Journal of

eISSN: 2377-4312

Proceeding Volume 3 Issue 5

Independent Poultry Consultant, Russia

Correspondence: Edward S Mailyan, Independent Poultry Consultant, Moscow, Russia, Tel 7 910 466 72 94

Received: July 20, 2016 | Published: August 19, 2016

Citation: Mailyan ES. Management related health issues in commercial turkey production. J Dairy Vet Anim Res. 2016;3(5):189-192. DOI: 10.15406/jdvar.2016.03.00097

Considering the achievements of the modern genetics and the outstanding on farm performance, we often observe and realize that the animals are becoming more demanding in terms of environmental conditions and management. Ignoring the needs and physiological demands of the young poults and grown-up turkeys compromises the flock’s uniformity and growth.

Among the numerous management issues (incubation and poults quality, brooding, feeding and drinking practices, litter and water quality, feed composition and form, transportation and veterinary manipulations etc.) we should always pay a very special attention to the ventilation control which is an integral part of proper microclimate management in a successful turkey production system. The mistakes admitted at an early stage of the flocks’ development can severely affect their health, performance and the overall results. A chronic stress initiated by the improper housing conditions (cold, hot, draft, high levels of toxic gases), triggers the irreversible catabolic reactions ending up with a severe immunosuppression, thus opening the gate for translocation of any conditionally/pathogenic microflora via intestinal (due to reduction of mucus production by goblet cells, damage to the villi, enterocytes, MALT/GALT elements, and tight junctions functionality) and/or respiratory tract (especially when compromised by live respiratory vaccines or field viruses).

The most frequently observed consequences of the improperly controlled microclimate in a turkey operation are the numerous respiratory problems (conjunctivitis, rhinitis, sinusitis, air sacculitis, pneumonia) and systemic bacterial infections (pericarditis, poliserositis, etc.), associated with high levels of NH3, CO, CO2, dust and humidity, which as well affects the litter quality, leading to foot pad lesions, breast blisters, dermatitis etc. A lot of damage due to the inappropriate microclimate happens in the brooding period, when young poults are very vulnerable to climatic stresses (Figure 1). This very common non-infectious problems lead to high levels of early culling and mortality (Figure 2) or late carcass condemnations at slaughter (Figure 3).

It would be much easier if the existing automatic climate controllers were capable of replacing the farmer in the barn, but unfortunately they are not. Thus we create and adjust ventilation regimes depending on seasons (minimum ventilation for winter, maximum for summer), but as well for different weather conditions during the transitional periods (heat/rain and day/night shifts in autumn and spring). The more severe the local and seasonal temperature and humidity variations are – the more control and manual adjustments we need to implement.

Although it comes without saying, but is not always a fact, that any ventilation system works as it supposed to! And the possible reason for that is not only improper application of the existing tools, but an initially wrong choice of building design, materials, heating and ventilation equipment, which eventually require even more presence and manual interference of the operator. Whereas for mild climatic conditions of Central European countries these situations are uncommon, for the intensively poultry producing regions of Russia and other continental regions we face them quite often.

By carefully observing the recommendations, given in the management guides, we can easily achieve good control over the water and feed quality and even day old poults, but ventilation and microclimate is a special subject, which can’t be always completely predicted and standardized. It requires a big deal of creativity and enthusiasm to achieve a deep understanding of animals’ demands and the climate impact on their behavior and health, to be able to create optimal conditions by using the installed equipment under any outside conditions. That’s why it is not surprising when farmers find their own specific combinations of setting and approaches for achieving the best performance, which can’t very often be blindly copied to another farm of even a barn!

Logically, the decision on the choice of the building design and ventilation system must be based on the local climate analysis. For instance: most of the poultry production in Russia is located in its Central European part. The annual climate fluctuations for one of these districts can be seen in the Table 1 (source: Wikipedia).

Month |

Jan |

Feb |

Mar |

Apr |

May |

Jun |

Jul |

Aug |

Sep |

Oct |

Nov |

Dec |

Year |

Recordhigh °C (°F) |

6.0 |

5.0 |

17.0 |

30.0 |

35.4 |

38.0 |

40.0 |

41.0 |

34.8 |

25.0 |

13.4 |

8.0 |

41.0 |

Averagehigh °C (°F) |

−6.9 |

−5.8 |

0.3 |

11.7 |

21.2 |

24.4 |

25.7 |

23.7 |

17.6 |

8.9 |

0.4 |

−4.3 |

9.7 |

Dailymean °C (°F) |

−9.8 |

−10.0 |

−4.2 |

6.4 |

13.9 |

18.0 |

19.2 |

17.1 |

11.6 |

4.5 |

−2.9 |

−7.7 |

4.7 |

Averagelow °C (°F) |

−13.9 |

−13.5 |

−7.1 |

1.7 |

8.1 |

12.5 |

14.2 |

11.9 |

7.1 |

1.3 |

−4.4 |

−10.4 |

0.6 |

Recordlow °C (°F) |

−39.0 |

−40.0 |

−31.1 |

−20.0 |

−6.0 |

−2.2 |

2.0 |

0.6 |

−6.1 |

−17.2 |

−31.1 |

−40.0 |

−40.0 |

Precipitation mm (inches) |

41 |

29 |

32 |

36 |

41 |

62 |

67 |

56 |

53 |

49 |

52 |

45 |

563 |

Table 1 Climate data for Penza region, Central Russia (1961-1990)

It is obvious that the housing, heating and ventilation solutions for such climatic conditions should be principally different from those for mild or hot climatic zones, where the lowest annual temperature is hardly below 0°C. But even in an ideally projected and built house the microclimate under extreme outside conditions (hot/cold) would be a compromise between the required parameters and economically feasible solutions – basically depending on the balance between the level of insulation, required ventilation, heating and cooling equipment capacities. One of the basic point is the way one calculates the required minimum(winter) and maximum (summer) ventilation rates for the birds. For the minimum ventilation there are approaches, based, for instance, on outlet fans capacity: m3/kg live weight/h or m3/kg of feed/h or on the capacity of the wall/roof inlets. These methods are quite different and theoretically they give different data (Table 2 & 3).

Аge, weeks |

№ of birds |

Feed, kg/bird |

Total feed per house, kg/day |

м3/bird (via feed) |

Total m3/h |

||||

♀ |

♂ |

Average |

8 |

15 (max) |

8 |

15 |

|||

7 |

10 000 |

0,236 |

0,270 |

0,253 |

2530 |

2,02 |

3,80 |

20240 |

37950 |

15 |

10 000 |

0,325 |

0,510 |

0,417 |

4175 |

3,34 |

6,26 |

33400 |

62625 |

20 |

5000 |

0,640 |

0,640 |

3200 |

5,12 |

9,60 |

25600 |

48000 |

|

Table 2 Minimum ventilation requirements based on 8-15m3/kg of feed/hour, as-hatched poults till 10 weeks

Age, weeks |

Live weight, |

Ventilation |

|

m3/bird/h |

м3/flock/h |

||

7 |

3,85 |

3,85 |

38 500 |

15 |

14,26 |

14,26 |

142600 |

20 |

20,37 |

20,37 |

101850 |

Table 3 Minimum ventilation requirements based on 1m3/kg live weight/hour, as-hatched poults till 10 weeks

The given minimum ventilation level in Table 2 seems to be too low, but it can be acceptable, if you don’t use open fire heaters, which produce CO/CO2, nevertheless you are risking to have a very low RH% level in the brooding period. On the other hand the levels in Table 3 are quite high, but if the temperature is -25 °C outside and you continuously burn your brooders and heaters to maintain an acceptable average temperature in the barn, then you definitely have to get rid of high CO/CO2/RH/NH3 levels, which can easily depress your poults activity and growth. And it still might be not enough!

You can base your calculations on any method you like, and use the results as set parameters in your climate controller, but the final adjustments will be done after assessment of the environment in the barn and your flock’s behavior. There are a few simple guidelines, which must be always kept in mind when accessing and adjusting the microclimate (Table 4).

Parameter |

Optimal level |

СО2 |

~ 2500ppm |

CO |

<10 ppm |

RH |

< 65% |

NH3 |

< 25 ppm |

V air |

< 0,2 m/sec (on bird level) |

∆ Т barn |

< 2°C |

Table 4 Optimal microclimate parameters

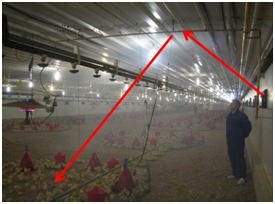

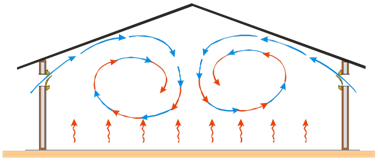

When adjusting the microclimate these parameters can be measured with electronic devices. But their optimal value does not necessarily mean comfort for the birds. Please, spend some time on the air flow control (preferably with a smoke test). This is something which is influenced by many parameters (barn design and construction, insulation and air tightness, inlet construction and position in the wall/roof, ceiling height and surface, under pressure and air inlet management etc.) (Photo 1 & 2).

Thus it becomes obvious, that the choice you make depends on what is the dominant climate in the area, where you are planning to grow your birds. Draught is very stressful for the poults, unless they are fully feathered and start manifesting signs of heat stress (gasping for air). That’s the right time to start using the cooling capacities of your ventilation system (transitional combi-tunnel, tunnel ventilation, fogging or pad-cooling systems). But be careful about starting them too early. Even for grown-up birds a cold humid draft can be dangerous. The cooling effect increases significantly (thus reducing the sensible/effective temperature for the birds) at low temperatures, high humidity and high air speed. It’s so easy to chill the birds by starting the tunnel too early in the morning or stopping it too late in the evening. To avoid it – shift slowly from minimum to maximum ventilation and tunnel, especially during the spring/autumn conditions with hot noon and cold night temperature (Photo 3)!

The major purpose of the maximum(summer) ventilation is to cool the birds with a high air speed: alone or in combination with an evaporative (adiabatic) cooling system (foggers and/or pads).The system works well while the humidity of the air outside is low. But be careful with high temperature and high humidity which sometimes rises very fast in summer (rain storms). Watch the weather forecast and be ready to stop it before the critical period. In high RH environment birds can’t cool themselves by evaporating the excessive heat via breathing and they die very fast from a heat strike. A similar effect can happen in the evenings when the air cools down allowing the RH to increase dramatically. So, always remember the interaction between the temperature and relative humidity (Molier diagram).

Microclimate is one of the most important and commonly debated issues among the numerous poultry management aspects. The reasons are obvious: it directly impacts the birds during 24hours a day. Under comfortable conditions the flock is capable of utilizing maximum of its genetics in combination with other environmental inputs (feed, water, vaccinations etc). But as soon as the climate goes wrong-the flock starts “picking up” all the other minor mistakes in nutrition, water quality, and adversely reacts to any vaccinations, especially with respiratory viruses. The chronic stress created by suboptimal environmental conditions negatively reflects on the activity and performance of the flock, increasing the morbidity, mortality, culling and condemnations at the slaughter.

None.

Author declares that there is no conflict of interest.

©2016 Mailyan. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.