Journal of

eISSN: 2574-8114

Research Article Volume 5 Issue 6

1Department of Fashion Technology, Kumaraguru College of Technology, India

2Department of Bio Technology, Kumaraguru College of Technology, India

Correspondence: Rajkumar G, Department of Fashion Technology, Kumaraguru College of Technology, Coimbatore – 641 049, India, Tel 9486127587

Received: October 12, 2019 | Published: November 19, 2019

Citation: Vaissnavi DP, Rajkumar G, Umamaheswari M, et al. Combined de sizing and scouring of cotton fabric using xylanase enzyme. J Textile Eng Fashion Technol. 2019;5(6):284-286. DOI: 10.15406/jteft.2019.05.00214

The textile materials used for healthcare products should be hygiene, free from impurities and chemical content. In order to reduce the hazards caused by the chemical effluents, use of enzymes in the pretreatment of textiles is the only alternative method. In this research, the effect of mode of treatment of xylanase enzyme and its process conditions such as enzyme concentration (1.5, 2 and 2.5g/l), temperature (40, 50 and 60˚C) and time (60, 90 and 120 min) on the combined de sizing and scouring of cotton fabric were studied. The cotton fabric was assessed by measuring the weight loss and water absorbency. It was found from the results that the fabric treated with xylanase enzyme, buffer and acetic acid has shown optimum weight loss and absorbency. The fabric sample treated at 1.5g/l, 50°C, and 90 min has shown better absorbency levels.

Keywords: xylanase, scouring, de-sizing, absorbency, weight loss

Natural fibers consist of natural and added impurities. Cotton being called as the king of fibers has wide application in many fields. Impurities present in cotton are removed by pre-treatment process in order to make it ready for dyeing or printing. It consists of various processes from singeing to bleaching. Pollution due to disposal of chemicals is a major threat for environment in textile processing. As technology improved, development has been made in these processes which had made it more effective and eco-friendly. Among the development from usage of chemicals, enzymes are used for textile pretreatment. The usage of enzymes has proved to be more eco-friendly, water and energy saving when compared to other methods of pretreatment. Enzyme usage has also proved to increase the product quality.

Much research has been directed to replace this chemical process by a more environmental friendly enzyme-based one .1,2 Dengani reported that increase in cutinase concentration increases the water absorbency of cotton fabrics.3 Shafie stated that the cotton fabric treated with cellulase enzyme in one step bio- scouring and peracetic acid bleaching has shown excellent wettability.4 Eren reported that the advantages of one bath enzymatic de sizing and bleaching of cotton fabric is less auxiliary demand, energy and water savings and low environmental impact when compared to the conventional preparatory process.5

Xylanase is an enzyme which is also being used in the textile wet processing and have been reported mainly from bacteria,6–8 fungi,1 actinomycetes9 and yeast.10,11 Xylanase treatment could lead to hydrolysis of the tiny fibers that attached the seed-coat fragments to the fabric. This could make the residual seed-coat fragments more accessible to chemicals, thereby reducing the consumption of hydrogen peroxide in the consecutive chemical bleaching step.12 Even though, the xylanase enzymes are used in textile wet processing, no study available on combined preparatory process in textile wet processing. Hence an attempt is made in this work to investigate the effect of mode of treatment of xylanase enzyme and also the influence of processing conditions of combined de sizing and scouring on the weight loss and water absorbency of cotton fabric.

Materials

Woven cotton fabric of thread density 60X60, linear density of 40sX40sNe, and 150GSM was used for the study. The commercially available xylanase (bacterial base) enzyme was used for de sizing and scouring of cotton.

Methods

The grey cotton fabric was de-sized and scoured with different modes of pretreatment (enzyme, enzyme+ buffer, enzyme + wetting oil, and enzyme +wetting oil +acetic acid) to study the effect of mode of treatment on cotton fabric. The enzyme concentration of 2g/l and the liquor ratio of 1:20 were used in all the processes.

Further to study the effect of enzyme concentration, time and temperature, the cotton fabric was treated with different processing conditions which are given in Table 1. The cotton fabric was treated in agitated system with a liquor ratio of 1:20 at pH 5. In the agitation system, agitation speed was set to 50 rpm during the bio-treatment. After enzymatic treatment, the fabrics were washed twice in boiling distilled water to deactivate the enzyme and to remove the sizing chemicals.

Sample no |

Enzyme concentration (g/l) |

Time (min) |

Temperature (˚C) |

S1 |

1.5 |

60 |

40 |

S2 |

90 |

50 |

|

S3 |

120 |

60 |

|

S4 |

2 |

60 |

40 |

S5 |

90 |

50 |

|

S6 |

120 |

60 |

|

S7 |

2.5 |

60 |

40 |

S8 |

90 |

50 |

|

S9 |

120 |

60 |

Table 1 The different processing conditions for combined de-sizing and scouring

Testing

Weight loss %

The weight of the cotton sample before and after the enzyme treatment was taken in electronic balance. The weight loss percentage of cotton fabric is determined by using the following formula.

Where W1and W2 are the weights of the fabric before and after treatment

Water absorbency: The absorbency test was carried out using the AATCC Test-79. The wetting time of fabric is measured to know the performance of enzyme treatment on cotton. It was measured by simple detection of the time required to absorb one drop (10μl) of water. Average values of five determinations were taken. Sample is placed in an embroidery hoop with all creases out of it. A burette dispenses a drop of water onto the surface of the fabric from a distance of 9.5mm below the burette. Time is recorded until the water drop absorbs completely.13–17

Effect of mode of pre-treatment on weight loss % and absorbency of cotton fabric

Figure 1 depicts the effect of mode of pretreatment on the weight loss percentage of the cotton fabric. It is observed that enzyme +wetting oil+acetic acid treated and enzyme treated samples has shown 8% weight loss. The enzyme + wetting oil treated fabric have shown a weight loss of 7%. The minimum weight loss of 4% is observed in enzyme + buffer treated fabric sample.

The Figure 2 depicts the effect of mode of pretreatment on the absorbency of the cotton fabric. It is observed from the figure that enzyme +wetting oil+acetic acid treated sample has shown quicker water absorption rate than other samples. This is due to the better reaction of enzyme in the presence of wetting oil and acetic acid. The enzyme + wetting oil treated sample has given absorbency in 6 sec where as the enzyme + buffer treated sample has given absorbency in 7sec.

3.2 Effect on varying the enzyme concentration, time and temperature on weight loss % and absorbency

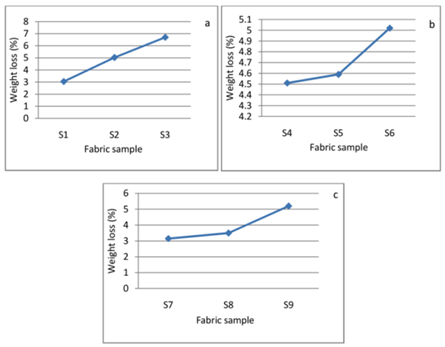

The Figure 3 illustrates the influence of varying enzyme concentration, time and temperature on weight loss percentage of cotton fabric. It is clear from the figure that weight loss value of the fabrics seemed to increase with an increase in the treatment time and temperature. Increase in reaction time and agitation also results in increase in weight loss percentage of the fabric.18 It is also observed that the weight loss percentage of cotton is higher initially in the samples treated at 2g/l enzyme concentration.

Figure 3 Influence of varying enzyme concentration, time and temperature on weight loss (%) (a) 1.5g/l (b) 2g/l (c) 3g/l.

Further it is also found that the wetting time values of fabrics obtained after 90min of treatment were significantly lower to that of fabrics obtained after 60min of treatment whereas further increasing the treatment time from 60 to 120min did not result in much lowering of the wetting time.18

Figure 4 illustrates the influence of varying enzyme concentration, time and temperature on absorbency of cotton fabric. It is noted that the sample S2 with the enzyme concentration of 1.5g/l, time 90min and temperature 50˚C has given better absorbency in 4sec. The wetting time of enzymatic pretreated fabrics is better than chemically scoured fabrics.

The effect of xylanase enzyme on the pretreatment of cotton fabric is investigated by varying mode of application and process conditions of combined de sizing and scouring. It is observed from the results that the fabric treated with xylanase enzyme, buffer and acetic acid has shown optimum weight loss and absorbency. Optimum conditions for the treatment of xylanase enzyme on the cotton fabric are found at 1.5g/l, 50˚C, and 90min in the combined desizing and scouring.

None.

©2019 Vaissnavi, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.