eISSN: 2574-9927

Review Article Volume 6 Issue 1

Air Pollution Research Department, Environmental Research Division, Egypt

Correspondence: Atef MF Mohammed, Air Pollution Research Department, Environmental Research Division, National Research Centre, Giza, Egypt, Tel +201151143456, Fax +20 2 33370931

Received: October 02, 2021 | Published: February 4, 2022

Citation: Mohammed AMF, Saleh IA, Ibrahim YH, et al. Theory and technology of air filtration: review. Material Sci & Eng. 2022;6(1):6-12 DOI: 10.15406/mseij.2022.06.00173

The development of modern science and technology, improving the level of industrialization, increase people's awareness of environmental protection were leaded to the world's demand for filter materials to purify the air. This review presented an overview of air pollutants classification, history of fiber materials, theory of air filtration technology, and traditional air filtration (materials, characteristics, advantages, disadvantages, and standards). In addition, the paper reviewed the mechanisms of filtration, which include diffusion, interception, intermolecular interaction, straining, inertial impaction, gravitation, and electrostatic interaction of particles on the filter surface. Different studies have revealed the possibilities for the utilization of activated carbon fiber in the removal of VOC or odor from gaseous emissions in the air.

Keywords: air pollutants, air filtration, HEPA, purification techniques

Air pollution had become the biggest ecological environment problem, seriously affecting human health and life. It was claimed thousands of lives every year in countries like the USA.1–14 Europe, Australia, Japan,15–45 China,11 and the Netherlands.18 asthma, nausea, skin irritation, high blood pressure, cancer, birth defects can cause exposure to air pollutants (particulate matter (PM) and gaseous pollutants)28,30,46–67 along with respiratory and cardiovascular diseases.58,11,47 The effective control of airborne pollutants, harmful biological agents, allergens, and aerosol particles were the main issues concerned by people. Generally, the diameter of dust particles floating in the atmosphere ranges from 10 nm – 10 µm, which were the main ingredients of air pollution.1,48,2 A high-efficiency air filter could effectively remove bigger than 0.3 μm particles, but not smaller particles. For air purification, the filtration industry had been looking for a material to prepare a filter medium that could effectively filter particles below 0.3 μm. Nano-fiber materials had attracted people's attention because of their excellent surface-to-volume ratio and potential to be used in filtration.63,29,39,46,24,2

Classification of air pollutants

Classification of air pollutants was shown in Figure 1.5,29 The concentration of pollutants in the indoor atmosphere was 2 -5 times more than concentrations in the outdoor atmosphere.17 Cooking, heating, smoking, and air conditioning increase PM concentration.5,65 While in the outdoor atmosphere industrial activities and vehicle emissions were increased PM concentrations.21,40

History of fiber materials

In 1940, a glass fiber filter material was prepared in the United States. From the 1950s to the 1970s, fiber filter materials developed rapidly, and HEPA (High-Efficiency Particulate Air) filters using glass fibers were applied to the purification of indoor air.32 To further improve, high-efficiency filters were used, and the filtration efficiency of particles ≥ 0.3 μm reaches 99.998%. Subsequently, an ultra-high efficiency filter (ULPA) was developed by Japan; the filtration efficiency of 0.1 μm particles could reach as high as 99.9955%.61

Technology theory of air filters

The theory of classical filtration was developed in the 19th century. Filtration and micro-porous filter theories were summarized in Table 1.

|

Researcher |

Achievement |

|

Robert Brown, Beginning of 19th century |

Brownian movement |

|

Freundlich |

Penetrating particle size of particles range: 0.1 – 0.2 μm |

|

Sell |

Improved Albrecht theory |

|

Kaufmann |

First derived the fiber filtering formula |

|

Langmuir |

Filtration theory of interception and diffusion |

|

Davies |

Isolated fiber theory |

|

Friedlander |

Summarized diffusion deposition with bigger Reynolds number |

|

Yoshioka & Clarenburg |

A mathematical theory of fiber filter micro-porous structure |

|

Payet & Renoux |

The classical theory |

|

Rosner |

Particle dispersed on the surface of a single fiber |

|

Thomas |

Theoretical and experimental researched air filters under blocking condition |

Table 1 Development process of filtration theory37

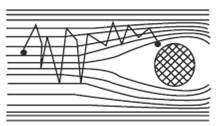

Filtration mechanisms included diffusion, intermolecular interaction, interception, straining, inertial impaction, gravitation, and electrostatic interaction of particles on the filter surface10,29 (Figure 2).

HEPA filters were captured Particles in five ways13:

This effect stoped large particles (> 5 µm in size) on a filter.

It took place when large particles were unable to adjust to changes in the flow around fibers (Figure 3a).

It occurred when a particle (0.1- 1 µm) came within the particle radius of a fiber (Figure 3b).

Very fine particles (< 0.1 μm) would collide with gas molecules and create a random path through the media as shown in (Figure 3c).

Figure 3c Brownian diffusion.

Figure 3 Ways of trapping particles in fine non-woven HEPA type filter media.13

A charge would build up when the air stream passes over the fiber. The fiber material would play a part in how much charge will get built. The geometry and humidity in the air would affect how much charge the fiber will hold.

HEPA filters were getting rid of contaminants and impurities from atmospheric air. HEPA filters could clear the air from dust, pollen, pet dander, smoke, and almost all pollutants present in the air. But HEPA filter was extremely fragile and needs to be shipped, stored, and handled in the same manner as delicate instrumentation.8,13 HEPA filters were used in a wide variety of applications. Filters could be used for office equipment to remove toner dust to applications for industrial vacuum cleaners for asbestos removal.6 HEPA filters were also used in surgical operating rooms, and other critical medical air filtration to prevent the spread of airborne bacterial and viral organisms.33

Types of air filtration: Filter was a better choice to capture air pollutants. Its efficacy depended on air pollutant type and capturing mechanism.25,53

Porous membrane filter: Porous membrane filter: it was membrane matrix, such as polytetrafluoroethylene (PTFE) which contains many small pores.66,64 This kind of material had a high filtration effect, low air flux, and high air resistance.

Nonwoven fiber filter: it was a kind of material that had high porosity, high air flux, and low filtration efficiency.15,22,23,52,59,62

a) HEPA (High-Efficiency Particulate Air)

HEPA filter could remove at least 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 μm.7,43

b) ULPA (Ultra-low particulate air)

It was captured PM with filtration efficiency53 (99.999%). These filters had the form of wet-laid papers, nonwoven fabrics, and air-laid glass fiber. These media contained low solids content, fiber volume < 10 % of the volume of the media. Its thickness was from mm to cm. Non-woven filtres were made from inorganic and organic fibers including wood pulp, cotton, or rayon.12,20 It had a mean flow pore (MFP) of 1 - 500 um.49

Nano-fibres: it was a new kind of filter material in recent years, which was developed by nano-technology. it had small fiber diameters with nano-scale pores, high specific surface area, and high van-der Waals forces.31,34,36,56,63,67,27,9,66,57,64,52

Materials of air filtres

Glass fiber material was used in 1940 as an air filter in the United States. The HEPA filter was used in the 1970s, with super fine glass fiber. It could achieve an efficiency of 99.9998% for ≥ 0.3 μm PM.38

High-efficiency particle air filter (HEPA): It was made from microfibers borosilicate in form of a pleated sheet. Its media was a glass and polymer blend, and it was pleated to provide more material in a smaller space. The pleats were separated by aluminum baffles. This combination was installed into an outer frame made from board aluminum or stainless steel.35 Different types of HEPA filters were shown in Table 2.13

|

Types |

Application |

Efficiency |

|

A |

Industrial, non-critical |

99.97 % for 0.3 μm |

|

B |

Nuclear containment |

99.97 % for 0.3 μm |

|

C |

Laminar flow |

99.99 % for 0.3 μm |

|

D |

Ultra-low penetration air (ULPA) |

99.9995 % for 0.12 μm |

|

E |

Stopping toxic, nuclear, chemical, and biological threats |

100.00% |

Table 2 Types of HEPA Filters13

Air filter characteristics: The factors affecting the purification characteristics of air filtration materials were examined in different studies.12,54,26,37 The researchers found that air permeability and porosity were important properties for filtration. There was an extreme relationship between air permeability and porosity, as the porosity increases, air permeability increases also. In previous studies, another relationship had been investigated between air permeability and non-wovens structural characteristics (weight, density, thickness, and fiber diameter). Air permeability of fabric was affected by weight more than the thickness followed by density.12,4,19 The previous studies were mentioned that filtration efficiency was affected by fiber charge density and face velocity more than other factors. Where, efficiency increased with increasing fiber charge density and efficiency decreased with decreasing face velocity.37 The main atmospheric air pollutants could be divided into suspended particulate matter (SPM), volatile organic compounds (VOCs), and microorganisms. The effect of individual purification techniques on atmospheric air pollutants was listed in Table 3.61 Table 4 shows the characteristics of different purification technologies in building environments. A summary of different atmospheric air filtration techniques and efficiency was listed in Table 5.

|

Purification techniques |

Main pollutants |

|

|

|

|

Suspended particles |

Volatile organic pollutants |

Microorganisms |

||

|

|

||||

|

Dust, pollen, secondary pollutants, etc. |

Formaldehyde, benzene, etc. |

|||

|

Diameter: 0.01 – 100 µm |

Diameter: 0.01 – 100 µm |

Bacteria |

Virus |

|

|

Diameter: 0.2 – 10 µm |

Diameter: 0.01 – 0.3 µm |

|||

|

Filtration |

Effective |

None effective |

Effective |

None effective |

|

Adsorption |

Partially effective |

Highly effective |

Partially effective |

None effective |

|

Water washing |

Effective |

Partially effective |

None effective |

None effective |

|

Electrostatic precipitation |

Effective |

Not obvious |

Partially effective |

None effective |

Table 3 Effect of individual purification techniques on main types of pollutants37

|

Technologies |

Pollutants |

Advantages |

Disadvantages |

Efficiency |

|

Fiber filtration |

- Particles |

- Low cost |

- High resistance |

100.00% |

|

- Microorganisms |

- Convenient installation |

|||

|

Electrostatic |

- Particles |

- High efficiency |

- Efficiency decline after dust discharge |

50% |

|

- Microorganisms |

- Wide range |

|||

|

Activated carbon adsorption |

- All pollutants except biological |

- Multiple sources |

- Saturation |

|

|

|

|

- High efficiency |

- Resistance |

|

Table 4 characteristics of different purification technologies in building environments37

|

Air filtration technique |

Effective particles diameter |

Efficiency (%) |

|

|

Fibrous filter |

Medium filter |

> 0.3 µm |

60 – 90 |

|

HEPA |

> 0.3 µm |

99.99 |

|

|

ULPA |

0.12 – 0.17 µm |

99.999 |

|

|

Glass fiber |

2 - 10 µm |

99 |

|

|

Nano-fiber |

< 0.3 µm |

> 99.99 |

|

|

Trombe wall |

< 10 µm & < 0.01 µm |

99.4 for PM10 |

|

|

Bio-filter |

A dynamic botanical air filtration system |

VOCs |

> 33 for toluene |

|

90 for formaldehyde |

|||

|

Integrated bio-filtration system |

99 |

||

|

Electrostatic air filter |

Electrostatic air filter |

< 0.1 mm |

82 - 94 |

|

Electrostatic precipitators |

> 0.1 mm |

Lower than HEPA |

|

|

Cold plasma air filter |

< 0.1 mm & VOCs |

85 - 98 |

|

Table 5 Summary of air filtration techniques37

Air filter standards

Table 6 presents the air filter classifications standards according to the EN 779: 2012 standard16 and GB/T14295:2008-2016.37

|

Classification according to |

Category |

Filter class |

Final pressure drop (Pa) |

Average capture (Am) of industrial dust (%) |

Average efficiency (Em) of 0.4 µm particles (%) |

Minimum efficiency (Em) of 0.4 µm particles (%) |

|

|

EN779:2012 |

Coarse |

C1 |

250 |

50 ≤ Am < 65 |

- |

- |

|

|

C2 |

250 |

65 ≤ Am < 80 |

- |

- |

|||

|

C3 |

250 |

80 ≤ Am < 90 |

- |

- |

|||

|

C4 |

250 |

90 ≤ Am |

- |

- |

|||

|

Medium |

M5 |

450 |

- |

40 ≤ Em < 60 |

- |

||

|

M6 |

450 |

- |

60 ≤ Em < 80 |

- |

|||

|

Fine |

F7 |

450 |

- |

80 ≤ Em < 90 |

35 |

||

|

F8 |

450 |

- |

90 ≤ Em < 95 |

55 |

|||

|

F9 |

450 |

- |

95 ≤ Em |

70 |

|||

|

Classification according to |

Category |

Filter class |

Rated wind speed (m/s) |

Purification efficiency (%) |

Initial pressure drop (%) |

||

|

Air filter |

Filter media |

||||||

|

GB/T14295:2008-2016 |

Sub high |

YG |

1 |

0.053 |

Diameter ≥0.5 μm |

99.9 > E ≥ 95 |

≤120 |

|

High medium |

GZ |

1.5 |

0.1 |

- |

95 > E ≥ 70 |

≤100 |

|

|

Medium 1 |

Z1 |

3 |

0.2 |

- |

70 > E ≥ 60 |

≤80 |

|

|

Medium 2 |

Z2 |

- |

- |

- |

60 > E ≥ 40 |

- |

|

|

Medium 3 |

Z3 |

- |

- |

- |

40 > E ≥ 20 |

- |

|

|

Coarse 1 |

C1 |

2.5 |

1 |

Diameter ≥ 2.0 μm |

E ≥ 50 |

≤50 |

|

|

Coarse 2 |

C2 |

- |

- |

Standard artificial dust weight efficiency |

50 > E ≥ 20 |

- |

|

|

Coarse 3 |

C3 |

- |

- |

- |

E ≥ 50 |

- |

|

|

|

Coarse 4 |

C4 |

- |

- |

- |

E ≥ 50 |

- |

Table 6 Air filter classification according to EN779:2012 and GB/T14295:2008-201616

Air filtration materials and techniques become essential in our life to reduce and eliminate high levels of atmospheric air pollutants, which affected human health and the environment. The advantages of classical fibrous filters were low cost, simple structure, and high efficiency. Although, they were characterized by high maintenance costs, filter colonization, and high-pressure drop. To overcome the disadvantages of classical physical filters need to be coated with chemicals or nano-particles. In addition, researchers were found single filtration techniques ineffective in presence of multiple atmospheric air pollutants types. Thus, they have suggested a combination of filtration techniques with other purification technologies to improve their efficiency to remove or eliminate pollutants.

The author state that there is no conflict of interest.

None.

©2022 Mohammed, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.