Journal of

eISSN: 2574-8114

Research Article Volume 5 Issue 1

Fashion Technology, Hong Kong

Correspondence: Rick CY Lam, Fashion Technology, 19/F Harbour Front, 22 Tak Fung Street, Whampoa Hong Kong, Tel 852 2798-3547

Received: February 17, 2019 | Published: February 26, 2019

Citation: Lam RCY. A study of fabric biasness with self developed fabric dimensional behaviour test. J Textile Eng Fashion Technol. 2019;5(1):58-62. DOI: 10.15406/jteft.2019.05.00181

While a garment can be cut on the warp-wise or weft-wise along the grain line, it can also be cut on bias. A 45-degree bias is one of the kinds of bias cut,1 which improves the draping and snug effects and provides closer fitting in order to achieve fashion and aesthetic purposes.2

According to Stanley1 and Joseph-Armstrong,3 due to the different elasticity of warp and weft yarns of the fabric, the bias-cut garment may slightly swing to one side, which possibly affects the balance of the hem line as well as the centre front and centre back. On the other hand, Sidabraite and Masteukaite4 suggested sewing conditions, such as seam types and seam directions could potentially cause the displacement of centre front and centre back and asymmetric drape due to twist leg effects.

To tackle the problems or characteristics mentioned above, Stanley1 recommended the bias garment should be cut longer than garments on straight grain, and adjusted it after the garment was made. She, however, did not mention how long the bias one should be. This study tried to build up a model to demonstrate the necessary adjustments should be made to the pattern.

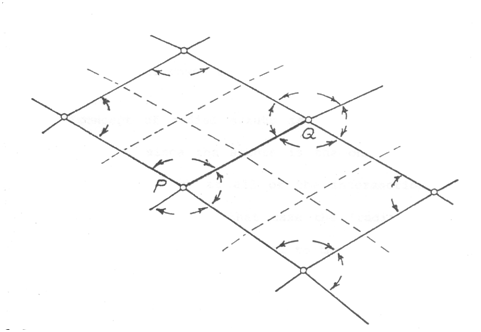

This study was based on the assumption of rod element of fabric.5 In short; fabric could be approximated by a system of rod. Figure 1 Rod Element of Fabric showed the links between rod element PQ and adjacent elements, arising due to shear. The assumption was associated with spherical surface, fraction between the fabric and the curved surface; however, this study concerned on the performance of the biased fabric solely and minimized the impact of fraction.

Figure 1 Rod Element of Fabric.

(Adapted from The Biaxial Tensile and Shear Properties of Textile Fabrics and Their Application to the Study of Fabric Tailoarbility5).

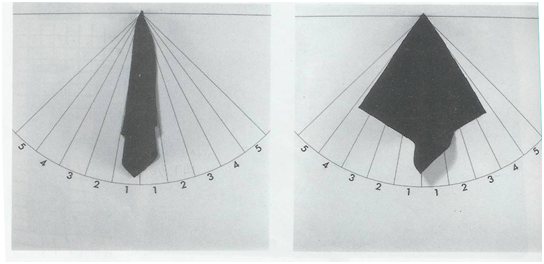

Figure 2 Drape Measurer.

(Adapted from Fabric, Form and Flat Pattern Cutting6).

FAST stood for ‘Fabric Assurance by Simple Testing which was a set of instruments and test methods developed by CSIRO Division of Wool Technology (Australia) for measuring those properties of fabrics which affected the tailoring performance and appearance of the garment in wear (FAST User’s Manual).7 FAST-3 Extension Meter and Eb5 testing method was be used in this study as an objective and comparative test. Eb5 tests the fabric extension on the bias and the testing results could be a valuable reference in this study.

A Fabric Dimensional Behaviour Test (B-Test) is developed and the FAST-3 Eb5 Test were used for the study. The B-Test was designed for collecting 3 sets of data related to dimensional properties of a piece of fabric cut on bias. They were the change of length and width of the fabric and the tilt of the center line with limited amount of drape. The Eb5 Test was used for measuring the extension of fabric cut on bias.

B-test

The schematic diagram of the B-Test instrument was shown below in Figure 3. Figure 4 showed the actual instrument developed for the study, which was designed as an upright board with graph paper attached on. The length and width of the specimens were recorded. Specimens were pinned on the testing board and graph at the top corner as a shape of diamond to demonstrate a rod-structure of textile materials. To avoid the falling of the two sides of the specimen, a plastic sheet installed on the specimen and attached on the platform. The distance between the plastic sheet and the platform was adjustable by means of adding and the removal of rings. Please refer to Figure 3.

In order to ensure that the setting and graph paper were perpendicular to the sea floor, two strings fastened with loads were attached on two sides of the platform. The graph paper would be attached on the platform based on the perpendicular indicator, the two strings with load to ensure the position of graph paper.

The draping of the specimen was using its own weight. Therefore, no weight was attached on the specimen directly. And the specimen was weighted by electronic balance in advance.

A transparent paper was fixed on the top of the plastic sheet to mark the position of the specimen in order to measure its extension and change of width as well as the tilt angel.

The fabric specimen was first to be cut in 22cmx22cm, a square on straight grain. After relaxation under standard atmospheric condition at temperature 21˚C±1˚C and relative humidity 65%±2%., then it was cut into exact specimen size 20cmx20cm. On the other hand, the instrument was conditioned in advance at least for 24 hours, including the graph paper. Static charge on the plastic sheet was discharged beforehand.

The data collected from the instrument directly was the length, the width and tilt of the specimen

FAST-3 Eb5 test

The FAST-3 Extension Meter with Eb5 testing method offered a direct measure of bias-fabirc extension under 5gf/cm. The instrument worked on a balance principle applying 5gf/cm to the rectangular fabric specimen. The position of the upper jaws was fixed while the lower jaws were on one end of the balance arm. Weight was placed on the other end of the balance arm.

When the locking knob was released, force would be applied on the specimen. The position of the arm was monitored by a sensor. Extension value would be shown as percentage fabric extension.

Fabric sample was conditioned for no less than 24 hours before cutting into specimen by using the template shown in Figure 5. And the data collected from the FAST-3 Extension Meter was mainly the percentage of fabric extension.

Ten types of fabric used for bias-cut style were collected from ladies wear manufacturer. Velvet, satin, linen plain weave, crinkle, georgettes, melton, burnout velvet and burnout satin were collected. Table 1 below showed more details of the fabric samples and Figure 3.9 showed the fabric swatches of the fabric samples. Both warp and weft bias was tested.

Fabric |

Weight |

Density/inch |

Yarn count (Tex) |

||

g/sq. m |

Warp |

Weft |

Warp |

Weft |

|

A Velvet 18%/Silk 82% Viscose |

204.28 |

96 |

112 |

5 |

4 |

B 100% Silk 16mm Satin |

88.65 |

335 |

128 |

4 |

6 |

C 100% Linen #2008 |

228.23 |

44 |

33 |

65 |

66 |

D 100% Silk 12mm Crinkle |

40.75 |

120 |

100 |

4 |

4 |

E 100% Silk 12mm GGT |

58.01 |

47 |

100 |

6 |

6 |

F 100% Viscose GGT |

94.97 |

88 |

80 |

16 |

18 |

G Viscose/Silk Burnout Velvet |

134.94 |

93 |

122 (2:1) |

4 |

5 |

H Viscose/Silk Burnout Satin |

93.02 |

88 |

160 (1:3) |

3 |

3 |

I Shantex 12mm GGT |

63.87 |

232 |

124 |

3 |

6 |

J 65% Wool/35% Viscose Melton |

289.2 |

42 |

42 |

29 |

14 |

Table 1 Details of Fabric Sample Used in this Study

The data was collected and averaged out, and shown in Table 2. Ext-A and Ext-B were the change in the length expressed in percentage. The % Width A and % Width B were the change in the width expressed in percentage. Angle-A and Angle-B showed the tilt angel from the centerline which was expressed in degree. For Ext and % Width, positive value referred to an increase in length or width and negative value represented to a decrease in the contrast. For the tilting angels, positive meant the angle swinging to the left from the centre whereas negative showed the tend to right from the centre. –A and –B referred to bias warp and bias weft respectively.

Test |

B-test |

FAST Eb5 |

||||||

Fabric |

% Vertical extension |

% Width change |

Tilt angle |

% Vertical extension |

||||

Warp bias |

Weft bias |

Warp bias |

Weft bias |

Warp bias |

Weft bias |

Warp bias |

Weft bias |

|

(Ext-A) |

(Ext-B) |

(Width A) |

(Width B) |

(Angle-A) |

(Angle-B) |

(Eb5-A) |

(Eb5-B) |

|

A |

2.06 |

3.06 |

-3 |

-4.63 |

-0.5 |

-0.1 |

6 |

6.37 |

B |

5.73 |

6.26 |

-6.89 |

-7.46 |

-0.05 |

-0.5 |

8.27 |

7.4 |

C |

0.18 |

0.53 |

-1.52 |

-2.08 |

-0.3 |

0.1 |

6.9 |

6.23 |

D |

13.74 |

16.01 |

-16.57 |

-17.42 |

-1.1 |

-0.2 |

16.97 |

20.97 |

E |

11.42 |

11.74 |

-14.03 |

-14.63 |

-0.6 |

-0.3 |

13.83 |

12 |

F |

9.89 |

9.79 |

-12.69 |

-12.51 |

0.1 |

-0.1 |

6.77 |

7.23 |

G |

5.12 |

7.19 |

-6.86 |

-9.26 |

0.6 |

0.25 |

10 |

8.3 |

H |

9.47 |

8.83 |

-11.27 |

-10.07 |

0.05 |

-0.1 |

8.4 |

9.83 |

I |

5.48 |

6.41 |

-7.81 |

-7.28 |

-0.1 |

-0.75 |

12.57 |

12.07 |

J |

-0.07 |

-0.14 |

-8.96 |

-9.48 |

-0.15 |

-0.2 |

3.03 |

3.2 |

Table 2 Results Collected from B-Test & Eb5 on Average

Remark: Figures are average value

B-test

The majority of B-Test specimens show certain degree of extension. Sample F and H show almost 10% extensions. Sample D and E have even greater extension up to 16%. Sample J, however, shows negative value, which means there is a decrease in length. Error may be implied in sample J.

At the same time, all specimens decrease in width at different magnitude. The most obvious decrease in width is 17% which is a Crinkle fabric (Fabric D) but the least change of width is 1.5% (Fabric C).

All the specimens tilt left or right within 1.2 degree. Most of the samples, 75% of raw data, tend to right. The other 25% swings to left.

Eb5

In Eb5, the specimens extend from the range of 3% to 20% (fabric D). The majority have greater than 6% of extension. The total average extension is about 9% on both bias warp and bias weft.

Correlation of extension and the change of width

The assumption this study based on is the rod-like element, which is the change of length of a diamond shaped fabric on bias affects the width. The correlations of length and width support this assumption with evidence.

Figure 6 and Figure 7 below show the correlations between the specimen length and width on bias warp and bias weft.

For the bias warp (Figure 6), the coefficient of correlation, R2 is 0.99 which suggests there is very strong relationship between the length and width of the specimen. The increase in the length leads to a decrease in the width which fits the rod-like assumption.

Refers to Figure 7, it shows the correlation of the bias weft direction. The coefficient, R2, is 0.98 which also suggests there is a very strong relationship between the length and width of the specimens.

To sum up, there is a very significant and strong relationship between the length and the width of the specimen regardless bias warp or bias weft direction. It demonstrates that the extension of the fabric leads to narrow down the width of the specimen. That means when a garment is cut on bias and fitted onto human body, the garment width and length change. It could be the reason that bias cut garment provides better fitting for human body. It, however, indicates the problem that the garment length decided on the pattern may not be suitable for the actual garment because the actual length is longer than the length marked on the pattern when the garment is hanged on human body. The extension property of bias cut fabric affects not lengthwise only but also the widthwise. The girth measurement, e.g. chest and hip measurements of the garment may also change to be smaller due to the phenomenon suggested by Bassett5 and Stanley.1

Correlations of B-test and Eb5

As mentioned previously, it seemed to be an error in Sample J, which resulted in negative value in extension, -7% and -14%. It is rejected and the figures below excluded sample J.

Figure 8 shows the coefficient of correlation between fabric extensions of B-Test and Eb5 on bias warp. Quite a significant relationship is shown between the results of B-Test and Eb5 with the coefficient, 0.46.

Figure 9 shows the coefficient of B-Test and Eb5 on bias weft is 0.66 which suggests a quite strong relationship between these two sets of testing results.

Both Figure 8 and Figure 9 suggest there is quite strong relationship between B-Test and Eb5. As B-Test is a test method developed in this study in order to provide the industry a low-cost and reliable method for measuring bias fabric extension, the coefficient of B-Test and Eb5, 0.46 and 0.66 recommend a degree of reliability for the B-Test. B-Test could possibly tell the extensibility of bias fabric.

Tilt angle

The tilt angles of fabrics are quite random among individual sample. It is difficult to forecast a trend of the tilt angles even in the same fabric sample. Specimens tilt with various angles and different directions, both left and right. It could be a kind of testing error, e.g. the handling of the specimens. Error caused during the specimen preparation. Fabric, forever, is difficult to handle regardless loose structured or tight structured. The grain line is problematical to be fully followed since the warp and weft yarns may not be necessarily perpendicular to each other.

Error analysis

Negative extension is found in Sample J which seems to be an error in the study.

When looking into the raw data, over 70% of specimens of sample J showed no extension and the residual shows negative. The majority, however, shows a trend that no fabric extension could be found in Sample J. The error is possibly occurred during the specimen preparation.

B-Test and Eb5 aim at measuring the biased fabric extension. B-Test collects both the change of length and width while Eb5 records the extension solely. Although their results are various, the capability of using the result of extensions in garment making is still uncertain. A further study of on-site evaluation is recommended to assess the suitability.

As a matter of fact, cover factors have been taken in to account but the co-efficient between the fabric extensibility and cover factors were too low to show a sign of relationship and it is not adequate to predict the fabric extensibility through the fabric tightness.None.

Author declares there is no conflict of interest in publishing the article.

©2019 Lam. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.