Journal of

eISSN: 2377-4312

Research Article Volume 2 Issue 3

1Department of Dairy Technology, Anand Agricultural University, India

2Innovation Center, Mother Dairy Fruit & Vegetables Ltd, India

3Department of Dairy Chemistry, Anand Agricultural University, India

4Baroda District Co-operative Milk Producers Union Ltd, India

Correspondence: Jana AH, Professor and Head, Department of Dairy Technology, SMC College of Dairy Science, Anand Agricultural University, Anand-388 110, Gujarat, India, Tel 91 937 501 2630, Fax 0269 226 1314

Received: April 19, 2015 | Published: June 24, 2015

Citation: Jana AH, Shah R, Aparnathi KD, et al. Influence of rennet casein levels on the chemical, baking and sensory quality of mozzarella cheese analogue. J Dairy Vet Anim Res. 2015;2(3):99-105. DOI: 10.15406/jdvar.2015.02.00039

An attempt was made to evaluate the effect of varying rennet casein levels (22.0, 24.5 and 27.0% w/w in the formulation) on the quality of Mozzarella cheese analogue (MCA) utilizing dairy fat (plastic cream). The formulation comprised of 25% plastic cream (72% fat), 3% tri-sodium citrate, 2% maltodextrin, 0.55% lactic acid, 1% NaCl, 1% cheese bud flavoring, and rest water; rennet casein was varied at three levels. Increasing the rate of addition of casein had a significant influence on the composition, baking qualities and sensory quality of MCA judged as a topping on pizza pie. Use of rennet casein at 24.5% in the formulation of MCA was found to be advantageous in terms of sensory quality, stretch, melt and fat leakage characteristics. The MCA obtained using 24.5% rennet casein conformed to the Food Safety and Standards Act (FSSA) requirements for ‘Pizza cheese’ in India and had all the requisite baking characteristics required as a pizza topping. It is recommended to use 24.5% of rennet casein in the formulation of MCA to obtain a product that is suitable for baking applications.

Keywords: cheese analogue, rennet casein, composition, baking quality, sensory quality, pizza pie, rennet casein, plastic cream, cheese analogue, composition, baking qualities

FSSA, food safety and standards act; MCA/MCAs, mozzarella cheese analogue/mozzarella cheese analogues; MFFS, moisture in fat free substances; FDM, fat on dry matter; Na, sodium; Ca, calcium

Cheese analogues synonymously known as cheese substitute or imitations, are the products that substitute or imitate cheese in part or whole. In such products milk fat, milk protein or both may be partly or fully replaced by non-milk components, usually of vegetable origin.1 Analogue cheese products are made utilizing processed cheese manufacturing technique with the help of heat, mechanical shear and emulsifying salts. Analogue cheese products can be classified as

Cheese analogues are easy to prepare requires less time for manufacture (i.e. about 2h for analogue vs. 5-7h for natural Mozzarella cheese) and can be ‘tailor-made’ as per the specifications of the pizza retailer. Cheese analogues are produced commercially in several countries, however, the information relating to their formulation and method of manufacture are mostly patented. Hence, the recipe and manufacturing techniques remains inaccessible to the scientific community. The cheese variety which has been imitated the most is Mozzarella cheese, due to the growing popularity of pizza world over. Cheese is the key ingredient in such applications. The major application of cheese analogue is in compounded or formulated foods manufactured by catering or industrial establishments.3 The manufacture of cheese analogue allows manufacturers greater scope in manipulating constituents toward nutritional, textural and economic ends.

Mozzarella cheese analogue (MCA) has been reported to be functionally more stable during refrigerated storage than natural mozzarella cheese. Such stability makes analogues very attractive to the food processing and service industries.4

The world cheese production reached 20.0million MT in 2011. Mozzarella is America´s favorite cheese and accounts for nearly one-third of the consumption, mainly because it is one of the main ingredients of pizza. Analogue cheese is available in retail sector and accounted for 18,000 tonnes for supermarket sales in 2005 (i.e. 7.0% of processed cheese sales).5 In the year 2000, the demand for Pizza cheese was growing in Europe by 8.0% per year. Analogue cheese is sold into the industrial sector, and the most common variety sold has functional properties designed to mimic those of natural Mozzarella cheese.6

Casein is the preferred source of protein in the preparation of MCA. The type of casein (i.e. acid or rennet casein) and its level of usage in the formulation of MCA play an important role in deciding the composition, rheology, sensory and baking characteristics of the resultant product.7 Besides fat, protein is the major constituent affecting the quality of the cheese analogue. MCA has been prepared using casein/caseinates at levels ranging from 23.0 to 28.5%.8‒10 The minimum level of protein at which the milk fat can be adequately emulsified in the cheese matrix and enables attaining the desired body-texture in the product required for shredding is desired. Use of casein incorporation at higher levels not only increases the cost, but may contribute to undesirable ‘casein flavor’ in the cheese analogue.

A key aspect of cooking performance of cheese is its heat-induced functionality, including melting or flowability.11 The main protein source in dairy-based imitation cheese products is rennet casein or sodium (Na) and/or calcium (Ca)-caseinates. Rennet casein, due to its functional properties and desirable flavor, is preferred over alternative protein sources. Since rennet casein has a high Ca/casein ratio (~36mg/g casein), the degree of calcium sequestration and para-casein aggregation is easily controlled by using the correct blend of emulsifying salt to give the desired degree of fat emulsification in cheese analogue. This, in turn, gives the desired degree of flow and firmness on cooking the cheese analogue.12 Thus, keeping in view the significance of dairy protein in cheese analogues, an attempt was made to study the influence of rate of addition of rennet casein on the quality characteristics of MCA, with due emphasis on the baking properties for which such cheese variety is prized for.

Raw materials

Fresh plastic cream (≥72% fat) was obtained by separating fresh whole milk, while powdered rennet casein was prepared from freshly separated skim milk at ‘Anubhav Dairy’ - an experimental dairy plant of the Anand Agricultural University, Anand, Gujarat. ‘Tata’ brand common salt was obtained from local market. Maltodextrin (M/s. Indian Maize and Chemicals Ltd. New Delhi), tri-sodium citrate, dehydrate (M/s. Qualigens Fine Chemicals, Mumbai), lactic acid extra pure (M/s. SD Fine Chemicals Ltd. Boisar) and Mozzarella cheese bud flavouring (M/s. Duke Thompson’s India Ltd. Indore) were obtained from respective places.

Rennet casein: Edible grade rennet casein was manufactured as per requirement from fresh mixed (cow+buffalo milk, 45:55 w/w) skim milk.13 Skim milk (0.05% fat, 9.0% SNF) was pasteurized (72oC/15 sec) and cooled to 31oC and added with Maxiren (fungal rennet, 1800 IMCU/g strength) at the rate of 1.5g/100kg milk in the form of a solution (rennet:water - 1:15 w/v). Once the curd was set in about 30min, it was cut into 1.0cm3 with cheese knives and then cooked to 55oC in 30min, with intermittent stirring. At the end of cooking period, the whey (pH ~7) was drained and the curd was washed with pasteurized (75oC/no hold) hot (55oC) water adjusted to pH 6.7 with dilute hydrochloric acid (HCl:water-1:9 w/v). After thorough washing of the rennet curd (wash water equal to quantity of whey drained), the wash water was drained. Subsequently, two more washings were carried out using pasteurized wash water at 55oC and 35oC respectively; third wash water was not adjusted for pH (pH was about 7.0). After draining the wash water, the rennet crud was collected in a cloth-lined stainless steel cheese hoops (35x30x6cm; length, width and height) and pressed in a spring loaded cheese press for about 3h, till the moisture content of about 55.0% was attained. The casein was then cut into pieces, made into shreds in a ‘Gopi Mixer Grinder’ and then dried to about 8.0% moisture in a forced-draft tray drier (M/s. Yorco Sales Pvt. Ltd. New Delhi) using hot (58oC±2oC) air for drying. A Hammer mill (Model - Magnum Gold No. F-826, M/s. Swastik Sales Corporation, Vithal Udyognagar, Gujarat) was used to mill the dried casein. The ground casein was then sieved through Indian Standard (IS) sieve of 355μm to obtain the desired sized particles.

Preparation of mozzarella cheese analogue

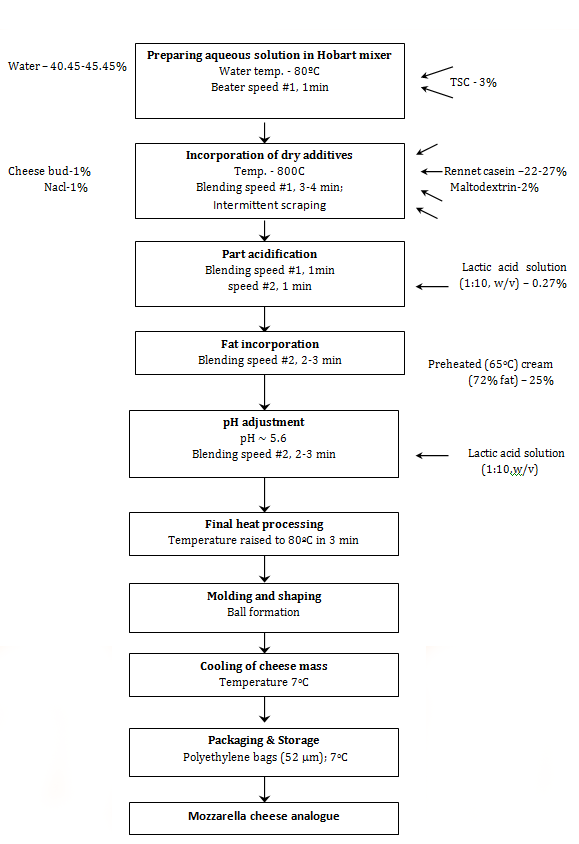

MCA was made as per the process standardized by Shah et al.14 A Hobart food processor (M/s. Hobart Corp. Canada-Model No. N 50) operating at 3 speeds was used to blend the ingredients (Figure 1). During the experimentation, 500g of cheese analogue was prepared for each treatment under study. The experiment was replicated five times.

Chemical analyses

The cheese analogues and rennet casein were analyzed for total solids using Mojonnier Milk Tester,15 fat by Van Gaulik method,16 protein by micro-Kjeldahl method,17 pH18 and ash.19 The salt content of cheese was determined by modified Volhard method.20

Sensory evaluation of MCA as pizza topping

Freshly prepared pizza base (~15cm diameter, 1.5cm thick) was procured from a local bakery from Anand, Gujarat. Seventy grams of freshly shredded cheese was topped on each pizza base. Vegetable topping was deliberately avoided to permit flavor perception from cheese used as pizza topping. The pizza base topped with cheese were transferred to a forced draft hot air oven (M/s. Narang Scientific Works, New Delhi, Model-143) maintained at 230oC and kept there until the cheese shreds melted completely and fused with each other. The segmented triangular pieces of pizza, obtained with the help of a pizza cutter, were then served to each judge in hot condition for sensory evaluation. The cheese analogue, as pizza topping, was assessed on the basis of sensory quality by a panel of ten judges (aged between 35 to 50years) who are well aware of the desired characteristics of Pizza cheese. The judges were selected based on ‘Duo-trio’ and ‘Triangle’ tests. The shredded cheese (70g) was topped on pizza base and baked in a forced-draft oven maintained at 230°C, until the cheese melted completely (about 6-8min). Maximum score of 10.0 was used for sensory attributes like appearance (including fat leakage, browning), flavor, melting, stringiness and chewiness. The final total sensory score for each cheese analogue was given out of 50.0.

Baking properties

MCA was analyzed subjectively for shredability using a manual shredder. Meltability was tested by Schrieber melt test,21 fat leakage by the method of Breene et al.,22 and stretchability using indigenously developed Stretch tester ‘Hi-TST-E-Cheese Machine’ (M/s. Hiranya Instruments, Vadodara).22

Statistical analysis

Five replicate values of each attribute were subjected to statistical analysis using Completely Randomized Design with equal number of observations.23

Formulation of mozzarella cheese analogue

MCA was made using three levels of rennet casein viz. 22.0, 24.5 and 27.0% w/w in the formulation. Rest of the ingredients (i.e. fat, maltodextrin, cheese flavoring, acid, emulsifying salt and common salt) and their levels were kept constant, except for water which was adjusted based on the level of rennet casein employed. The rate of incorporation of each ingredient is depicted in Figure 1. The photographs of all the MCAs containing three levels of rennet casein are shown in Figure 2.

Proximate composition of MCA

Figure 2C MCA made using 27% rennet casein.

Figure 2 Photograph of Mozzarella cheese analogues made using three levels of rennet casein.

It is evident from Table 1 that all of the compositional attributes of MCA studied were significantly affected by the rate of addition of rennet casein in the formulation. MCA with 22.0% casein had the highest moisture, moisture in fat-free substances (MFFS), fat and fat-on-dry matter (FDM), whereas MCA with 27.0% casein had the highest protein at constant (46%) moisture, salt, ash and pH amongst the three types of cheeses. The least value for moisture, MFFS, fat and FDM content associated with MCA containing 27% casein was significantly different (P<0.05) from those of other two MCAs. The difference was also significant (P<0.05) for MCAs containing 24.5 and 22.0% rennet casein. The least protein (at constant moisture), salt, ash and pH associated with MCA having 22.0% casein was significantly different (P<0.05) from the values of the other two cheeses; the values of the latter two cheeses (i.e. MCA with 24.5 and 27.0% rennet casein) also differed significantly (P<0.05) from each other (Table 1).

Constituents |

MCA Made Using |

CD (P<0.05) |

||

22.0% Casein |

24.5% Casein |

27.0% Casein |

||

Moisture % |

47.43 |

45.91 |

44.45 |

0.138 |

MFFS % |

60.64 |

58.06 |

55.22 |

0.164 |

Fat % |

21.79 |

20.95 |

19.5 |

0.082 |

FDM % |

41.44 |

38.73 |

35.1 |

0.152 |

Protein % |

21.96 |

24.06 |

26.57 |

0.106 |

Protein (46% Moisture) |

22.55 |

24.02 |

25.83 |

0.078 |

Salt % |

1.18 |

1.2 |

1.24 |

0.005 |

Ash % |

5.54 |

5.68 |

5.89 |

0.032 |

pH |

5.48 |

5.53 |

5.59 |

0.008 |

Table 1 Proximate composition of Mozzarella cheese analogue as affected by varying levels of rennet casein

MCA: Mozzarella Cheese Analogue; MFFS: Moisture in Fat Free Substances; FDM: Fat on Dry Matter; CD: Critical Difference

The significantly higher moisture, MFFS and lower protein in MCA with 22.0% casein was due to the maximum amount of water used in the formulation; the quantity of water decreased as the rennet casein content was raised from 22.0 to 27.0%. It is important to note that the FDM content of MCA containing 27% casein could barely satisfy the minimum FDM (i.e. 35.0%) specified by Food Safety and Standards Act (FSSA) for ‘pizza cheese-a variant of Mozzarella cheese’ for sale in India.24 With an increase in the quantum of rennet casein in MCA formulation, it is expected that the product would contain higher ash, since the ash content of rennet casein was 8.0%. The increase in pH of MCA with an increase in the level of rennet casein could possibly be due to the increased buffering capacity of casein.25

Baking characteristics of MCA

Hydration of rennet casein during cheese analogue manufacture requires the use of calcium-sequestering salts such as trisodium citrate (TSC) to disrupt the calcium-mediated cross-bridges between the proteins. The addition of emulsifying salts promotes casein peptization, which increases the water binding capacity of the proteins and exposes their polar hydrophilic and a polar hydrophobic segments, allowing the caseins to function as emulsifiers in the water-oil interface.26 Hydration of the protein may also be affected by the shear conditions used; high shear leading to faster and more extensive disruption of the rennet casein particles and an increased opportunity for protein-solvent interactions. Interaction between proteins particulates may lead to network formation and increased viscosity of the rennet casein dispersion. Exposure of increased numbers of hydrophilic regions on protein molecules would allow the rennet casein to hydrate and form a highly viscous protein-aqueous phase capable of emulsifying oil and increasing the viscosity of the dispersion. There are changes in the viscosity index of the protein dispersion as a consequence of the rennet casein hydration including particle swelling, clumping, network formation and subsequent breakdown of the network. Hence, the state of protein (rennet casein) hydration influences the rheological parameters of the resultant product.27,28 which should be sufficiently firm to allow shredding and when cooked, the cheese should exhibit good meltability, stretchability and elasticity. These performance characteristics of the cheese analogues are influenced by the precise nature of protein in aqueous phase, and the nature of the emulsion formed.

Table 2 indicate that all of the baking qualities (i.e. shred, melt, fat leakage) were significantly (P<0.05) affected by the level of rennet casein used in the formulation of MCA. The individual baking characteristics are discussed in detail here under.

Baking Parameters |

MCA Made Using |

CD (P<0.05) |

||

22.0% Casein |

24.5% Casein |

27.0% Casein |

||

Shredability |

Good |

Very Good |

Excellent |

- |

Melt time in Oven at 230oC (min) |

7.08 |

7.51 |

8.17 |

0.383 |

Schreiber Meltability (Arbitrary Value) |

4.72 |

4.11 |

3.46 |

0.286 |

Fat Leakage (cm2) |

10 |

8.19 |

0.71 |

0.549 |

Stretch Test (cm) |

29 |

36 |

44 |

3.43 |

Table 2 Baking properties of Mozzarella cheese analogue as affected by varying rennet casein levels

MCA: Mozzarella Cheese Analogue; CD: Critical Difference

Shredding

Shredability and resistance to clumping after shredding are the major determinants of overall functional characteristics of cheese.29 The shredding property (subjective) of MCA improved with increasing level of rennet casein from 22.0 to 27.0% (Table 2). The ‘long and thin’ shreds obtained through a manual stainless steel shredder was considered as ‘desirable shreds’, while ‘short and thick’ shreds were considered to be less suited to pizza application. The tendency of the shreds to mat with each other, post shredding, is not a desirable trait. As the protein content increased (from 22.0 to 27.0%), the moisture content of MCA decreased (Table 1), while the bound water probably increased, culminating in superior shredding characteristics (Table 2).

Meltability

Meltability refers to the capacity of cheese particles to coalesce to a uniform, continuous layer of melted cheese when placed in the baking oven. Table 2 shows that the meltability of MCA was best when it had the least casein (22.0%) content; the Schreiber meltability values decreased and the time required by the cheese to melt in the baking oven increased with an increase in the level of rennet casein used (Table 2). The difference in the ‘melt time’ and ‘meltability values’ was found to be significant (P<0.05) at each level of casein utilized. The MCA with higher casein content (i.e. 27.0 vs. 24.5 or 22.0%) probably exerted more emulsification of milk fat (cream). In addition, the lower moisture content of such cheese analogue might have led to the impaired meltability of cheese. Such an adverse influence of low moisture content and improved fat emulsion on the meltability of cheese analogue has been reported.30,31

Fat leakage

Free oil formation is the tendency of oil to separate from the melted cheese and form oil pockets, upon baking. Some degree of free fat is desirable; excessive amount is derogatory to its appearance, palatability and crispness.22 The fat leakage drastically declined with an increase in the level of rennet casein used in the formulation (Table 2). The effect was significant (P<0.05) at each level of rennet casein used. The minimal fat leakage observed in MCA with 27.0% rennet casein was not relished by the judges during pizza consumption. The other two MCAs (i.e. with 22.0 and 24.5% casein) exhibited fat leakage that was considered acceptable by the judges. The reduced fat leakage observed in MCA when using rennet casein at higher level (i.e. 27.0%) in the MCA formulation could be attributed to the improved fat emulsification in the dominant rennet casein based cheese matrix compared to the ones made using lower (i.e. 22.0 and 24.5%) casein levels. Greater the status of fat emulsification in the cheese matrix, lesser is the tendency of cheese to fat leakage upon baking.28

Stretch

Stretchability is the ability of the melted cheese to form fibrous strands that elongate without breaking under tension. It is also referred to as ‘stringiness’ as mentioned in Table 3. The extent of stretch of cheese decreased with reducing level of rennet casein in the MCA formulation; the effect was significant (P<0.05) at each level of rennet casein used (Table 2). The declining trend in the stretch of MCA when using lower rate of rennet casein in the formulation can be explained to the less dense protein matrix (due to lower protein content) in the cheese leading to reduced casein-casein and/or casein-fat interactions (Table 1) (Table 2). Commercial samples of MCA having 18.7% and 16.1% protein were reported to exhibit a stretch of 22.0cm and 15.0cm respectively.32

Evaluation of cheese analogue as a topping on pizza pie

The main utility of MCA is as a topping on pizza pie. Hence, actual baking trial will decide the optimal level of rennet casein to be used in the MCA formulation. In actual baking trials, all the sensory attributes evaluated were significantly affected by the level of rennet casein used in MCA formulation; the effect was significant (P<0.05) at each level of rennet casein utilized (Table 3). MCA made using the least amount of casein (i.e. 22.0%) had the maximum score for appearance, flavor, melting and chewiness, culminating in highest total sensory score of 41.04 out of 50.00. The least sensory total score (i.e. 38.03) was associated with MCA utilizing the highest level (i.e. 27.0%) of rennet casein.

Sensory Score |

MCA Made Using |

CD (P<0.05) |

||

22.0% casein |

24.5% casein |

27.0% casein |

||

Appearance (Max. 10) |

8.14 |

7.76 |

7.16 |

0.311 |

Flavor (Max. 10) |

8.57 |

8.12 |

7.4 |

0.189 |

Melting (Max. 10) |

8.28 |

7.9 |

7.56 |

0.283 |

Stringiness (Max. 10) |

7.5 |

8.19 |

8.49 |

0.235 |

Chewiness (Max. 10) |

8.55 |

8.01 |

7.42 |

0.198 |

Total Score (Max. 50) |

41.04 |

39.98 |

38.03 |

0.354 |

Table 3 Influence of level of rennet casein on the sensory quality of Mozzarella cheese analogue judged as a pizza topping

MCA: Mozzarella Cheese Analogue; CD: Critical Difference

The appearance score of MCA with 22.0% casein was maximum, which differed significantly (P<0.05) from the scores assigned to other two MCAs. This was due to the fact that cheeses with higher rennet casein content (24.5, 27.0%) did not melt as uniformly as did MCA with 22.0% casein. Nevertheless, the former two MCAs were whiter than the latter one. The reduced (lower than desired) fat leakage observed in MCA with 27.0% rennet casein also contributed to its lower appearance score. The tendency for peripheral browning of cheese increased with increasing rennet casein used in the MCA formulation.

The trend observed for appearance score also held true for flavor score; the influence was significant (P<0.05) at each level of rennet casein used. The flavor (cheese) impact of MCA containing higher casein content (i.e. 24.5, 27.0%) was lower compared to the one provided by MCA with 22.0% casein. This could be attributed to the masking of cheese flavor by the more compact casein network, compounded by the interference of cheese flavor by ‘casein’ flavor, native to rennet casein.

There was a gradual decrease in the melting score with an increase in the level of rennet casein used in MCA. Such effect was significant (P<0.05) at each level of rennet casein used. The above effect is clearly corroborated by the values of Schreiber meltability depicted in Table 2. The melting score was best for MCA containing 22.0% casein. The higher degree of fat emulsification and lower moisture content of MCA containing higher casein content (i.e. 24.5, 27.0%) probably led to the decreased meltability of cheese analogue.33,34

The stringiness score allotted to MCA with 27.0% casein was highest (i.e. 8.49 out of 10.0), which differed significantly (P<0.05) from the scores of other two cheeses (i.e. 8.19 and 7.50); the latter two cheeses also differed significantly (P<0.05) from each other (Table 3). MCA with 24.5% casein had superior stringiness score over MCA with 22.0% casein. This matches very well with the objective stretch test depicted in Table 2. Greater casein-casein interaction in MCA having higher casein content might have led to such an observation.

The tenderness or toughness of the product during mastication was perceived as chewiness. The chewiness score of MCA declined progressively with increasing level of rennet casein used in the formulation. MCA with 27.0% casein had the maximum chewiness, which led to such cheese having the least score (i.e. 7.42); such score differed significantly (P<0.05) from the scores assigned to other two MCAs (i.e. with 24.5 and 22.0% casein). Consumers prefer pizza cheese with moderate chewiness. It is obvious that chewiness would increase with an increase in the protein content of MCA.

MCA containing 22.0% casein was associated with the highest total sensory score (i.e. 41.04 out of 50.0), which differed significantly (P<0.05) from the total sensory scores of other two MCAs (i.e. with 24.5 and 27.0% casein). MCA with 27.0% casein had the least (i.e. 38.03) total sensory score. In absence of relevant study by other researchers, the comparison of sensory aspect of cheese as pizza topping could not be made.

Based on the above results, either of 22.0 or 24.5% of rennet casein may be used in the formulation of MCA taking into consideration the sensory and objective baking qualities of cheese analogues. MCA made using 27.0% rennet casein could barely satisfy the legal requirements (fat on dry matter content) for natural Mozzarella cheese and had total sensory score, judged as pizza topping, that was inferior to the MCA containing 24.5% rennet casein. However, looking to the superiority of MCA made using 24.5% rennet casein (over 22.0% casein) with regard to stretch quality, moderate fat leakage and adequate melting of cheese in the baking trials, the former MCA (i.e. with 24.5% casein) is recommended for commercial manufacture. Hence, a usage rate of 24.5% of rennet casein (8% moisture) is advocated for use in the manufacture of MCA having properties amenable to baking applications.

The authors thankfully acknowledge the gifted samples of cheese flavorings provided by M/s. Duke Thomson’s India Pvt. Ltd. Indore for the research project.

Author declares that there is no conflict of interest.

©2015 Jana, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.