eISSN: 2574-9927

Review Article Volume 8 Issue 4

Consultor Geologist, Colombia

Correspondence: Italo Reyes, Consultor Geologist, Carrera 10 # 5-11 Tibasosa, Colombia, Tel 57 3134398899

Received: November 11, 2024 | Published: December 17, 2024

Citation: Reyes I. Study of the “D” limestone bed for steelmaking use. Material Sci & Eng. 2024;8(4):134-140. DOI: 10.15406/mseij.2024.08.00246

The limestone deposits located in the Sogamoso region, Boyacá District, in the Eastern Cordillera of Colombia, provide the raw material for the steel industry and cement manufacturing. The main limestone deposits are developed along and adjacent to the great Soapaga Fault, which is the main geological structure in the region. Nowadays, the aim is to load the blast furnace with raw materials of the highest quality and, in the case of the calcination process, the need to produce highly competitive steels implies the use of limestone with optimal chemical characteristics. The Cretaceous rocks that outcrop in the region are of particular interest since they contain calcareous sequences that have been used for the steel and cement industries. Both the quality studies carried out in the different deposits in the region, as well as the analysis of the core samples obtained in the drilling programs, clearly indicated a great lateral continuity of the geochemical characteristics of some of the limestone layers. In the present study, the characterization of “D” limestone bed is carried out with special emphasis on the quality of the rock, and the results of the investigation clearly indicate that the material meets the specifications required for the steel manufacturing processes.

Keywords: limestone, biomicrite, steelwork, calcination, geochemical characteristics

The need to have limestone that meets the quality requirements for steel use has always been the main objective of geological exploration work in the limestone deposits of the Sogamoso region, Boyacá District, in the Eastern Cordillera of Colombia. In general, the exploration of the calcareous rocks has been facilitated from the beginning by the good exposure of the outcrops, especially on the western side of the Sogamoso valley, where the steep relief has allowed the recognition of the limestone beds with good precision.

Traditionally, the limestone used in blast furnace has been “B” bed, located in the Cretaceous calcareous sequence that outcrops in the Sogamoso región,1 given that other materials with the quality required by local industry are found at great distances from local deposits, outside the district of Boyacá.2 “B” bed also provides the limestone for the calcination process, which corresponds to the part of rock with SiO2 content less than 2% required.

Other calcareous rocks, located in the same stratigraphic section that contains “B” bed, present limestone horizons with chemical contents within the ranges specified for steelmaking use, which would allow it to be used either as corrector for the blast furnace charge, or exclusively for the calcination process.

It is worth highlighting here the traditional classification of clay-limestone mixtures by Barth, Correns, Eskola, based on the CaCO3 levels required for the manufacture of products. Figure 1 shows, in the upper box, the ranges of limestone rock according to its CaCO3 content, and its relationship with the percentages of clay. The lower box indicates the industrial products, within the percentage limits of CaCO3 and clay required for each of them.3

The interest of the local steel industry in obtaining additional raw material of optimum quality, and therefore in having greater resources, has led to an intensification of research in the deposits of the region.

The objective of this work is to characterize a calcareous rock that presents the necessary requirements for its use in the steelmaking process.

Geological setting

The studied region extends between two major thrust faults, the Boyacá Fault to the northwest and the Soapaga Fault to the southeast, which develop in a SW-NE direction dipping towards the NW. The Cretaceous rocks of interest in the study area are between the Hauterivian and Middle Albian in age, and rest in angular unconformity on the Jurassic and Paleozoic formations (Figure 2).

Figure 2 Geological map of the Duitama-Sogamoso-Floresta region. It can be observed that the Lower Cretaceous (Ki) rocks, which include the Tibasosa Formation, are limited by the main Boyacá and Soapaga faults (indicated with a thick red line), outcrop along the Floresta Massif and develop southwest of Tibasosa covering a vast area.

The limestone beds of interest belongs to the succession of strata of the uppermost member of the Tibasosa Formation, called the Upper Calcareous Member,4 of lower Cretaceous age (Figure 3). This formation borders the Floresta Massif, marking the flanks of the great Floresta Anticline in the belt between the Boyacá and Soapaga faults. The outcrops of the calcareous section on the eastern flank are continuous along the Soapaga fault from the southeast of Pesca to Otengá Creek. Those on the western flank develop in sectors from Duitama to the Belén-Tutazá area to the northeast.5 In the Tibasosa sector and towards the southwest, the outcrops cover the entire axial zone of the anticline as shown in Figure 2.

Figure 3 Upper portion of the stratigraphic section containing the limestone layers of industrial interest.

Along the Soapaga Fault the entire calcareous formation is overturned, so the useful limestone beds are at the bottom of the stratigraphic section.

Since the first studies in the región, the geologists named the Sogamoso limestone beds with letters from top to bottom in the stratigraphic sequence, a nomenclature that has continued to be used in the local mining works. Thus, the limestone beds A, B, C, D, E, G-G1, H, I were identified. Later, bed 3 above E, bed 5 below G and bed 7, the latter on the roof of bed G-G1, were included.6

The results of geological resarchs for cement factory projects showed that, whether due to lithology or chemical content, the D limestone bed could be divided into two units, of which the upper one (structurally inverted) was suitable for the steelmaking process, while the lower one was for cement use.

Geological exploration of D limestone bed began in a quarry near the local steel plant, using diamond drilling. Although manual channel sampling on the ground surface was numerous, the extraction of drilling cores has been the type of sampling that provides the greatest guarantee for chemical analysis, because the samples are perfectly continuous and of constant volume.

Initially, vertical boreholes obtained cores with a diameter of NQ (47.6 mm) and cores with AQ (27 mm). This implied that, if there was lateral variability in the chemical contents within a few centimetres, different values would be obtained due to differences in the size of the cores. In any case, the operation with the small drill was experimental, but when comparing the results of the chemical analyses of the samples from all the boreholes, it was observed that the contents had similar values, which indicated little variability in the composition of the limestone.

For example, the % R2O3 content in the AQ and NQ cores corresponding to the upper seven meters of D limestone bed drilled is compared:

|

(Diameter 27 mm) |

(Diameter 47.6 mm) |

|

0.73% |

1 .30% |

|

1.20 |

0.5 |

|

0.93 |

1.08 |

|

0.75 |

1.05 |

|

1.00 |

0.98 |

|

1.00 |

1.08 |

|

1.08 |

1.23 |

As can be seen, the difference between the values of the two analyses is on average of the order of 0.08%, so the sampling of drilling cores of any diameter was considered reliable. The strong variations that may occur within the same deposit are attributed to tectonic faults present, regardless of the quality of the rock, and which in any case are evident in the drilling cores.

In diamond drilling, sampling was carried out at intervals corresponding to one metre of the actual thickness of the limestone bed, that is, according to the dip value of the strata. However, not all sampling in other locations complies with this regularity, for various technical reasons derived from the fracturing of the rock,7 or in some cases due to the low recovery of the cores. This fact leaves doubts in the correct knowledge of the degree of systematic variability of the tenors. Nevertheless, the correlation of the chemical contents from one drilling to another, and vertically in each site, guides the visualization of the trends of chemical variability both locally and regionally, for which an attempt has been made to use the calcareous sequence at intervals as homogeneous as possible.

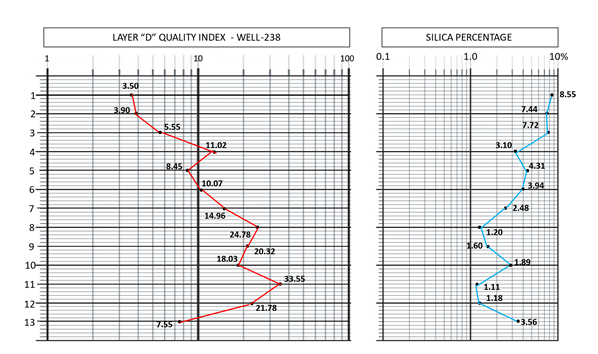

The content levels are shown in vertical variability diagrams at each sampling site. The fact that they are represented on semi-logarithmic paper has no mathematical significance, but simply allows the variations in the intervals of best quality to be highlighted.

Characterization of the “D” limestone bed

The results of the geological exploration verified that, due to both lithology and chemical content, the D limestone bed could be divided into two units, of which the upper one was suitable for the steelmaking process, while the lower one was for cement use.

In an old well, identified as T-238 and located in Cerro Cuistá northeast of Sogamoso, the exploitable upper portion of D limestone bed presented average CaCO3 contents of 96.18% and SiO2 of 1.40%, corresponding to the six meters from the top, classified as “pure limestone” to produce lime suitable for the steel industry. To check the results of this first phase of exploration, a specific program was carried out for this limestone with broad sampling in the T-238 test area. The results of the investigation confirmed the excellent quality of the limestone, although the useful thickness showed variations between five and seven meters, which would imply strict selective control in the extraction.

As part of regional exploration works, in 1972 photogeological studies indicated the existence of a limestone deposit in the San Antonio sector (Municipality of Duitama), located approximately 20 km SW of well T-238, on the opposite flank of the Floresta Anticline. Given that the results of the chemical analyses of a preliminary sampling were satisfactory and that the geological conditions of the deposit were apparently favorable, field surveys were intensified and a sampling program of the limestone beds of greatest interest was carried out.

The limestone outcrops in the Belén-Tutazá region extend from the quarries located north of the urban area of Belén to the vicinity of the Pargua River, northeast of the town of Tutazá. The stratigraphic section presents the same characteristics as the San Antonio deposit in Duitama, that is, a bed of steelmaking limestone that is superimposed on the limestone beds for cement use. The local section consists of four limestone beds (A, B, C and D), which are interbedded with calcareous claystones and nodular marls, with a total explored thickness of 140 m (Figure 4). Exploration at the Tutazá site indicated a clear stratigraphic correlation, confirming the great continuity of the limestone beds over an area of nearly 6,000 hectares.

Thickness of “D” limestone bed

As part of the geological exploration work outside Sogamoso, D limestone bed was probed in the Corrales, Duitama and Tutazá deposits. The values of the stratigraphic thickness of the limestone are indicated in Table 1. Compared with the T-238 drilling in Cerro Cuistá, the good regularity of the actual thickness of D limestone bed can be noted in all the explored areas, with a tendency to decrease only towards the Tutazá deposit.

|

Sampling program |

Cerro Cuistá |

Corrales |

Duitama |

Tutazá |

|

T-238 |

12.18 |

|||

|

1 |

11.65 |

|||

|

2 |

12.00 |

|||

|

3 |

11.82 |

|||

|

4 |

12.70 |

|||

|

5 |

12.47 |

|||

|

6 |

10.32 |

|||

|

7 |

9.28 |

|||

|

8 |

9.47 |

|||

|

9 |

9.54 |

|||

|

10 |

9.51 |

|||

|

11 |

|

|

|

9.24 |

Table 1 Stratigraphic thickness of the “D” limestone bed

Petrographic characterization of the “D” limestone bed

The petrological analyses were carried out on three point samples chosen from the first seven metres of the limestone bed in the El Volador quarry, northeast of Cerro Cuistá. Two preparations are from the same cylindrical sample at a distance of half a centimeter, to determine the degree of textural variation.

Due to its sedimentary characteristics, D limestone bed is framed within the marly detrital limestones, that is, it is an impure allochemical rock, with a variable degree of purity throughout the thickness and laterally along the deposits. According to the granulometry of the allochemical elements and of the accessory minerals present, this limestone is a calcarenite, with a grain size between 0.125 and 0.50 mm.

From the point of view of texture, that is, the arrangement of the rock constituents, limestone is classified by the relative proportions between its three main components, which are the orthochemicals of microcrystalline calcite ooze, the sparry orthochemicals and the allochemicals, according to the classification of R. Folk.8

Microcrystalline orthochemical constituents: The microcrystalline calcite matrix is the main component of biomicrites. However, the ratio of calcareous ooze to sparry calcite is more important. In the biomicrite from D limestone bed, this ratio is normal around 1.4 to 2.4. Only in the lower section of the cylindrical sample is there a value that reaches 1.05, that is, an almost equal content of both components, placing the limestone within the poorly washed biosparites. The spar in the samples generally varies between 11.7 and 14.6%.9

The rock of the D limestone bed can be considered as a biomicrite composed of 56.6 to 57.4% allochemical constituents, 35 to 39.9% orthochemicals and 3.6 to 7.6% terrigenous material (Figure 5).

Figure 5 Photomicrograph of the D limestone bed. This is a biomicrite with 57% allochemicals, mainly mollusc fragments filled with spar (white masses) and peloids (dark rounded granules). The microcrystalline matrix (opaque area) occupies 38% of the volume. The terrigenous components reach 5% and consist of disseminated clay with little quartz. Magn. X 3.6.

Allochemical constituents: The dominant allochemical constituents are bioclasts, i.e. fossils or fragments of these, but a good percentage is made up of pellets. The most frequent fossils are fragments of Pelecypods, Gastropods and Echinids, with Foraminifera being less abundant. Fragments of Algae and Fish bones are also present.10

Terrigenous constituents: The biomicritic facies of D limestone bed is essentially a facies of good purity, as indicated by the content of more than 91% of the carbonate present. Therefore, the amount of terrigenous materials is low, reaching a maximum of 8%. Most of the insoluble residue of the limestone is disseminated clay.11

Authigenic constituents: The fact that the quartz present in the insoluble residue is almost entirely idiomorphic indicates that it was generated after sedimentation. The grain size is around 20 microns.

The geochemical quality of the “D” limestone bed

The results of numerous samplings carried out throughout the region, between Sogamoso, Duitama and Tutazá, where the Upper Calcareous Member of the Tibasosa Formation crops out, clearly reflect the regional variability of the chemical composition of the D limestone bed.

Taking the column from the drilling T-238, as a pattern of the chemical contents, the percentages of the basic compounds of the other sites can be compared, to have an idea of the regional chemical variability and, therefore, of the real usefulness of the different deposits.

The CaCO₃ content in pure limestone is theoretically 100%, which means a maximum CaO content of 56.03%. Such a rock type is very rare in nature and can only be found in industrial marble deposits. Since the D limestone bed is classified petrographically within sedimentary rocks as an “impure allochemical limestone”, due to the contents of terrigenous materials associated with the sedimentation process, the undesirable compounds in the steel industry that participate in the impurity level are basically silica-aluminates, generally represented by the contents of SiO2 and R2O3.

SiO2 content: Samplings carried out in the deposits located along the Soapaga Fault, on the northeastern flank of the Floresta Anticline, indicate a similarity in the vertical variability of silica at each site and a great lateral continuity of the grades from T-238 area to the Corrales region. The diagram of the SiO₂ grades shows the vertical variability at the site of well T-238 (Figure 6). In Corrales, eight kilometers northeast of well T-238, a decrease in the percentage of silica can be observed from the top to the base of the column, but the diagram shows that the minimum values are between the 7th and 12th meter.

At Corrales the characteristics of the D limestone bed remain the same, with a decrease in silica content in the lower part of the sequence of strata. Figure 7 shows the percentage diagram of Sampling 1. However, the vertical variability is different in Sampling 2, where only the last two meters are below 2% SiO₂. The influence of tectonics on the Corrales deposit must be considered, so two sampling programs are not enough to define the lateral chemical variability of the deposit.

Exploration work carried out on the northwestern flank of the Floresta Anticline from Duitama to Tutazá, that is, along a strip located about 20 km northwest of the Soapaga Fault, indicated good continuity of the limestones of the Tibasosa Formation, so sampling was carried out systematically to determine the degree of industrial use of the material. Regarding the SiO₂ content, a regional variation was observed with respect to the T-238 outcrops, either due to a higher average content in the limestone, or because it presents a somewhat different vertical variability pattern.

In the San Antonio deposit, area of Duitama, the average content of the total of the D limestone bed in Sampling 3, 4 and 5 was 8.85%, 9.09% and 9.37% respectively. In all the samples the vertical distribution of silica across the bed is very characteristic, alternating areas of high and low content, as shown in the graph in Figure 8. This fact makes a selective extraction impossible, in addition to the fact that the lowest contents are always above 3%.

In the samplings carried out in the Tutazá deposit, 30 km northeast of Duitama, the SiO2 content diagrams (Figure 9) indicate lower percentages in the first six meters from the stratigraphic top of the bed. However, these values are between 3 and 5%, so the limestone is not usable to obtain high purity lime.

It can be concluded that the D bed in the limestone deposits adjacent to the Soapaga Fault is the one that presents continuity of the geochemical characteristics in the explored sectors between T-238 area, to the southwest, and Corrales, to the northeast, fulfilling all the requirements for its use in the steel industry.

CaO content: Being a biomicrite, the calcium carbonate content of the D limestone bed is obviously high and its variability depends on the terrigenous material mixed during the geological sedimentation process. Therefore, the impurities are distributed, areally and locally, randomly according to the original environmental conditions. These may have been favorable with little contribution of clays and sands, or unfavorable disturbed by intense climatic changes.

Since the basic compound for the calcination process is CaO, its content is what defines the goodness of the limestone for the production of pure lime. In the limestone deposits along the Soapaga fault, the average CaO contents corresponding to the first 5 to 7 m of the stratigraphic depth of the D limestone bed, that is, the lowest interval in silica, remain practically the same, as indicated by the following averages of 53.30%, 53.00% and 52.03% respectively in the T-238, Cerro Molino and Corrales sector.

On the other hand, in the deposits of the Duitama-Tutazá belt, the samples taken in the first 7 m of the limestone bed give lower CaO contents, as expected, and there is variability from one deposit to another, indicating 47.61%, 48.23%, 50.67% and 50.81% values.

Undesirable chemical components: To obtain lime for steelmaking, it is obvious that a high purity limestone must be used, that is, one that is low in components foreign to the calcining process, such as silica, alumina, iron oxide, magnesia and other elements such as sulfur, phosphorus, sodium, potassium, titanium, etc. In the first seven meters of the D limestone bed, not counting calcium carbonate and silica, the rest of the chemical constituents reach a maximum of 3%.

Alumina and iron oxide, generally identified as R2O3, are associated with the aluminosilicates of the clay present, so they are components that must be taken into account. The R2O3 content of the upper seven meters of the D limestone bed remains constant, around 2.7% in the deposits along the Soapaga Fault.

The sulfur content shows good regularity in the T-238-Malsitio belt, indicating more frequent values between 0.02 and 0.05%. In Corrales, the samples from the best part of the bed in sampling 2 gave an average of 0.07%, thus confirming the small chemical variability of the limestone in that direction. Locally there may be peaks exceeding 0.15% due to the fact that in the tectonized sectors there was authigenic pyrite formation.

Phosphorus is associated with the presence of collophane, which is a carbonate rich in fluorapatite. This mineral originates during the diagenesis of limestone, replacing organic material such as peloids and fossil fragments. The phosphorus content is fairly constant in the useful portion of the D limestone bed, ranging between 0.02 and 0.07%.

The low titanium and zirconium contents are due to the presence of sphene (Ca and Ti silicate) and zircon (zirconium silicate) in the terrigenous constituents of the limestone. Titanium is around 0.08% in the purest limestone, but exceeds 0.20% when it is marly.

Sodium and potassium are generally associated with clay, so they vary proportionally according to the purity of the limestone. In the upper seven meters of D bed the Na2O content remains close to 0.05%, while K2O is more variable between 0.06 and 0.30%.

The D limestone bed quality index: To have a quick overview of the quality of limestone suitable for the steelmaking process, the rock quality index could be the ratio of the percentage of CaO versus the sum of the SiO2 and R2O3 contents, which are the factors that most influence the purity of the final product.

The graph in Figure 10 shows the quality diagram of well T-238, at intervals of approximately one meter. The index increases progressively towards the bottom of the bench, except for the last sample. Figure 11 shows the quality diagram of the Cerro Cuistá and Corrales deposits. The regularity of the vertical variation of the two Cerro Cuistá and Malsitio samples, located at a distance of around 500 m from each other, is notable, while the Corrales diagrams are uneven in the upper part but similar in the last five intervals.

Figure 10 Limestone quality diagram in the T-238 well. Compared with the SiO2 content, it is observed that the variability of the silica content is inversely proportional to the steelmaking quality.

The values of the average quality indices of the total thickness of the D limestone bed, calculated in the most representative samples of all the explored areas, are illustrated in Table 2. The better quality of the deposits in the Cerro Cuistá-Corrales belt compared to the northeastern blocks of Duitama and Tutazá can be definitely observed.

|

Deposits |

Quality |

|

Belencito-T-238 |

14.25 |

|

Belencito-MXXX |

14.98 |

|

Malsitio-T-409 |

14.37 |

|

Corrales-PC1401 |

10.96 |

|

Corrales-PC1402 |

11.13 |

|

San Antonio-T-403 |

6.71 |

|

Tutazá-T-393 |

9.03 |

Table 2 D limestone bed quality index

Mining exploitation of the “D” limestone bed

The best quality outcrop belt of the D limestone bed explored runs along the Soapaga fault, from the Cerro Cuistá sector to the Corrales area. Due to the inversion of the strata caused by the influence of the fault, the useful limestone horizon for steelmaking is therefore at the base of the limestone succession exploited for cement manufacturing. This fact represents a drawback in open-pit mining due to the presence of a thick layer of overburden that must be removed, with the associated problems such as waste dumps or the destabilization of the slopes, among others, factors that naturally influence exploitation costs.

The need to have a high quality material for the production of steelmaking lime requires, not so much the study of the quality of the limestone, which is already sufficiently known, but an economic evaluation of the possible alternatives for obtaining the usable material.

The alternatives for the use of a limestone of optimal quality for the local industry would be the following:

Each of these possibilities has its advantages and disadvantages. Naturally, it is the Mining Engineer's criteria that prevails in the decision to develop a particular project, which guarantees a high degree of technical and economic security.

An important exploration concept confirmed by this study is that there are other limestone horizons of the Upper Calcareous Member of the Tibasosa Formation that can replace the limestone traditionally used for the steelmaking process.

The aforementioned Upper Calcareous Member has the same stratigraphic characteristics known in the type locality of Belencito throughout the region studied, guaranteeing the regional continuity of the calcareous succession.

As a result of this research, the D limestone is a biomicrite bed with great regional continuity. The 5 to 7 m from the top of the stratum show little lateral and vertical variability in chemical contents.

This limestone represents an important source of raw material for the local industry, both due to its thickness and the continuity of its geochemical characteristics. Specifically, this limestone has the quality required for its use in the manufacture of steel and for the production of pure lime.

None.

None.

Author declares that there are no conflicts of interest.

©2024 Reyes. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.