eISSN: 2379-6367

Research Article Volume 11 Issue 1

1Department of Pharmacology and Traditional Medicine, Faculty of Medicine and Biomedical Sciences, University of Yaoundé I, Cameroon

2National Drug Quality Control and Valuation Laboratory, Cameroon

3Department of Pharmacotoxicology and Pharmacokinetics, Faculty of Medicine and Biomedical Sciences, University of Yaoundé I, Cameroon

4Department of Pharmaceutical Sciences, Faculty of Medicine and Pharmaceutical Sciences, University of Douala, Cameroon

Correspondence: Ngono Mballa Rose, Department of Pharmacology and Traditional Medicine, Faculty of Medicine and Biomedical Sciences, University of Yaoundé I, Cameroon

Received: February 12, 2023 | Published: March 7, 2023

Citation: Rose NM, Yves T, Lauraine TJ, et al. Knowledge, attitudes and practices of screen printers on toxic risks related to their profession in Yaoundé (Cameroon). Pharm Pharmacol Int J. 2023;11(1):36-42. DOI: 10.15406/ppij.2023.11.00399

Manual screen printing is a growing printing market in Cameroon. This activity presents risks due to the substances to which workers are exposed. The low level of information on the toxicological risks to which screen-printing workers are exposed hides the dangers. This study was conducted to assess the level of knowledge, attitudes and practices of the participants on the risks associated with the products used, via a cross-sectional descriptive study approved by the Institutional Ethics and Research Committee of the Faculty of Medicine and Biomedical Sciences of the University of Yaoundé 1. To achieve this objective, the study was conducted in 91 screen-printing workshops, where a total of 118 participants answered all questions on a form. The survey phase consisted of a questionnaire administered to each screen printer. Assessment of screen printers' knowledge, attitudes, and practices regarding the toxic hazards inherent in screen printing revealed that 13% of employees had a good level of knowledge, 9% had correct attitudes, and 28% had adequate practices. This suggests that there is a significant need for preventive measures, including health education program for screen printers and ongoing research into the toxic effects of screen printing to reduce risk to its lowest level and to promote public health in the population.

Keywords: screen printers, knowledge, attitudes, practices, toxic risks, Cameroon

Scientific and technological development is associated with a significant increase in the number of various chemicals in circulation, and consequently with an increase in the number of people exposed, especially in the workplace.1-3 For example, the main printing processes used today involve multiple inks and chemicals, which can be toxic or even carcinogenic.4-6 In Cameroon, the printing market is currently expanding rapidly.7 Working in this field implies not only a mastery of processes but also permanent contact with various potentially dangerous substances. Indeed, working in the printing and graphic industry exposes practitioners to several specific risks, including those of a chemical, mechanical, visual and psychological nature.6,8 For example, a study conducted in Pakistan on occupational exposure to cleaning solvents among workers in screen printing units found that memory loss was the main manifestation among these workers and that the percentage of patients suffering from this disorder reached 72%. Other common complaints included high blood pressure (47%), depression (53%), dizziness (55%), dry skin (49%), headache (56%), occupational fatigue (49%), sore throat (30%), and visual disturbances (38%).9 The objective of this study is to evaluate the knowledge, attitudes and practices of screen printers in the city of Yaoundé (Cameroon) on the risks related to their profession.

Type and framework of the study

Our study took place in different screen-printing workshops in the city of Yaoundé in the Cameroon department of Mfoundi, Center Region. The climate here is sub-equatorial with 2 dry seasons alternating with 2 rainy seasons. With an area of approximately 187 km2, it has a population of approximately 4,100,000 inhabitants in 2019 according to the National Institute of Cartography (INC).10

Study duration

The study ran from December 18, 2019 to August 13, 2020. The duration of the study which corresponds to the time period dedicated to data collection, was from January 31 to June 30, 2020.

Sampling

The target population was employees of screen-printing units located in the city of Yaoundé who were familiar with the use of inks, thinners and additives in their daily work. The location of the printing workshops was possible through their identification label.

The recruitment of screen printers was done within the selected screen-printing structures. We presented our study and its objectives to the participants targeted above in order to obtain their consent. Only those who gave their written consent were included in the study and were subjected to the questionnaire.

For this purpose, any screen printer who met the criteria listed above was involved in the study. Non-probability consecutive and non-exhaustive sampling combined with network sampling (snowballing) was performed to select the people working in the screen-printing units. In total, 91 screen printing shops were visited and 118 actors were interviewed. The exclusion criteria were mainly based on age, in fact any participant under 18 years old was excluded.

Procedure

To conduct our study, a data collection form was designed for this purpose and was administered to the participants. This data collection consisted of a question-and-answer session with each screen printer, in a suitable room, in order to foster a climate of confidentiality.

More specifically,

Data analysis

After entering the collected data into the CSPro version 7.3 software, a data processing phase was carried out. The analysis of the data was done using the IBM SPSS statistics software version 23.0. First of all, the descriptive analysis of the data was carried out. For variables with a normal distribution, the mean and standard deviation were the two parameters calculated. In the opposite case, the median and the interquartile range were calculated.

The CAP survey data analysis framework was used to assess screen printers' knowledge, attitudes and practices based on a well-defined method by Essi MJ et al.11 Thus, after assigning points to each question, we made an overall evaluation of each of these parameters. The level of knowledge was quantified and reported in 4 levels (poor, insufficient, average and good). Thus, the level of knowledge was considered poor if the score ≤ 50, insufficient if the score = [50-65], average if the score = [66-85], good if the score ≥ 85. Similarly, the level of attitudes was provided and qualified as bad, wrong, approximate, and good. The quality of attitudes would be bad if the score ≤ 50, wrong if the score = [51-65], approximate if the score = [66-85], good if the score ≥ 86. Following the same logic, the level of practices was quantified and rendered in the modalities wrong, inadequate, and adequate; practice quality was poor if score ≤ 50, inadequate if score = [51-65], adequate if score ≥ 66.11

Characteristics of the study population

A total of 91 screen printing shops were visited. The majority 82% of these shops were one-man businesses. All these screen-printing units were mainly located in four districts of Yaoundé 1, 2, 4 and 6. One hundred and twenty-nine (129) screen printers were surveyed, but only 118 screen printers (91.47%) were included in the statistical analyses. Men represented 95.76% of our sample and women 4.24%, for a sex ratio of 22.60. The average age of a screen printer in the city of Yaoundé was 35.33 years (with a minimum of 21, a maximum of 64 and a standard deviation of 10.13).

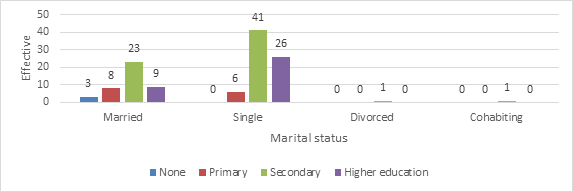

The bar chart below illustrates the distribution of the study population according to education level and marital status (Figure 1).

Figure 1 Level of education by marital status of the study population.

Source: Junie Lauraine TN. Risques toxicologiques chez les travailleurs de sérigraphie dans la ville de Yaoundé. Thèse Doctorat en Pharmacie, FMSB/Université de Yaoundé 1, Cameroun; 2020.

The distribution of our population according to the level of study revealed that 66 (55.9%) participants had not gone beyond secondary education, followed by the group of those who had access to higher education with a total of 35 (29.7%) attendees. Regarding marital status, 73 (61.9%) participants were single and 43 (36.4%) were married.

Smoking and alcoholism

In our study population 88 (74.6%) consumed alcohol with an average of 6.22 ± 7.024 bottles of beer per week. In addition, 11 (9.3%) of them consumed tobacco with an average of 6 ± 5,604 sticks per day.

Knowledge of the danger

Several questions were asked to the study population in order to assess their knowledge of the dangers associated with their profession. Regarding knowledge of the dangers associated with exposure, 114 screen printers (96.6%) knew that they were exposing themselves to risks. Among them, 100 (84.7%) were not worried about these risks and 39 (33.1%) claimed to know the composition of the products they handled.

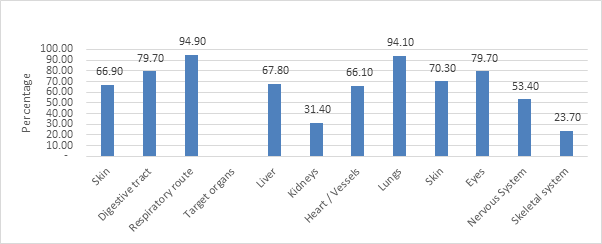

The assessment of the participants' knowledge of the different exposure routes and target organs provided the results presented in Figure 2. According to 112 reports, the main route of exposure to screen printing products was the respiratory route with a rate of 94.9%. 94 reported the digestive tract with a rate of 79.7%, while 79 reported the cutaneous route with a percentage of 66.9%. In addition, the target organs according to the screen printers were lungs, eyes and skin with 94.1% (111), 79.7% (94) and 70.3% (83) respectively.

Figure 2 Knowledge of the different exposure routes and target organs.

Source: Junie Lauraine TN. Risques toxicologiques chez les travailleurs de sérigraphie dans la ville de Yaoundé. Thèse Doctorat en Pharmacie, FMSB/Université de Yaoundé 1, Cameroun; 2020.

Several channels, as shown in Table 1, have helped screen printers to become aware of the risks associated with their profession. The ways which provided them information about dangers related to their area of activity, in ascending order, were: medical personnel 7.6% (9), media 10.2% (12), colleagues 35.6% (42), trainer/employer 38.1% (45), the screen printer himself 44.1% (52).

Methods of knowing the risks related to the hazards |

Number of persons (n) |

Percentage (%) |

Colleague |

42 |

35.6 |

Media |

12 |

10.2 |

Trainer/employer |

45 |

38.1 |

Medical staff |

9 |

7.6 |

Self |

52 |

44.1 |

Table 1 Methods of hazard risk knowledge 5 (n=118)

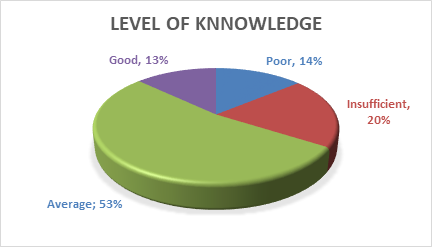

All these data were used to calculate the level of knowledge of the participants by summing up the scores assigned to each question. According to the evaluation grid defined in the methodology, the results presented in the pie chart were obtained. Only 13% of screen printers had good knowledge of the toxic risks that exist in screen printing (Figure 3).

Figure 3 Diagram to determine the level of knowledge of screen printers regarding toxic risks in screen printing.

Attitudes of participants regarding the handling of inks, thinners and additives

Attitudes recommended by screen printers and relating to the handling of inks, thinners and additives was searched.

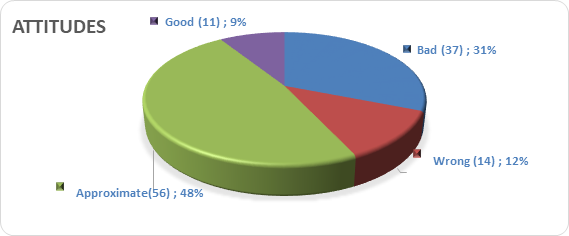

The majority of participants thought that it was necessary to bring protective equipment when handling these various substances. These were the mask 95.8% (113), gloves 88.1% (104) and 86.4% (102) found Personal protective equipment useful. In addition, most of the participants 66.9% (79) admitted that they did not sufficiently control the risks within the screen-printing workshops. By grouping these data, an overall evaluation of the attitudes of screen printers was made, by summing the scores assigned to each question (Figure 4). The determination of the level of attitudes showed that 48% had approximate attitudes and 9% with good attitudes.

Figure 4 Diagram for determining the level of screen printers' attitudes regarding toxic risks in screen printing.

Participants' practices regarding the handling of inks, thinners and additives

The screen print shops were 80.5% ventilated (windows and doors open), for a total of 95 out of 118. We also noted that 99.2% (117) screen printers worked without an air exhaust system. 25.4% of them worked with open containers when available, as products were generally stored in plastic bags: 49.2%.

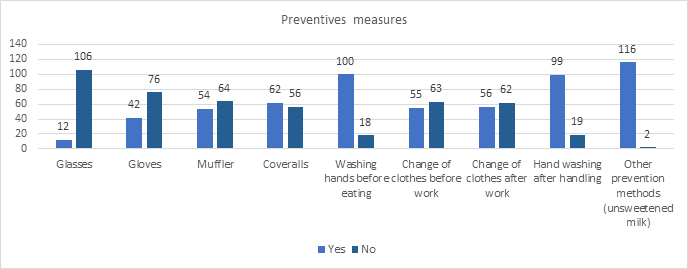

Several preventive measures related to the risks present in workshops were recommended by the screen printers. They are listed in the bar chart in Figure 5. The wearing of glasses, gloves, face masks and protective suits were respectively effective at 10.2%, 35.6%, 45.8%, 52.5%. The consumption of unsweetened milk among the participants was a regular practice with a percentage of 98.3% for 116 ones (Figure 5).

Figure 5 Assessment of hygiene and wearing of protective equipment.

Source: Junie Lauraine TN. Risques toxicologiques chez les travailleurs de sérigraphie dans la ville de Yaoundé. Thèse Doctorat en Pharmacie, FMSB/Université de Yaoundé 1, Cameroun; 2020.

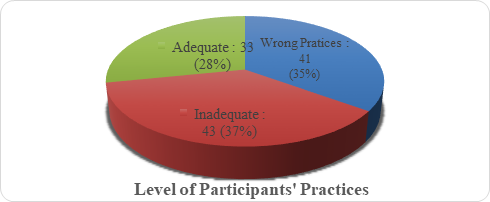

By aggregating the data on risk prevention measures and product use patterns, we were able to make an overall assessment of participants' practices by summing the scores for each question (Figure 6).

Figure 6 Diagram for Determining the Level of Participants' Practices Related to Toxic Risks in Screen Printing.

The diagram in figure 6 illustrates the determination of the level of the participants' practices. It shows that 28% of screen printers had adequate practices, inadequate practices were found in 37% of participants, against a percentage of 35% for those who had wrong practices.

We looked for the relationship between knowledge/attitudes and practices. But statistical tests revealed no significant association between these parameters (Table 2).

Variables |

Practices |

OR (IC à 95 %) |

P Value |

|

Good % (n) |

Bad % (n) |

|||

Good knowledge |

33.3 (10) |

66.7 (20) |

1.41 (0.68-2.36) |

0.4 |

Poor knowledge |

26.1 (23) |

73.9 (65) |

||

Good attitudes |

35.1 (20) |

64.9 (37) |

1.64 (0.88-4.52) |

0.09 |

Poor attitudes |

21.3 (13) |

78.7 (48) |

||

Table 2 Relationship between knowledge/attitudes and practices

Despite the fact that manual screen printing is a growing market in Cameroon, many questions remain unexplored regarding the toxicological risks to which screen printers are exposed. This lack of information turned out to be a problem that motivated the present study.

Concerning the characteristics of the population in our study, among 118 people included in the study, (95.76%) 113 were men and 5 (4.23%) women; this result is close to those obtained by Paramasivam P et al.,20 who obtained a majority of men workers 93% and the rest 7% for women. These are different in the study conducted by Shankar et al.,12 who obtained a percentage of 54.8% for the male sex and 45.2% for the female sex. This difference can be explained by the fact that in the Cameroonian context, certain professions like screen printing, are still not accessible to women.

The age range varied from 21 to 64 years and the average age was 35.33 ± 10.13; these results are similar to those of Shankar et al.,12 in 2017 at India and Vouriot et al.,13 at 2005 in France, who respectively obtained an age group of 20 to 60 years, with an average of 35.08 ± 5.85 for the former and an average of 34.5 for the latter.

Moreover, 73 (61.9%) participants were single and 43 (36.4%) were married: this could be explained by the fact that screen printing is not yet perceived as a profession in which one could make a career, but rather as an informal sector profession which thus becomes an option for young single people in search of incomes to survive.

The analysis of the level of study revealed that 66 (55.9%) serigraphs were limited to secondary studies, followed by the group of those who had access to higher education as 35 (29.7%). Those who were limited to primary studies were 11.9% as were 14 people. These results differ from those obtained by Yu et al.,14 in 2005 in China. They obtained respectively 25.2% for the primary level and 30.6% for the secondary. This difference could be explained by the fact that the city of Yaoundé is an urban area, which exactly reflects the distribution of pupils and students by level of education in the center region according to the Cameroon National Institute of Statistics, in 200515 and the Central Bureau of Censuses and Population Studies in 201016 This distribution would therefore be different from that observed in China where the comparative study was conducted.

We also found that 88 participants (74.6%) consumed alcohol and 11 (9.3%) consumed tobacco; seven of them (5.9%) were former tobacco users, and six (5.1%) were former alcohol users. These results differ from those obtained by Yu et al.,14 in 2005 in China. Indeed, they had obtained percentages of 42.5% for active smokers, 9.2% of former smokers, 10% for alcohol consumers and 2.4% for alcohol former consumers. This difference could be explained by the fact that, due to cultural values, these two populations have widely different prevalence in terms of alcohol consumption and smoking as described by the WHO.18,19

The screen printing workshops were 80.5% ventilated although narrow, it was also noted that 117 (99.2%) screen printers worked without an air evacuation system. This result is different from that obtained by Decharat17 in 2014 in Thailand which had obtained a percentage of 34.7% (52) for the ventilation of screen printing workshops (door and windows open) and a percentage of 65.3% (98) for the presence of ventilation systems in the workshops. This difference would be due to the fact that several studies have already been conducted in certain foreign countries, regarding the toxicity of the products used and these studies have led to the establishment of several protective measures, including the installation of ventilation systems in the screen printing workshops. Indeed, the absence of a ventilation system favors the accumulation of solvents in the working atmosphere and especially in hot periods, thus facilitating the inhalation of solvents and increasing the toxicological risks.

Thus, the means that allowed the screen printers to know that risks could exist concerning their field of practice, were in ascending order the medical personnel: 9 (7.6%), the media: 12 (10.2%), the trainer/employer: 45 (38.1%), colleagues 42: (35.6%), the serigraph himself: 52 (44.1%). One of these results is similar to those obtained by Yu et al.,14 who had obtained for the same question a percentage of 44.0% in favor of their colleagues. But the percentages obtained for the other means of knowledge were different, namely 22.3% for the media, 6.3% for employers. In addition, our results seem to be getting closer to those obtained by Yu IT et al. who obtain 44% for co-workers and 22% for media. This difference could be due to the fact that the issue of toxicology and its occupational hazards is still a subject that is very little discussed in Cameroon.

According to the screen printers, the organs/systems most likely to be exposed were the respiratory tract: 111 (94.1%), eyes: 94 (79.7%), and skin: 83 (70.3%). These results differ from those obtained by Yu et al.,14 in 2005 in China who had obtained for the same question the skin at the top of the list with 72.9 %, then the lungs with 68.1 %, and nervous system with 49.7 %. This can be explained by the fact that the majority of screen printers included in our study (55.9%) had not gone beyond high school, their ability to detect a symptom relevant to the nervous system is very low.

In the study population, 108 screen printers (91.5%) felt the need to improve their knowledge. This result was lower than that obtained in the study by Yu et al.,14 who obtained 73%. This difference could be explained by the fact that only 33.1% declared to know the composition of the products they use. Being aware of this great deficit, they would like to have more knowledge.

The wearing of protective glasses was not effective in our study population. 10.2% of eyewear pots were recorded; this result is similar to the one obtained by Decharat18 in 2014 which amounted to 13.3%. As for the wearing of mufflers, it seemed to be better (45.8%), quite close to that obtained by Decharat18 which amounted to 58.7%. Concerning the wearing of gloves and overalls, the percentages were 35.6% and 52.5% respectively; in other words, the screen printers did not scrupulously respect the wearing of gloves, but most wore coveralls during their work. This would be due to the fact that, according to them, wearing gloves during screen printing sessions has an impact on the possibility of being able to appreciate the quality of the print with bare hands on the one hand. On the other hand, wearing gloves could increase the possibility of staining the print medium, creating a kind of insensitivity in the palm of the hand.

In sum, the objective of this study was to evaluate the degree of toxicological risks to which screen printers are exposed in the city of Yaoundé, Cameroon. It was found that the respective levels of knowledge, attitudes and practices of screen printers with respect to toxic risks inherent in screen printing are, for the majority of the study population, average, approximate and inadequate.

Our thanks go firstly to late Dr Evrard NGUIJOE+, Head of Department of Pharmacotoxicology and Pharmacokinetics, for his strategic direction and technical management to achieve this research; My gratitude to technical staff of LANACOME, for the assistance that aim to fulfill the work on screen printers.

No conflicts of interest were recorded during our work.

DATA COLLECTION FORM

Sheet No. 1

Patient identification code _______ Date__/__/____

Screening facility identification code _______

|

S1Q1 |

What is your age? |

……… |

|

S1Q2 |

Gender |

Male=1 Female=2 |

|

S1Q3 |

Level of education : |

None=1 Primary=2 |

|

S1Q4 |

Secondary=3 Higher education=4 |

|

|

S1Q5 |

What is your current marital status? |

………. |

|

S1Q6 |

Number of screen printers employed at the facility, |

……… |

|

S1Q5 |

Do you use tobacco? |

Yes=1 No =2 |

|

S1Q6 |

Are you a former tobacco user? |

Yes=1 No =2 |

|

S1Q7 |

If yes, how many sticks do you use per day? |

|

|

S1Q8 |

How long (years) have you used tobacco? or how many years have you smoked? |

|

|

S1Q9 |

Do you drink alcohol? |

Yes=1 No =2 |

|

S1Q10 |

If not, have you ever used alcohol before? |

Yes=1 No =2 |

|

S1Q11 |

If yes, how many bottles do you drink per week? |

|

|

S1Q12 |

How long have you been working in this field? |

Months ____________ |

|

S1Q13 |

How many hours do you work per week? |

Years ___________ |

Section 1 Socio-demographic data

|

S2Q1 |

Do you know that you are exposed to harmful effects as screen printers? |

Yes =1 No=2 |

|

S2Q2 |

Do you get this from your co-worker? |

Yes =1 No=2 |

|

S2Q3 |

Do you get it from the media? |

Yes =1 No=2 |

|

S2Q4 |

From your employer/trainer? |

Yes =1 No=2 |

|

S2Q5 |

From medical personnel? |

Yes =1 No=2 |

|

S2Q6 |

From yourself? |

Yes =1 No=2 |

|

S2Q7 |

Other |

Yes =1 No=2 |

|

S2Q8 |

Are you aware that there are personal protection methods to protect yourself from these effects? |

Yes =1 No=2 |

|

S2Q9 |

Do you know the composition of the products you use? |

Yes =1 No=2 |

|

S2Q10 |

Do you think you have sufficient knowledge about the products you handle? |

Yes =1 No=2 |

|

S2Q11 |

Do you feel the need to improve your knowledge about them? |

Yes =1 No=2 |

|

S2Q12 |

Do you know that you can be exposed through the skin |

Yes =1 No=2 |

|

S2Q13 |

By the digestive tract |

Yes =1 No=2 |

|

S2Q14 |

By the respiratory route |

Yes =1 No=2 |

|

S2Q15 |

Do you think your liver can be affected? |

Yes =1 No=2 |

|

S2Q16 |

Do you think your kidney can be affected? |

Yes =1 No=2 |

|

S2Q17 |

Do you think your skin can be affected? |

Yes =1 No=2 |

|

S2Q18 |

Do you think your heart/vessel may be affected? |

Yes =1 No=2 |

|

S2Q19 |

Do you think your lungs can be affected? |

Yes =1 No=2 |

|

S2Q20 |

Do you think your eyes can be affected? |

Yes =1 No=2 |

|

S2Q21 |

Do you think your nervous system may be affected? |

Yes =1 No=2 |

|

S2Q22 |

Do you think your skeletal system may be affected? |

Yes =1 No=2 |

Section 2 Participants' knowledge of the exposure

|

S3Q1 |

Do you think that there is no need to worry about harmful effects due to the use of inks, thinners and additives? |

Yes =1 No=2 |

|

S3Q2 |

Do you think that the risks of handling inks, thinners and additives are sufficiently controlled by you? |

Yes =1 No=2 |

|

S3Q3 |

In your opinion, should the information on the label of the products used be taken into account? |

Yes =1 No=2 |

|

S3Q4 |

In your opinion, should screen printers wear glasses? |

Yes =1 No=2 |

|

S3Q5 |

In your opinion, should screen printers wear gloves? |

Yes =1 No=2 |

|

S3Q6 |

Do you think screen printers should wear nose plugs? |

Yes =1 No=2 |

|

S3Q7 |

Do you think screen printers should wear coveralls? |

Yes =1 No=2 |

|

S3Q8 |

Do you think this information should be provided by authorized bodies? |

Yes =1 No=2 |

Section 3 Participants' attitudes towards handling inks, thinners and additives

|

S4Q1 |

Do you read the labels on the products you use? |

Yes =1 No=2 |

|

S4Q2 |

Do you wear glasses when you work? |

Yes =1 No=2 |

|

S4Q3 |

Do you wear gloves when you work? |

Yes =1 No=2 |

|

S4Q4 |

Do you wear a muffler when you work? |

Yes =1 No=2 |

|

S4Q5 |

Do you wear coveralls when you work? |

Yes =1 No=2 |

|

S4Q6 |

Do you take time to wash your hands before eating or drinking? |

Yes =1 No=2 |

|

S4Q7 |

Do you change your clothes before you start your workday? |

Yes =1 No=2 |

|

S4Q8 |

Do you change your clothes after you finish your workday? |

Yes =1 No=2 |

|

S4Q9 |

Hand washing after handling products |

Yes =1 No=2 |

|

S4Q10 |

Do you remove ink deposits from your work area? |

Yes =1 No=2 |

|

S4Q11 |

If yes, with soap? |

Yes =1 No=2 |

|

S4Q12 |

If yes, with petroleum? |

Yes =1 No=2 |

|

S4Q13 |

If yes, with thinner? |

Yes =1 No=2 |

|

S4Q14 |

If yes, with water? |

Yes =1 No=2 |

|

S4Q15 |

If yes, with gasoline? |

Yes =1 No=2 |

|

S4Q16 |

If yes, with bleach? |

Yes =1 No=2 |

|

S4Q17 |

Any other? |

Yes =1 No=2 |

|

S4Q18 |

If yes, please specify! |

|

|

S4Q19 |

Do you recommend another prevention method? |

Yes =1 No=2 |

|

S4Q20 |

If yes, please specify! |

Yes =1 No=2 |

Section 4 Participant Handling Practices and Prevention of Effects

Working area

|

S4Q21 |

Ventilated space (open windows and doors) |

Yes =1 No=2 |

|

S4Q22 |

Lighted space |

Yes =1 No=2 |

|

S4Q23 |

Air exhaust system ? |

Yes =1 No=2 |

|

S4Q24 |

Space for hand washing ? |

Yes =1 No=2 |

©2023 Rose, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.