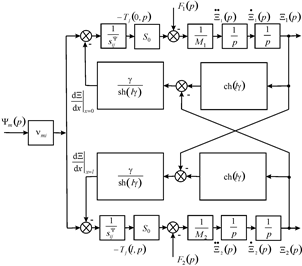

The structural diagram of the actuator for composite telescope is obtained in difference from Cady's and Mason's electrical equivalent circuits of the piezo transducer. Electromagnetoelasticity equation has the form of the equation of reverse effect for the deformation of the actuator

,

where

,

,

,

,

are the relative deformation; the module; the control parameter; the elastic compliance; the mechanical stress.10−25 The second order linear ordinary differential equation for the actuator.10−25,28 has the form

Figure 1 Structural diagram of actuator for composite telescopes in astronomy and physics research.

,

where

is transform of Laplace the displacement,

,

,

are the parameter of transform, the propagation coefficient, the coordinate. For the structural diagram on Figure 1 and the structural model of the actuator for composite telescopes in astronomy and physics research the system of equations has the form

;

,

where

,

,

,

, E, H are the strengths of the electric and magnetic fields.

Therefore, the system of the equations for the structural model of the actuator has the form

;

,

where

is the stiffness of actuator.

The matrix equation of the actuator has form

.

From the electromagnetoelasticity equation at

the regulation characteristic of the actuator has the form

,

where

, F are stiffness and force of the load. Therefore, the regulation characteristic of the actuator has the form

,

,

,

where

,

are the stiffness and the transfer coefficient of the actuator. The transfer function with lumped parameter of the actuator7,11–30 has the form

,

,

where

,

are the transforms of the displacement and the control parameter,

,

are the time constant and the damping coefficient of the actuator, M is the load mass. The transfer function with lumped parameter of the transverse piezo actuator7,11–30 has the form

,

,

,

where

is the Laplace transform of the voltage and

is the transfer coefficient. At

=2×10-10 m/V,

=12, M=1 kg,

=3.4×107 N/m,

=0.2×107 N/m the transfer coefficient

=2.27 nm/V and the time constant

=0.17×10-3 s are obtained for the transverse piezo actuator from ceramic PZT.

From the electromagnetoelasticity equation at elastic load the regulation characteristic of the multilayer longitudinal piezo actuator is obtained in the following form

,

,

,

where

is the transfer coefficient.

For the multilayer longitudinal piezo actuator from ceramic PZT at

=4∙10-10 m/V, n = 6,

=4∙107 N/m,

=0.2∙107 N/m, U=100 V are received

=2.29 nm/V and

=229 nm.

The mechanical characteristic of the actuator has form

or

and the regulation line of actuator has form

or

. The mechanical characteristic is obtained in the following form

.

The regulation characteristic of the actuator has the form

.

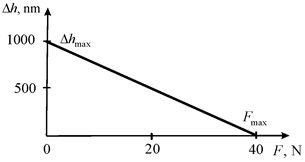

The mechanical characteristic of the actuator has the form

,

,

,

where

is the maximum displacement for

and

is the maximum force for

.

The maximum displacement and the maximum force of the transverse piezo actuator on Figure 2 have the form

,

.

At

=2∙10-10 m/V,

= 2∙105 V/m, h = 2.5∙10-2 m,

=1.5∙10-5 m2,

=15∙10-12 m2/N parameters of the transverse piezo actuator are found

=1000 nm and

=40 N. The discrepancy between the experimental data for the piezo actuators and the calculation results is 10%.

Figure 2 Mechanical characteristic of transverse piezo actuator for composite telescopes in astronomy and physics research.