenge for any health system. For example, Ernest Man, Clare Hosking, estimate that the economic cost of wound care to the NHS in England is in excess of £5 billion per year, and these challenges require new approaches and new materials for wound care.18

One of the most important aspects of wound study, diagnosis, and treatment is wound assessment. Assessment includes the size, depth, extent, and severity of the wound. Skin wounds typically involve the epidermis and dermis. Some wounds can extend deeper, involving the hypodermis, fascia, muscle, tendon, bone, and internal organs, and are referred to as ulcers.19,20

The studies were conducted on samples of antimicrobial nonwoven fabric H1, H2, H3, H4, H5 and silk waste , which are considered the most suitable materials for medical purposes in terms of their structure and fiber composition.

To determine the thickness of nonwoven fabric obtained from natural silk waste, a 10 x 10 cm sample was cut from different skeins of nonwoven fabric based on the requirements of the GOST 6943.18-94 (ISO 4603-78) (ISO 9073-2) standard and the fabric sample, which was stored in accordance with the ISO139 standard (temperature 20 ± 2 °C and relative humidity 65 ± 2%) for 24 hours, was measured using a thickness gauge YG141. was put into the equipment.

In addition, the thickness was measured under a specified pressure of 0.5 kPa. For this obtained nonwoven fabric, the sample was re-measured 5 times and the results were recorded in Table 1 below.

|

No. |

H1 |

H2 |

H3 |

H4 |

H5 |

Silk |

|

1 |

0.20 ±0.001 |

0.25 ± 0.001 |

0.16±0.001 |

0.16±0.001 |

0.22 ± 0.001 |

0.22 ±0.001 |

|

2 |

0.17 ±0.001 |

0.23 ± 0.001 |

0.15±0.001 |

0.18±0.001 |

0.23±0.001 |

0.23 ±0.001 |

|

3 |

0.19 ±0.001 |

0.25 ± 0.001 |

0.13±0.001 |

0.19±0.001 |

0.25±0.001 |

0.23 ±0.001 |

|

4 |

0.19 ±0.001 |

0.25 ± 0.001 |

0.16±0.001 |

0.16±0.001 |

0.23 ± 0.001 |

0.22 ±0.001 |

|

5 |

0.20 ±0.001 |

0.24 ± 0.001 |

0.15±0.001 |

0.19 ± 0.001 |

0.24 ± 0.001 |

0.20 ±0.001 |

|

One. |

0.19 ±0.001 |

0.24 ± 0.001 |

0.15±0.001 |

0.17 ± 0.001 |

0.23 ± 0.001 |

0.22 ±0.001 |

Table 1 Thickness measurements of nonwoven fabrics made from H1, H2, H3, H4, H5 and silk waste

Together, we used this formula to determine the average thickness.

(1)

This is where:

: Medium thickness.

: Results of the samples taken (Figure 1).

The coefficient of variation was calculated using the following formula:

(2)

This is where:

: of variation (%).

: Standard deviation.

: Medium thickness.The 95% confidence interval was calculated using the formula below.

(3)

This is where:

CI: 95% confidence interval.

t : Imitation coefficient (with n-1 degrees of freedom).

: Standard deviation.

n : Number of measurements

The average thickness of the H1 nonwoven fabric shown in Table 1 is 0.19 mm, and the H2 nonwoven fabric is 0.24 mm. In addition, the H5 fabric is 0.23 mm thick, which is considered to be the average thickness among these nonwoven fabrics. In addition, they are used in applications requiring relatively high strength and protection. H3 fabric is 0.15 mm and H4 fabric is 0.17 mm thick, which is considered a thin fabric and they are usually soft and light, making them easier to touch the skin. At the same time, they are non-woven fabrics with good breathability but low durability.

The thickness of the non-woven fabric made from non-standard and non-standard cocoons is 0.22 mm, which is also considered a medium-thick non-woven fabric. Despite its thickness, non-woven fabric made from silk has several advantages over other fabrics. For example; it is soft and flexible, durable and antibacterial, and has good air permeability. In addition, the natural regenerative capacity of silk fibroin means that fabrics made from it have faster healing and healing compared to synthetic fabrics.

(4)

This is where:

m - Sample weight (grams).

A - Sample area (m²).

The surface density of the obtained sample was determined under climatic conditions in accordance with ISO 139 and is presented in Table 2 below.

|

No. |

Name |

Mass, g |

Surface density, g/m2 |

|

1 |

H1 |

0.72 ±0.01 |

36.92 |

|

2 |

H2 |

0.92±0.01 |

47.17 |

|

3 |

H3 |

0.44±0.01 |

22.56 |

|

4 |

H4 |

0.50±0.01 |

25.64 |

|

5 |

H5 |

0.95±0.01 |

48.71 |

|

6 |

Silk (H1) |

0.97±0.01 |

49.74 |

Table 2 Density values and average value calculation for each sample

Table 2 As can be seen from the data, the mass of the antimicrobial material samples H1, H2, H3, H4, H5 and silk were different from each other and met the surface density specified in the standard. The surface density of silk, H5 and H2 fabrics was closer to each other and different from that of H1, H3 and H4 fabrics.

2 above, the tensile strength and elongation of nonwoven fabrics are calculated in accordance with the international standard ISO 9073-3: 2023 Tensile Testing Machine HZ-1007E in the ward Based on the general technical requirements of the GOST 28840-90 standard, testing was carried out on materials previously conditioned in accordance with ISO 139 at a temperature of 20 ± 2 °C and a relative humidity of 65 ± 4% (Figure 2).

For the experiment, 5 samples of 50x200 mm were taken from 6 different types of nonwoven fabrics: H1, H2, H3, H4, H5 and silk waste. The distance between the clamps of the experimental laboratory machine was set to (100±1) mm. When the elements are mounted in the clamps of the specimen testing machine, one end of the specimen is clamped in the upper clamp and the other end is clamped in the lower clamp, and the surface density is pre-weighed according to Table 3 based on the ISO 9073-1 standard (Table 3).

|

|

Surface density, g/m² |

Initial weight sN |

|

1 |

50 < |

5 |

|

2 |

From 50 to 100 |

25 |

|

3 |

From 100 to 200 |

50 |

|

4 |

From 200 to 500 |

100 |

|

5 |

500 > |

500 |

Table 3 Determines the initial weight depending on the fabric surface density

The force was gradually increased, and then the breaking force and elongation at break coefficients were obtained from the coefficients corresponding to the force gauge of the testing machine after the element sample was broken, based on the formula below.

Breaking strength:

This is where:

Stretching:

(5)

This is where:

L0 - initial length of the fabric (mm).

L is the length of the fabric at the time of breakage (mm) (Table 4).

|

Breaking strength and elongation at break (index name) |

Number of tests |

Elementary sample size, mm |

|

By length |

5 |

50x200 |

|

By width |

5 |

50x200 |

Table 4 The ISO 13934-1:2013 standard describes the analysis of test results obtained from samples of non-woven fabrics

As can be seen from the data in Table 5, the strength characteristics of antimicrobial fabric samples H1, H2, H3, H4, H5, non-woven fabrics differ significantly. This is due to the structure of the tested fabrics and materials, which, in turn, determine their properties by the length, linear density and location of the fibers, the method of reinforcement of the fibers relative to each other, as well as the surface density and thickness. The rupture and elongation of the tested fabric are presented in the graphs below. Also, these results are clearly displayed on the monitor in the results section of the Tensile Testing Machine HZ-1007E laboratory device.

|

No. |

Symbols of samples |

Surface density, g/m2 |

Max Force Kgf |

Endurance MPa |

Percentage of increase % |

|||

|

By length |

By width |

By length |

By width |

By length |

By width |

|||

|

1 |

H1 |

36.92 |

4,734±2 |

3,261±2 |

1.658 ±1 |

1.142 ±1 |

121,881±3 |

118,564±3 |

|

2 |

H2 |

47.17 |

4,674±2 |

2,634±2 |

1.637 ±1 |

0.923 ±1 |

120,739±3 |

112,040±3 |

|

3 |

H3 |

22.56 |

0.872±2 |

0.913±2 |

0.305 ±1 |

0.320 ±1 |

134,841±3 |

125,834±3 |

|

4 |

H4 |

25.64 |

5,136±2 |

3,950±2 |

1,799 ±1 |

1.383 ±1 |

129,485±3 |

121,276±3 |

|

5 |

H5 |

48.71 |

3,649±2 |

1.875±2 |

1.278 ±1 |

0.657 ±1 |

133,666±3 |

117,925±3 |

|

6 |

Silk |

49.74 |

5.022±2 |

3,840 ±2 |

1.705 ±1 |

1.282 ±1 |

124,425±3 |

120,133±3 |

Table 5 Results of experiments to determine the surface density and strength of nonwoven fabrics used in medicine

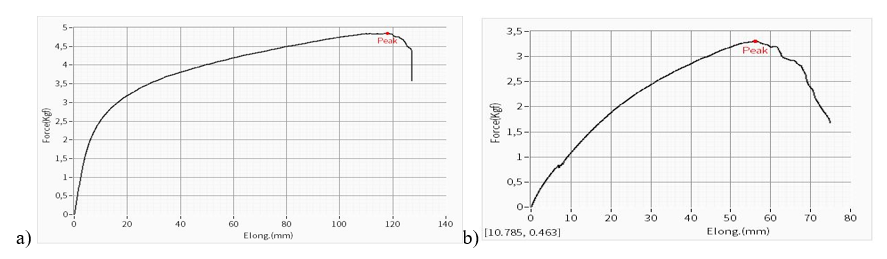

In Figure 3 below, H1(Spunlace) is 4.734±2 Kgf, 3.261±2 Kgf in width, 45.2% stronger than the width, and the tensile strength is 1.658±1 MPa and 1.142±1 MPa, respectively, which is 45.1% higher than the width. The elongation percentage is 121.881±3% in width, 118.564±3% in width, 2.3% higher than the width. It stretches.

Figure 3 a) H1 nonwoven fabric strip, b) average tensile strength and elongation at break of the experimental results obtained along the width of the strip.

H2 (SMS) 4.674±2 Kgf, 2.634 ±2 Kgf in width, 77.4% stronger than the width, and the tensile strength indicators are 1.637±1 MPa and 0.923 ±1 MPa, respectively, which is 77.3% higher than the width. Also, the elongation percentage is 120.739±3% in width, 112.040±3%, and the elongation of the strip is 7.8% higher than the width, as shown in Figure 4 below.

Figure 4 c) The average tensile strength and elongation at break of the experimental results obtained for the width of the H2 nonwoven fabric, d) the width of the nonwoven fabric.

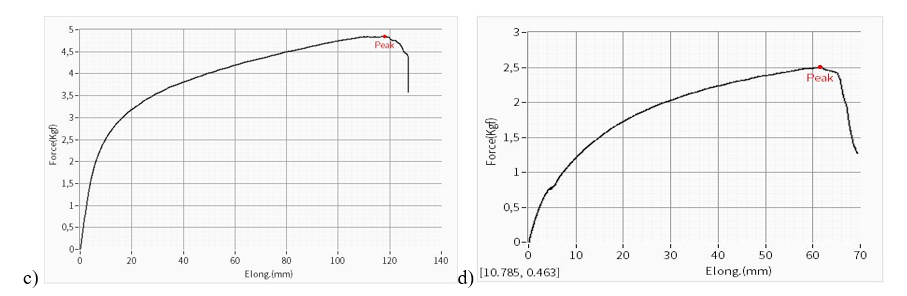

The results in Figure 5 show that H3 (Meltblown) is 0.872±2 Kgf, 0.913±2 Kgf in diameter, 4.7% stronger, and the tensile strength is 0.305±1 MPa and 0.320±1 MPa, respectively, which is 4.9% higher than that of the original. Also, the elongation percentage is 134.841±3% in diameter, 125.834±3% in width, 7.15% higher than that of the original. This non-woven fabric is more elastic and stronger than other fabrics, and this uncertainty is due to the compositional characteristics of the fabric, which is not a defect in the technological process.

Figure 5 e) The width of the nonwoven fabric H3, f) The average breaking force and elongation at break of the experimental results obtained in the width of the nonwoven fabric.

H4 (Spunbond-PP) 5.136±2 Kgf, 3.950±2 Kgf in width, 30.0% stronger than the width of the tube, and the tensile strength indicators are 1.799±1 MPa and 1.383±1 MPa, respectively, which is 30.1% higher than the width of the tube. Also, the elongation percentage is 129.485±3% in width, 121.276±3% in width, 6.8% higher than the width of the tube. Shown in Figure 6.

Figure 6 j) The average tensile strength and elongation at break of the test results obtained for the width of the nonwoven fabric H4, h.

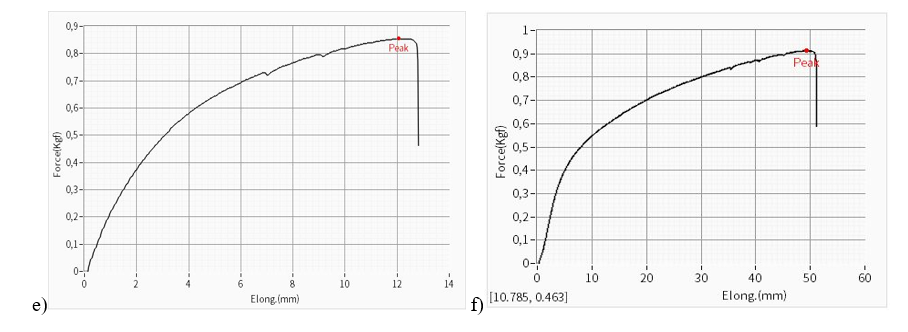

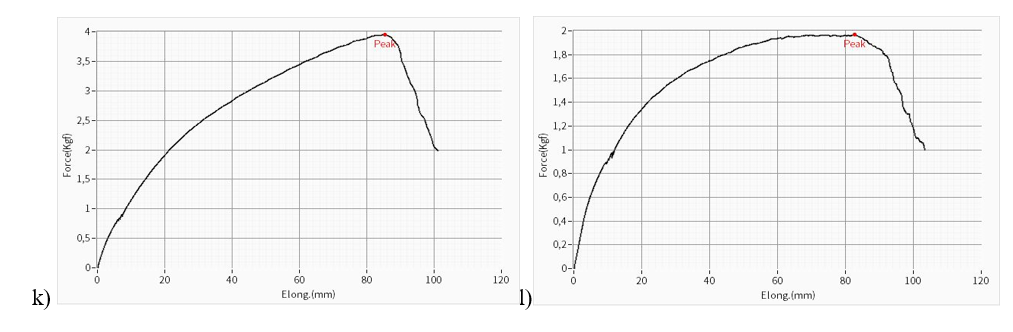

In Figure 7, H5 (Elastic Spunbond) is 3.649 ±2 Kgf, 1.875 ±2 Kgf in width, 94.6% stronger than the width of the strip, and the tensile strength is 1.278 ±1 MPa and 0.657 ±1 MPa, respectively, which is 94.5% higher than the width of the strip. Also, the elongation percentage is 133.666 ±3% in width, 117.925 ±3% in width, 13.35% higher than the width of the strip. It stretches a lot.

Figure 7 k) Average tensile strength and elongation at break of the experimental results obtained for the width of the H5 nonwoven fabric, l) width of the nonwoven fabric.

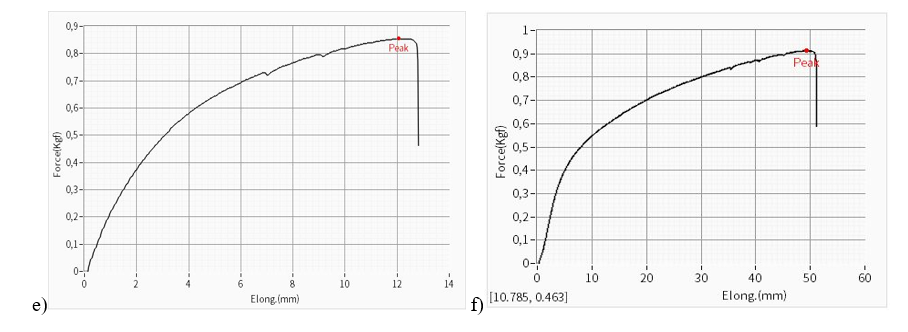

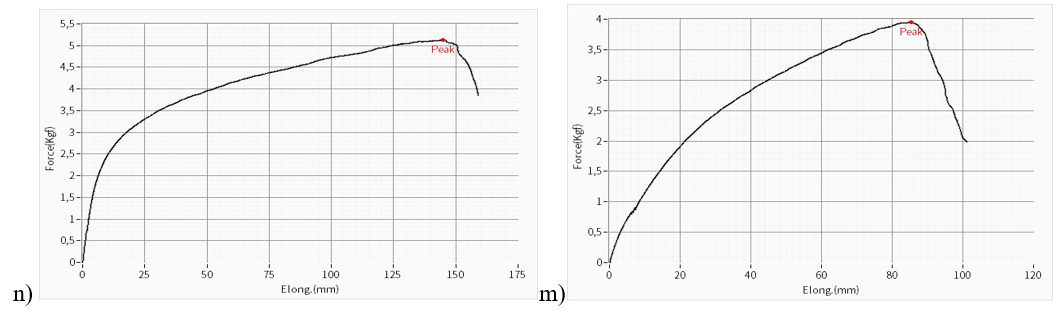

In Figure 8 below, the non-woven fabric obtained from ungraded and non-standard cocoons has a strength of 5.022 ± 2 kgf, a width of 3.840 ± 2 kgf, which is 30.8% stronger than the width of the core, and the tensile strength indicators are 1.705 ± 1 MPa and 1.282 ± 1 MPa, respectively, which is 33.0% higher than the width of the core. Also, the elongation percentage is 124.425 ± 3%, a width of 120.133 ± 3%, which is 1% higher than the width of the core. It stretches more when exposed to sunlight. The strength and durability of the fabric are reduced by 30-33%, while the elasticity is reduced by only 8.6%. This indicates the stability of silk and its balanced properties in terms of deformations.

Figure 8 n) The average breaking strength and elongation at break of the experimental results obtained for the width of the nonwoven fabric obtained from low-grade and non-standard cocoons, m).

In addition, in accordance with ISO 6330 Standard, in order to test the washing resistance of nonwoven fabrics, the samples were conditioned for 24 hours at a temperature of 23±2°C and relative humidity of 50±5%, and after three consecutive washings (each lasting 20 minutes) in a soft regime (in a vibration-type machine) with water temperature t = 55–60°C, the nonwoven fabric samples prepared from waste and nonstandard cocoons, cut by length and width, withstood all the washing cycles (Table 6).

|

No. |

Example |

Maximum force Kgf |

Strength MPa |

Percentage of increase % |

|||

|

Length |

Width |

Length |

Width |

Length |

Width |

||

|

1 |

Silk |

5.022±2 |

3,840 ±2 |

1.705 ±1 |

1.282 ±1 |

124.425 ±3 |

120.133 ± 3 |

|

2 |

1 |

4,587±2 |

3,610±2 |

1.603 ±1 |

1.158 ±1 |

121.44 ± 3 |

117,212 ± 3 |

|

3 |

2 |

4,320±2 |

3.455±2 |

1.404 ±1 |

disruption |

118.02 ± 3 |

disruption |

|

4 |

3 |

4,205±2 |

3,288±2 |

1.396 ±1 |

disruption |

115.93 ± 3 |

disruption |

Table 6 Nonwoven fabric made from substandard and substandard cocoons is often Resistance to abrasion

In table.6 above has very fine nanofibers, a large surface area, non-structural similarity and biocompatibility, making it suitable for lightweight products, and is resistant to high temperatures and low water filtration. The H2 (SMS) nonwoven fabric is moderately elastic (121%), has fast-wearing properties and is resistant to multiple washings. H3 (Meltblown) is very low (0.3 MPa), this type of material requires further processing from a material science point of view. H5 (Elastic Spunbond) is considered to be too elastic and has poor wear resistance. H4 (Spunbond-PP) is recommended as an optimal material, but due to its stiffness and synthetic texture, there are fewer disadvantages compared to the use of natural materials.

In the first, second, and third bendings, the maximum strength (Kgf) along the length was 8.7%; 14.0%; 16.3% and along the width was 6%; 10%; 14.4%, the tensile strength (MPa) along the length was 6.0%, 17.7%, 18.1% and along the width was 9.6%; in the 2nd bending and 3rd bending, failure occurred, and the elongation (%) along the length was 1%, and along the width was 1%; in the 2nd bending and 3rd bending, failure was observed and the strength was improved.

In Table 6 above, it was found that the results of the post-hardening strength test were carried out in accordance with the ISO 6330 standard, with a strength loss of ≤20%, a durability loss of ≤15%, and a change in elongation of ≤10%.

Nonwoven fabric samples obtained from natural silk waste, obtained in this study, withstood a single wash, after which the fabric was damaged during subsequent processing. However, for nonwoven fabrics used as a carrier layer for antimicrobial materials, 3 washes were sufficient for fabrics used for single-use products. According to the results of the study, nonwoven fabrics made from non-standard and non-standard cocoons are very suitable for medical purposes, especially for disposable products (for diapers, wipes and masks). Nonwoven fabrics retain their physical, mechanical and medical-biological properties for a certain time. They exhibit high bioactivity and biocompatibility when interacting with human biological tissues. Having studied the results of the above experiments, we identified important advantages of antimicrobial nonwovens obtained from natural silk waste. Silk waste has high biological activity, hypoallergenicity, biomaterial and antibacterial properties. In addition, fibroin and sericin proteins contained in non-standard and non-standard cocoons accelerate the regeneration processes.

Ecologically clean raw materials, simple recycling process, no additional chemical treatment required. The possibility of producing import-substituting products due to waste recycling is created. Mechanical strength and elastic properties of products suitable for medical use are of great importance. During the use of products and fabrics, they are mainly exposed to forces that are insufficient for their tensile strength.

When comparing the water and air permeability of nonwoven fabrics with existing samples, it was found that water absorption was 55.5% higher and air permeability was 25% higher than samples H2, H3, H4, and H5.

When comparing the thickness and strength of nonwoven fabrics with existing samples, it was found that H2, H5 was 4.5-9% thinner than samples, and the tensile strength increased by 5.7-27% compared to H1, H2, H3, H5

None.

None.

The author declares that there is no conflict of interest.

©2025 Khabibullayevna, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.