Journal of

eISSN: 2378-3184

Research Article Volume 2 Issue 5

American University of Armenia, Armenia

Correspondence: Karen Aghababyan American University of Armenia, Baghramian 40, Yerevan, Armenia, Tel +37495 544405

Received: June 22, 2015 | Published: September 8, 2015

Citation: Khanamirian G, Aghababyan K (2015) Towards Sustainable Aquaculture in Armenia: Strengthening Capacity through Advanced Technologies of Trout-Farm Management for Small-Scale Producers. J Aquac Mar Biol 2(5): 00039. DOI: 10.15406/jamb.2015.02.00039

The present study examines the possibility of introducing a new approach for rainbow trout production for small scale producers in Armenia. This approach is based on the intensity of economic activity by modernizing the production processes leading to measurable economic and environmental benefits. The study shows that the modernization of the standard model of the enterprise, which initially produces two tons, results in an increase of the annual performance of the module up to eight tons. By investing; slightly over 25,000 USD; in modernizing the production processes, it becomes possible to reduce the production cost (USD/kg fish) from 3.04 USD using the traditional approach to 2.68 USD in the first year reaching 2.24 USD by the fourth. At the same time, the production technology changes; during the implementation of the pilot module (including change of water disinfection technology); result in a water consumption reduction of the enterprise of more than 300,000 m3 per year, along with the pollution reduction of natural water bodies by persistent disinfectants. Thus, introducing the advanced technology leads to:

Keywords: Small scale producers, Profitability, Cost reduction, Prime cost, Payback, Intensification of production, Recirculation aquaculture system, Water resource management, Impact on freshwater ecosystems

Kg, kilogram; kW, kilowatt; L/sec., Liters Per Second; L/min., Liters Per Minute; m, Meters; mg/l, Milligrams Per Liter; m2, Square Meters; m3, Cubic Meters; Mm3/year, Million Cubic Meters Per Year; AMD, Armenian Drams (local currency)

According to the “Food and Agriculture Organization”,1 a steady growth trend of the aquaculture sector worldwide is observed. Modernized technological approaches are being actively developed and implemented in many countries (Denmark, Norway, Germany, Australia, New Zealand, Singapore, China, Canada, and USA).2 Such efforts aim to the formation of a new type of enterprises that is corresponding to the modern demands (rational use of water resources, applying environmental friendly technologies of disease prevention and disinfection, optimization management of the enterprise), leading to production intensification, and Nature rational use. In these countries, the state agencies responsible for natural resources management are creating a legal, regulatory and tax environment for supporting services and promotion of activities of aquaculture enterprises.3

The aquaculture sector in Armenia shows stable growth since early 2000s with an annual growth rate of 12 to 20%.4 In 2013, the Arminian fish production was 11,600 tons, of which 6,300 tons were rainbow trout.5,6 However, out of more than 230 enterprises represented in the sector, only 2% is responsible for about 44% of the production output. The remaining 56% of the production (6,500 tons) comes out of small scale producers. However, the water resource suitable for the aquaculture of both salmon and sturgeon is limited, with an annual consumption rate of 10-17%.7 Meanwhile, the regulatory measures established by the government, mainly aimed at enhancing the rates of water. Thus, the tariff for artesian water taken from the well, according to the decree № 864 from 30.12.1998 with the amendment number 123-N from 30.12.2013, was increased by 10 times.8. Thus, the total payments for the exploitation of water resources are now one of the major cost items, especially for small scale producers. Such cost directly affects the production prime cost, since all enterprises in the sector, except for one cage farm on Lake Sevan, practice flow-through method. In that method the water (the vast majority of which comes from artesian source) flows through a series of fish-tanks, without being reused and is discharged in a volume corresponding to the volume of intake. In such systems, according to our surveys, the productivity does not exceed 25-30 kg of fish per cubic meter of water which is very low, in terms of the economics of the farm, as well as the resource use.

Introducing the modern production practices, in small-scale producers, will intensify their current production between 75 and 100 kg of fish per m3 and increase the water reuse, reducing its intake to 70%. In other words such practice can thereby raise the efficiency of resources used and significantly improves the farm economic performance. Such practices can also strengthen the competitive capacity of these producers as well as their market share.2

The objective of the present study is to prepare a preliminary feasibility study including:

Traditional management approach data (common production approaches, system design, feeding & disinfection practices, farm operation modes, and staffing) where collected from over 30 deferent trout-farms across the country. Information on seed material suppliers and cost, feed manufacturers and cost, as well as the cost of local logistics and basic conditions of credit resources were also collected. Other information was also collected as follows:

Moreover, the computation data of a realistic experimental model were collected from 12 trout-farms in Denmark. These data includes information on the types of production systems, the volume of resources (water, energy, land) consumption and their costs, common systems of farm management, including approaches of feeding, disinfection, disease prevention and internal logistics. Information on standard operational procedures and regulations, the number of personnel in the enterprise, the modes of its operation, as well as automated control systems, if any, were also collected. More data were collected on the methods of water resource natural-cleaning via buffer wetlands (which have a wide distribution), as well as on existing systems of tax stimulations of such approaches.

For modeling of the proposed technology we used fish-farming enterprise with the following annual profile: water consumption–548,658 m3, electricity consumption–34,146 kW and productivity–10 tons of trout per year. The production area consisted of 10 standard fish-tanks; the dimensions of each were 9 m length x 2.5 m width x 1.5 m depth. Fish rearing was implemented using traditional technology, resulting in an annual production capacity (productivity) of 2 tons for each standard module consisting of two fish-tanks (Figure 1). In the experimental model, an area of two fish-tanks was allocated and modernized by the plan, as shown in Figure 1, leading to an increase in the annual production capacity from 2 to 8 tons.

Description of the model, main processes, components’ cost and work

In the present study, an upgraded experimental module was used. This upgraded module consists of two fish-tanks, mechanical and biological water treatment components in addition to a number of supporting elements (Figure 2). The first compartment is a water collector (point 1) in which the controlled water proportions1 are mixed. Water resource used in most of fish-farming enterprises was artesian. This water, in most cases, has low in nitrates, phosphates, heavy metals, and relatively stable temperature (from 13ºC to 18ºC, depending on the source) which are favorable characteristics for production. On the other, the level of dissolved oxygen (DO) saturation this water was very low (3.9 mg/l at 13ºC), whereas the level of carbon dioxide (CO2) was quite high (80-90 mg/l). There used water, representing 70% of water falling in the collector, has a significant oxygen potential (7 mg/l at 13ºC), in comparison with the makeup water. Along with this, disinfectant per acetic acid was added to the mixed water. Such acid, was used as it decays in less than a minute9,10 leading to much faster impact on the environment that the other sustainable disinfectants (like malachite green and formalin) commonly used with end products carbon dioxide, water and oxygen. The disinfectant supply was carried by droplets through the PAA dozer (point 4) directly into water collector, then the mix of reuse and makeup waters with oxygen saturation of 65%, flows from the bottom of the water collector into the second compartment.

In the second compartment the airlift pump (point 5) was set. It is a 60 cm width channel which is connected to the air blower (point 8) via pipes (point 7) with a bottom extending along the entire length of the diffuser (point 6). The blower was used to inject the air to raise the water level to the top of the fence, leading to the next compartment. Along with this, the water becomes more saturated by dissolved oxygen reaching the level of 90% that is favorable for trout. The third compartment is the fish-tanks (point 9), in which the rearing for the rainbow trout fish was implemented and the fish were fed by demand feeders (point 31). Each tank has The dimensions of each of these tanks were 9 m length x 2.5 m with a depth of 1.5 m at the beginning of the tank and 2 m at the end of it, forming a ramp of about 5o, whereby there is a near-bottom current towards a settling cone (point 11). This settling cone is a part of sludge removl section where both uneaten food residue and feces were accumulated. At the bottom of this cone there is a hole with sludge plug (point 12), periodic lifting which allows the settled particles to be washed, outputting them via pipe system (point 13) to the buffer wetland see Figure 1, together with 4-5% water. Then the water falls by gravity to the next compartment. The fourth compartment is a canal # 1 (point 14), which precedes a mechanical filtration compartment (point 17). This canal is provided with a flow separator (point 15), and pipe plugs on the output (point 16) that is intended to distinguish the water streams during the tank cleaning. In normal operation mode the flow separator is closed.

The fifth compartment is the mechanical filter (point 17)where the mechanical filtrationprocesstakes place.It consists of two swimming pools with dimentions of 3x2.8x1 m, where the vertically-situated bio-bloks of 70 cm high (point 18) are located. Water is supplied into the lower part of the tankthrough a pipe, then slowly rises up to the top, passing through bio-bloks in which suspended particles are deposited, andbio-decomposed by heterotrophic bacteria. Both thebio-bloks and the tank itself require regular cleaning (once every two days). Waste water that emerges during this cleaning procedure is washed off by waste removal pipe (point 19). Canal # 2 (point 20) is the sixth compartment which has a buffering function and is identical to canal # 1.

The biological filtration process takes place in the fifth compartment (point 21). This compartment consists of two tanks with dimensions of 3x2.8x1.5m. This type of bio-filter is filled with light-weight bio-filter media (point 22), and provided with four air diffusers (point 23), located in the corners of each tanks, to ensure constant water circulation. These two bio-filter Medias provide a growth substrate for nitrifying bacteria promoting transformation of ammonium into relatively safe nitrate for trout fish. Then the water that passes through the barrier fences (point 24) falls by gravity to the next compartment. The biofilter cleaning procedure is identical to that of the mechanical filter mentioned abovebut only once every two weeks.The waste water is also washed offby waste removal pipe (point 25).

The last compartment is a canal # 3 (point 26), in which water flows from both sections of biofilter, is united, then before passing through the barrier fence (point 29) that prevents large mechanical particles from enteringthe pipe. Most of the water (70%), by gravity, is moved back into the water collector, closing the cycle. The remaining 25% of the water is discharged from the system byvalve regulation (point 28), outputting them via pipe system to the buffer wetland see Figure 1, which in the basic variant has a serpentine shape (in our case–with a total area of 2420m2). The aquatic plants, abundantly planted in it, absorb decaying organic compounds, serving as a natural filter. The configuration and size of buffer wetlands can vary depending on the farm production characteristics. Table 1 shows the estimated costs for the modernization of the module. This estimation showed in the table includes the cost of purchase, delivery and installation of equipment.

|

Species: Rainbow Trout |

Unit |

Price per Unit USD |

Number of Units |

Total |

|

1. Equipment and supplies |

19,019 |

|||

|

1.1. Bioblocks |

m3 |

350 |

8 |

2,800 |

|

1.2. Bio-filter media |

m3 |

450 |

16 |

7,200 |

|

1.3. Air Blower |

unit |

1200 |

1 |

1,200 |

|

1.4. Diffusers |

unit |

200 |

6 |

1,200 |

|

1.5. Sludge Removal Units |

unit |

120 |

4 |

480 |

|

1.6. PAA dozer |

unit |

320 |

1 |

320 |

|

1.7. Demand Feeders |

unit |

150 |

4 |

600 |

|

1.8. Fence for Fishes |

unit |

500 |

2 |

1,000 |

|

1.9. Flow Separator |

unit |

70 |

2 |

140 |

|

1.10. Preventive Fences |

unit |

20 |

2 |

40 |

|

1.11. Valves and Counters |

unit |

50 |

2 |

100 |

|

1.12. Stopper |

unit |

6 |

8 |

48 |

|

1.13. Covering Fences |

m2 |

10 |

10 |

100 |

|

1.14. Water Pipes |

m |

2 |

67 |

134 |

|

1.15. Air Pipes |

m |

1.2 |

54 |

65 |

|

1.16. Electro Infrastructure |

set |

600 |

1 |

600 |

|

1.17. Diesel Generator |

unit |

550 |

1 |

550 |

|

1.18. Hygienic Equipment |

set |

60 |

1 |

60 |

|

1.19. Oxymeter |

unit |

650 |

1 |

650 |

|

1.20 Concrete Canals and Filter Tanks |

m2 |

35 |

49.5 |

1,733 |

|

2. Construction |

2,700 |

|||

|

2.1. Construction of Tanks |

800 |

|||

|

2.2. Construction of Buffer Wetland |

400 |

|||

|

2.2. Plumber |

600 |

|||

|

2.3. Electrician |

900 |

|||

|

3. Logistics |

3,810 |

|||

|

3.1. Delivery of Equipment |

kg |

15 |

70 |

1,050 |

|

3.2. Transportation |

day |

80 |

1 |

80 |

|

3.3. Custom Service |

cycle |

250 |

1 |

250 |

|

3.4. Taxes |

20% |

2,430 |

||

|

Total |

25,529 |

Table 1 Cost estimate for modernization of the module

Computation of prime cost and payback

The enterprise modernization process was carried out gradually, taking into account the important socio-economic factors. One of these factors is the credit loan, which should be a value balanced between the company’s economic characteristics (turnover, revenues, costs, etc.)

Table 2 summaries both the prime cost of rainbow trout and the modernization’s payback of one of the enterprise modules. In the local market, rainbow trout fish is usually reared to the market weight of 800 grams, which was taken into account when calculating the number of seeding material. The loss due to fish mortality was estimated to be 10%, whereas in practice this percentage was somewhat lower. The tangible aspects of farm optimization, was the change of water usage operation that lowered the water consumption around 70%. Such reduction lowers the inlet water cost from 0.06 to 0.02 USD per kilogram of fish, and the outlet cost from 0.09 to 0.01 USD. However, the large scale introduction of such systems can have a significant cumulative effect.

|

|

1 year |

2 year |

||||||||||||

|

Category |

|

Comments |

Unit |

Price Per Unit USD |

No. of Units |

Traditional Production |

Modernized Production |

Traditional Production |

Modernized Production |

|||||

|

|

Total production volume (kg) |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

|||||

|

Species: Rainbow trout |

|

Table weight (gram) |

800 |

|||||||||||

|

|

1. Seeding material (5 gram fry, mortality - 10%) |

|||||||||||||

|

1.1. Traditional production |

|

80 AMD |

item |

0.17 |

11,000 |

1,872 |

0.23 |

1,872 |

0.23 |

|||||

|

1.2. Modernized production |

|

80 AMD |

item |

0.17 |

11,000 |

1,872 |

0.23 |

1,872 |

0.23 |

|||||

|

|

2. Water |

|||||||||||||

|

2.1. Inlet water |

|

1 m3 - 0.5 AMD |

m3 |

0.0011 |

439,365 |

467 |

0.06 |

140 |

0.02 |

467 |

0.06 |

140 |

0.02 |

|

|

2.2. Outlet water |

|

1 m3 - 0.75 AMD |

m3 |

0.0016 |

439,365 |

701 |

0.09 |

70 |

0.01 |

701 |

0.09 |

70 |

0.01 |

|

|

|

3. Electricity (Price per 1 kW - 41 drams) |

|||||||||||||

|

3.1. Traditional production |

|

3.41 kw/kg fish |

kW |

0.087 |

27,344 |

2,385 |

0.3 |

2,385 |

0.3 |

|||||

|

3.2. Modernized production |

|

1.5 kw/kg fish |

kW |

0.087 |

12,012 |

1,048 |

0.13 |

1,048 |

0.13 |

|||||

|

|

4. Feed (Price for 1 kg - 1050 drams) |

|||||||||||||

|

4.1. Traditional method |

|

1 kg feed - 1 kg fish |

kg |

2.23 |

8,008 |

17,890 |

2.23 |

17,890 |

2.23 |

|||||

|

4.2. Modernized method |

|

-26% |

kg |

2.23 |

5,926 |

13,239 |

1.65 |

13,239 |

1.65 |

|||||

|

|

5. Disease prevention |

|||||||||||||

|

5.1. Monthly disinfection |

|

potassium permanganate |

kg |

100 |

1 |

100 |

0.01 |

100 |

0.01 |

|||||

|

5.2. Permanent disinfection |

|

peracetic acid |

liter |

5 |

126 |

630 |

0.08 |

630 |

0.08 |

|||||

|

|

6. Personnel |

|||||||||||||

|

6.1. Full time |

|

Owner |

mon |

0 |

12 |

|||||||||

|

6.2. Part time |

|

1-2 employees |

mon |

200 |

3 |

600 |

0.07 |

600 |

0.07 |

600 |

0.07 |

600 |

0.07 |

|

|

|

7. Local transportation |

|||||||||||||

|

7.1. Feed supply |

|

4 times (per quarter) |

mon |

50 |

4 |

200 |

0.02 |

200 |

0.02 |

200 |

0.02 |

200 |

0.02 |

|

|

7.2. Fish delivery |

|

2 times (holydays) |

mon |

50 |

2 |

100 |

0.01 |

100 |

0.01 |

100 |

0.01 |

100 |

0.01 |

|

|

|

8. Loan |

|||||||||||||

|

8.1. Initial sum of loan |

|

see Table 1 |

US$ |

25,529 |

||||||||||

|

8.1. Balance of loan |

|

US$ |

|

|

25,529 |

19,147 |

||||||||

|

8.2. Loan interest |

|

14 % per year |

% |

3,574 |

0.45 |

2,681 |

0.33 |

|||||||

|

|

Total costs |

24,316 |

21,473 |

24,316 |

20,580 |

|||||||||

|

|

||||||||||||||

|

|

Consolidated prime cost per kg on types of production systems |

3.04 |

2.68 |

3.04 |

2.57 |

|||||||||

|

|

Sales |

|||||||||||||

|

|

Wholesale channel (from the total sales volume) |

100% |

Trading margin |

16% |

3.62 |

17% |

3.62 |

16% |

3.62 |

20% |

3.62 |

|||

|

|

Retail channel (from the total sales volume) |

0% |

Trading margin |

21% |

3.85 |

22% |

3.85 |

21% |

3.85 |

25% |

3.85 |

|||

|

|

Turnover |

28,989 |

28,989 |

28,989 |

28,989 |

|||||||||

|

|

Income by types of production systems |

4,673 |

7,516 |

4,673 |

8,409 |

|||||||||

|

|

Total income |

12,188 |

13,082 |

|||||||||||

|

|

Annual repayment of capital |

25% |

6,382 |

6,382 |

||||||||||

|

|

Profit before taxes |

5,806 |

6,699 |

|||||||||||

|

Taxes |

|

Fixed tax from turnover |

0% |

0 |

0 |

|||||||||

|

|

Other taxes VAT |

0% |

0 |

0 |

||||||||||

|

|

Other taxes (turnover, profit) |

0% |

0 |

0 |

||||||||||

|

|

Profit to be allocated |

5,806 |

6,699 |

|||||||||||

|

|

3 year |

4 year |

5 year |

|||||||||||

|

Category |

|

Comments |

Traditional Production |

Modernized Production |

Traditional Production |

Modernized Production |

Traditional Production |

Modernized Production |

||||||

|

|

Total production volume (kg) |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

per 1 kg |

8,008 |

per 1 kg |

8,008 |

per 1 kg |

||

|

Species: Rainbow trout |

|

Table weight (gram) |

||||||||||||

|

|

1. Seeding material (5 g fry, mort. - 10%) |

|||||||||||||

|

1.1. Traditional production |

|

80 AMD |

1,872 |

0.23 |

|

1,872 |

0.23 |

1,872 |

0.23 |

|||||

|

1.2. Modernized production |

|

80 AMD |

1,872 |

0.23 |

0.23 |

1,872 |

0.23 |

|||||||

|

|

2. Water |

|||||||||||||

|

2.1. Inlet water |

|

1 m3 - 0.5 AMD |

467 |

0.06 |

140 |

0.02 |

467 |

0.06 |

0.02 |

467 |

0.06 |

140 |

0.02 |

|

|

2.2. Outlet water |

|

1 m3 - 0.75 AMD |

701 |

0.09 |

70 |

0.01 |

701 |

0.09 |

0.01 |

701 |

0.09 |

70 |

0.01 |

|

|

|

3. Electricity (Price per 1 kW - 41 drams) |

|||||||||||||

|

3.1. Traditional production |

|

3.41 kw/kg fish |

2,385 |

0.3 |

|

2,385 |

0.3 |

2,385 |

0.3 |

|||||

|

3.2. Modernized production |

|

1.5 kw/kg fish |

1,048 |

0.13 |

0.13 |

1,048 |

0.13 |

|||||||

|

|

4. Feed (Price for 1 kg - 1050 drams) |

|||||||||||||

|

4.1. Traditional method |

|

1 kg feed - 1 kg fish |

17,890 |

2.23 |

17,890 |

2.23 |

17,890 |

2.23 |

||||||

|

4.2. Modernized method |

|

-26% |

13,239 |

1.65 |

1.65 |

13,239 |

1.65 |

|||||||

|

|

5. Disease prevention |

|||||||||||||

|

5.1. Monthly disinfection |

|

potassium permanganate |

100 |

0.01 |

100 |

0.01 |

100 |

0.01 |

||||||

|

5.2. Permanent disinfection |

|

peracetic acid |

630 |

0.08 |

0.08 |

630 |

0.08 |

|||||||

|

|

6. Personnel |

|||||||||||||

|

6.1. Full time |

|

Owner |

||||||||||||

|

6.2. Part time |

|

1-2 employees |

600 |

0.07 |

600 |

0.07 |

600 |

0.07 |

0.07 |

600 |

0.07 |

600 |

0.07 |

|

|

|

7. Local transportation |

|||||||||||||

|

7.1. Feed supply |

|

4 times (per quarter) |

200 |

0.02 |

200 |

0.02 |

200 |

0.02 |

0.02 |

200 |

0.02 |

200 |

0.02 |

|

|

7.2. Fish delivery |

|

2 times (per holydays) |

100 |

0.01 |

100 |

0.01 |

100 |

0.01 |

0.01 |

100 |

0.01 |

100 |

0.01 |

|

|

|

8. Loan |

|||||||||||||

|

8.1. Initial sum of loan |

|

see cost estimate |

||||||||||||

|

8.1. Balance of loan |

|

12,765 |

0 |

|||||||||||

|

8.2. Loan interest |

|

14 % per year |

1,787 |

0.22 |

0.11 |

0 |

0 |

|||||||

|

|

Total costs |

24,316 |

19,686 |

24,316 |

24,316 |

17,899 |

||||||||

|

|

||||||||||||||

|

|

Consolidated prime cost per kg on types of production systems |

3.04 |

|

2.46 |

3.04 |

2.35 |

3.04 |

2.24 |

||||||

|

|

Sales |

|||||||||||||

|

|

Wholesale channel (from the total sales volume) |

16% |

3.62 |

23% |

3.62 |

16% |

3.62 |

3.62 |

16% |

3.62 |

30% |

3.62 |

||

|

|

Retail channel (from the total sales volume) |

21% |

3.85 |

28% |

3.85 |

21% |

3.85 |

3.85 |

21% |

3.85 |

34% |

3.85 |

||

|

|

Turnover |

28,989 |

28,989 |

28,989 |

28,989 |

28,989 |

28,989 |

|||||||

|

|

Income by types of production systems |

4,673 |

9,303 |

4,673 |

10,196 |

4,673 |

11,090 |

|||||||

|

|

Total income |

13,975 |

14,869 |

15,762 |

||||||||||

|

|

Annual repayment of capital 25% |

6,382 |

6,382 |

0 |

||||||||||

|

|

Profit before taxes 0% |

7,593 |

8,486 |

15,762 |

||||||||||

|

|

Fixed tax from turnover 0% |

0 |

0 |

0 |

||||||||||

|

|

Other taxes VAT 0% |

0 |

0 |

0 |

||||||||||

|

|

Other taxes (turnover, profit) 0% |

0 |

0 |

0 |

||||||||||

|

|

Profit to be allocated |

7,593 |

8,486 |

15,762 |

||||||||||

Table 2 Computation of prime cost of rainbow trout farmed by conventional and modernized approaches, and payback of modernization of one of the modules of enterprise.

Another important aspect for the farm optimization was the change of the production method leading to electricity consumption reduction. According to surveys of local farmers, energy consumption, in the conventional approach, ranged from 3.39 to 3.47 kW per kg fish per year on average. Whereas according to some authors11 the intensification of production requires 1.27 kW per kg fish per year, which is achieved by means of centrifugal pump power of 0.75kW, which supplies 3107 L/min. of water and provides a necessary water flow of 10 L/sec.. The survey of the farmers in Denmark showed that the electricity needs in practice is slightly higher (about 1.5 kW per kg). Thus, as a basis for the comparative calculations, we took the survey data for both the modernized module (1.5 kW per kg), and the traditional module (3.41 kW per kg), leading to cost reduction between 0.3 to 0.13 USD per kg of fish.

Another important economic factor of the optimization is the regular management of water parameters and feeding technology. In conventional approach, local farmers calculate the daily feeding rate based on the fish size only (excluding the other related factors), water temperature was only considered in some individual cases. However, according to some studies,6,12 the fish activity and their appetite is conditioned not only by seasonal temperature variations, but also largely by the water physicochemical parameters, in particular the oxygen saturation level (at least 80%) as well as the ammonia concentration (less than 0.2 mg/l). Lack of control systems for these parameters in the business practices manual feeding method lead to a significant loss of feed in the conventional approach. Obviously, the standard operational procedures and regulation development aimed at controlling the level of oxygen and other significant water characteristics on the one hand, and the introduction of demand feeder on the other, significantly reduce the feed cost (up to 26%). In Denmark, the efficiency of demand feeder technology is confirmed by its wide spread through all trout farms with a deferent automation levels. Thus, the experimental module modernization, accompanied with the regulations controlling the oxygen level, and the demand feeder of the basic technology will lead to cost reduction per kg fish from 2.23 to 1.65 USD. Since the production intensification is inevitably associated with fish diseases so the introduction of permanent but gentle method of water disinfection as part of the technological process is a musts,13 this disinfection process will increase the costs, but the overall production increase and cost reduction per unit of production in other categories, eliminates these costs. It also leads to some inevitable changes to the enterprise management approach as well as the qualification requirements to the personnel.

Questioning of private farms on rainbow trout rearing in Denmark clearly showed that the average farm (with the water intake of 200 L/sec., power consumption 375,000 kW per year, producing 250 tons of rainbow trout of standard size) can be operated by one person. This is due to the development and implementation of standard operating procedures, rules, collection of production statistics and high personal motivation, which allow the farmer to be daily engaged in the industrial management (spending 2 to 4 hours per day) and to involve the auxiliary unqualified personnel upon necessity. Most of the small scale producers surveyed in Armenia are not engaged in active sales, they focus more on wholesalers. The Table 2 explains, to a large extent, the relatively low transportation costs. The surveys present study allowed us to estimate the price range of sales from the farm, which was ranged from 1,600 to 1,800 AMD, with the averaged value of 3.62 USD per kg. As the prices for live fish, in this segment, fluctuates between 4.68 to 6.38 USD, it will be more beneficial if to the farmers to be engaged in the retail sale on their own to increase their revenue.

As the loan balance was decreasing annually by about 25%, its annual interest value was also decreased. This reduction beside other factors helped in reducing the annual total cost from 21,473 USD in the first year to 17.89 USD in the fifth year. A quick look in table 2, one should notice that the consolidated cost per kilogram, were gradually reducing over a period of four years to reach 2.24USD. In comparing the impact of both the traditional and the modernized production approaches on the income, during each of the five years, Table 2 one can see the obvious advantage of using the modernized technique. In using such technique, the annual income was increased from 4.673 USD (using the conventional approach) to 7,516 USD in the first year (Total of 12,188 USD) reaching up to 11,090 USD by the end of the fifth year (Total of 15,762 USD). Obviously, the increased attention from the state authorities and the banking sector towards the development of incentive programs of preferential lending will contribute in the development of small scale producers. Along with this, we note that most of fish-farms of the republic, according to the decree of the RA LA-118, are not subject to tax scale, till it reaches an annual turnover of more than 100-million AMD (or 212,000 USD) then it will be subjected to VAT (Value Added Tax) which is about 20%.14

The potential target group of enterprises is encountered with no less than 100 farms, with individual performance exceeding 10 tones. However, the success of such approach will largely depend on its popularization, which requires the implementation of a pilot project, which will encourage the small scale producers. Choosing the enterprise of average production which has minimum necessary infrastructure and motivation to increase the current production, as a model, will create a favorable atmosphere for the implementation of pilot initiative. To accelerate the process, it will be much more convenient for farmers to be informed about the equipment’s’ suppliers, delivery times, construction and installation dates, seasonal and technical aspects of the RAS, the growth rate, the stocking density, and the fish mortality rate, etc.. Such information, will allow the farmers to get acquainted with their available options to take the best choices for their favor. Along with this, the development of specialized educational trainings aimed at improving the farmer’s skills and personnel management of fish-farms will further motivate the benefit of switching to a modern production mode.

Modernization, use of resources, ecological benefits

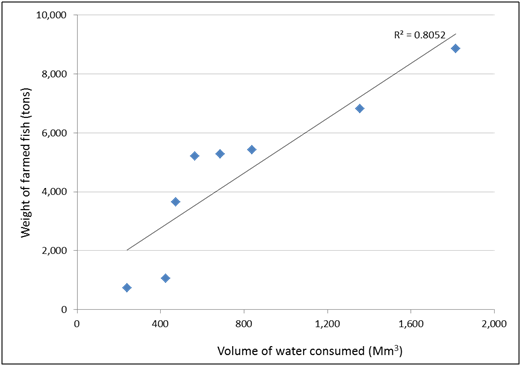

Figure 3 revealed that the Armenian fish production from the aquaculture sector increases with the increase in water consumption. Unfortunately, there was no official statistical data available for the annual artesian water consumption (either for total or aquaculture aspect). However, according to the available literature, the total annual artesian water consumption was found to be ranging between 2,021 Mm3/year in 198515 and 1,624Mm3/year16 in 1983. The USAID report,17 monitoring the intake artesian water for both 2007 and 2013, indicated that the total annual artesian water consumption were more or less that same (Figure 4) while the share of artesian water used in the aquaculture sector was increased to from400.6 Mm3/year in 2007 to 1119.4 Mm3/year in 2013 (Figure 4).

Figure 3 Interrelation between fish production and use of water.3

In our present study, the module that produces about two tons of trout in the conventional way consumed about 440,000 m3 of water, while its modernization can reduce this amount by 70%, saving more than 300,000 m3 of water per year. Thus, based on a single enterprise, with production capacity of about 10 tons of trout will save around 1.5 Mm3/year. In other words it will not only result in obvious economic effect of resource use, but also generate significant environmental benefits in the future. In addition, as mentioned earlier, to the gentle, permanent disinfection method,13,18 thereby reducing the pollution of freshwater ecosystems.

Efficiency and sustainability of the above mentioned systems, does not cause a reasonable doubt, as proved by many years of statistics and a number of countries. One can say that the introduction of the modern approaches will help in improving of the welfare of small scale producers and local communities and establishing new level of resources usage in the country.

None.

None.

©2015 Khanamirian, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.