Parallel robots are widely used in various fields of engineering and industrial applications such as, machine tools, flight simulators, earthquake simulators, medical equipment and etc. However, they have some limitations such as small and complex workspace, combination of translational and rotational motions and clearance in joints. They are also restricted by other limitations such as existence of singular points which should be studied and analysed for effective and efficient use. Therefore, their complex dynamics and forward kinematics require a very sophisticated real time control.1-3

Since this type of robotic manipulators have a complex dynamic model, many different approaches have been applied to control them which can be classified based on the controller design methods. In this regard, classical controllers such as simple.4 PID controllers which are the most commonly used in industrial applications, do not need complete dynamic information of the robot. Although, these controllers usually show desirable performance in tracking of plants with linear time–invariant models, however, for robots with nonlinear dynamics, more advanced techniques such as Lyapunov based methods5,6 or computed torque control (CTC)7,8 improve the control performance. These methods require complete dynamic model of the robot, while the exact model is unreachable due to uncertainties. This problem restricts the performance of these nonlinear controllers. The deficiency caused by uncertainties can be compensated by adaptive back–stepping sliding mode controller which is proposed in this paper.

Sliding mode control is one of the most applicable nonlinear control strategies9,10 which counteracts the effects of the dynamic model uncertainties. The main reason why sliding mode controller is so widely used in control of nonlinear systems is the capability of solving the two most challenging issues, stability and robustness2 In order to reduce the effect of uncertainties which exist in dynamic model of parallel manipulator, a sliding mode .11,1controller is designed in.13 Gracia et al.14 proposed an integrated solution based on sliding mode for trajectory tracking of a 6R robot model PUMA–560. They presented three sliding–mode algorithms for speed auto–regulation, path conditioning and redundancy resolution and finally evaluated their approach by simulations. Recently, many researchers have been characterized on designing and improving control of the parallel robots with uncertainties. Robust control based on Lyapunov’s control is the principle of most of robust and nonlinear control methods, adaptive control, sliding mode control, and combination of sliding mode and adaptive controls.15,16 Based on the standard nonlinear adaptive methods, the controller tries to obtain specific structurally developed dynamic variable parameters; this might achieve an acceptable tracking performance and cover structuralized uncertainties and limited disturbances.17 Consequently, these factors might affect nonlinear adaptive controllers when dynamic model of the robot is not clearly known or when fast real–time control is needed.3-5

Combined controllers of sliding mode and adaptive controls have been studied as a solution to overcome the problem of adaptive control and sliding mode. The main idea is to use adaptive control to estimate unknown parameters of the dynamic system and sliding mode control is used to overcome non–modeled dynamics and external disturbances.18,19 However, adaptive combined control needs a parameterized liner model of the system that is analyzed and prior knowledge about the bound of uncertainty. In addition, a large number of parameters and an adaptation gain (e.g. designing parameter) corresponding with each parameter demonstrate the extent of complicacy. The problem of a robust and adaptive controller without knowledge of the bounds of uncertainties is addressed in,20 where a parameterized linear model of the system is needed to design the controller. To control robot tracking in presence of uncertainties of the model and time–variable external disturbances, Notash et al.21 introduced a robust adaptive controller based on fuzzy logic model using neural network as a regulator tool. The controller was designed based on theoretical sliding mode control and stability of the controller was analyzed based on Lyapunov’s theory. Their findings supported very high performance and acceptable robustness in presence of disturbances. Back–stepping technique is only used to control strict feedback systems without considering the uncertain factors in practice,22 and its application is severely restricted. To gain adequate performances of control methods, many researchers have interested to the sliding mode control based on back–stepping and applied in different fields, such as chaos synchronization,22,23 quadrotor,24,25 motor drive,26 tracking control27 and etc.

In this paper, kinematic and dynamic modeling of a 3–[P–2(US)] parallel mechanism28,29 is investigated and equations of motion are derived via Lagrange formulation. Then, optimal trajectory planning is done based on Harmony Search Algorithm (HSA) and two trajectories are obtained by spline interpolation of optimal accuracy points in an area containing obstacles. An adaptive back–stepping sliding mode control combining both the advantages of adaptive back–stepping control and sliding mode control is used to achieve accurate control of parallel robot. In order to design of this controller, a back–stepping sliding mode controller is derived supposing that the bound of the uncertainty is well–known. Then an adaptive approach is used to estimate the uncertainties and disturbances of the derived dynamic model of the parallel robot. A Lyapunov function is used to prove the stability of the proposed controller. The proposed controller guarantees closed loop stability in spite of nonlinearities of the parallel robot. Compared with the back–stepping control scheme,30 the proposed controller has the advantages of both adaptive method and robust control, which in presence of uncertainty, nonlinearity and external disturbances have a good performance. In order to overcome the existing uncertainty in this model, adaptive method is used. The main idea of back–stepping approach is to choose recursively some proper functions of state variables as fictional control inputs for lower dimension subsystems of the total system.31

The rest of this paper is organized as follows. In section 2, the configuration of the robot is investigated. Kinematic and dynamic modeling is depicted in section 3. In section 4, adaptive back–stepping sliding mode controller is designed. Section 5 deals with optimal path planning. Simulation results of controller implementation are reported in sections 6 and finally, conclusion is drawn in section 7.

Inverse Kinematics

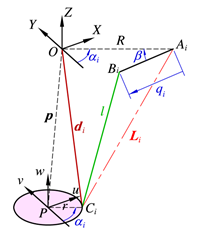

In the inverse kinematics, the goal is obtaining the actuators positions, given the end–effector position with respect to the fixed platform frame. Figure 3 demonstrates kinematic variables of a robot limb in which the end–effector position P is described in fixed platform (Frame O).

Figure 3 Kinematic variables of one of the limbs.

Referring to Figure 3, the following vector relation can be written

(1)

Where

,

and

are the unit vectors along AiBi and BiCi, respectively, and qi represents the linear displacement of the i–th actuator.

Through rewriting Eq. (1),

(2)

After some mathematic simplification, the constraint equation is derived as:

(3)

Lagrange equations

In this section, the dynamics of the robot is investigated and the dynamic model of the mechanism is derived based on the kinematic modeling which was presented in previous section. In dynamic modelling, the mass of connecting link is considered as a mass point and so waiver the joint inertia, energy dissipation and link flexibility. It is supposed that the un–modeled dynamic is evident as a disturbance in exact model. To drive the dynamic model of the robot, the Lagrange method is used. Since there are constraints on generalized coordinates in the parallel mechanism the general formulation of constrained Lagrange equations with Lagrange multipliers is considered as follows

(4)

Where

the j–th generalized coordinate and

is the corresponding generalized force. Also,

,

and k indicate the Lagrange multipliers, constraint functions and the number of system constraints, respectively. Generalized coordinates to describe the system are

(5)

Where q includes the positions of actuators (prismatic joint variables) and p includes end–effector position components. The general formulation of Lagrangian function is written as

(6)

Where, K and U are the kinetic and potential energies of the robot, respectively. The kinetic energy term of the mechanism can be written as

(7)

where

,

, and

are the masses of end–effector, two connecting rods, and actuators piston, respectively. Thus four concentrated moving masses constitute the kinetic energy (three masses of m1 associated to sliding parts of actuators and one mass of m2 associated to moving platform). According to the Figure 4, it is supposed that the masses of six connecting rods are equal and concentrated at rod ends, neglecting their rotational inertia. (Table 1)

Figure 4 Mass elements of one of the limbs.

Value |

Parameters |

|

|

(i-1)×120° |

|

|

40 ° |

|

28mm |

R |

325mm |

|

340mm |

me,mp |

0.5 kg |

|

0.2 kg |

Table 1 Geometric parameters

Now, the potential energy of the mechanism can be written as

(8)

Where,

is angle of prismatic joint direction angle. Substituting Eq. (7), and (8) in Eq. (6) will result Lagrangian function as follows

(9)

By taking partial derivatives of constraint equations used in Lagrange equations and substituting in Lagrange equation and then some simplification,32 matrix form of equations of motion is extracted as follows:

(10)

Partitioned form of the equations is written as

(11)

So,

(12)

Eq. (12) is actually forward kinematics of acceleration and can be used in inverse dynamics module of control loop as follows

(13)

Controller design

In this section three controller is designed which is introduced in the following.

Adaptive back–stepping sliding mode control

Referring to the derived dynamic model of the proposed mechanism and defining

, state equations of the robot can be written as:

(14)

Considering as the desired trajectory of the parallel robot, the trajectory tracking error is

(15)

Virtual control variables for the parallel robot are defined as follows:

(16)

where is a positive definite diagonal coefficient matrix. The velocity error of the system is defined as

(17)

In order to show the stability of the method, a Lyapunov function is found as follows:

(18)

Differentiating Eq. (18) with respect to time

(19)

If

, then

, therefore the first subsystem of the parallel robot is stable. Differentiating Eq. (17) with respect to time gives:

(20)

To indicate stability of the system, a second Lyapunov function is chosen as follows:

(21)

Where

(22)

Where

is a positive definite diagonal coefficient matrix. So, the derivation of Eq. (21) is:

(23)

To satisfy

, and stabilize the second sub–system, the controller can be designed as:

(24)

In a real–time control system, it is difficult to predict the general uncertainty D. To avoid adopting the upper bounds of D, an adaptive algorithm is applied based on back–stepping sliding mode control. By defining:

(25)

Where

is the estimation of the general uncertainty

and

is the estimation error. Then

(26)

The third Lyapunov function is defined as

(27)

Where

is a positive constant. By taking time derivative of

and substituting Eq.(24) in it,

is as follows:

(28)

Due to

should be negative, consider the adaptation law as follows:

(29)

Then, the adaptive back–stepping sliding mode control law is derived as:

(30)

Where

is a positive definite constant and

is a positive definite diagonal coefficient matrix. To avoid the enhanced chattering phenomenon, a hyperbolic tangent function is chosen in which

is an adjustable parameter. Substituting (29) and (30) in (28), the derivative of

is as follows:

(31)

Where

,

,

,

(32)

Introducing a matrix as

(33)

Then,

(34)

By selecting the suitable parameters

,

and

to satisfy

, matrix

is regard as the positive definite matrix. Due to

(35)

The Eq. (31) is rewritten as

(36)

Considering suitable values for

,

and

then

can be a positive definite matrix and Eq. (36) satisfies that

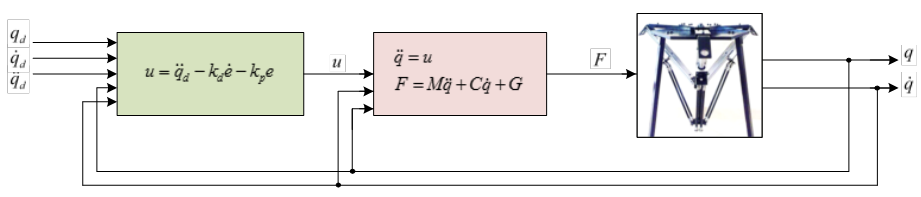

Therefore, the globally exponential asymptotic stability of the proposed parallel robot is guaranteed. Block diagram of the proposed controller is depicted in Figure 5.

Figure 5 Block–diagram of adaptive back–stepping sliding mode control.

Inverse dynamics feedback linearization controller

Feedback linearization technique using inverse dynamics is implemented in contouring control of the proposed mechanism. Joint space variables

and

are measured and taken as feedback signals to the controller. The following control law is applied in the controller.

(37)

Substituting

in the inverse dynamics equations, the computed actuator forces can be determined. Block diagram of the applied control loop is illustrated in Figure 5. This control action leads to error dynamics in the form of

(38)

Elements of the two matrices and should be chosen that the linear time–invariant error dynamics system is stable. There exists exponential convergence in the system if and re positive definite, symmetric matrices. Tuned values of the control parameters and is required for the close loop system to have desired performance in transient and steady–state responses. (Figure 6)

Figure 6 Block–diagram of feedback linearization scheme.

Sliding mode controller

A single input–single output nonlinear system can be defined as

(39)

Where,q(t) is the state vector, is the control input (in our case braking torque or pressure on the pedal) and q is the output state of the interest, f(q,t) and b(q,t) are generally nonlinear functions of time and states. The control problem is to get the state q to track a specific time–varying state

in the presence of model imprecision on f(q,t) and b(q,t).Considering the sliding surface equation of the form

(40)

Differentiation of the sliding variable yields

(41)

Consider a simple second order system

(42)

The approximation of control law

to achieve

is

(43)

Which a simple solution for determining the sliding surface conditions, when the system parameters are uncertain, is the switching control law

(44)

Where k is a positive definite diagonal matrix. After some simplification, the Sliding mode control law for parallel robot is obtained as follow:

(45)

In this section, the objective of optimal path planning is to design a trajectory for the end–effector path in an area containing some obstacles so that the trajectory is of minimum length and avoiding any collision to the obstacles. A predetermined margin is considered around the obstacles that the end–effector would keep a minimum distance with the borders of the obstacles.

To create a 2–D trajectory from starting point

to final point

in the time interval of

, a number of accuracy points are considered as:

(46)

Where

is the time instant at which the end–effector is planned to be located at

. All accuracy points will be checked to be placed in the reachable workspace and far enough from singular points. End–effector trajectory is derived by cubic spline interpolation of accuracy points coordinates

and

with respect to time that guarantees the continuity of velocity and acceleration. So, the trajectory curve can be obtained as,

(47)

Where, N is the number of interpolated points along the curve. Spatial and time vectors are defined as,

(48)

The optimization problem is to obtain 2n variables consisting of

and

such that the interpolated trajectory has minimum length from

to

and keeping the predefined margin from the obstacles. So, an objective function is considered for the optimization problem as the following form to be minimized:

(49)

Where L and C denote the trajectory length and the index of collision constraints, respectively, and the coefficients

and

are the corresponding weights. The length of the trajectory is calculated by:

(50)

In this research, the obstacles are considered as some circular objects. So, the index of collision constraints can be obtained as follows:

(51)

Where

is the number of circular obstacles,

and

are the center coordinates and the radius of the k–th obstacle, and m is the margin, respectively. The margin is considered in order to avoid the tool attached to the end–effector to collide with the obstacles. In this paper, we assume that the obstacles have been placed lower than parallel mechanism and there is no possibility for collisions of robot links with the obstacles. (Figure 7)

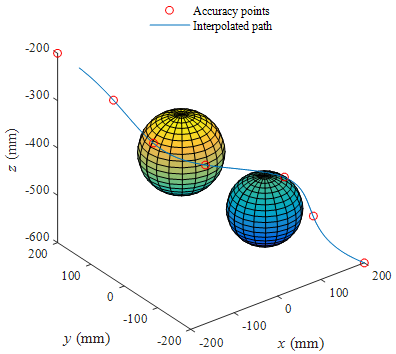

Figure 7 Optimal trajectory generated by HAS.

Same problem definition can be done for 3–D trajectory planning by introducing third coordinate Z, and solving the optimization problem with 3n variables to obtain the shortest collision–free trajectory with, for example, spherical obstacles. A harmony search algorithm is utilized for solving the optimization problem which has advantages over some other algorithms such as GA.

In this section, simulations are performed to illustrate the effectiveness of the proposed adaptive back–stepping sliding mode controller (ABS) in tracking the end–effector position. For this purpose, two trajectories are designed as a reference path and are optimized using HSA in presence of obstacles. The controller is then implemented to the robot over the designed trajectories and simulation results are obtained. Also, to indicate the robustness of the designed ABS controller, parametric uncertainties and time–varying disturbances are considered in all simulations. In order to show the outperforming of the proposed controller, their results are compared with two other controllers, a feedback linearization controller (FL) and a conventional sliding mode controller (SM). Optimal reference trajectories are tracked by the robot end–effector and discussed separately in the following. Control parameters are obtained based on harmony search algorithm. To do this, cost function which is considered is as follows:

(52)

Optimal parameters are depicted in Table 2.

Kp

|

Kd

|

ζ

|

Λ

|

ε

|

b

|

γ

|

127.3752 |

4.9863 |

0.0512 |

3.2843 |

2.9827 |

1.9789 |

1.1258 |

Table 2 optimal parameters of controllers

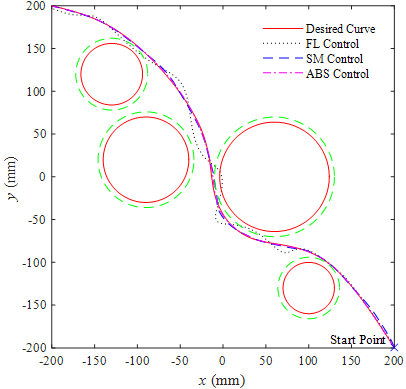

Test case 1: The first trajectory is depicted in Figure 8 and tracking performances of ABS, SM, and FL controllers are shown in Figure 9, Figure 10.

Figure 8 End–effector trajectory in the maneuver 1.

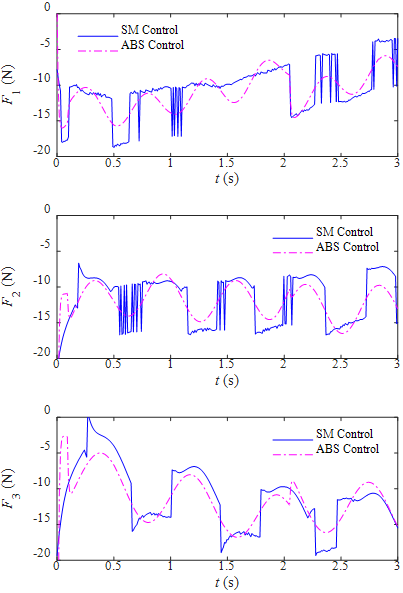

Figure 9 Control signals of proposed controller.

Figure 10 Error components of end–effector position in the maneuver 1.

As it can be seen in above figures, the proposed ABS controller provides a more reasonable tracking performance compared to the SM and FL controllers. The tracked trajectory of the ABS controller converges to the reference trajectory with a faster rate and less fluctuations than that of the SM and FL controllers. Figure 6 compares the control signal of the SM and ABS controllers which are more robust than the FL controller. As is obvious, the range of control effort in both controllers are approximately equal, however the control signal of the SM controller has larger values and intense fluctuations. Tracking errors are also indicated in Figure 10 which shows the unacceptable performance of the FL controller. The RMS of error in the SM is 2.354mm, while in the ABS method, this value is reducing to 0.7007mm.

To demonstrate the performance of the proposed controller, three criteria named as the Integral of the Time multiplied by the Absolute value of the Error (ITAE), the Integral of the Time multiplied by the Absolute value of the Squared of the Error (ITASE) and the Integral of the Absolute value of the Error (IAE) for different controller have been investigated. Three error criteria including ITAE, ITASE and IASE are considered which are defined in the following equations:

(53)

Cost function may be chosen one of the defined error criteria in the paper as Eq. (53). Table 3 compares the results with different criteria. As can be seen, the results of ABS are significantly better than others.

Controller |

ITAE |

IASE |

ITASE |

FL |

0.075386 |

0.000957 |

0.001339 |

SM |

0.048203 |

0.000408 |

0.000559 |

ABS |

0.008611 |

0.00001 |

0.000019 |

Table 3 Different criteria for comparing the performance of the controllers

In order to show robustness of the proposed controllers, standard deviation (STD) of error is extracted in presence of different uncertainties and depicted in Table 4.

Controller |

5% |

15% |

25% |

35% |

FL |

0.00548 |

0.02907 |

0.06569 |

0.09652 |

SM |

0.000847 |

0.000849 |

0.000871 |

0.000951 |

ABS |

0.000075 |

0.000075 |

0.000075 |

0.000075 |

Table 4 Altitude and error STD in presence of uncertainty

As it can be seen, the robustness of proposed ABS controller is more than two other controllers. It should be noted that in each simulation of the controllers, external disturbances were applied.

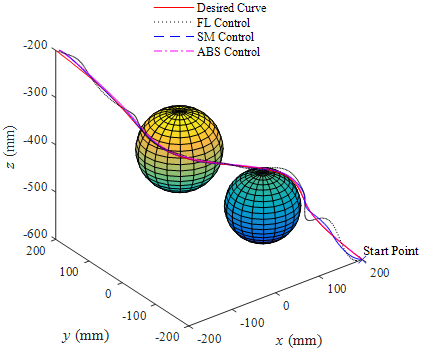

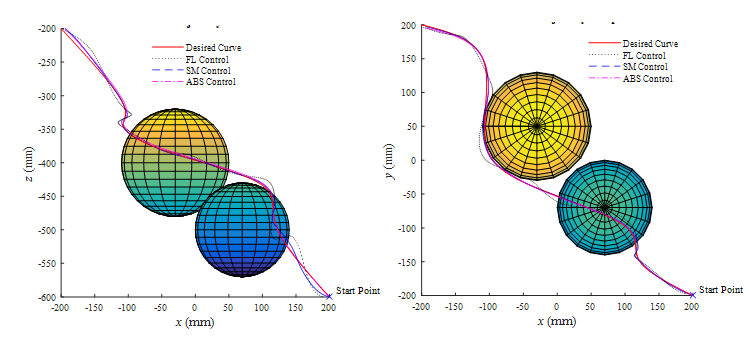

Test case 2: A 3D spatial trajectory is considered for the second test case which is indicated from two different views in Figure 11, Figure 12. Again the tracking performances of ABS, SM, and FL controllers are simulated and shown in Figure 11, Figure 12.

Figure 11 3D end–effector trajectory in the second maneuver.

Figure 12 End–effector trajectory in the second maneuver Top view.

Figure 13 indicates the performance of the proposed ABS controller which has faster convergence compared to the SM and FL controllers. Also, less fluctuations are observed in response of the ABS controller than that of the SM and FL controllers. Tracking errors are also indicated in Figure 13 which shows the unacceptable performance of the FL controller and the 20% error reduction achieved by the ABS controller compared to the SM controller. The RMS of error in the SM is 2.652mm, while it has been reduced to 1.520mm in ABS control.

Figure 13 Error components of end–effector position in the maneuver 2.

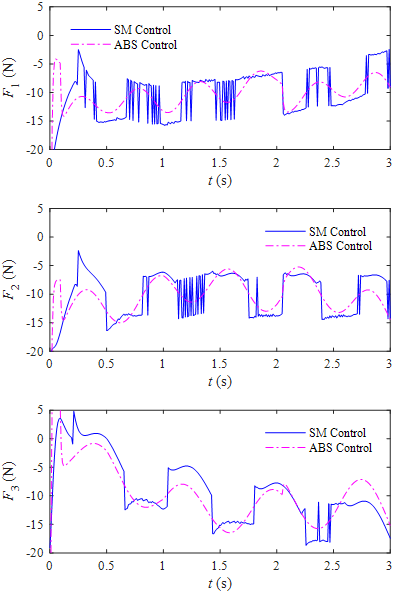

Figure 14 compares the control signal of the SM and ABS controllers which are more robust than the FL controller. As is obvious, the range of control effort in both controllers are approximately equal, however the control signal of the SM controller has larger values and intense fluctuations. According to Figure 14 the control signal of the ABS controller has a relatively smooth behavior and no signal saturation is occurred.

Figure 14 Control signals of proposed controller.

In order to resemble some actual conditions in laboratory setup of the mechanism, the simulations are performed in presence of disturbing forces and uncertainties considered in the dynamic model. Three sinusoidal disturbing forces with amplitudes of 2, 3, and 4 N and frequencies of 12, 10, and 8 rad/s are considered to be applied on prismatic joints. Also, a 30% deviation is parameters considered to account for uncertainties in the model. Small error components appeared in both simulations which show outperforming of the control technique in spite of the applied disturbances and uncertainties. This performance could be improved by parameter optimization of the controller. Result of the error criteria for this case is depicted in Table 5.

Controller |

ITAE |

IASE |

ITASE |

FL |

0.079069 |

0.001067 |

0.001483 |

SM |

0.045551 |

0.000067 |

0.000076 |

ABS |

0.015567 |

0.000023 |

0.000043 |

Table 5 Different criteria for comparing the performance of the controllers