Journal of

eISSN: 2469 - 2786

Research Article Volume 9 Issue 3

Federal University of Agriculture, Nigeria

Correspondence: Momoh Clement Owoicho, Department of Food Science and Technology, Federal University of Agriculture, Makurdi, Nigeria

Received: May 01, 2021 | Published: August 10, 2021

Citation: Ogah, Abah R, Ahure D, et al. Quality evaluation of noodles produced from wheat (Triticum spp) and almond seed (Prunus dulcis) flour blends. J Bacteriol Mycol Open Access. 2021;9(3):122-128. DOI: 10.15406/jbmoa.2021.09.00307

In this study, the qualify evaluation of noodles produced from wheat and almond seed composite flour was studied. A preliminary was carried out to ascertain the optimum acceptable level of almond seed flour in wheat flour noodle processing using 0-50%w/w, samples were subjected to sensory evaluation and the most acceptable samples was chosen. Hence, in the main study, level of almond seed flour was varied within the most acceptable level using 5, 10, 15 and 20% w/w inclusion giving rise to four samples. Functional properties, anti-nutrient content, proximate composition, essential amino acid profile, selected mineral content, textural and cooking analyses and sensory evaluation were done using standard methods. The bulk densities of the blend ranged from 0.801 to 0.884 g/ml, WAC, ranged from 2.20g/g to 3.60g/g and swelling index ranged from 6.27 to 2.27 as the proportion of almond seed flour increased from 0-20 %. The values of phytate, oxalate, and tannin range from 0.12 to 0.75g/100g, 0.03 to 0.92g/100g and 0.08 to 1.23g/100g respectively. An increase (9.99 % - 14.55 %) in protein content was observed in the flour blends with increased addition of almond flour, there were significant difference (P<0.05) in mean samples. Lysine value ranged from 3.44 to 5.09%, Valine value ranged from 3.71 to 5.01% and leucine value ranged from 7.06 to 7.24% as the level of almond flour increases from 0 to 20% in the flour blends. Potassium (412.40 mg/100g), magnesium (167.00mg/100g) and calcium (66.55mg/100g) were predominant minerals in the formulated noodles while Iron and sodium were found in low concentration. The values of B1, B2 , B3 ,B6 B9, C, D and E ranged from 1.95 to 2.12mg/100g, 0.45 to 1.12 mg/100g, 0.72 to 0.68mg/100g, 1.25 to 2.12mg/100g, 12.09 to 22.02mg/100g, 19.55 to 22.12 and 0.21 to 2.12 mg/100g respectively as the proportion of almond seed increases from 0 to 20% in the blends used in noodle preparation. The results for length, porosity apparent density and weight for noodle sample from wheat flour (control) were 3.34cm, 0.52mm, 0.87 and 1.94 g respectively. The corresponding values for noodle from 95% wheat flour and 5% almond seed flour were 3.25cm, 0.50mm, 0.89 and 1.93g respectively. . Cooking time and cooking lose increased on addition of almond seed flour while percent rehydration reduced as the quantity of almond seed increased in the noodle samples. Blend formulation 80:20 W : A was mostly acceptable. This study therefore has presented a way of increasing consumption and utilization of almond seed with high nutritional content yet are underutilized increasing food security, providing more affordable noodle from local available food sources and further converts waste to wealth.

Keywords: noodle, almond seed and wheat

Noodles are quick cooking foods that are increasingly gaining acceptance in Nigeria and gradually displacing most traditional diets that serve as breakfasts and snacks due to convenience, improved income, nutritional values, status symbol and job demands especially among urban dwellers.1 The popularity of noodles has been attributed to its sensory appeal, versatility of form and ease of preparation at consumers end, nutritional content and long shelf life.2 Pasta extrusion is known to result into products where the starch is slowly digested and absorbed.3 The main ingredient in noodles is wheat and water mixed at appropriate concentrations.4 Wheat is not only deficient in protein and other micronutrients as with cereals in general; it is also a foreign exchange depleter as a result of importation from scarce resources due to unfavorable climate for large scale production in Nigeria.5 It will be therefore thought worthwhile to produce noodle from wheat and almond seeds which are abundant in Nigeria. Almond is a cereal that is predominantly grown in all the ecological and dietary zones.6 Almond seeds are high in protein and other micronutrient.7 Almonds are 4% water, 22% carbohydrate, 21 % protein and 50% fats. It is a good source of minerals (Faiyazet al., 2007). One ounce of almond seeds is an excellent source of vitamin E, magnesium, copper, potassium, calcium, iron and B vitamins. Almond seeds are currently underutilized; it is used as agricultural will bete and increases postharvest loss in spite of its high potential as a raw material for the preparation of functional foods and neutraceuticals.8–10 Apart from the nutritional benefits of almond seeds, it has anti nutritional factors. Tannins and phenols are enzymes present naturally in almond which attacks nutrient absorption. Extrusion and thermal processing denatures the naturally occurring anti-nutritional factors and thus has been widely used in reduction of anti-nutritional factors in plant based food products.11 In Nigeria where there is an increasing demand for ready-to-eat, convenient and quick cooking food as well as malnutrition due to deficiency in protein calories contributing to more than half a million deaths of newborn and growing children,12 Almond seeds can be utilized as a supplementary protein in wheat-based extruded foods to improve their nutritional quality. However, this will achieve the desired result as long as the sensory characteristics of the end product are not discernibly changed and the product is affordable to people at the bottom of the income pyramid. Incorporating almond seeds with wheat in noodle processing could result in low cost noodles with enhanced protein-energy, in addition almond will add reasonable amount of minerals which would serve as a potential solution to the consequences of hidden hunger in Nigeria. Although information on the use of wheat in pasta production has been reported, there is little information on incorporating almond seed flours for production of pasta despite the fact that these are indigenous food sources. They are produced in large quantities in Nigeria and are major sources of protein and micronutrients. This study thus, seeks to produce high protein-energy and more affordable noodles from wheat and almond see composite flours and to evaluate the chemical composition, cooking, textural characteristics and sensory attributes of the noodles with the aim of promoting utilization of almond seeds.

Imported whole wheat flour and Almond seeds flour were purchased from Makurdi Modern Market, Benue State.

Equipment

A laboratory scale LSG65 twin screw extruder (Jianansaibaibainuo Technology LMT) with 15.5cm screw length, 10.01cm screw diameter and 0.8mm die diameter was used for extrusion cooking. Extruder, tray drier (M/s Balaji enterprise, Shaharanpur, India) and moisture analyser (GRD 60H20 China) was used.

Sample preparation

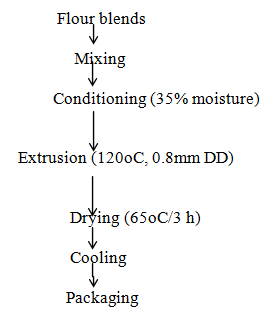

Wheat flour and Almond seeds flour were purchased from the market and sieved through a 0.5mm size mesh and were packaged in Low density polyethylene bags prior to analyses. African yam bean flour was prepared as shown in Figure 1. The flour blend formulation is captured in Table 1. The flour blends were conditioned to 35% moisture content, mixed manually and extruded at 120°C through 0.8 mm die diameter of a laboratory scale twin screw extruder (Jianansaibaibainuo Technology LMT) with 15.5cm screw length, 10.01cm screw diameter. Extrusion of flour blends was done following the method described by Momoh et al.13 for noodle production . Two (2) kilograms of each composite flours were conditioned to 35% moisture content; and kept for 30mins. The composite flours were separately extruded at 120°C barrel temperature. The extruder was stabilized for each run with 2kg whole rice flour at steady state operation; samples were collected in open pans. The extrudate was allowed to cool and dried for 3hours in a tray drier at 60°C to a moisture content of 6-8%, sealed in low density polyethylene bags and store in a refrigerator for subsequent analysis. Samples for analyses were milled into flour.

|

Samples |

||||

A (Control) |

B |

C |

D |

E |

|

Wheat (%) |

100 |

95 |

90 |

85 |

80 |

Almond seed flour (%) |

0 |

5 |

10 |

15 |

20 |

Table 1 Mixing proportions of wheat and almond seed flours

Figure 1 Flow chart for preparation of noodle from wheat and almond seed composite flour.

Source: Momoh et al.13

Analytical methods

The proximate analysis, amino acid analysis and mineral elements (Na, Ca, K, Mg, and Fe) to determine how much of major or macro components which include Moisture, Ash, Fiber, Fat and Protein were determined according to standard methods AOAC, (2012). The carbohydrates were determined by difference using the formula: % carbohydrate = 100 -% protein + % ash + % crude fiber + % crude fat + % moisture.

Statistical analysis

Statistical Package for Social Sciences (SPSS) V23 computer software was used to analyze the data. Means and Standard deviation were calculated where appropriate. One way Analysis of variance (ANOVA) was used to determine the treatment that was different from others in the various parameters tested; differences were considered significant at 95% (p<0.05) significant level and 99% (p<0.01) significant level where mentioned.

The values for bulk density, foam capacity, water absorption capacity, oil absorption capacity, Swelling index and gelation temperature for wheat flour and almond seed composite flours are similar although with different ingredients to that reported by Ekop (2006) and Eneche (2005) for composite flours produced from African yam beans and wheat flour. Wheat flour has the lowest value for foam capacity (10.50%), water absorption capacity (1.00g/g) and oil absorption capacity (0.98g/g) while swelling characteristic (7.25) was highest in wheat flour. This is probably attributed to the fact that protein characteristic of wheat and almond which are same at room temperature are believed to be largely responsible for functional properties such as foaming, emulsification, oil and water absorption capacity, while swelling characteristics and gelation temperatures are starch related. Foam capacity of composite flours ranged from 18.00 to 32.00%. There was a gradual increase in foam capacity with increasing addition of almond seed flour, this value is higher than those obtained for flour from boiled dates (1.98%). Physiochemical changes in proteins such as denaturation at high temperature may affect functional properties such as water and fat absorption capacities, protein solubility and product characteristics.14 The bulk density of the composite flours ranged from 0.80 to 0.88g/ml, with the highest value found in sample 80:20:W:A formulation, flour samples where significantly different (P<0.05) from each other. Higher value of bulk density (2.45 and 2.45g/ml) were reported by Agunbiade & Ojezele15 for breakfast cereals made from maize, sorghum, African yam beans and soybeans. Severtz & Desrositer reported bulk density ranges of 0.31 g/ml and 0.20 g/ml for roasted ground coffee and instant coffee powder respectively. The bulk densities suggest that the samples may require different package space and material. The less the bulk density, the more packaging space is required.15 Water absorption capacity (WAC) of the flour blends ranges from 1.00 to 2.20 g/g. The water absorption capacity increased with increase in almond seed flour inclusion. This may be due to the hygroscopic properties of almond seed flour, thus absorbing moisture on exposure to water. Similar values were recorded for breakfast cereal from blends of maize; African yam beans, defatted coconut cake and sorghum extract.1 Values obtained varied significantly (P<0.05). Oil absorption capacity (OAC) of the flour blends vary in trend as those obtained for water absorption capacity. The values ranged from 0.91 to 1.4 g/g with the highest recorded for sample 80:20W: A formulation. There was significant difference (P<0.05) amongst samples mean. Oil absorption capacity also increased with increasing addition of almond seed flour. There is a gradual decrease in the values for swelling index with increasing almond seed flour. Mean values ranged from 7.25 to 6.21, with the highest value recorded for wheat flour. Sample means with respect to oil absorption capacity vary significantly (P<0.05). The Gelation Temperature of the flour blends ranged from 69.30 to 73.11oC. Gelation Temperature of the blends generally increased with increasing addition of almond seed flour. Extrusion cooking however reduces the energy required since it becomes pre-cooked. Gelation temperature might be associated with the relative ratio of amylase and amylopectin in the composite flour. Case et al. reported that waxy and regular maize flour gelatinize at 62-72oC, whereas high-amylose starches begin to swell below 100oC; temperatures of 120oC and above are required to fully disperse these starches.

Anti-nutrient content of wheat and almond seed composite flour

The anti-nutrient composition shows that wheat flour contained 0.11g/100g of phytic acid, 0.03g/100g Oxalate and 0.09g/100g tannin. The values of phytic oxalet, tannin and affloxaxin range from 0.11 to 0.75g/100g, 0.03 to 0.92g/100g, 0.08 to 1.23g/100g and 0.00 to 0.14g/100g respectively as the proportion of almond seed increases from 0 to 20% in the blends used in noodle preparation. The increase in these anti-nutrient proportion with respect to increasing levels of almond seed flour is probably due to higher levels of these anti-nutrients in almond seeds flour. The values obtained are in range to the recommended by FAO for anti-nutrient in flour samples and are similar to those reported by pyakas, 2016 for anti-nutrient factors in selected plants.

Proximate composition of noodles prepared from wheat and almond composite flours

The results of proximate composition of noodles prepared from wheat (W), and almond seed composite flours showed that the protein contents ranged from 8.95 to 13.00%. The increase in the protein content could be attributed to high protein content for almond seed flour, these values are in agreement with those reported by Nwosu (2014), Ameh (2007), Eneche (2005), Obatolu et al. (2003) and Oshodi et al. (1997) are 23.2%, 21.0%, 22.3%, 20.5% and 23.0% respectively. A similar trend was observed by Igbabul et al. (2014) and Ekop (2006) with cookies produced from wheat, cocoyam and African yam beans composite flours and extruded cakes from wheat and African yam beans flour blends respectively. All noodle samples have dissimilar protein content and are significantly different (P<0.05). Sample 80:20:W:A had the highest protein content greater than that of wheat noodles (13.00%). The result obtained for ash content showed significant difference (P< 0.05) among noodle samples. Similar values have been recorded by other researchers with ‘Kokoro’ a Nigerian snack made from Maize and African yam bean flour blends: 1.87, 2.17 and 2.42%. The relative increase in ash values of noodle samples may be attributed to the presence of almond seed used as part of the ingredients with relative high ash content. The crude fat content of noodle samples ranged from 1.24 to 5.06%, these values agrees with that reported by Priyanka et al. (2012) with extruded ready-to-eat snack produced using egg albumin cheese powder and African yam beans flour. Significant differences (P<0.05) were observed among samples. The increase in value obtained for fat content of noodle samples may be attributed to almond seed having high fat content. Low fat food products are less susceptible to rancidity and hence more shelf stable. Dietary fats that provide essential fatty acids (EFA) have been shown to enhance the taste and acceptability of foods, slow gastric emptying and intestinal motility, thereby prolonging satiety and facilitate the absorption of lipid-soluble vitamins. The lipid component also helps to determine the texture, flavor and aroma of foods. The crude fiber content of noodle samples ranged from 3.25 to 3.43%. Samples had dissimilar crude fiber and were significantly different (P<0.05) from each other. Crude fiber is very important in adding bulkiness to food and for prevention of some disease of the colon. Fiber is important for the removal of waste from the body thereby preventing constipation and many health disorders. The noodles therefore have a great potential for application as diabetic food because of the fiber source in their formulation that could be modified to generate a near perfect recipe for production of diabetic food/snacks. The carbohydrate content of noodle samples ranged from 75.10% to 66.53%. This implies that the noodles are good sources of energy needed for normal body metabolism. However, carbohydrate content of noodle samples decreased with addition of almond seed flour, Wheat noodle had the highest value. This could be because wheat flour used as the principal ingredient in the formulation has higher starch content than almond seed flour. All noodle samples were significantly different (P<0.05) from each other in carbohydrate content. The values for carbohydrate are in agreement with values reported for flakes produced by substitution of wheat flour with rice flour and rice bran.

Essential amino acid (%) composition of noodles prepared from wheat and almond seed composite flours

The results of essential amino acid content of noodles produced from wheat (W), and almond seed composite flours showed that the predominant amino acid in the noodle are Lycine (5.09%), Leucine (7.85%), phenylalanine (3.30%), threonine (3.54%) and Valine (5.00%). The least in the noodle samples was tryptophan (1.00%). This probably is due to its low content in the raw materials used. The values of all the essential amino acids in the noodle samples compared favorably with other extruded legume based food products from soya beans and peas. The observed value of 5.09% for lysine content of 80:20:W:A formulation is high when compared with the range of values (1.20 to 3.90%) reported for most cereal based extruded food products. The values for essential amino acids observed for all noodle samples also compare favorably with Recommended Daily Intake for children (2-5years) which imply that these noodle samples are rich in amino acid and are nutritive. The values obtained compares favorably to the recommended (37.6%) and considered to be adequate for idea protein for children and 24% for adults.

Mineral (mg/100g) composition of noodle prepared from wheat and almond seed composite flours

The mineral content of noodles produced from wheat (W) and almond seed (A) composite flours was found to vary significantly (P<0.05) with increasing almond seed flour. This increase could be attributed to the relative high mineral content of almond flour. 80:20:W:A had the highest values for all minerals analysed. Potassium (411.10mg/100g), magnesium (166.50mg/100g) and calcium (66.50mg/100g) were predominant minerals in the formulated noodles while Iron and sodium were found in low concentration, this is similar to the report of Edem et al. (1990) that low concentration was found of iron and zinc with extruded food from African yam bean flour and fonio flour. Higher mineral content were found in sample containing higher quantity of almond seed flour which contributed to the relative high ash content in noodle samples. Uwaegbute et al. (2012) reported similar values for calcium content of African yam beans flour.

Vitamins composition of noodles prepared from wheat and almond seed composite flours .

The vitamin composition shows that wheat noodle contained 1.95mg/100g of B1, 0.46mg/100g B2, 0.73 mg/100g B3, 1.26mg/100g B6, 12.56mg/100g vitamin C, 19.00mg/100g vitamin D, 0.22 vitamin E, 0.02 vitamin B9 and 0.14 mg/100g B12. The values of B1, B2 , B3 ,B6 B9, C, D and E ranged from 1.95 to 2.16 mg/100g, 0.46 to 0.55mg/100g, 0.73 to 0.66mg/100g, 1.26 to 1.48mg/100g,12.56 to 23.56mg/100g and 0.21 to 2.23 mg/100g respectively as the proportion of almond seed increases from 0 to 20% in the blends used in noodle preparation. These values are in agreement with that reported by Singapore, 2015: for chemical composition of extruded food from almond seed flours and maize. Momoh et al., 2018 further reported similar values for vitamin content of noodles produced from broken rice, rice bran and African yam beans composite flours. All noodle samples had dissimilar (P<0.05) minerals content and were significantly different at 5% significant level. The noodle prepared from 20% level of almond seed flour was significantly (P<0.05) higher in all minerals analyzed.

Textural properties and cooking quality of noodles prepared from wheat and almond composite flours

Wheat noodle (Control) had the lowest apparent density(1.94) and weight (0.87) while the highest was recorded for sample formulation 80:20: W:A ( 0.93 and 1.94g respectively), these results were similar to the study by Sajilata et al. (2006), who found that weight and porosity value of noodle sample added with banana flour were higher than those of wheat noodles. It is highly vital that the structural integrity of noodles need to be maintained throughout the cooking process. High porosity is unacceptable as there can be high amount of solubilized starch present, which leads to cloudy boiling water and “sticky” mouth feel with lower tolerance. There was significant difference (P<0.05) in means with respect to porosity and weight of noodles. The decrease in length and porosity on addition of almond seed flour in this study is in agreement with previous findings on quality evaluation of ‘flat’ noodle noodles. Textural characteristics of noodles are also a critical characteristic, which determines consumer acceptance of the product.

Sensory properties of noodles prepared from wheat and almond composite flours

Sensory perception varied significantly (P<0.05) among samples. Values obtained for taste showed a low level of acceptance of the noodles with increasing level of almond seed flour. However, no significant difference (P>0.05) was obtained for appearance (color) of the samples with change in quantity (%) of almond seed flour. Higher sensory scores for flavor with increasing almond seed flour in the sample shows the undesirable choky flavor usually associated with almond seeds is negligible in the noodle. This may be attributed to the method used during almond flour production and extrusion, which might have off-set the chocky flavor. There was no significant difference (P>0.05) for flavor of the samples with change in quantity (%) of almond seed flour. All noodle samples were generally accepted for all attributes evaluated as none scored below the minimum acceptable rating of 5 on a 9 point hedonic scale. This indicates a high level of acceptance of the noodle prepared from wheat and almond seed composite flours, thereby improving the nutritional contents and as well as increasing the utilization of almond seed which was added as part of the ingredient.

Extrusion of wheat, and almond seed composite flour produced acceptable noodles with significantly increased protein and ash contents in blend ratio 80:20:W:A. Crude fat and crude fibre were similarly increased. The noodles could contribute significant amounts of mineral with respect to FAO/WHO/UNU recommended daily intakes for Mg (130mg/day), Na (1000mg/day), Ca (500mg/day), K (3000mg/day) and Fe (10mg/day). Functional properties of wheat and almond seed flour composite compared favorably with other legumes and cereals, hence it could find application in food industries. Length and porosity reduced as apparent density and weight increased on addition of almond seed flour. The sensory attributes showed that acceptable noodle can be produced from wheat supplemented with almond seed flour. Blend formulation 80:20 W:A was mostly acceptable. This study therefore presents a way of increasing consumption and utilization of almond seed: with low economic value, which are underutilized. Almond seeds could therefore serve as ingredients in food formulation to reduce malnutrition and hidden hunger among children and vulnerable groups in Nigeria, increase food security and further convert waste to wealth.16–101

The authors acknowledges the department of Food Science and Technology of the Federal Polytechnic Mubi, Adamawa State for making their extruder available.

The authors declare that there is no conflict of interest.

©2021 Ogah,, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.