Journal of

eISSN: 2378-3184

Technical Notes Volume 10 Issue 5

1University of Carthage, Higher Institute of Fisheries and Aquaculture of Bizerte, Exploitation of Aquatic Environments, Tunisia

2Technical Center of Aquaculture, Tunisia

Correspondence: Sami MILI, University of Carthage, Higher Institute of Fisheries and Aquaculture of Bizerte, Department: Exploitation of Aquatic Environments, Tunisia

Received: August 20, 2021 | Published: October 29, 2021

Citation: Mili S, Ennouri R, Fatnassi M, et al. Technical notes on structures of small-scale freshwater fish farming in Tunisia. J Aquac Mar Biol. 2021;10(5):218-223. DOI: 10.15406/jamb.2021.10.00324

In this study, we present the technical characteristics and the methods applied for fashioning different types of cages used in the aquaculture of Nile tilapia. This study was based on experiments made in geothermal water and fresh water reservoirs in Tunisia. The structures showed high efficiency in small-scale freshwater fish farming. The results of the growth of tilapia fry, reared in the two areas, showed a wide variation. However, with regards to cages’ effect on its behavior and growth rate, a negligible influence was noted. In fact, after the pre-growth phase of the fry in cages in geothermal waters during 35 days, we obtained a daily growth rate (DGR) of 0.41g/day and a specific growth rate of 7.11%/day. These changes are superior to those found in freshwater cages whose DGR was around 0.18g/day and specific growth rate (5.98%/day). Besides, the grow-out trials carried out in the SidiSaad, Ghezala and Lahma Reservoirs have given encouraging results with respective densities of 75 P/m3, 77 P/m3 and 61 P/m3. The use of 2m3 and 3m3 cages, which are relatively of low cost, showed high efficiency during their handling, such as good shape retention in water and especially low mesh clogging.

According to the results of the present study, it is recommend the use of cages with a volume of 50m3 above the water surface in order to prevent fish jumping out of the cage, also the assembly of the cages for pre-growth and the grow-out must be carried out within the same reservoir in order to minimize the production costs.

Keywords: nile tilapia, structures, cages, freshwater, fish farming

AMBISEPT, application de nouveaux modèles bio-socioéconomiques pour l'exploitation piscicole dans les barrages tunisiens; CR, conversion rate; DGR, daily growth rate; INAT, institut national agronomique de tunisie; ind, individual; IRESA, institution of agricultural research and higher education; ISPAB, higher institute of fisheries and aquaculture of bizerte; PA, polyamide; PE, polyethylene; PVC, polyvinyl chloride;TCA, technical centre of aquaculture

Tunisia, a country, particularly interested in the development of its aquaculture, has put in place a strategy to develop its freshwater resources.1 In addition to the reservoirs, the main system of extensive fish breeding in the geothermal waters of southern Tunisia are now exploited for the intensive breeding of Nile tilapia Oreochromis niloticus.2 This species represents a group of fish whose biological and ecological characteristics are very interesting from a piscicultural point of view. Some authors characterize it as a fish of excellence for intensive aquaculture.3,4 Indeed, O. niloticus has a wide ecological valence, a good adaptability to all farming systems, a spawning period spread over the whole year and a high growth rate.5 In Tunisia, tilapia was first introduced in 1966, in the Kebili Oasis where its survival and reproduction were observed.6,7 The idea of tilapia aquaculture was put into practice, following the creation of an experimental research station in geothermal fish farming in 1999 by the INSTM in Bechima (Gabes). The success and mastery of the rearing of this species in the geothermal waters of southern Tunisia,8 as well as a success of its grow-out in floating cages in SidiSaad Reservoir in central Tunisia have been noted.9 However, most of the production of tilapia in Tunisian reservoirs is located in Lakhmes (Siliana), Lebna (Nabeul) and SidiSaad (Kairouan) with a very low production compared to other freshwater fish (5.428 Tonnes against 1034.035 for the rest of species).10 In this situation, an alternative is to encourage fish farming actions in agricultural development projects or small-scale farming for young investors. Rearing of the Nile tilapia by separate age classes consists of carrying out rearing and grow-out in different spaces. This can be done in two different ways depending on the environment: in a place destined for the reproduction and the production of fry up to 30g with a different place for the grow-out; and the second one is reserved only for the reproduction with a different place for the pre-grow-out of fry up to 15 to 20g, and a third space for the grow-out. Cage culture allows an intensive exploitation of the water system at a relatively low cost. The advantages of this type of aquaculture are numerous, especially when the means of implementation are affordable. The anarchic reproduction and the overpopulation of tilapia can be controlled in an effective and advantageous way by cage culture.11 Indeed, this technique allows to inhibit the reproductive behavior and to reduce the number of eggs that are lost through the mesh. The use of different types of cages is essential to contribute to the success of the rearing of this species. Floating cages are the most common type of cage used for tilapia rearing, but submerged or bottom cages can also be used.

The present study consists in a presentation of the different techniques of breeding adopted in Tunisian fish farming through the use of different types of cages for the pre-growth and grow-out of tilapia in geothermal water and in reservoir dams. The choice of the cage model is an essential step in the process of design and operation in aquaculture. This choice is based on economic (low cost) and technical criteria, taking into account the requirements of the species to be reared.

Fish cages vary in size and shape. Rectangular, square or circular shapes are the most used in Tunisian waters. These cages can be either floating or fixed. Smaller cages provide excellent water renewal rate but they are generally expensive to make (Table 1).

|

Dimensions |

V (m3) |

SL : V (m2 : m3) |

Renewal rates (%) |

|

1 x 1 x 1 |

1 |

4 : 1 |

100 |

|

2 x 2 x 1 |

4 |

2 : 1 |

50 |

|

2 x 4 x 1 |

8 |

1.5 : 1 |

38 (25 – 50) |

|

4 x 4 x 2 |

32 |

1 : 1 |

25 |

|

7 x 7 x 2 |

98 |

0.57 : 1 |

14 |

|

6 x 11 x 2 |

132 |

0.52 : 1 |

13 (9 – 17) |

|

13 x 13 x 2 |

338 |

0.31 : 1 |

8 |

|

11 x 11 x 3 |

363 |

0.36: 1 |

9 |

Table 1 Variability of the renewal rate according to the volume of the cage6

Methodology and implementation

The methodology adopted for conception and mounting of all types of cages and for the different rearing phases is summarized in Figure 1.The pre-growth experiment started with the collection of fries of 1 to 2g. This fry was transferred to floating cages with a unit volume of 3m3 placed in large geothermal water basins or to cages with a unit volume of 2m3 placed in reservoirs. Whatever the site is, pre-growth started with fry of 1 to 2g and was completed when they become juveniles of 10 to 15 g. The pre-growth phase took place at rearing densities of 500fry/m3. The recommended grow-out density for tilapia fry depended on the water quality of the holding tank, the volume of the cage, the desired size, the production volume and the duration of the grow-out.

The minimum weight expected for the growth of fry was15g. In practice, the grow-out phase was ended with a weight of 200g. This size was retained by a 12mm mesh. The number of fries estimated for the start of the project wasaround 90,000 fries. The grow-out cycle in the reservoirs was estimated at 6 months.

Structures adopted for pre-growth

The two models of structures chosen for the pre-growth phase were differed in their materials, external assembly (shapes), dimensions (volume), as well as in their place of installation. Thus, the rectangular shape of 2m3 and the cubic shape of 3m3 for the cages were chosen in order to facilitate the handling and transport of fry and to minimize the costs. The cages used had different structures and volumes. The difference appeared in the type of cut, the dimension of the net pieces as well as in the method of assembly and ballasting. For the preparation of the cages for freshwater rearing, we adopted the plan as shown in Figure 2.The necessary materials needed to make the two types of cages are summarized in Table 2,Table 3 summarized the different stages of the construction of the 2 types of cages.The buoyancy of the cages used in geothermal water was ensured through the installation of PVC tubes at the level of the upper faces of these cages. A total of 4 tubes of 1.50m length and 7.5cm diameter were used for each cage. These were connected by elbows to obtain a square structure on which the upper part of the cage will be fixed (Figure 3A).

Materials |

Braided net of 6mm mesh in polyamide. This net is cut to make the base and side pieces; |

Polyethylene (PE) reinforcement rope of 6mm diameter; |

|

Lead rope for the lower luff tape in PE with a diameter of 6mm; |

|

Mounting wire in polyamide 210/36; |

|

Lead for ballast with a unit weight of 100g; |

|

PVC pipes with a length of 1.60 m and a diameter of 10 cm; |

|

Structure in galvanized iron. |

Table 2 The materials required to make the two cages of 3m3 and 2m3 volume

|

|

Cage of a 3m3 volume |

Cage of a 2m3 volume |

||

|

Dimensions |

- 1.50m of length - 1.50m of width - 1.70m of depth with 1.5m submerged - Volume of 3m³ with a useful volume of 2.5m³ |

-2m of length - 1m of width - Volume of 2m³ with a useful volume of 1.5m³

|

||

|

Step 1 |

Cutting the side and bottom pieces of 6 mm mesh net with the following dimensions: - Side pieces: length 1.70m and width 1.50m - Bottom piece: length 1.50m and width 1.50m |

Cutting parts from a 6mm mesh net with the following dimensions Large piece: - Length 2m - Width 1m Small piece: length 1m and width 1m |

||

|

Step 2 |

The side and bottom pieces are assembled with a 2.5m long reinforcing rope. The four parts of the cage are assembled mesh by mesh with the bottom until a cubic shape is obtained. |

The parts are assembled with a 2.5m long reinforcing rope. The assembly is made mesh by mesh with pieces of the enclosure between them. |

||

|

Step 3 |

The reinforcement ropes are attached to the parts with a needle and polyamide threads with a diameter of 10mm. |

|||

|

Step 4 |

Making splices and fixing them by means of shuttles and polyamide wires. |

|||

|

Step 5 |

The ballasting step consists in weighing down the cage by adding 2kg of lead. This operation follows the preparation of the 4 lower selvedges, each comprising 5 pieces of lead with an average weight of 100g. Once ready, the bolts will be fixed on the bottom piece. |

|||

Table 3 Steps for the construction of cages used in Tunisian freshwater fish farming

Figure 3 Attaching the net to the PVC structures of the pond cage (A) and cages (2m3) mounted on a galvanized iron structure used in reservoirs (B).

For the cages used in the reservoirs, the net was mounted on a structure made of galvanized iron tubes (8 tubes of 1m length and 4 tubes of 2m) which were connected at each corner. This operation was followed by the hanging of the reinforcement ropes at the corners of each cage. The assembly of the nets on the structure was carried out by braided wire of diameter 1.5. A small opening was made in the upper side to facilitate the handling of the fry. Compared to the cages for ponds, those intended for pre-growth in reservoirs were mounted directly on galvanized iron structures (without the addition of ballast or floats) (Figure 3B).

The cages for geothermal rearing were attached and aligned by ropes within the grow-out tank (Figure 4A). The cages used in reservoirs were attached two by two with ropes and set in the middle of the reservoir at about 6m from the shore. To make handling easy, a 30cm of net was left untangled. The space between the underside of the net and the iron structure was kept to allow for better water circulation and to minimize pollution from farm wastes (Figure 4B).

Adopted frames for grow-out

In Tunisia, two types of structures have been tried. The first one was used in SidiSaad Reservoir (in 2004) during the development project of freshwater fish farming in Tunisia1. The technical characteristics of the cages were summarized in Table 4.The technical characteristics of the materials used to construct the cages used in the grow-out phase were described below:

- Square mesh (Ø=2mm): 12mm and 20mm

- Bottom of the cage: length and width: 5m

- Sides’ length: 3m and width: 5m

- Assembly thread for seams and joints in PA (Ø=1.5 and 2000m/kg)

- Reinforcement ropes in braided PA (Ø =10mm and 6mm)

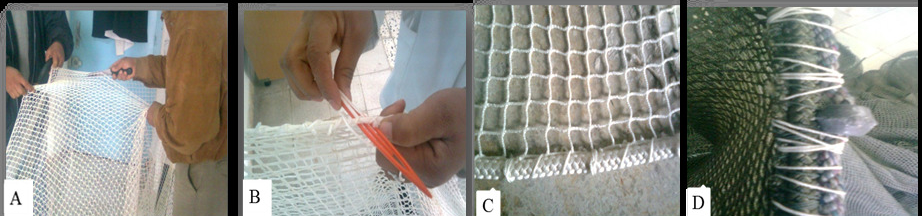

The steps below were followed during the cage assembly (Figure 5)

|

SidiSaad Reservoir13 |

Lahma and Ghezala Resservoirs |

|

|

Platform |

Rectangular frame in rosemary white wood offering a useful surface of 12.25m2.

|

Stainless steel plates with a useful surface of 11.25m2.

|

|

Floating |

Barrels of 200 l, PVC, Polystyrene. |

Barrels of 200 l. |

|

Net |

Polyamide (PA) net with a mesh size of 16mm and a useful drop of 3.5m ending with a conical pocket. |

Braided net in PA with 12mm and 20mm braided mesh (wire diameter 2) offering a useful unit volume of 50m3 (5*5*2.5m) |

Table 4 Technical characteristics of the cages used for the grow-out stage

Figure 5 Cross-section (A), assembly of the nets (B), Attachment of the reinforcement ropes (C) and Ballasting of the lower bolt rope (D).

The first step consisted in cutting pieces of net. To obtain the square meshes, we proceeded with the T-cut method. The bottom of the cage was square with a length and a width of 5m; while the sides of the cages had a length of 3m and a width of 5m. Subsequently, the sides were first sewn together with the bottom, and then the sides of the cage were assembled to obtain the square shape (Figure 5A-B).The next step consisted in fixing the reinforcement ropes of20m long at the horizontal edges of each layer. The material used was PA rope with a diameter of 10mm. The 6mm diameter ropes were mounted in the direction of the fall of the cage (Figure 5C).The ballasting consisted in fixing of 80 lead olives (100g) on each lower bolt rope which had the following dimensions of length: 20m; diameter: 8 mm and the interval between the lead olives: 25cm (Figure 5D). The last step consisted in fixing two ropes, one with a diameter of 4mm for the 12mm mesh cage and the other with a diameter of 6mm for the 20mm mesh cage to facilitate their handling in the water.

The feed used in our experiment is composed of raw materials available on the local market which weremixed in varying proportions depending on the tilapia breeding development stage14(Table 5).

|

Ingredient (%) |

Genitors |

Larvae |

Fry |

Adults |

|

Soybean meal |

41 |

45 |

50 |

43 |

|

Fishmeal |

14 |

25 |

20 |

14 |

|

Mealies |

35 |

20 |

20 |

35 |

|

Vegetable oil |

8 |

8 |

8 |

6 |

|

Vitamin-Mineral Supplement |

2 |

2 |

2 |

2 |

|

Total protein level |

20 |

40 |

30 |

20 |

Table 5 Food composition of Tilapia according to the breeding cycles3

The zoo technical parameters obtained for the fry at the pre-growth stage within the cages placed in the geothermal water are reported in the table 6. The average weight increased from 1.30g to 15.70g in 35 days, i.e. a daily growth rate of 0.41 g/day and a specific growth rate of 7.11%/day were noted. The gain in biomass recorded was obtained following the distribution of 18806.85 g of feed, which lead to a conversion rate of 0.88 (Table 6).According to the collected samples from the cages placed in the reservoir water, we found that after 22 days, even though the initial average weight in the cage was1.50 g, the conversion rate (1.60) and the specific growth rate (5.98%/day) were widely different from those of the cages which were located in the geothermal water.

|

Breeding parameters |

Geothermal water |

Reservoir water |

|

Rearing time (days) |

35.00 |

22.00 |

|

Initial number |

1500.00 |

1500.00 |

|

Final number |

1494.00 |

1500.00 |

|

Mortalities |

6.00 |

0.00 |

|

Survival rate (%) |

99.46 |

100.00 |

|

Initial average weight (g) |

1.30 |

1.50 |

|

Final average weight (g) |

15.70 |

5.67 |

|

Initial biomass (g) |

1950.00 |

2272.50 |

|

Final biomass (g) |

23455.80 |

8512.50 |

|

Quantity of distributed food (g) |

18806.85 |

10000.00 |

|

Daily growth rate (g/day) |

0.41 |

0.18 |

|

Specific growth rate (% / day) |

7.11 |

5.98 |

|

Conversion rate (CR) |

0.88 |

1.60 |

Table 6 Zootechnical parameters of the fry in the two sites

In the grow-out trials, it was observed that tilapia reached from an initial size of 20g to a final size of 250g in the floating cages placed in the reservoirs for a period of 6 months (average density of 75ind/m3) (Table 7). The survival and growth rates of the grow-out tilapia at the end of the experiment were obtained to be more than 95%and 1.51 g, and the feed conversion rate was found to be 1.80, while the tilapia were supplemented with a feed composed of 28.64% protein.

|

|

Reservoir Ghezala |

Reservoir Lahma |

Reservoir Sidi Saad13 |

|

Initial weight (g) |

27.42 |

16.28 |

18.07 |

|

Initial density (ind/m3) |

76.80 |

77.00 |

75.00 |

|

Final Weight (g) |

204.49 |

238.00 |

169.62 |

|

Survival rate |

99.50 |

99.00 |

96.60 |

|

Final density (g/m3) |

12.45 |

18.27 |

12.30 |

|

Daily growth rate (g) |

1.51 |

1.69 |

2.02 |

|

Food conversion rate |

1.80 |

1.84 |

2.40 |

Table 7 Zootechnical parameters of reared fishes in the three reservoirs

The Nile tilapia (Oreochromisniloticus) was the first exotic species raised for aquaculture in Tunisian geothermal waters. The remarkable adaptation and the very encouraging results of the breeding of this species have encouraged the private sector to invest in this activity. Currently 6 farms, which perform semi-intensive breeding of this species, are operational.15 In addition, there is an exploitable water potential at the level of the reservoirs that present a favorable temperature for the rearing of tilapia during most of the year. This potential has made it possible to carry out the pre-growth of fry in floating cages during the winter period in geothermal waters. Besides, the grow-out trials carried out in the SidiSaad, Lahma and Ghezala Reservoirs during the summer period of the years 2004,13 20106 and 201216 have given encouraging results with respective densities of 75 P/m3, 77 P/m3 and 61 P/m3. The use of 2m3 and 3m3 cages, which are relatively of low cost, showed high efficiency during their handling, such as good shape retention in water and especially low mesh clogging. The last study, dated 2017,17,18 showed that the results of the pre-growth phase in cages placed in the grow-out pond in Bechima and in cages in the Smati Reservoir are encouraging.

Cage rearing of tilapia offers several advantages such as, the inhibition of reproduction by using a sufficiently wide mesh at the level of these cages; the avoidance of problems related to recruitment which is at the origin of the growth delay observed during tank rearing; a low initial investment compared to tank rearing; easy and low-cost harvesting; and a high stocking density and the absence of land concessions. On the other hand, this technique has major disadvantages that cannot be overlooked, namely the need for specialized labor for feeding, control and maintenance of the cages; a relatively short life span for these cages; a rearing period limited to 6 months in the reservoirs; and the risk of anoxia associated with the drop in temperature during the night at the beginning and end of the rearing cycle (during the months of May and October). Finally, we can conclude on the basis of the results of previous experiments carried out in Tunisian dams, the following recommendations that should be considered:

- Collapse due to the winds which can be violent during the breeding season.

- The difficulty of treating fish in large cages (surveillance fish health, monitoring growth, securing fishing nets, partial fishing, etc.)

- The low water renewal rate inside the large cages caused by the limited water renewal in the dams during the rearing period.

The author declares that there are no conflicts of interest.

The Institution of Agricultural Research and Higher Education (IRESA) has provided financial support for the research project with impact (AMBISEPT) from which this paper emerged.

The authors thank the (IRESA) for the financial support; they thank too, all the staff of Technical center of Aquaculture (Tunisia) and the General Directorate of Fisheries and Aquaculture (Tunisia) and students from ISPA Bizerte for their efforts on the practical part of this work.

©2021 Mili, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.