eISSN: 2574-9927

Mini Review Volume 1 Issue 2

1State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, China

2College of Mechanical and Equipment Engineering, Hebei University of Engineering, China

Correspondence: Fucheng Zhang, State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, China, Tel 0086 335 8063949, Fax 0086 335 8074568

Received: June 05, 2017 | Published: August 17, 2017

Citation: Zhang F, Wang Y, Yang Z, et al. Research and application progress of nanostructured bainitic steel in bearings. Material Sci & Eng Int J. 2017;1(2):46-50. DOI: 10.15406/mseij.2017.01.00008

The research and application progress of nanostructured bainitic steel in bearing manufacturing field at home and abroad are summarized in detail. Some problems on the application of nanostructured bainite on bearing that need to be solved are proposed, such as short period process, the appropriate working condition and prediction of service life. The solution of these problems will promote the application of nanostructured bainite on bearing.

Keywords: nanostructured bainite, bearing steel, wear resistance, rolling contact fatigue, progress

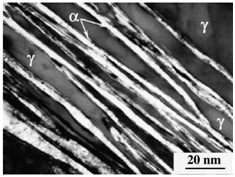

Research into nanostructured bainitic steels has attracted much attention in the past twenty years. The nanostructured bainite was studied by Bhadeshia and his coworkers. They reported that the nanostructured bainitic microstructure consisting of 20-40 nm thick bainitic ferrite plates dispersed in retained austenite matrix exhibited a hardness value in excess of 650 HV30, a tensile strength of ~2.3 GPa and a toughness of 30-40 MPa·m1/2.1-3 The nanostructured bainitic microstructure, which is shown in Figure 1, was formed in high-carbon Si-rich steels by austempering at 125-350 °C for a long time. The nanostructured bainite is also known as hard bainite owing to its high hardness, low temperature bainite because of its low transformation temperature, super bainite due to its excellent mechanical properties.

Figure 1 Nanostructured bainite on high carbon and high silicon steel treated at 200 °C for 15 days.3

Recent years, the microstructure and mechanical properties of the nanostructured bainitic steels have been extensively studied.4-9 Meanwhile, the material researchers and the bearing production enterprises have realized the great potential of the application of nanostructured bainite in bearings and carried out the related research work gradually. This paper mainly introduces the research and application progress of the nanostructured bainitic steel in the field of bearings.

A series of significant achievements have been acquired in the research and development of the nanostructured bainitic steel used for bearings in recent years. Zhang et al.7 have developed a variety of Al-rich nanostructured bainitic steels, whose chemical compositions are shown in Table 1, with excellent performances used for bearings and gears.10-17 The alloying element Al has many good effects on steel, such as promoting bainite transformation, suppressing carbide precipitation and reducing hydrogen embrittlement sensitivity.18 The nanostructured bainitic microstructure was first introduced in the surface of low-carbon steels based on carburization and succeeding low-temperature austempering at 2008, with the transformation inducing a compressive stress of about 200 MPa into the surface,10 which is beneficial to the rolling contact fatigue performance. The nanostructured bainitic steel achieved a service life of about two times more than the tempered martensitic steel, exhibiting an excellent resistance to rolling contact fatigue, which was shown in Figure 2,.13 The excellent rolling contact fatigue resistance was mainly due to the very thin nanostructured bainitic plates (~80 nm in thickness) and the fine-scale dispersion of austenite between the plates. The apparently increased hardness in the surface layer may also enhance the rolling contact fatigue resistance.

Steels |

C |

Si |

Mn |

Cr |

Mo |

Ni |

Al |

References |

|

20CrMn2MoSiNiAl |

0.19 |

0.57 |

1.77 |

1.37 |

0.33 |

0.42 |

1.35 |

10 |

|

20CrMnMoSiAl |

0.2 |

0.36 |

1.2 |

1.35 |

0.24 |

--- |

0.92 |

11 |

|

38CrMoAl |

0.38 |

0.4 |

--- |

1.37 |

0.23 |

--- |

1.03 |

14 |

|

G23Cr2Ni2Si1Mo |

0.20~0.25 |

1.20~1.50 |

0.20~0.40 |

1.35~1.75 |

0.25~0.35 |

--- |

≤0.05 |

22 |

|

G23Cr2Ni2SiMoAl |

0.20~0.25 |

0.90~1.20 |

0.20~0.40 |

1.35~1.75 |

0.25~0.35 |

--- |

0.30~0.50 |

||

GCr15SiAl |

1.15 |

0.58 |

0.21 |

1.42 |

--- |

--- |

0.65 |

19 |

|

GCr15Si1Mo |

0.95~1.05 |

1.20~1.50 |

0.20~0.40 |

1.40~1.70 |

0.30~0.40 |

--- |

≤0.05 |

20,23 |

|

Table 1 Chemical compositions of nanostructured bainitic bearing steel (wt%)

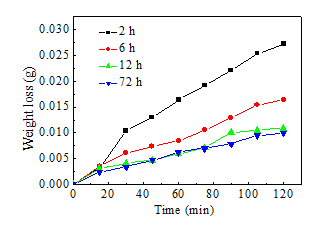

Novel high-C-Cr nanostructured bainitic bearing steels GCr15SiAl by Si-Al alloying and GCr15Si1Mo by Si-Mo alloying were developed at 2015.19-21 Research results showed that the fully nanostructured bainitic microstructure not only had excellent strength and toughness, but also had the optimal wear resistance compared with the mix microstructure of nanostructured bainite, martensite and retained austenite (Table 2 & Figure 3). The microstructure without martensite but with nano-scaled bainitic ferrite (~50 nm in thickness) and a small amount of film-like retained austenite was responsible for the increase in toughness, elongation and strength. The excellent wear resistance was attributed to the more thermal stability of the microstructure obtained by austempering for longer period time, which reached 72h.

Holding time (H) |

AK (J) |

Hardness |

UTS |

YS |

El |

FVA |

FVB |

FVM |

FVC |

(HRC) |

(MPa) |

(MPa) |

(%) |

(%) |

(%) |

(%) |

(%) |

||

2 |

12 |

62 |

2277 |

2158 |

1.5 |

22.3 |

2.1 |

69.6 |

6 |

6 |

30 |

58 |

1614 |

890 |

2 |

45.3 |

40.8 |

7.4 |

6.5 |

12 |

52 |

61 |

1826 |

1180 |

2.6 |

29.5 |

60.2 |

3.5 |

6.8 |

72 |

66 |

61.3 |

2373 |

1697 |

3.5 |

7.2 |

86.6 |

0 |

6.2 |

Table 2 Properties and phase constitutions of GCr15SiAl steel after austempered for different time.19

Note: fVA, fVB, fVM, fVC stands for the volume fraction of retained austenite, bainite ferrite, martensite and undissolved carbides respectively.

Figure 2 Rolling contact fatigue performances of nanostructured bainitic steel 20CrMnMoSiAl and martensitic steel 20CrMnTi:13 (a) the vibration curves, (b) the lives under different loads (The straight lines in Fig 2b represent the average values of the rolling contact fatigue life).

Supported by the national high technology research and development program of China, the novel nanostructured bainitic steels G23Cr2Ni2Si1Mo and GCr15Si1Mo used for high-power wind power bearing were developed.22,23 The carburizing G23Cr2Ni2Si1Mo bainitic steel is suitable for manufacturing high-power wind power spindle bearing ring. After carburizing plus high-temperature tempering and low-temperature austempering, nanostructured bainite with the plate thickness of 68 nm and dispersed carbide particles with the average equivalent diameter of 0.25μm were obtained in the surface, which were shown in Figure 4a. The rolling contact fatigue lives of the carburizing G23Cr2Ni2Si1Mo nanostructured bainitic steel were approximately 210%-254% greater than those of the traditional carburizing G20Cr2Ni4 martensitic steel23,24 (Table 3 & Figure 5a). Moreover, the impact toughness of the center with low-carbon martensite after isothermal treatment is improved 33% as compared with that of the oil-quenched treatment. With excellent hardenability and properties, the G23Cr2Ni2Si1Mo steel was chosen to manufacture 6 MW wind power spindle bearing ring, whose external diameter reached 3200 mm. The high-C-Cr nanostructured bainitic bearing steel GCr15Si1Mo, whose microstructure is shown in Figure 4b, has been adopted in the manufacture of rolling element of 5 MW wind power yaw bearings, pitch bearings and spindle bearings. The rolling contact fatigue lives of the nanostructured bainitic bearing steel GCr15Si1Mo were approximately 106%-112% greater than those of the bainitic bearing steel GCr15SiMo,23,25 (Table 3 & Figure 5b).

Steels |

β |

L10 / (×107) |

L50 / (×107) |

Vs / (×107) |

G23Cr2Ni2Si1MoA |

1.582 |

1.375 |

4.534 |

5.714 |

G20Cr2Ni4A24 |

1.742 |

0.444 |

1.308 |

1.614 |

Life increase of new steel |

-- |

210% |

246% |

254% |

GCr15Si1Mo |

2.117 |

1.326 |

3.228 |

3.838 |

GCr15SiMo25 |

2.02 |

0.645 |

1.484 |

1.812 |

Life increase of new steel |

-- |

106% |

117% |

112% |

Table 3 Comparison on the rolling contact fatigue lives of the new developed and the traditional bearing steels

Note: β -Weibull slope, L10 -rated life, L50 -median life, Vs-characteristic life.

Solano-Alvarez et al.26 have studied the rolling contact fatigue phenomena and proposed the damage mechanism of a nanostructured bainitic steel without undissolved carbides intended for bearing applications . They pointed out that the degradation mechanism is ductile void formation at the interfaces, followed by growth and coalescence into larger voids that cause fracture along the direction of the softer phase. This degradation mechanism is different from the conventional damage mechanism, which involves crack initiation at inclusions and propagation in typical bearings steels. Liu et al.27 have reported that the rolling contact fatigue life of an ultrahigh carbon steel with a mixed microstructure composed of nanostructured bainite, martensite, retained austenite, and un-dissolved carbides is approximately 3.3 times longer than that of the steel with tempered martensite. The improvement in the rolling contact fatigue life of the steel is attributed to nanostructured bainite and stable film-like retained austenite. The nanostructured bainite can delay crack initiation via alleviating the stress concentration at the hard phases (such as carbide particles or non-metal inclusions), and the stable film-like retained austenite can retard crack propagation. These research findings provide a theoretical basis and technical support for the eventual usage of nanostructured bainitic steels in rolling bearing field.

Figure 3 Comparison on the wear resistant of GCr15SiAl steel with different phase constitutions.19

The dimensional stability is crucial to bearings, especially for the precision bearings. Studies have shown that the nanostructured carbide-free bainite experienced nearly no distortion.28 The dimension change of 100Cr6 bearing steel after bainitic austempering was five times larger than that of the nanostructured bainitic steel. Wang et al.29,30 have reported that the sliding wear resistance and the high-cycle bending fatigue performance of the nanostructured bainite were superior to those of the tempered martensite with the same chemical composition. Besides, the wear resistance in dry rolling-sliding of the nanostructured bainitic steels was also significantly superior to that of the bainitic steels transformed at higher temperatures with similar hardness values.31 In order to develop nanostructured bainitic steels intended for bearing applications, Swedish SKF Company has established University Technology Center together with University of Cambridge.32

Figure 4 TEM micrographs of nanostructured bainitic microstructure in the surface layer of G23Cr2Ni2Si1Mo steel (a) and GCr15Si1Mo steel (b).

The nanostructured bainitic microstructure, which is consisting of nano-scale extremely fine bainitic ferrite plates and carbon-enriched retained austenite film, possesses high strength, high toughness, excellent wear resistance and rolling contact fatigue performance and has a good application prospect in the bearing steel. However, the application of nanostructured bainitic bearing steel is still in its infancy at present. Therefore, there are still some problems needed to be further in-depth studied, for example, the transformation of retained austenite during the serving process and the dimensional stability problem caused by it, the microstructure evolution during bearing service and its influence on service life, what kind of working condition is more suitable for the nanostructured bainitic bearing steel, shortening the cycle of the heat treatment process and so on. Hoping that there are more bearing industries and related scientific or technical workers to research and solve these problems together, promoting the development and application of the nanostructured bainitic bearing steels.

This work was supported by the National High Technology Research and Development Program of China (863 Program) (Grant No. 2012AA03A504) and the Natural Science Foundation of China (No. 51471146).

The author declares no conflict of interest.

©2017 Zhang, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.