eISSN: 2574-9927

Research Article Volume 7 Issue 4

Plastic Liquid Crystal Technology, Italy

Correspondence: Hakemi H, Plastic Liquid Crystal Technology, Via Lambro 80, 20846 Macherio (MB), Italy

Received: November 26, 2023 | Published: December 19, 2023

Citation: Hakemi H. The effect of liquid crystal concentration on electro-optical properties of five flexible polymer dispersed liquid crystal formulations. Material Sci & Eng. 2023;7(5):217-221. DOI: 10.15406/mseij.2023.07.00226

We investigated the effect of concentration on the electro-optical properties of some flexible PDLC formulations with various liquid crystal mixtures. The PDLC films were prepared on flexible ITO-PET supports by UV-PIPS phase separation method and the uniform film thickness was insured by plastic micro-spacers. We found that depending on the type of liquid crystal and PDLC process conditions, the electro-optical properties (off-state and on-state transmissions, switching voltages and response times) provide different concentration dependency with various trends in the studied flexible PDLC formulations.

Keywords: liquid crystal, concentration, flexible PDLC, phase separation, electro-optics, transmission, voltage, response time

The field of Polymer Dispersed Liquid Crystal (PDLC) has been the subject of many academic and industrial research and development in the past four decades. The correlation between PDLC materials and process conditions with morphology and electro-optical properties is essential in the industrial development and manufacturing technology. The chemical structure and physical properties of raw materials, thickness, phase separation and curing processes are essential parameters which influence the performance of PDLC film products. Almost all PDLC literature are based on academic research on the effect of material and process conditions, such as type, composition, thickness, curing UV radiation, temperature and time on the electro-optical properties in glass-based PDLC films. According to some recent studies on PDLC films, it has been demonstrated that the morphology and electro-optical properties of PDLC devices were affected by many material and process parameters, such as thickness, concentration, cure temperature and cure time.1–12

In this respect, the control of inter-dependent material and process parameters have to be identified and their correlations require experimental verification. The electro-optical properties of thermoset PDLC film depend on a number of factors, such as the type of liquid crystal, molecular structure of pre-polymers and process conditions. These factors are shown to affect the micro-structure of polymer matrix, size, shape and number density of LC domains, as well as the anchoring of LC molecules within droplets. 12–16

In this work, we studied the effect of liquid crystal (CLC) on electro-optical properties of five flexible UV-cured PDLC formulations by Polymer Induced Phase Separation (PIPS) method. This study has been part of industrial R&D program to establish empirical relations between curing parameters and electro-optics of PDLC products for eventual scale-up and manufacturing. Such relations are essential for direct quantitative correlations between process parameters and electro-optical properties during manufacturing of PDLC products.

Materials

The utilized materials were consisted of UV-curable NOA65 pre-polymer resin (Norland Optical Adhesives), five nematic liquid crystal mixtures including TNO623 and TNO403 (Hoffmann-La Roche), E43 and E7 (Merck Ind. Chem.) and YM55 (Valiant Fine Chem.), 10-20 m thick plastic micro-spacer Micro-Pearl (Sekisui), Irgacure819photo-initiator (Sigma-Aldrich) and 100 / ITO-PET film supports (Sheldahl). All materials were used without further purification. The optical and thermal properties of liquid crystal mixtures are tabulated in Table 1.

|

Liquid crystal |

No |

n |

Tni (°C) |

|

TN0623 |

1.507 |

0.198 |

105 |

|

TN0403 |

1.524 |

0.258 |

82 |

|

E7 |

1.521 |

0.225 |

61 |

|

E43 |

1.525 |

0.238 |

83 |

|

YM55 |

1.526 |

0.249 |

92 |

Table 1 Optical and thermal parameters of liquid crystals

Sample preparation

The PDLC preparation was carried out with Polymerization Induced Phase Separation (PIPS) method by UV radiation (UV-PIPS). The flexible PDLC films were prepared by a custom-made in-situ coating and lamination system8,9 of a homogeneous mixtures of liquid crystals and NOA65 pre-polymer at corresponding liquid crystal concentration range of 30-80 wt%, Irgacure819 (1% vs total formulation) and pre-heated for 10 minutes at 50°C temperature. The thickness homogeneity of PDLC layers were achieved by utilizing plastic micro-spacers (0.2% of total formulation).

The uncured PDLC formulations were then poured between the vertical gap of two rolls of ITO-PET supports films on a custom-made plastic coater/laminator system (see Figure 1). Immediately under the coating rolls, the uncured PDLC films were passed through a pressure roll to insure the uniformity of the film by micro-spacers. The uncured PDLC films were then cut and transferred to a custom-built conveyor system (see Figure 1) and cured by a high-intensity UV lamp with corresponding radiation intensities of 10-80 mW/cm2 at line speeds of 0.5 meter/minutes and at relevant cure temperatures of 22-80°C. The cure temperature was measured with a thermocouple during the curing process. The experiments were carried out on three PDLC samples for each formulation and the reported experimental results are the average values of four samples. The specific processing and curing conditions of the five PDLC formulations are tabulated in Table 2.

Figure 1 PDLC coater/laminator (left), UV curing conveyor (middle) and electro-optical system (right).

|

PDLC |

Thickness (mm) |

UV Intensity (mW/cm2) |

Cure temperature (°C) |

|

TNO623 |

10 |

60 |

80 |

|

TNO403 |

10, 15 |

20 |

55 |

|

E43 |

10 |

8 |

30 |

|

E7 |

20 |

1 |

25 |

|

YM55 |

20 |

1 |

22 |

Table 2 Processing and parameters of the PDLC formulation

The electro-optical properties of the PDLC films were measured on the as-made PDLC samples. The electro-optical measurements were carried out with a specially constructed photometric system (see Figure 1) consisting of a white light source, sample chamber, a photometer, an amplifier, a function generator and electronic data acquisition network. The normal haze in some PDLC films were measured by Gardner model XL835 colorimeter by a white light source. The transmission-voltage curves of the PDLC samples were measured with VAC square wave at 100 Hz frequency. The switching times were carried out at peak-to-peak voltage of VRMS = 80 volts at the frequency of 100 Hz and pulse life time of 1/8 second. The nematic-isotropic transition temperatures of liquid crystals were measured under Nikon Eclipse-50i polarizing optical microscope equipped with Linkam LTS120 microscopic hot-stage.

We studied the electro-optical properties of PDLC formulations with TNO623, TNO403, YM55, E43 and E7 mixtures as a function of liquid crystal concentration (CLC). The measured electro-optical parameters include the threshold (V10) and saturation (V90) voltages; the optical transmissions off-state (Toff), on-state (Ton) and Haze; the rise ( ) and decay ( ) response times. The results of these experimental studies are provided in the following sections:

Switching voltages

In Figure 2, we present the effect of liquid crystal concentration on the threshold (V10) and saturation (V90) voltages in the five flexible PDLC-TNO623, PDLC-TNO403, PDLC-E43, PDLC-E7 and PDLC-YM55 formulations.

As tabulated in Figure 2, the switching voltages of all five PDLC film formulations, indicate that both "threshold voltage" (V10) and "saturation voltage" (V90) exhibit decreasing trends with liquid crystal concentration. The predominantly decreasing trends of switching voltages with liquid crystal concentration in various UV-cured PDLC systems are in agreement with previous literature,10,17,18 which directly correlate with the increasing micro-droplet dimensions by increasing CLC. For example, an approximate relation between the threshold voltage (V10) and micro-droplet size can be expressed by Equation 1.17

Where d is film thickness, <R> is average droplet radius, K is average elastic constant, e11 is parallel electric suseptibility and Δε is dielectric anisotropy of LC, respectively. According to Equation-1, V10 should decrease with increase of PDLC droplet radius, which is in agreement with increasing of droplet dimension with liquid crystal concentration.10 Regardless of other different parameters that contribute to different values of V10 in the four PDLC formulations (see Figure 2), Equation-1 clearly indicate the effect of LC droplet size (<R>) increase on decreasing trend of V10 values.

According to Figures 2, it is also noticed that in the studied PDLC systems the order of magnitude of switching voltages V10 and V90 are correlated with the liquid crystal droplet morphologies, where it is lowest is in YM55-PDLC and highest in PDLC-TNO623 and PDLC-E7 formulations. For example, at CLC = 40%, the decreasing trend of V10 values are around 25volts in PDLC-E7, 15volts in PDLC-TNO623, 14volts in PDLC-YM55 and 11volts in PDLC-TNO403 samples. Similarly, the V90 values are >70volts in PDLC-E7, 42volts in PDLC-TNO623, 37volts in PDLC-E43, 32volts in PDLC-TNO403 and 27volts in PDLC-YM55, respectively. These results indicate that the decreasing trend of switching voltages in these five PDLC formulations, as well as in other reported UV-cured and thermoset PDLC studies,19,20 are mainly due to increasing of droplet dimensions and decrease in number densities as a function of liquid crystal concentration.

The quantitative differences in CLC dependencies of operating voltages in these PDLC formulations are mainly due to differences in their material and process parameters (see Table 2), which result to qualitative variations in the mechanisms of phase separation and polymer curing kinetics. It is known that the phase separation, morphology and electro-optical properties of PDLC films are also the outcome of other inter-dependent factors, such as the type, chemical, physical and optical properties of materials; solubility temperature of liquid crystal and pre-polymer; degree of cross-linking and matrix plasticization by liquid crystal and curing parameters. In short, due to different chemical, optical and thermal properties of commercial liquid crystal mixtures (see Table 1) and their different PDLC process parameters (see Table 2), a direct comparison between the switching voltages of the studied PDLC formulations is difficult for the time being.

Optical transmissions

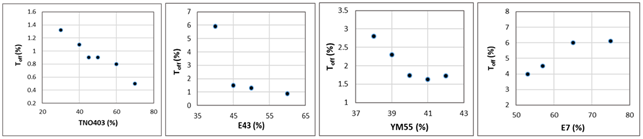

In Figure 3, we present the effect of liquid crystal concentration (CLC) on the off-state transmission (Toff) or opacity of four PDLC-TNO403, PDLC-E43, PDLC-YM55 and PDLC-E7 formulations.

Figure 3 Effect of liquid crystal concentration on off-state transmission (Toff) of four PDLC formulations.

According to Figure 3, whereas the Toff (opacity) of PDLC-TNO623, PDLC-E43 and PDLC-YM55 samples exhibit linear and exponential decreasing trends of opacity with CLC. On the other hand, E7-PDLC shows an unexpected linear increasing trend of Toff with CLC. Although the thickness, curing UV intensity and time are quite different in these formulations (see Table 2), we can only indirectly correlate the decreasing trends of Toff with CLC according to following relation.

(2)

where T is the off-state transmitted light intensity, T° is the incident light intensity, is the droplet number density, is the "scattering cross-section" of a single droplet and d is the sample thickness. According to Equation-2, only the increase of scattering cross-section by CLC increase could explain the observed decreasing trends in these three PDLC samples. On the other hand, due to the lack of morphological information, in E7-PDLC the increasing trend of Toff or decreasing opacity with CLC could not be properly explained in the present study.

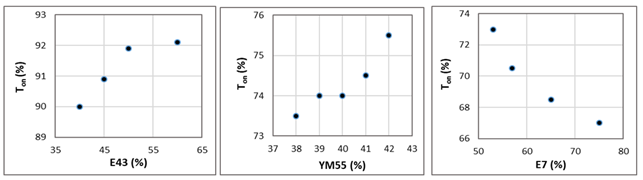

In Figure 4, we present the effect of CLC on-state transmission (Ton) or transparency in three PDLC-E43, PDLC- YM55 and PDLC-E7 formulations. The results indicate that Ton in E43-PDLC and YM55-PDLC show apparent linear increasing trends, whereas E7-PDLC exhibits a nonlinear decreasing trend with CLC. The Ton trends are similar to Toff trends in these three PDLC samples.

Figure 4 Effect of liquid crystal concentration on on-state transmission (Ton) of three PDLC formulations.

These unexpected behaviours of Ton and Toff in PDLC-E7 sample could be attributed to different in its curing condition and thickness with respect to those in E43-PDLC and YM55-PDLC (see Table 2). In contrast to this study, other UV-cured PDLC and thermoset (epoxy) PDLC films claims that, only in agreement with Toff of PDLC-E7, the Toff increases modestly with CLC within 35-50% concentration range, whereas the Ton is almost independent of CLC.

Also, one may observe the effect of CLC on Ton, which provides its effect on light transmission due to index miss-matching in the absence of mirco-droplet scattering. This behaviour may explain the reason for linear trend of Ton with CLC in PDLC-E7 system, which can be used as the initial step to obtain a more complete empirical relationship to explain the surface and bulk effects on morphology (micro-droplet size, shape and number density) and electro-optics of PDLC films.

Although rather speculative, the different trends of Toff and Ton of PDLC-E7 could be due to the influence of matrix-substrate surface phenomena on phase separation and polymer curing kinetics at higher CLC of this sample with respect to those of PDLC-E43 and PDLC-YM55 films. Another words by increasing the CLC, the contribution of surface effect diminishes in favour of bulk effect, which affects the kinetics of phase separation and polymer curing, and consequently the morphology of the film due to variations in temperature distribution and shear stress at the matrix-surface boundary. Because, if the morphology is influenced by the surface phenomena, then both Toff and Ton values should be affected likewise. In addition to morphology, the geometric boundary conditions could be another factor to influence the phase separation and matrix curing kinetics, which is different at the surface boundary than in the bulk.

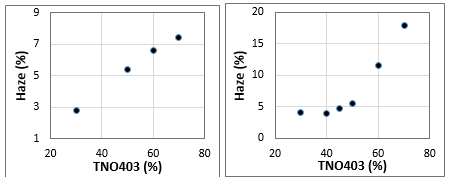

With regards to the haze behaviour, we only studied the PDLC-TNO403 formulation at 10mm and 15mm thicknesses, which are presented in Figure 5 accordingly. The results of this formulation indicate that haze at both studied thicknesses increase with liquid crystal concentration, which has been an observed phenomenon in other PDLC literature.

Figure 5 Effect of liquid crystal concentration on the Haze of PDLC-TNO403 at (left) 10m and (right) 15m.

Response times

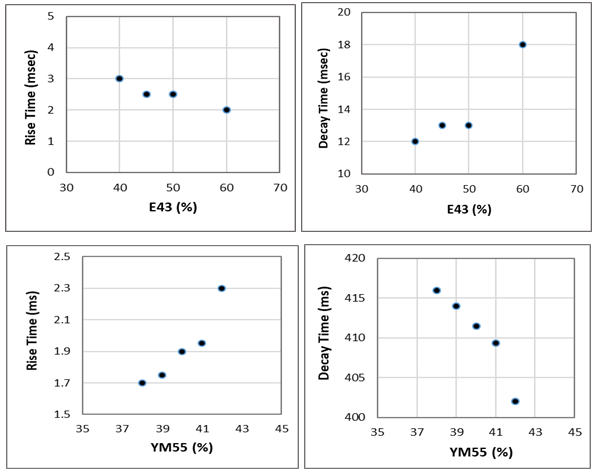

The effect of liquid crystal concentration on the rise ( ) and decay ( ) response times in two PDLC-E43 and PDLC-YM55 formulations are presented Figure 6. The overall outcome of the present results is that whereas the decreases and increases in PDLC-E43, but in PDLC-YM55 increases and decreases as a function of liquid crystal concentration (CLC). Also according to Figure 6, the toff of PDLC-YM55 film is more than one order of magnitude larger than that in PDLC-E43 film.

Figure 6 Effect of liquid crystal concentration on rise (on) and decay (off) times of E43-PDLC (top) and YM55-PDLC (bottom).

This differences in response times of the two PDLC systems are due to their different morphologies, thicknesses and UV intensities as tabulated in Table 2. We also noticed that, the trends of response times are predominantly linear within the studied liquid crystal concentration range in both PDLC systems. The trends of response times in PDLC- E43 and PDLC-YMM55 systems are qualitatively similar and in agreement with the reported literature in various PDLC systems. It is also noticed that, in other UV-cured and thermoset PDLC, is independent whereas increases with CLC. The only agreement with those studies is the increase of the rise time with CLC in PDLC-E43 (see Figure 6).

The different trends of and with liquid crystal concentration in the two studied PDLC films (Figure 6) with respect to the literature could be explained by taking account of different material and process parameters, such as chemical and physical properties of liquid crystal, thickness, morphology, anchoring energy, as well as surface and bulk effects.

In the present work, we investigated the effect of liquid crystal concentration on electro-optical properties of five flexible PDLC film formulations. The experiments were carried out by UV-PIPS phase separation method. The results indicated that, regardless of the type of formulation and process parameters, the effect of liquid crystal concentration on the studied switching voltages, transmissions and response times mainly exhibited the expected results. However, in few unexpected cases we speculated that the differences were due to variations in materials, process conditions, thickness and morphology between the studied PDLC formulations.

Aside from quantitative effect of CLC on the electro-optical properties, the experimental results are also due to a subtle qualitative change in the mechanisms of phase separation and polymer curing kinetics. In another words, the phase separation of PDLC is also governed by a series of inter-dependent factors, such as the solubility temperature, intensity and cure temperature of UV intensity, the degree of liquid crystal plasticization in matrix, which all require further investigation and understanding.

We believe that further detail investigations are necessary to provide a deeper understanding of the electro-optical performances of PDLC films. Such knowledge is essential for research, development and manufacturing of high-quality industrial-scale products. Once the structure-property relations are quantified, it will be possible to develop meaningful empirical models to improve the electro-optical properties of PDLC films for manufacturing for industrial application.

The author would like to acknowledge the Electro-Optical Film Group of Sniariceche, Snia BPD (Fiat Group), Via Pomarico, Pisticci Scalo (MT), Italy, who sponsored and financed the research and development projects on PDLC film technology during 1993-1996 period.

There is no conflicts of interest.

©2023 Hakemi. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.