International Journal of

eISSN: 2576-4454

Review Article Volume 4 Issue 1

1Geological Survey of Pakistan (GSP), H-8 office Islamabad, Pakistan

2Department of Earth Sciences, University of Sargodha, Pakistan

3Geoscience Advance Research Labs, GSP Islamabad, Pakistan

4National Centre of Excellence in Geology, University of Peshawar, Pakistan

5Geological Survey of Pakistan (GSP), Quetta, Pakistan

Correspondence: Mehboob UR Rashid, Geoscience Advance Research Labs, GSP Islamabad, Pakistan

Received: January 29, 2020 | Published: February 12, 2020

Citation: Hassan EUL, Hannan A, Rashid MUR, et al. Resource assessment of sakesar limestone as aggregate from salt range Pakistan based on geotechnical properties. Int J Hydro. 2020;4(1):24-29. DOI: 10.15406/ijh.2020.04.00222

The Sakesar limestone of Eocene age from Salt Range has been studied in detailed based on geotechnical properties with emphasis on its aggregate potential. The Sakesar Limestone was selected based on its easy availability and access with basic aim focused on economic aggregate source for future if proved as good potential. The rock samples were analyzed based on standards procedures of AASHTO by adopting ASTM standards to prove its potential and recommendation. A total of four potential sites are sampled that are A total of four localities are selected for sampling that are Tobar Valley, Bestway Cement Plant Quarry and Pail-Padhrar section. The results were analyzed for suitability as Sub Base, Base Course, Surface Course and Concrete potential. The study portrays that all sample of Sakesar limestone fall in the permissible limits of ASTM and classified as suitable aggregate for road construction work, except for Dhak Pass (<125m) which are considered as weak and porous.

Keywords: limestone, aggregate, assessment, geotechnical, salt range

ASTM, american standards of testing materials; AASHTO, american association of state highway and transportation officials; AIV, Aggregate Impact Value; ACV, Aggregate Crushing Value; ST, Soundness test

Aggregate is defined as any coarse to medium grained material of origin from natural materials (igneous, Sedimentary or metamorphic rocks) or un-natural materials (geosynthetic aggregates) depending upon the source and mode of use. Aggregate is an important component of concrete by mixing an appropriate amount of cement.1 Aggregate are much important both economically, dimensional firmness and better wear resistance with quality depends upon aggregate quality.2 Aggregate occupy 70% of concrete volume, henceforth the quality of concrete (Firmness & durability) is directly dependent upon mechanical and chemical properties of aggregates.3 The properties of aggregates that are, mineralogy, strength, hardness, specific gravity and porosity are directly inherited from parent rock from which it originated.4 The level of productivity and economic growth of developed country is dependent upon extensive used of aggregate.5 Limestone is widely used as a raw material for aggregates, attributed by factors due to it’s easy availability and extensively utilization by construction and cement industries. The limestone aggregates are derived from quarrying and crushing of rocks with in potential areas of Punjab and KP.6‒10

Pakistan is having a total area of 796,095sq.km area with population greater than 200millions (Census -2017) with total road network of 228.026km. The construction industry are in full swing both in commercial, individual, private and government section aided by construction of roads by National Highways of Pakistan. The infrastructure activity are exerting pressure on aggregate demand, to cope with demand and supply gap new resources should be mapped and its potential is to be characterized. The current research work is focused upon resource assessment of Sakesar limestone for feasibility as aggregate based on geotechnical properties. This study will assist and new addition of potential site for resource potential which should be exploited in near future.

Location and accessibility to area

The Sakesar Limestone of Eocene age is well exposed throughout the Salt Range with potential thickness from 70m to 150 m in Salt Range, 220m in Chichali Pass and 300m above in other localities of Surghar Range.11 The lithology of Sakesar Limestone is mainly limestone which is light grey to off white nodular to massive, with occasional occurrences of marls and chert. The sample are collected from four potential sites based on feasibility and good quality limestone (Figure 1).

Field work has been conducted to the study area to collect representative samples for further analysis in the labs. The samples collected are mostly in block and crushed samples by adopting ASTM D-7512 standard depending upon the feasibility. The samples are collected from the quarry, outcrop and crushing plant.

The samples have been brought to the Laboratory of Uni etc.... to University of Engineering and Technology to perform different geotechnical test by adopting standard procedures of American Standards of Testing Materials (ASTM) designed by American Association of State Highway and Transportation Officials (AASHTO). The following mechanical and chemical test are performed tests were carried out on all five representative samples according to the given standards

Sodium Sulfate (Na2SO4) Soundness Test.18

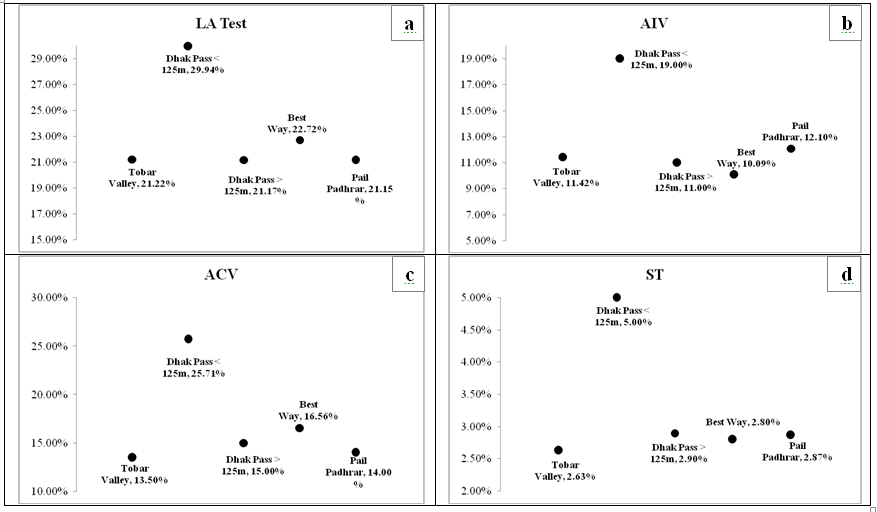

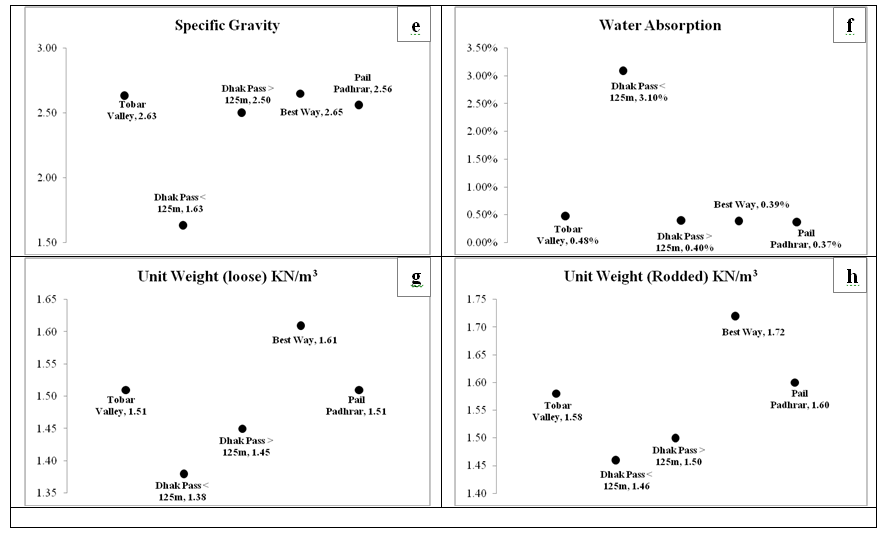

The LA test was performed using standard operating procedure of ASTM C-131,13 with basic aim to determine abrasion and resistance of aggregate to skidding. The analyzed sample are having abrasion values range from ≥21.15%-≤29.94%, with higher value recorded by Dhak pass (less than 125meters) while low value shown by Pail Padhrar area (Figure 2a).

The AIV is determined to portray the resistance of an aggregate to abrupt impact by outside forces either mechanical or applied with basic aim to determine toughness and feasibility of an aggregate to short term instantaneous applied force. The test was performed on Sakesar Limestone at five localities using British Standards BS-812/112.14 The AIV range from ≥10.09%-≤19%, with high value recorded by Dhak pass (less than 125meters) while minimum value shown by Best way cement (Figure 2b).

The basic principle of the test is to determine resistance of an aggregate to crushing under a gradually applied compressive load. The aim is to show the crushing ability and its resistance to crushing against traffic wheel load. The ACV directly affecting the stability of pavement, if weak aggregate with low ACV is used the pavement is readily destroyed with ease. The ACV is determined adopting British Standard procedure BS-812/110.15 The ACV values portrayed by selected samples range between ≥13.5%-≤25.71%, with maximum value by Dhak Pass (less than 125meters) and minimum value by Tobar Valley (Figure 2c).

The ST is performed on representative samples of Sakesar Limestone according to standard procedure of ASTM C88-99a.18 The aim of the test is to demarcate the resistance of aggregate against weathering with focus on freeze and thaw cycle. The soundness value range from ≥2.63%-≤5.00%, with high value shown by Dhak pass (less than 125meters) while low value recorded by Tobar valley (Figure 2d).

The specific gravity and water absorption value explains strength and quality of an aggregate, related with water retaining and percolating capacity. An aggregate having more water absorption capacity refers to be porous and prone to weathering considered as non suitable aggregate. If an aggregate have low specific gravity and more water absorption then the aggregate is considered as weaker or poor aggregate and good aggregate with vice versa properties. The water absorption and specific gravity is determined using standard procedure of ASTM 127/07.16 The results shows that Sakesar lime stone are having specific gravity range from ≥1.63-≤2.65, with water absorption of ≥0.37%-≤3.1%. The maximum value of Sp.gr is shown by Bestway Cement Factory cement while low values by Dhak pass (less than 125meters), while water absorption is high for Dhak Pass (less than 125meters) and minimum for Pail Padhrar (Figures 2e&f).

The aim of this test is to find unit weight of the coarse aggregate which is useful in concrete mix design and generally gave the clue that how much the aggregate is sound or porous. The test was performed at both loose and compacted (Rodded) aggregate adopting ASTM C-2917 to portray its unit weight both loose and compacted conditions. The un compacted (Loose) unit weight ranges from ≥1.38KN/m3 to≤1.61KN/m3 (Figure 2g), while rodded unit value ranges from ≥1.46KN/m3 to≤1.72KN/m3 with minimum value shown by Dhak pass (less than 125meters) and maximum by Best Way cement (Figure 2h).

Figure 2 Assessment of Sakesar Limestone based on Geotechnical Tests, (a) Los Angeles; (LA) Abrasion Test Values; (b) Aggregate Impact Value (AIV) Test; (c) Aggregate Crushing Value (ACV) Test; (d) Soundness Test (ST) Values; (e) Specific Gravity Test Value; (f) Water Absorption Values; (g) Unit Weight (loose) Values; (h) Unit Weight (Rodded) Values.

The values of different tests performed on Sakesar Limestone as an aggregate are compared with the standard value of AASHTO,19,20 and manual of Punjab Highway division standardized by Road Research and Material Testing Institute Punjab (Table 1). The standard values are adopted and compared with analyzed values for Sakesar limestone and classified as recommended for road aggregate or not.

|

Test |

Base value |

|

LAAV |

Base Course ≤50% |

|

Cement Concrete ≤16% |

|

|

Surface Course ≤30% |

|

|

AIV |

Very Strong <10% |

|

Very Strong >10% -≤20% |

|

|

Wearing Course <30% |

|

|

Base Course <45% |

|

|

ACV |

Good Aggregate <45% |

|

Wearing Course <30% |

|

|

Water Absorption |

Good aggregate <0.6% |

|

Specific Gravity |

Good aggregate ≥2.6-≤2.9 |

|

Soundness Test (ST) |

Max 12% for Na2SO4 and 18% for MgSO4 |

Table 1 Standard base values of aggregate according to AASHTO19

The standard value for LA test for Sub Base is 50%, Base course is 40% and 35% for concrete, the results obtained for LA test are ≥21.15%-≤29.94% which are in permissible limits of concrete (Table 2). All the analyzed samples of Sakesar Limestone are recommended for use as concrete, Base course and Sub Base and Surface course (Table 3). The Pail Padhrar and Dhak Pass are having low LA value (21.15%&21.17%) and classified as the hardest aggregate best suitable for Base course and Surface course. The standard values for AIV are classified, < 10% considered very strong, >10-≤20% as strong and >20-≤30% classified as suitable for road surfacing while for base course the maximum limit is 45%. According to AIV of analyzed sample having range of ≥10.09% -≤19% which fall in the range of strong aggregate and suitable for road surfacing and Base course (Table 2). The Best Way and Dhak Pass (>125m) are designated as the hardest aggregate best suitable for Surface course in landslide prone area due to very low AIV (10.09%&11.00%) (Table 3).

|

|

LA |

AIV |

ACV |

ST |

Sp.gr |

Water Abs |

γ(loose) |

γ(rodded) |

|

Tobar Valley |

21.22% |

11.42% |

13.50% |

2.63% |

2.63 |

0.48% |

1.51 |

1.58 |

|

Dhak Pass<125m |

29.94% |

19.00% |

25.71% |

5.00% |

1.63 |

3.10% |

1.38 |

1.46 |

|

Dhak Pass>125m |

21.17% |

11.00% |

15.00% |

2.90% |

2.5 |

0.40% |

1.45 |

1.5 |

|

Best Way |

22.72% |

10.09% |

16.56% |

2.80% |

2.65 |

0.39% |

1.61 |

1.72 |

|

Pail Padhrar |

21.15% |

12.10% |

14.00% |

2.87% |

2.56 |

0.37% |

1.51 |

1.6 |

|

Limit |

≥21.15% to ≤29.94% |

≥10.09% to ≤19% |

≥13.5% to ≤25.71% |

≥2.63% to ≤5.00% |

≥2.6 to ≤2.9 |

≥0.37% to ≤3.1% |

≥1.38 to ≤1.61 |

≥1.46 to ≤1.72 |

Table 2 Geotechnical test results conducted on five representative samples at four potential sites of Sakesar Limestone

|

|

LA |

AIV |

|

ACV |

|

ST |

|

S+W |

UV |

|||||||||

|

SB |

BC |

SC |

SB |

BC |

SC |

C |

SB |

BC |

SC |

C |

SB |

BC |

SC |

C |

S |

P |

S |

|

|

Tobar Valley |

R |

R |

R |

R |

R |

R |

R |

HR |

HR |

R |

R |

R |

R |

R |

R |

Y |

Y |

Y |

|

Dhak Pass<125m |

R |

R |

R |

R |

R |

R |

R |

W |

W |

W |

W |

R |

R |

R |

R |

N |

N |

Y |

|

Dhak Pass>125m |

R |

R |

R |

R |

R |

HR |

R |

R |

R |

R |

R |

R |

R |

R |

R |

Y |

Y |

Y |

|

Best way |

R |

R |

R |

R |

R |

HR |

R |

R |

R |

R |

R |

R |

R |

R |

R |

Y |

Y |

Y |

|

Pail Padhrar |

R |

R |

R |

R |

R |

R |

R |

HR |

HR |

R |

R |

R |

R |

R |

R |

Y |

Y |

Y |

Table 3 Recommendation of Sakesar limestone’s based on geotechnical test

The ACV should have a maximum limit of 45% for Base course and 35% for Surface course, the limit of analyzed samples are ≥13.5% -≤25.71% (Table 2). The analyzed value fall in the permissible limits except Dhak Pass (<125m) which are considered as weak, based on these values Sakesar limestone is recommended for aggregate potential as Base and Surface course, sub base and concrete, with best suitable are Tobar valley and pail Padhrar (Table 3). The recommended value for Soundness Test (ST) are average weight loss on each sieve should not exceed 12% reference to ASTM standards,18 the analyzed values of Sakesar limestone range from ≥2.63%-≤5.00% (Table 2). The Sakesar limestone is resistance to freeze and thaw cycle of weathering as all values are less than 12%, with maximum value recorded are 5% for Sakesar limestone and recommended for aggregate potential (Table 3).

The water absorption test is having values of ≥0.37%-≤3.1% for analyzed limestone sample, the standard value should be≤0.60%. The lower absorption limit are shown by Pail Padhrar and Best Way (0.37%&0.39%) and high value by Dhak Pass (<125m) (Table 2). Based on the result, all sample are recommend to be strong and non porous except Dhak Pass (less than 125meters) (Table 3).

The Specific gravity is indicative of strength of a stone with high specific gravity values considered as strong. The recommended sp.gr value fall in the range of ≥2.6-≤2.9, with analyzed samples having range of ≥1.63-2.65 (Table 3), based on comparisons all sample are recommended to be strong except Dhak Pass (less than 125meters) (Table 3). The main reason for determining the unit weight (void content) is to establish accurate material proportions for designing concrete mixes. A minor reason is to determine mass/volume values of products for purchase agreements. The unit weight value of limestone in loose and compacted condition is from ≥1.38KN/m3 to≤1.61KN/m3 and ≥1.46KN/m3 to≤1.72KN/m3 (Table 2). The value refers that the limestone are bulky and compact requiring little compaction with % value change of 5.8% for minimum and 6.8% from maximum, and classified as suitable for concrete and mix design (Table 3).

The conclusion has been drawn based on geotechnical samples of Sakesar Limestone to classify its feasibility as usage as Base Course, Sub Base and Surface Course. The representative samples are analyzed for hardness, durability, crushing strength and toughness by adopting designated test. The conclusion has been drawn based on results by comparing it with standard values. Based on the results it is concluded,

The authors are highly indebted to Transportation Laboratory, University of Engineering and Technology Lahore, Pakistan for Analysis of Rock samples to finalize this project. The Authors are also thankful to Bestway Cement Plant for quarrying sampling.

The authors declare that there is no conflict of interest.

None.

©2020 Hassan, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.