Journal of

eISSN: 2573-2897

Research Article Volume 7 Issue 3

Professor, Federal University of Fronteira Sul, Brazil

Correspondence: Jaisson Teixeira Lino, Professor, Federal University of Fronteira Sul, Brazil

Received: October 19, 2022 | Published: December 19, 2022

Citation: Lino JT. Industrial heritage of a lumber company in Santa Catarina state, Brazil: considerations about industrial archaeology and the history of material culture. J His Arch & Anthropol Sci. 2022;7(3):144-150 DOI: 10.15406/jhaas.2022.07.00264

The current article introduces industrial landscape formation in Brazil’s southern backcountry early in the 20th century, and the implementation of a large log extraction and processing complex – the extracted lumber was well preserved in midwestern Santa Catarina State up to that time. The operation of large lumber processing facilities (including the construction of company-town), which was boosted by substantial changes in destruction of the natural environment was little affected by such ventures, at that time. A population of squatters composed of Portuguese-Brazilians and indigenous peoples lived in this area before enterprise was implemented. Subsistence in this region was based on systems that were little systems that had little impact on the environment. The present study focuses on industrial archaeology of the lumber company; thus, we herein present the basic background of both cultural heritage and archaeology studies that have been slowly developed in this area.

Keywords: industrial archaeology, cultural heritage of the Brazilian industrialization, material culture, Brazilian Southern lumber company.

A whole series of capitalist ventures were undertaken in Latin America in the 20th century, with emphasis on railways and industrial enterprises. Accordingly, a number of North American entrepreneurs, among them Percival Farquhar, oversaw the construction of railways in a number of Latin American countries, such as Cuba and Brazil. Farquhar acted in different enterprises in Brazil, rather than just in railways, among them the tragic Madeira-Mamoré railroad in Northern Brazili. impossible He used European bankers’ capital in rubber extraction industries, as well as in street lighting, urban transportation, livestock, the acquisition of harbors and navigation companies, among others. Farquhar’s company “Brazil Railway Company” was granted with dozens of concessions to build railways countrywide, including the São Paulo-Rio Grande Railroad”. The construction of the railroad between Itararé and the Uruguay River was concluded in 1906, and it followed a land and forest commercial exploration. Therefore, “the stations were distributed not so far from each other, because the goal to colonize and the explore lumber would be made easier”.ii,1 This railroad crossed the Brazilian Southern region at early 20th century and its subsidiaries accounted for forest exploration and for the colonization of such a territory.

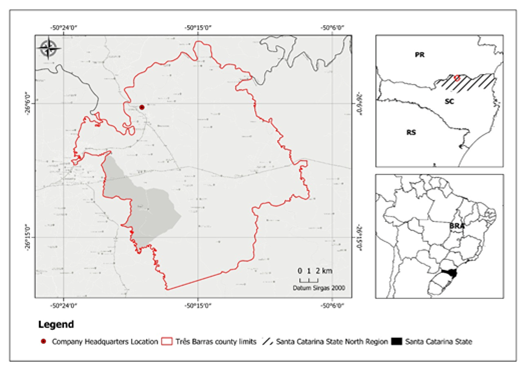

The contract to build the railroad determined the company to be in charge of this venture – the Brazil Railway Company –; it had the right to explore lands adjacent to the railway, within an extension up to 15km to each side of the railway. These lands were covered by millions of araucaria pine, walnut, black shank, cedar and ‘cabriúva’ (Myrocarpus frondosus) trees. The aim was to extract and export these high economic value wood types and, later on, sell part of the land to European immigrants. A subsidiary of Brazil Railway Company,: the Southern Brazil Lumber and Colonization Company, was built in this area (Figure 1). In 1912, Lumber implemented a modern sawmill in Três Barras, Paraná State’s territory, which was claimed by Santa Catarina State, later on.2 After starting its activities in 1911, Lumber started developing innovative lumber exploration processes based on industrial complexes of unprecedented proportions; at that time, Lumber was the biggest lumber company in South America.3 Lumber Company focused on capitalist exploitation, and it used the railway structures recently launched, at that time, to implement a large sawmill facility in Três Barras, and a smaller one in Calmon. Together, these facilities processed approximately 4 million pine trees and 2 million walnut and cedar trees, besides other species.1

Figure 1 Location of Lumber Company, Três Barras County, Santa Catarina State, Brazil.

Source: Map drawed by Fábio Araújo.

The company implemented a highly mechanized industrial process, with high technical organization. The beginning of the production process used logs cut in the forest; this task was carried out by groups of workers who went into the forest to select and saw the trees. Subsequently, logs lying on the ground were held by steel cables – each of them were hundreds of meters long – and hoisted by compressed-steam powered winches. These huge logs (which could be up to 30km long) were grabbed all the way to the margins of the company’s railway branches. These logs destroyed all the vegetation throughout the pathway while they were grabbed; in other words, they put down smaller trees, less economically interesting species and also large amounts of mate trees, whose extraction consisted in essential resources for the survival of populations living in the region. The winch would lift the log and put it on wagons that were taken to the sawmill facility, downtown Três Barras village, after getting close to the main railway. The logs were mechanically sawed, selected and stored in the mill. Then, they were loaded on wagons and taken to São Francisco do Sul and Paranaguá harbors; from there, they were sent abroad as logs. In 1940, during the World War II, a decree issued by President Getúlio Vargas had the country take over took over the Lumber Company. The company’s nationalization process was materialized by Decree n. 2436, from July 22, 1940; after it, the company was incorporated to the Patrimony of the Brazilian State and survived in limbo for some years, when the company was managed by the Brazilian Army.4

The presence of these industrial enterprises remarkably marked the herein assessed region, mainly when it comes to observed environmental impacts. At that time, the Brazilian Southern highlands were composed of Mixed Ombrophilous Forests (MOF), of part of the Atlantic Forest biome and of the environment featured by the presence of Araucaria forests. This natural formation was observed at late 19th century in 40% of the total territory of Paraná State, in 30% of Santa Catarina State and in 20% of Rio Grande do Sul State.1 This natural richness boosted the implementation of capitalist enterprises in Contestado region. These enterprises were associated with profitable industrial projects, “vacant lands”iii procession, and log extraction and processing, which resulted in large-scale changes made in the region.

Besides environmental impact, railroad constructions led to countless changes in the assessed region; among them, one finds land-access nationalization, compulsory removal of traditional populations and disruption of socioeconomic relationships all over the territory. This process worsened social tensions and contributed to the emergence one of the most important social movements in the Brazilian history, the so-called Contestado War (1912-1916). It was a Brazilian civil conflict that has caused thousands of deaths in the assessed region, mainly among local populations that have tried to defend their lands from these capitalist projects.

iMadeira-Mamoré, nickname “Devil’s Railroad”, was built between 1907 and 1912; it was quite similar to Contestado railways, in historical terms. Consistent historical analyses about this railroad in Northern Brazil can be found in studies conducted by Francisco Foot Hardman (1988) and Manoel Rodrigues Ferreira (2005).

iiThe direct quotes in this article have been translated from Portuguese to English, except in cases where the publication is already in English.

iii Public lands without effective use by the public power.

Archaeology has been consolidating its research field and productively broadening the scope of approached topics and periods, since the late 20th century. In the very core of these epistemological changes, which inserted material aspects of the contemporary world in research agendas, this process broke up with the old bases of Archaeology that only had “very old stuff” as study object.5

The term “industrial archaeology” was firstly used in England, given the obvious link between England and industrialization. This scenario was cited in studies focused on preserving and valuing the British industrial patrimony at late 1950s and early 1960s, although it was closely linked to discipline archaeology, itself.6,7

In temporal terms, the present study adopted industrial archaeology, whose temporal cut must be relativized based on the region it assesses, because industrialization changes depending on its development in different parts of the world. Industrial Archaeology must be understood as the study of cultural heritage during the capitalist industrialization, which emerged in England in the 18th century and expanded to other countries. This process implied close association among archaeology, material culture and capitalism, whose social theory (from the 1990s) inputs added to the interpretation of the industrial past.8 In any case, based on discussions about a “revolution” (in its straight meaning, or not), industrialization had deep impact on the material world from that time on, and reached changes that could never be ignored by archaeology. By sharing this argument, Martin states that “ These forces have fundamentally shaped the scope and scale of the remains studied by historical archaeologists. To ignore or discount the central role of industrialization is to risk overlooking the obvious, if not to doom any attempt at understanding from the outset”.6 After that said, we current study adopted the following definition of industrial archaeology:

Industrial archaeology is interested in all witness physical remnants of the industrial organization in the territory, rather than just those related to production and what is done since the continuous reference of the role played by several objects in the production mode. Industrial archaeology was selected and assessed the objects of their physical features as the concrete expression of the production mode: the factory as meeting point among production factors, the machine, a set of instruments used to perform workmen’s labor to produce goods, workers’ housing, transportation means and communication pathways, and produced resulting from the industrial activityiv.7

Changes in the cultural and natural landscape caused by industrialization due to few capitalist interventions are clear; thus, it implies impact on territories known as “backcountry”. Araucaria forests, clean rivers, farms, cabocla houses, fresh air, muddy paths, reliefs without artificial cuts opening room for railways, locomotives’ smoke, intervention in landfills, monuments in stations, winches and saws ripping off the forest, sawmills swallowing trees, planned villages, and so on, could be seen in the Southern plateau at early 20th century.

iv Translated from the original text in Spanish.

The implementation of Lumber’s sawmills in the herein assessed region caused deep changes in the cultural and natural landscape, if one takes into account that it concerned an industrial enterprise whose goal was to explore large pine forests, by deeply changing both the environment and the labor relationships, as well as extractive processes explored at large scale. Lumber’s huge industrial complex at Três Barras still waits for deep archaeological research and bibliographic studies, given the several possibilities of cultural heritage studies that would work as example of great material impact on a region that was only affected by transnational capital, at that time. The description of Lumber’s material aspects in Três Barras will be herein gathered into three different groups: 1 – log extraction activities outside the industrial complex; 2 – the industrial complex and; 3 – company-town projected to house employees.

Since the beginning of the sawing labor, trees’ transportation used technological systems aimed at mitigating efforts and time, and, consequently, profit resulting from the use of production technologies. Accordingly, several equipment and structures were employed for forest exploration purposes (Figure 2); they were different from technologies used at that time in few of the existing sawmills. According to Valentini, the first Lumber’s stage can be summarized as follows:

Figure 2 Cranes used to collect tree logs from the interior of the forest to the edges of the trail.

Source: Index25

Overall, the effective work starts with forest observation due to the opening of roads to lay railway sleepers and for the best understanding of rails that would take machines to the chosen trees. Subsequently, the settlements were assembled and the tree cutting work was started.1

Thus, the first concern was to provide the road structure necessary to transport the best examples of tree species to the factory. Log transportation was carried out in ox-cart on precarious dust roads; thus, option was made for building railways that would go into the forest to contribute to an advanced exploration process. The construction of these railways consisted in forest-opening activities, landfill constructions, land cuts, in the implementation of railway sleepers and railroads. The railway would become a new via every time the extraction fronts changed; in other words, Lumber’s railroad branches were always close to the cutting areas. There were approximately 150 km of rails to serve the sawmill in Três Barras: “When the area was fully deforested, the rails would be removed, as well as the settlements, workers’ houses, which would be installed in other pine crops”.1

The mobile material was formed by small six-wheel towed locomotives that could transport log. Wooden boards were distributed in 45 wagons that supported approximately 36 tons, each. Machines, called “donkeis”, and winches were used to move logs all the way to rails’ sides by grabbing trees with the aid of steel cables (from 300 to 500m) in each side of iron pathwaysv.

There were specific winches for wagons’ loading to mitigate manual work at these stages. These operations and machinery that caused great interventions in the forest were used.1,9,10

Technological innovations did not rule out the great effort and importance of using man power involved in tree cutting and felling activities. The first service to be carried out was to assess and point out the best trees to be taken down. Axes were used to initial cutting in order to guide tree felling; subsequently, an American saw with two finishing on each tip was used; it was operated by two workers. After tree felling, which often times caused small trees to fall, along with the highest tree species, the first processing was carried out in loco by cutting logs and gathering them before being carried by winches and donkeis.

There were workmen’s villages settled in extraction fronts and it avoided manpower to have to return to Três Barras; consequently, time was spared and it would allow the company to have almost full control over workers, even to exert functions outside the company-town. Basically, this process consisted in implementing small wooden houses that were assembled and transported by locomotives; they changed places when workers were moved to other deforestation fronts. Assumingly, precariousness was a mark of this rustic houses that had only one room and that, most of the time, housed the whole family. Differences in labor conditions and housing, between workmen in and outside the industrial complex, can be observed in descriptions of Três Barras company-town.2

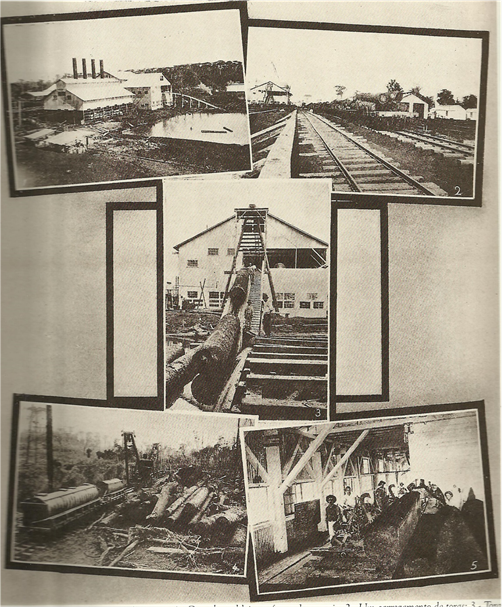

The industrial complex implemented by Lumber in Três Barras was, at the time, the biggest of all Latin America, and one of the most modern sawmills worldwide (Figure 3). It was mostly composed of machinery imported from the USA and Europe.9 There are difficulties in inventorying and assembling a detailed layout of a big factory based on bibliographic data, maps and images. A study developed based on Valentini1 must use systematic archaeological excavations and detailed search in primary sources, with emphasis on technology and cultural heritage. In any case, in order to meet the aim of the present article, a fast description will show issues that can be screened through archaeological studies about this giant industry, which was implemented in backcountry lands and sawed approximately 300m³ of wood a day.1,9

Figure 3 Scenes of the wood processing steps in the large Lumber factory in Três Barras

Source: Index25

The company employed approximately 800 highly specialized workers to operate machines in all activities. Lumbers’ internal structure was settled in a 60-hectare area11 and counted on a system of rails that would allow locomotives to transport wood among several processing sections - from log arrival from the forest to its final load in trains. Spatial organization in the factory would comprise rails, managerial offices and power generation in furnaces, boilers and chimneys; sawmills for sawing and selection; mechanical workshop; drying deposits, high-quality product storage and efficient cleaning system based on using wood waste as fuel for boilers and furnaces; stacking yard; and furniture manufacturing and woodwork - all these sections were gathered in a 5-store wooden building.12 The energetic system adopted to move the big sawmill used compressed steam technology based on the power system described below:

Lumber developed a set of ten steam boilers capable of producing 1,800 HP and, yet, steam machines with power of 1,050 HP, 800 HP, 350 HP and 75 HP [...]. At that time, it was a real mechanical colossus, which was just justified by the amount of existing wood to be industrially explored.1

Using modern steam machinery13-although more expensive–would reduce risks of accidents caused by fire-driven machines focused on power generation; it is important taking into account that a fire event in such a big sawmill would account for great losses. Hydraulic power was also not used, assumingly due to lack of watercourses with waterfalls that would allow the functioning of big boilers. Hydraulic engineering was not used to capture water for steam tanks, and this task was performed by locomotives that supplied 35,000-L and 32,000-L tanks on a daily basis. Power was generated as follows: water was heated in the ground floor in furnaces heated by fire; this water would leave the locomotives, which would go to the tanks and, subsequently, reached the 10 existing boilers by passing through canalization pumps. The produced smoke was expelled through 5 big chimneys, the produced vapor would make a big cylinder generate the power distributed in the factory to move the straps.1 Nodari13 analyzed data about the total power used by Lumber’s driving force in 1920, and it summed more than half of the total HPs of all other companies in Santa Catarina State, altogether.

The mechanized sawmill section had the following material features: it had a big saw (2-m in height) operating a 1,200 HP engine. The same winch type used in the wagons was used to download logs (that have arrived to the sawmill) coming from the forest on a conveyer that would grab it through chains until reaching the saw, but it would first undergo a moistening process to make its cutting easier. Logs would pass through several saws after the initial cutting to give the final shape to the produced wooden boards, which were sent to a stove and, then, stored in warehouse to dry. Classification was the following stage; it was based on using conveyers and chains to allow logs to be subjected to the selection process performed by workmen – waste was collected to feed furnaces at this stage. Finally, the product was taken to stacking yards where well-elaborated techniques were used to help achieving better drying outcomes:

The pilling technique observed in the countless piles of log allowed homogeneous drying, which was made easier by sun and wind absorption, by the way the sawed log was carefully stored; besides, the basis of the pile was narrower and had smaller proportions than the top.1

With respect to final destinies given to processed wood, most pine trees were sold as wooden boards in the domestic market (mainly in the Southeastern region) or in the international market (mainly to Argentina). However, part of the production was manufactured in Lumber, itself; it was destined to produce boxes to be used as package for different goods.

There was also a furniture factory in the location; it mainly processed walnut to manufacture furniture featured by sophistication and fine finishing. Machinery in this sawmill was driven by a 40 HP steam engine. Based on the observation of high-degree industrial mechanization, factory had a mechanical workshop to make sure that all machinery would work perfectly and would not delay the work in the production line. It would have played important role at Lumber; thus, it counted on several equipment, as well as on modern repairing and reposition tools.1

A company-town was created in Três Barras, close to the great sawmill. It aimed at covering a large amount of manpower coming from other parts of the country and from overseas. This village model, typical to the capitalism model, was copied from countries such as England and the United States, a fact that enables entrepreneurs to have higher social control over their workers. According to Lima, company-towns are closely linked to transnational-capitalism projects; therefore, these locations are automatically associated with progress, modernity and development ideas. Consequently, “slowly, the altered modernity changes the space, where the ‘farmish’ world is changed by the urbanization process”.14 It is possible picturing the impact such modern urban structures must have on settlements in Contestado region, where only few existing cities resembled small villages lacking basic urban resources. Actually, the material symbol of such modernity - despite the sumptuousness of architectonic structures - was the flag of the United States hoisted for 4th of July celebrations, US’ Independence Day.12

Anna Finger15 introduced the history of workmen villages and of their changes since the British Industrial Revolution in her dissertation, with emphasis on improvements in housing conditions and in workers’ wholesomeness, and on several control forms that could lead to confinement. The researcher highlighted the peculiar conditions these spaces were built in Brazil, given a whole series of factors that have involved lack of infrastructure in cities, and the rural zone where they were installed in; the precarious communication pathways and new concepts of time and work for hinterland populations. The Brazilian company-towns would be built to give access to workers’ basic housing conditions that would mostly come from other locations, rather than to actually have control over themselves, as highlighted by Finger: “at late 19th century and early 20th century, the initial issue concerned lack of sufficient houses to attract, keep and qualify manpower close to the working locations, because other forms of factory functioning would not be feasible”.15 Archaeological studies can contribute to this scenario in Três Barras’ company-town, if one takes into account social control, at higher or lower scale, in comparison to other similar contexts based on cultural heritage.

According to Lima, houses were built based on urban planning presenting British-style streets and alleys; it totaled 210 houses whose comfort aspects were provided by technology application, such as piped water, electricity and internal heating system generated by sawmill's boilers.14

According to Surek,12 houses were built in half-circle space shape; the manager’s house was built in the center of the settlement, and it would represent a sort of ‘panopticon’, since all other houses could be seen from this one. There was an ice manufacture in the village to supply residents’ internal needs.

The socioeconomic status of different workers could be expressed by purchases made in the city’s mercantile, which had mainstream place as purchase and meeting center, but also as indebtedness source, since workers were forced to buy in this establishment, which was run by the company itself. Goods available for sale in this mercantile were much desired, given the scarcity of several goods in backcountry areas. The research based on primary and oral sources carried out by Delmir Valentini12 resulted in an inventory of several goods available in this location, they came in exclusive wagons for such Lumber’s ends. The available goods were silk, whiskey, wine, fish, seafood, bread, meat, Chinese dishes, crystals, cookies, sweets, movie tickets, ice, firewood, match packs, cigars, cigarettes, fish, cheese, beer, sparkling wines, kerosene, tobacco, coffee, desserts, fruits, yeast, fabric such as cotton and wool, clothing and accessories, footwear, sugar, salt, gunpowder and fuse, among others.

Health services in the company-town were provided in hospitals and drugstores. The hospital was made of wood and presented a comfortable structure with rooms, bathrooms and beds; that was the place where doctors performed deliveries, surgeries, administered injections and provided health assistance to factory accidents. There was also a wagon-hospital, which was used as outpatient clinic to assist workers who were subjected to constant labor accidents at the extractive fronts. There are no data about the drugstores’ building, but a complete inventory of available drugs for sale was carried out by Valentini. It was possible comparing all this information to bottles of medicine recovered during systematic excavations that presented new goods and made it possible discarding others due to quality and quantity factors. The list of articles available in drugstores comprised:

Fontoura Biotonic Syrup, Nogueira Elixir, Purgative Water, Antilebrin, Sodium Bicarbonate, Capybara Oil, Arnica oil, Ross Pill, Reuter Pills, Vegetarian Remedy, Needles, Phoenix Porous Patch, Quinine Ampoule, Saline Ampoules, Serum Ampouleanti-diphtheria, anti-dysenteric, anti-ophidic serum, aspirin capsules, magnesium sulfate, disinfectant, castor oil, tin tubes, gelatin capsules, bitter drops, mothballs, white roses, lead acetate, sulfur flower, extract avocado tree fluid, lettuce, boldo, five roots and other remedies and drugs suited to the therapeutic uses of that time.1

Teaching facilities were also found in the city; there was a Polish school and a child education center. There were “temporary” outdoor schools that followed workers into the forest and that have helped with the education of their children. Therefore, they were part of the spatial organization of improvised villages.1

The old politics of “bread and circus” was established in Três Barras through a series of structures aimed at occupying workmen at their leisure time and at reducing dissatisfaction, evasions and strikes. Thus, a soccer stadium - with modern drainage system and bleachers - was built,12,16 the city also had sports courts,vi two hotels, restaurants, a casino and two movie theaters. With regards to these last buildings, it is important highlighting the existing social division at the time; one of the casinos and one of the movie theaters was used by higher education employees, whereas the other was used by workmen, in general.1 One of these rooms was described by Surek: “under the projection room there was a sand box to avoid fire, and the projection machine was moved by coal and stopped every half hour, and this is the reason why there were boxes in local restaurants, delis and hat shops”12 assumingly, is was the most sophisticated movie theater. It is most likely that only managers and high-hierarchy employees had free access to the casino.17,18

What is the final destiny of all this industrial apparatus, which was deactivated at mid-20th century? Nowadays, most equipment and buildings have disappeared: “the American company’s patrimony in buildings in Três Barras, throughout almost one century of History, has gone through many changes, and suffered with the action of wildfires, cleaning bonfires and scraps, among others”.1 Assumingly, part of Lumber’s machines and tools, and the daily artifacts of company-town residents are gathered in a whole collection of museums, or are waiting for archaeological excavations in the location of the original settlement.

In 2014, we made the first archaeological screening where the company-town was implemented in; it recorded structures that remained visible in the surface. Nowadays, there is a barrier to more detailed research because the area was militarized after the sawmill was deactivated; therefore, most structures were located within a training field of the Brazilian Army, and it implies more obstructions to access to the remaining elements. We recorded the following structures during the visitations: management offices became the headquarters of the military command (Figure 4), it kept the original wooden furniture; railroad station, which was recently restored and is currently housing a museum; casino; some houses, a mercantile and a soccer field; remaining factory structures, tennis court and movie theater ruins (Figure 5). Although the hospital has already disappeared, the area where it was located in is at good preservation conditions; thus, in the future, it can be subjected to an extensive excavation campaign. Despite the archaeological possibilities, architectural remaining could allow a phenomenological study like the one developed by Clarissa Rahmeier19 in an excavated farm from the 19th century in Southern Brazil.

Based on oral information, the area where the workshop for machinery maintenance and the hotel were placed in, in the past, is now out of the military perimeter. Yet, in 2014, some archaeological interventions were made in the soil based on test-well (50 x50 cm) to best feature the cultural heritage in the underground (Figure 6). Metal materials were found (mainly steel cables used to move logs from the forest to the factory), besides glass fragments. There was an attempt to locate hotel’s trash that, according to our informant, had a large amount of cultural heritage; it was done by enquiring information provided by the current landowner. Unfortunately, it was not possible finding an accurate location, and it has made this task difficult, since it was a flooding area. Nevertheless, it is important looking for this trashcan in the close future.

Lima14 assessed the urban design of Três Barras city from the historical perspective, and she noticed that the development of the modern city followed the original design of the company-town - street organization remains nowadays.

The margins of SP-RG railroad in Calmon, in 1990, also housed another Lumber’s sawmill, which is approximately ten times smaller than Três Barrasvii.20 It worked to produce sleepers and materials for civil construction, which were used in projects designed for the capitalist conglomerate. Long land extensions of São Roque farm were acquired in this same region, and other four sawmills were implemented in it.9,13 In addition to this set of sawmills, one finds dozens of small sawmill engines owned by third parties that worked as Lumber’s subsidiaries; they used to supply the log company with wood boards.

During the Contestado War, Lumber sawmills were the target of attacks by country people as reaction to capitalism, which has taken this population from their lands and traditional production modes. The attacks to headquarters in Três Barras and to the industrial complex did not succeed due to the company-town’s defense by a well-armed and numerous group of the company’s private security. However, Thomé9 stated that, on September 5, 1914, Calmon sawmill was attacked and destroyed by countrymen who set the sawmill’s structure at blaze, including the storage yard, which had a large amount of lumber – witnesses could see “flashes” on the horizon from long distances. The sawmill was turned into a bunch of contorted machinery, some light poles and several carbonized corpuses after the fire.

v This process of grabbing trees around caused the destruction of smaller species, such as mate trees (Machado, 2004, p. 151).

viWith emphasis on a tennis court, which was also used by managers and their families.11

viiAccording to these researchers, other sawmills outside Contestado region were also built by Lumber, such as Cachoeirinha sawmill, which is located in Jaguariaíva, Paraná State.

Based on the assessed studies, it is important herein highlighting that all and any study about cultural heritage concerning Lumber’s different activities must have in its agenda three fundamental questions. Firstly, it is important analyzing how modernity, and its material technological apparatus, has contributed to substantial changes in landscape, due to the devastation of huge areas of Araucaria forests and of other species. Secondly, it is important addressing how cultural heritage helped consolidating the ways to legitimize a life style based on the “American way of life”. Finally, although not less important, one must focus on the non-verbal communication modes21 activated by material elements to exert social control, in association with elements that provide data about the socioeconomic/social differentiation within the company-town itself, be it due to limited access to certain spaces, or to the excluding forms to acquire assets and goods.

Since 2010, we are screening Lumber’s archaeological potential of Três Barras.22,23 This first data-screening stage focuses efforts on prospective field studies, based on intervention activities aimed at identifying locations of archaeological interest and, consequently, at collecting artifacts in locations associated with this great industrial complex on the Brazilian Southern plateau, at early 20th century.

Briefly, the article presented the history of Lumber Company’s cultural heritage in Três Barras, Santa Catarina, from the industrial archaeology perspective; it shone light on the archaeological possibilities that, as observed, are at their initial stage.24None.

Author declares there are no conflicts of interest.

©2022 Lino. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.